Professional Documents

Culture Documents

Elastollan® 1100 Series

Elastollan® 1100 Series

Uploaded by

korma5Copyright:

Available Formats

You might also like

- EBOOK Human Services in Contemporary America 10Th Edition Ebook PDF Download Full Chapter PDF KindleDocument61 pagesEBOOK Human Services in Contemporary America 10Th Edition Ebook PDF Download Full Chapter PDF Kindlejames.mcneil99698% (46)

- Shoulder Pain The Solution Prevention Fourth EditionDocument120 pagesShoulder Pain The Solution Prevention Fourth EditionMarko Štambuk97% (33)

- Don Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboFrom EverandDon Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboRating: 4.5 out of 5 stars4.5/5 (12)

- DESMODUR MDQ23165+BAYTEC D22-70MF+BAYTEC XL B (SD6-2) Ang Ind0Document2 pagesDESMODUR MDQ23165+BAYTEC D22-70MF+BAYTEC XL B (SD6-2) Ang Ind0Jorge Miguel Bravo Cardenas100% (1)

- Sigma Fluid PDFDocument2 pagesSigma Fluid PDFHubertt Chacon AntonioNo ratings yet

- New Energy TherapiesDocument202 pagesNew Energy TherapiesFaty LeeNo ratings yet

- Polyurethane Properties PDFDocument1 pagePolyurethane Properties PDFdestroNo ratings yet

- Geotextiles DatasheetDocument1 pageGeotextiles DatasheetMohammad TalalNo ratings yet

- Bontec Non-Woven Geotextiles - TDSDocument11 pagesBontec Non-Woven Geotextiles - TDSAnang BagusNo ratings yet

- Nylon Materials ChartDocument1 pageNylon Materials ChartPrabhat SharmaNo ratings yet

- Techgeo Nonwoven Geotextiles Technical Data SheetDocument1 pageTechgeo Nonwoven Geotextiles Technical Data Sheetakkieuap100% (1)

- Tecothane TPU ClearDocument3 pagesTecothane TPU ClearKhoa HuynhdangNo ratings yet

- High Impact Polystyrene: Product InformationDocument1 pageHigh Impact Polystyrene: Product InformationOswald SolorzanoNo ratings yet

- Summary of Fluoropolymer Properties - 1Document1 pageSummary of Fluoropolymer Properties - 1Amir KhanNo ratings yet

- 1 Wa-Catalog9Document1 page1 Wa-Catalog9johnNo ratings yet

- Ficha Tecnica de Geotextil Tejido de BaunovoDocument1 pageFicha Tecnica de Geotextil Tejido de BaunovoJose ReyesNo ratings yet

- 01.03.03.101 Spesifikasi-BPM HDPE SmoothDocument1 page01.03.03.101 Spesifikasi-BPM HDPE SmoothRezky BaskoroNo ratings yet

- FRPC Properties EN-RUDocument1 pageFRPC Properties EN-RUVahNo ratings yet

- PDS - GulfSea Hydraulic AW Series-1Document2 pagesPDS - GulfSea Hydraulic AW Series-1Zaini YaakubNo ratings yet

- Operation Manual: Pile Driver DPD 350Document31 pagesOperation Manual: Pile Driver DPD 350Joseph Emmanuel ParedesNo ratings yet

- PDS - GulfSea Hydraulic HVI Plus 68Document2 pagesPDS - GulfSea Hydraulic HVI Plus 68Obydur Rahman100% (1)

- DESMODUR MTX6076BAYTEC D24BAYTEC XL B SD2 4MF 2 60A 76D Ang Ind1Document2 pagesDESMODUR MTX6076BAYTEC D24BAYTEC XL B SD2 4MF 2 60A 76D Ang Ind1Алексей ПанасюгинNo ratings yet

- Hydraulic Torque Wrench Operation ManualDocument18 pagesHydraulic Torque Wrench Operation Manualahmad fahmeyNo ratings yet

