Professional Documents

Culture Documents

Tna Cereals Brochure (EN)

Tna Cereals Brochure (EN)

Uploaded by

Bindu PanickerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tna Cereals Brochure (EN)

Tna Cereals Brochure (EN)

Uploaded by

Bindu PanickerCopyright:

Available Formats

cereals

handling & preparation

distribution

packaging

case packing

processing

distribution

weighing

coating

metal

detection

verification

controls & integration processing coating distribution weighing packaging

electrical design installation commissioning SCADA cooling solution oil slurry combination horizontal motion vibratory motion belt conveyors weighing vertical form fill & seal packaging

HMI & network system remote control elevation conveyors metal detection verification

total aCCess super Cooled sugar-Coated whole movement preCision aCCuraCy high performanCe

Operate your line with precision timing and efficiency to preserve Toast, dry and cool extruded or flaked products to create cereal Produce cereals with ingredients that are coated consistently to Combine horizontal and vibratory motion conveyor technology Choose from single or multi-head scales to weigh and package Package a variety of cereal products and ingredients, bag sizes

the quality of all cereal ingredients including grains, dried fruit and with the perfect texture, colouring and taste. preserve and enhance ingredient quality. to quickly move cereal ingredients from start to finish, minimising multiple cereal ingredients with ultra-fast product transfer, and formats on a single system – from the bag to box.

extruded varieties. breakage and dust. reduced footprint and lower energy consumption.

• Control temperatures with innovative airflow technology to • Coat cereal with sugar, vitamins and nutraceuticals using innovative • Reach packaging speeds of up to 200 bags per minute while

• Keep your entire equipment line running smoothly, operating as protect the quality of your cereal ingredients from start to finish technology that is precise and minimises oil and slurry wastage • Take total control of speed and direction with almost instantaneous • Handle delicate cereals with gentle, stainless steel buckets and minimising dust and reducing waste

a single unit from one location – on site or remotely response to control signals programmable motor patterns, while minimising dust

• Reduce the footprint of your cereal line with technologically • Incorporate solutions like advanced spraying technology to ensure • Ensure the highest level of sustainability with the world's

• Collect data from anywhere, anytime with software that advanced heating systems that incorporate shorter conveyors consistent coverage on every batch of product regardless of size • Create the perfect mix of cereal ingredients using state-of-the-art smallest footprint and highest speeds in the cereals industry

• Clean and maintain weighers quickly with easy to reach parts

includes customised interfaces, dashboards and reports for quick or shape blending systems using 20% less energy than competitor systems

• Spend less time on maintenance with easy-to-clean materials like that can withstand full washdowns

and easy analysis

stainless steel to ensure optimum sanitation • Prevent clogging with low-maintenance designed nozzles that are • Choose from flexible configuration options and a range of different • Get the ultimate in packaging flexibility with multiple jaw

• Get site support, project management and training services all as easy to clean and minimise downtime conveyors that are available in gateless proportional, gated, configurations that allow you to package a variety of cereals

part of your complete controls & integration package washdown and bi-directional configurations and cereal ingredients using one machine

“Customise distribution “Keep your products

to your plant layout in line with regional

“tna’s turnkey and for just about any safety regulations

solutions and project product regardless of using tna’s patented

management services size, weight or texture” metal detection and

give you an on-time, verification solutions”

on-budget, high-

quality installation

that’s stress-free

from start to finish”

es support

sal

r service projec

me tm

to

us

an

-market c

age

ment

ter

CEREALS

af

my-tna 360°

customer care

c t t e sti n g

programme

tr ai ni n

du

g

ro

p

tna is your single sourCe supplier

for proCessing and paCkaging solutions

o rt al

np

tec

whether you’re producing cold, hot, indulgent or healthy cereals, ni m

io

at

h

ca y -t

opportunities are pouring in, and for over 30 years tna and its l s e r vic e n a infor m

family of brands has helped food manufacturers capitalise on this

growing industry. with more than 14,000 installations in over 120

countries, tna’s complete line of solutions brings simplicity,

flexibility and performance to cereal production lines everywhere

– and can do the same for you!