- Property of Polyfelt TS Nonwoven GeotextilesDocument1 pageProperty of Polyfelt TS Nonwoven GeotextilesAgis Satryo Falck100% (1)

- Cpi 4600 F Series TdsDocument2 pagesCpi 4600 F Series TdsNguyễn ThưNo ratings yet

- Desmodur MAX-T MOCADocument2 pagesDesmodur MAX-T MOCAFrench CorvetteNo ratings yet

- Gulf Oil Marine - Product Data SheetDocument10 pagesGulf Oil Marine - Product Data SheetObydur RahmanNo ratings yet

- StaripDocument2 pagesStaripTahir FadhilNo ratings yet

- Desmodur TDL6xx XL1705Document2 pagesDesmodur TDL6xx XL1705French CorvetteNo ratings yet

- Matrix EP and TK TDS 2035Document1 pageMatrix EP and TK TDS 2035Don HowardNo ratings yet

- 42 CR Mo 4Document2 pages42 CR Mo 4ElMacheteDelHuesoNo ratings yet

- Okada Hydraulic Breakers: Introduction MaterialDocument3 pagesOkada Hydraulic Breakers: Introduction MaterialHarol MendozaNo ratings yet

- Daphne Super Hydro A Series: Lubricant Product InformationDocument2 pagesDaphne Super Hydro A Series: Lubricant Product InformationGayuh Wahyu Eska NegaraNo ratings yet

- DD Series Guide Rod Diesel Pile Hammer D Series Diesel Pile HammerDocument7 pagesDD Series Guide Rod Diesel Pile Hammer D Series Diesel Pile HammerMuqorobinNo ratings yet

- Estizulia PSAI-4150 PDFDocument1 pageEstizulia PSAI-4150 PDFOriana Gudiño GaliñoNo ratings yet

- Pulley DetailsDocument2 pagesPulley DetailsKristin FitzpatrickNo ratings yet

- New DPD350T ManualDocument36 pagesNew DPD350T Manualequipadojacob796No ratings yet

- Silicone Rubber Compounds, Curing Agent Dicumyl Peroxide, 40-75 Shore A, Q, Peroxide Cure (M 608 - 5 DCP)Document2 pagesSilicone Rubber Compounds, Curing Agent Dicumyl Peroxide, 40-75 Shore A, Q, Peroxide Cure (M 608 - 5 DCP)sunitaNo ratings yet

- 102 CR 6Document2 pages102 CR 6ceca nikolicNo ratings yet

- VCMO140Document3 pagesVCMO140samsul hudaNo ratings yet

- 1 Wa-Catalog7Document1 page1 Wa-Catalog7johnNo ratings yet

- Guia Codigos Astm D2000Document19 pagesGuia Codigos Astm D2000Federico PayáNo ratings yet

- Pebax Product Range and PropertiesDocument2 pagesPebax Product Range and Propertiesabhishek_negi_41No ratings yet

- Hongruntong Marine Co., Ltd.Document27 pagesHongruntong Marine Co., Ltd.HONGRUNTONG MARINENo ratings yet

- Teflon® FEP (Fluorinated Ethylene Propylene)Document1 pageTeflon® FEP (Fluorinated Ethylene Propylene)mohammed goudaNo ratings yet

- Desmodur TD6xx Based SystemsDocument2 pagesDesmodur TD6xx Based SystemsKris SzongNo ratings yet

- TITANIA 1717en-4Document4 pagesTITANIA 1717en-4bre brilianNo ratings yet

- DESMODUR - MDQ75164+BAYTEC - D75+BAYTEC - XL - AL32 (SD25.1 or SD25.2) - Ang - Ind4Document2 pagesDESMODUR - MDQ75164+BAYTEC - D75+BAYTEC - XL - AL32 (SD25.1 or SD25.2) - Ang - Ind4N ThulasiramanNo ratings yet

- Novec Heat Transfer Product Line CardDocument2 pagesNovec Heat Transfer Product Line CardJimilShahNo ratings yet

- DN Turbine OilDocument2 pagesDN Turbine OilPrapat SabsinthaweelapNo ratings yet