to make the most of your opportunities, it’s more important than

ever to partner with a supplier who can offer innovative and

modular solutions to meet today’s consumer demands including:

• Being able to grab a cup or pouch of cereal on-the-go

• Producing healthier options with more protein, fibre and other

natural ingredients

• Offering a variety of flavours at a low-cost

as your partner, tna offers complete, turnkey solutions from a

single, global source that also gives you the power and control to

boost production with:

• Improved line efficiency with integrated product controls and

sCada reporting

• Maximised use of oil during processing with advanced filtration

and consistent coating

• Increased weighing and packaging speeds with precision accuracy

• Reduced energy footprint for improved sustainability

• Maximised production with innovative distribution solutions

that minimise breakage and dust

tna’s family ContaCt us anywhere, anytime: tnasolutions.Com

all of this in addition to our my-tna 360° customer care of brands

tna is a leading global supplier of integrated food packaging and processing solutions with over

programme that’s available to you 24 / 7.

14,000 systems installed across more than 120 countries. The company provides a comprehensive

Find start-to-finish solutions for cereals or just about any range of products including materials handling, processing, coating, distribution, seasoning,

food application weighing, packaging, cooling, freezing, metal detection and verification solutions. tna also

offers a variety of production line controls integration & SCADA reporting options, project

controls integration & sCada | materials handling | processing |

management and training. tna’s unique combination of innovative technologies, extensive

freezing & cooling | coating | distribution | seasoning |

project management experience and 24 /7 global support ensures customers achieve faster,

weighing | packaging | metal detection | verification |

more reliable and flexible food products at the lowest cost of ownership.

project management | training |

Cooling the Globe: Printed on recycled paper

cereals_solutions_en_v1_7-2015

You might also like

- Drypix 6000 12eDocument501 pagesDrypix 6000 12eraj_meditech100% (1)

- 2018 - 2017 Portfolio - Nyoman Anjani - MIT IDM 923364378 PDFDocument25 pages2018 - 2017 Portfolio - Nyoman Anjani - MIT IDM 923364378 PDFRendy PutraaaNo ratings yet

- Mindmap For Global Logistics Integration Ism EyefreightDocument1 pageMindmap For Global Logistics Integration Ism EyefreightEdison Reus SilveiraNo ratings yet

- Tna Baked Snacks Brochure (EN)Document3 pagesTna Baked Snacks Brochure (EN)Bindu PanickerNo ratings yet

- Tna Confectionery Brochure (EN)Document3 pagesTna Confectionery Brochure (EN)Bindu PanickerNo ratings yet

- Tna Training Brochure (EN)Document3 pagesTna Training Brochure (EN)Bindu PanickerNo ratings yet

- Tna Nuts and Legumes Brochure (EN)Document3 pagesTna Nuts and Legumes Brochure (EN)Bindu PanickerNo ratings yet

- Tna French Fries Brochure (EN)Document3 pagesTna French Fries Brochure (EN)Bindu PanickerNo ratings yet

- Deepborewell - Ishwar House - Kichto PanchayatDocument13 pagesDeepborewell - Ishwar House - Kichto PanchayatShubham SinghNo ratings yet

- Deepborewell - Near Santosh Munda House Badkibhedi Patal PanchayatDocument13 pagesDeepborewell - Near Santosh Munda House Badkibhedi Patal PanchayatShubham SinghNo ratings yet

- Agile Product RoadmapDocument1 pageAgile Product RoadmapVitória SlompoNo ratings yet

- The Communications Rainbow - MasterDocument1 pageThe Communications Rainbow - MastersavioursofpopNo ratings yet