- GeotextleDocument2 pagesGeotextleShashwati DobaiNo ratings yet

- Physical and Piezoelectric Properties of APC MaterialsDocument2 pagesPhysical and Piezoelectric Properties of APC MaterialsTrương Anh DuyNo ratings yet

- UPVC Pipe DIN 8062 TdsDocument3 pagesUPVC Pipe DIN 8062 TdsAdany AdenNo ratings yet

- Huskey: Hi-Lo Series OilsDocument1 pageHuskey: Hi-Lo Series OilsMuhammad FauziNo ratings yet

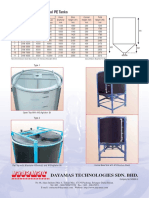

- Dayamas Rotational Molded PE Tank Brochures-09Document4 pagesDayamas Rotational Molded PE Tank Brochures-09Koay Chee WaiNo ratings yet

- Data Sheet: Scrd-Ut SeriesDocument2 pagesData Sheet: Scrd-Ut SeriesMustafa PardawalaNo ratings yet

- Submersible Agitator Pumps: Toyo DPDocument2 pagesSubmersible Agitator Pumps: Toyo DPBasit Edu0% (1)

- 13-Polyethylene RollDocument2 pages13-Polyethylene RollAkramNo ratings yet

- Gulf EP Lubricant SY - PAODocument1 pageGulf EP Lubricant SY - PAOatripathi2009No ratings yet

- Catalog - Maxbrio Ripper Seires - Ver.1504 - Eng (1M)Document6 pagesCatalog - Maxbrio Ripper Seires - Ver.1504 - Eng (1M)henry vegaNo ratings yet

- DESMODUR MDQ45163+BAYTEC D45MF+BDO Ang Ind0 BUK OnlyDocument2 pagesDESMODUR MDQ45163+BAYTEC D45MF+BDO Ang Ind0 BUK OnlyJagdish Patel100% (1)

- Single Core Oil Filled Cable 60-36-kvDocument2 pagesSingle Core Oil Filled Cable 60-36-kvRazvan DonciuNo ratings yet

- Kavanagh3e LN17 Styled 17Document17 pagesKavanagh3e LN17 Styled 17InciaNo ratings yet

- Case Study: COVID-19 Impact On Diversity & Inclusion (DEI)Document11 pagesCase Study: COVID-19 Impact On Diversity & Inclusion (DEI)ALEX kinstonNo ratings yet

- Price List Rapid SD Bioline 2021Document2 pagesPrice List Rapid SD Bioline 2021adiajahcNo ratings yet

- FL 382Document24 pagesFL 382Dany GunawanNo ratings yet

- Gut Rebuilding Protocol : Standard Process Supplements Lunch DinnerDocument1 pageGut Rebuilding Protocol : Standard Process Supplements Lunch DinnerSteve KellerNo ratings yet

- Dissertation On Food Security in IndiaDocument7 pagesDissertation On Food Security in IndiaPaperWritingServiceReviewsSingapore100% (1)

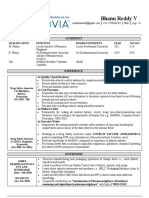

- Bhanu Reddy CVDocument3 pagesBhanu Reddy CVpamisetty ramNo ratings yet

- Teaching Resume For MedailleDocument3 pagesTeaching Resume For Medailleapi-579167947No ratings yet

- Brochure - 26th World Congress On Pediatrics, Neonatology & Primary CareDocument6 pagesBrochure - 26th World Congress On Pediatrics, Neonatology & Primary CareSpandana RoyNo ratings yet

- Calf Rumen DevelopmentDocument5 pagesCalf Rumen DevelopmentWaqas NawazNo ratings yet

- Spaq CoDocument7 pagesSpaq Cofadila mohammedNo ratings yet

- Action Plan of Activities LuponDocument7 pagesAction Plan of Activities LuponMaria RinaNo ratings yet