- BSP1702 NotesDocument7 pagesBSP1702 NotesliyangwongNo ratings yet

- Brosur AVANI Homes PDFDocument2 pagesBrosur AVANI Homes PDFCornelius SvenmorNo ratings yet

- Spyder Broccoli VariationDocument1 pageSpyder Broccoli VariationesoreaderNo ratings yet

- Built Env 223Document4 pagesBuilt Env 223abeerah2234No ratings yet

- The Abington Journal 04-13-2011Document28 pagesThe Abington Journal 04-13-2011The Times Leader100% (1)

- Cruise Ship Interiors 2023 - Sales PlanDocument1 pageCruise Ship Interiors 2023 - Sales Planpetrasb.amgNo ratings yet

- Existing Pool: (N) Shed 6'x18'Document1 pageExisting Pool: (N) Shed 6'x18'thiandarchiNo ratings yet

- Stat Phys Exam Sample ProblemsDocument5 pagesStat Phys Exam Sample ProblemsReshamNo ratings yet

- Aeroplane 02.2020Document108 pagesAeroplane 02.2020Maxi RuizNo ratings yet

- HW 3Document1 pageHW 3김가온No ratings yet

- Paper MakingDocument1 pagePaper MakingBurak KucukkelesNo ratings yet

- Parenthood: General Dynamic Factors - Age - Gender - Ethnicity - Social Economic Status - Educational BackgroundDocument1 pageParenthood: General Dynamic Factors - Age - Gender - Ethnicity - Social Economic Status - Educational Backgroundjunebug3No ratings yet

- AbstractDocument3 pagesAbstractCivil BasundharaNo ratings yet

- WD 77132Document1 pageWD 77132Bhaumik BhuvaNo ratings yet

- FloorplanDocument1 pageFloorplanPopcathrobyNo ratings yet

- Spares Management Technical ArchitectureDocument1 pageSpares Management Technical ArchitectureSenthilkumarNo ratings yet

- UntitledDocument13 pagesUntitledRaul MendezNo ratings yet

- rc0913 AlliedDocument4 pagesrc0913 AlliedsymonpatenNo ratings yet

- DocScanner 30 Mar 2024 12-33 PMDocument20 pagesDocScanner 30 Mar 2024 12-33 PMLOHITH K TNo ratings yet

- The Wynner Issue 2Document1 pageThe Wynner Issue 2Evan DaviesNo ratings yet

- St-Anton-am-Arlberg-Piste-Ski-Map-2024Document2 pagesSt-Anton-am-Arlberg-Piste-Ski-Map-2024roiantmanNo ratings yet

- Smartocto User Needs 2 PosterDocument1 pageSmartocto User Needs 2 PostergraceyangxiaoNo ratings yet

- Christmas Medley Wind Chimes 27395Document2 pagesChristmas Medley Wind Chimes 27395Jose AntonioNo ratings yet

- Christmas Medley Wind Chimes 27395Document2 pagesChristmas Medley Wind Chimes 27395Carlos VallejoNo ratings yet

- Route 24 Nov 2020 10 1 PDFDocument2 pagesRoute 24 Nov 2020 10 1 PDFJuan GasparNo ratings yet

- WD 77131Document6 pagesWD 77131Bhaumik BhuvaNo ratings yet

- Masterpact NT RETURN NS1600b... 3200 RETURN Masterpact NW 34560Document1 pageMasterpact NT RETURN NS1600b... 3200 RETURN Masterpact NW 34560Jatupol PongsirisartNo ratings yet

- The Abington Journal 05-18-2011Document28 pagesThe Abington Journal 05-18-2011The Times LeaderNo ratings yet

- Mayor Adams Claims NYC Is Back and A ParadiseDocument1 pageMayor Adams Claims NYC Is Back and A ParadiseRamonita GarciaNo ratings yet

- C-STR-DWG-000-31008-0 - PR-102 Structural Steel GA - Plan & Det at Base PL LevelDocument1 pageC-STR-DWG-000-31008-0 - PR-102 Structural Steel GA - Plan & Det at Base PL LevelHUSSEIN FNEISHNo ratings yet

- B2 Turret Cladding PlanDocument1 pageB2 Turret Cladding PlanCatalin HagiNo ratings yet

- Universal, 900 Packing Layout (23.6.2023) - ModelDocument1 pageUniversal, 900 Packing Layout (23.6.2023) - Modelthinh daoxuanNo ratings yet

- NW 2023 WS S Ifc 03Document1 pageNW 2023 WS S Ifc 03sanjay100% (1)

- Vicinity Map Site Devt Plan: Property LineDocument1 pageVicinity Map Site Devt Plan: Property LineCharleneMendozaEspirituNo ratings yet

- Layouts Bootcamp-Vmw08Document18 pagesLayouts Bootcamp-Vmw08Jorge Landim CarvalhoNo ratings yet

- Jcu 2023Document3 pagesJcu 2023sj21-11s-963No ratings yet

- As Built: O U S EDocument1 pageAs Built: O U S EEdson HuertaNo ratings yet

- Merino Lam India 2023Document118 pagesMerino Lam India 2023Sourish MitraNo ratings yet

- Pronostico PeriodontalDocument25 pagesPronostico PeriodontalRodrigo RojasNo ratings yet

- Result B Certiificate Exam 2020 1 GirlsDocument12 pagesResult B Certiificate Exam 2020 1 Girlshardly a mathematicianNo ratings yet

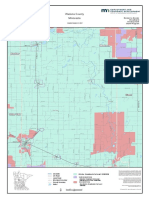

- Wadena County Broadband 2021Document1 pageWadena County Broadband 2021inforumdocsNo ratings yet

- KX-series - Manual - en - 23-01-12Document1 pageKX-series - Manual - en - 23-01-12manhduc191297No ratings yet

- 2010 CENSUS - CENSUS BLOCK MAP (INDEX) : Colbert County, AL: MILFORD 47500 Davis 18100Document1 page2010 CENSUS - CENSUS BLOCK MAP (INDEX) : Colbert County, AL: MILFORD 47500 Davis 18100Igor SemenovNo ratings yet

- HILTI Anchor Selection ChartDocument1 pageHILTI Anchor Selection ChartHASSAN SK MDNo ratings yet

- Key Plan: Chancay Multipurpose Terminal New First Stage, Peru Detailed Engineering Layout Plan For Curb of ZOP AreaDocument1 pageKey Plan: Chancay Multipurpose Terminal New First Stage, Peru Detailed Engineering Layout Plan For Curb of ZOP AreaJoel MontoyaNo ratings yet

- Mindmap For Operational Transparency in SAP: Supply Chain MindmappingDocument1 pageMindmap For Operational Transparency in SAP: Supply Chain MindmappingobNo ratings yet

- 21MB0001 ModelDocument1 page21MB0001 ModelPhreetzi ÜnseenNo ratings yet

- RWENZORI 1+231 CROSS @2m ExtensionDocument1 pageRWENZORI 1+231 CROSS @2m ExtensionKasirika EnterprisesNo ratings yet

- AqualisaDocument2 pagesAqualisaRoland DzNo ratings yet

- Tna Training Brochure (EN)Document3 pagesTna Training Brochure (EN)Bindu PanickerNo ratings yet

- Tna French Fries Brochure (EN)Document3 pagesTna French Fries Brochure (EN)Bindu PanickerNo ratings yet

- Tna Baked Snacks Brochure (EN)Document3 pagesTna Baked Snacks Brochure (EN)Bindu PanickerNo ratings yet

- Tna Confectionery Brochure (EN)Document3 pagesTna Confectionery Brochure (EN)Bindu PanickerNo ratings yet

- Palletizing EquipDocument16 pagesPalletizing EquiptintucinbNo ratings yet

- Cold Milling Machine W 100 H / W 130 H: Effi Cient Milling in The 1-m ClassDocument28 pagesCold Milling Machine W 100 H / W 130 H: Effi Cient Milling in The 1-m ClassAzza JogjaNo ratings yet

- Liebherr Complete Brochure enDocument24 pagesLiebherr Complete Brochure enناصرقوجيلNo ratings yet

- Maspric ATS - M V02 LowresDocument25 pagesMaspric ATS - M V02 LowresvenkatNo ratings yet

- Resultados de La Web: Conveyors For Bulk Materials 6th Ed - CMEDocument4 pagesResultados de La Web: Conveyors For Bulk Materials 6th Ed - CMEDIEGO FERNANDO CADENA ARANGONo ratings yet

- Conveyors, ElevatorsDocument54 pagesConveyors, ElevatorsMatthew DelgadoNo ratings yet

- Flyingbelt Factsheet July2016Document28 pagesFlyingbelt Factsheet July2016nicolasNo ratings yet

- Coal Conveyor GuardDocument18 pagesCoal Conveyor GuardDSG100% (1)

- FLS Minerals Brochure PDFDocument8 pagesFLS Minerals Brochure PDFmonam ellghorbeliNo ratings yet

- InternshipDocument13 pagesInternshipazmattaqvi8No ratings yet

- Datasheet - Vertical Lifter Conveyor For Multi Story Conveyor System DesignDocument10 pagesDatasheet - Vertical Lifter Conveyor For Multi Story Conveyor System DesignImpel IntralogisticsNo ratings yet

- Flexowell® New-Installation enDocument3 pagesFlexowell® New-Installation enhashem62No ratings yet

- Machinery List For Dashboard Conditions Report WIP 2021 Maret Week 2Document4,262 pagesMachinery List For Dashboard Conditions Report WIP 2021 Maret Week 2slamet supriyadiNo ratings yet

- 5886 EN Palletizing CellDocument2 pages5886 EN Palletizing Cellbernardo95No ratings yet

- Volta Application Album 2017 - Low - Res PDFDocument120 pagesVolta Application Album 2017 - Low - Res PDFAnna FrederikaNo ratings yet

- Model 959af Air-Feed Autofolder: Installation, Maintenance, & Operating InstructionsDocument20 pagesModel 959af Air-Feed Autofolder: Installation, Maintenance, & Operating Instructionsm_kocherovNo ratings yet

- Bastian Solutions Conveyor PWD Installation and Maintenance Manual Rev BDocument39 pagesBastian Solutions Conveyor PWD Installation and Maintenance Manual Rev BJulio César HernándezNo ratings yet

- Ball Bearings For Conveyor RollersDocument3 pagesBall Bearings For Conveyor RollersMehran KhNo ratings yet

- MK Profile Technology PDFDocument307 pagesMK Profile Technology PDFNick BentaNo ratings yet

- SFR 582018Document36 pagesSFR 582018Milos KosticNo ratings yet

- Ex 1Document3 pagesEx 1Daniyar NurkeevNo ratings yet

- Y-Puratek Telescoping Belt ConveyorDocument4 pagesY-Puratek Telescoping Belt ConveyorYousef AlipourNo ratings yet

- AlfaDocument114 pagesAlfaLeonelGonzales100% (1)

- MSD MergedDocument56 pagesMSD MergedAnish KulkarniNo ratings yet

- SM Dough ChunkersDocument2 pagesSM Dough ChunkersacecinownNo ratings yet

- Chain ConveyorrabDocument36 pagesChain ConveyorrabPrayogo Hadi SNo ratings yet

- Ax Wagon LeafletDocument40 pagesAx Wagon LeafletemmanolanNo ratings yet

- Amba Flex SV - SeriesDocument75 pagesAmba Flex SV - SeriesVasiliyNo ratings yet