- Decent Work Employment Transcultural Nursing SAS Session 6Document10 pagesDecent Work Employment Transcultural Nursing SAS Session 6King NavsunNo ratings yet

- Jean Piaget ReflectionDocument2 pagesJean Piaget Reflectionapi-236351635100% (3)

- Fowler, Gasiorek, & Giles (2015) - Don't Talk Yourself Into An Early Grave! The Role of Communication in Aging WellDocument2 pagesFowler, Gasiorek, & Giles (2015) - Don't Talk Yourself Into An Early Grave! The Role of Communication in Aging WellCraig FowlerNo ratings yet

- Developing A Civic Action Plan WorksheetDocument3 pagesDeveloping A Civic Action Plan WorksheetMirella CostaNo ratings yet

- University Malaysia Sabah School of Food Science & Nutriton NP20303 Human Nutrition Lap Report Anthropometry'Document4 pagesUniversity Malaysia Sabah School of Food Science & Nutriton NP20303 Human Nutrition Lap Report Anthropometry'fengmanNo ratings yet

- GI Bleeding Case 2Document4 pagesGI Bleeding Case 2Imah ArmildezNo ratings yet

- module-LTM 2019-3Document97 pagesmodule-LTM 2019-3Ed SandanNo ratings yet

- Physical Education: Quarter 2 - Module 1: Physical Activities Related To Team SportsDocument26 pagesPhysical Education: Quarter 2 - Module 1: Physical Activities Related To Team SportsEvelyn SuNo ratings yet

- हिंदी प्रश्न कोशDocument80 pagesहिंदी प्रश्न कोशNithin krishnaNo ratings yet

- Radiology of Acute Mastoiditis and Its Complications: A Pictorial Review and Interpretation ChecklistDocument6 pagesRadiology of Acute Mastoiditis and Its Complications: A Pictorial Review and Interpretation ChecklistSalma Nurisna UfairohNo ratings yet

- CBTP Research PaperDocument67 pagesCBTP Research PaperEskindir Solomon100% (2)

- Lesson Plan Mapeh 8Document52 pagesLesson Plan Mapeh 8Jean Dee Marie DanucopNo ratings yet

- Update On The Management of Symptoms in Schizophrenia: Focus On AmisulprideDocument11 pagesUpdate On The Management of Symptoms in Schizophrenia: Focus On AmisulpridepaulNo ratings yet

- Imaging Tables: Instruction/Maintenance ManualDocument48 pagesImaging Tables: Instruction/Maintenance ManualJamalBazziNo ratings yet

- SIP Annex 1B Child Mapping ToolDocument8 pagesSIP Annex 1B Child Mapping ToolLawrence RolluquiNo ratings yet

Elastollan® 1100 Series

Elastollan® 1100 Series

Uploaded by

korma5Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Elastollan® 1100 Series

Elastollan® 1100 Series

Uploaded by

korma5Copyright:

Available Formats

Elastollan® 1100 Series

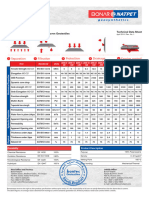

Technical Bulletin Polyether Type

Elastollan 1100 series of products are polyether-based thermoplastic polyurethanes. They exhibit excellent low

temperature properties, hydrolysis resistance and fungus resistance. These products can be injection molded,

blow molded and extruded.

Extrusion grades: Elastollan 1175AW, 80A, 85A, 90A and 95A

Injection molding grades: Elastollan 1175AW to 1174D

ASTM

Physical properties Units Method 1175AW* 1180A 1185A 1190A 1195A 1154D1 1164D1 1174D

Specific gravity gr./cm 3 D-792 1.14 1.11 1.12 1.13 1.14 1.16 1.18 1.19

Hardness Shore A D-224 76 ± 2 80 ± 2 86± 2 91± 2 95 ± 2 - - -

D - - - 42 ± 2 47 ± 2 53 ± 2 64 ± 2 73 ± 2

Tensile strength MPa D-412 30 32 33 37 36 40 41 45

psi 4500 4700 4800 5300 5200 5800 6000 6500

Tensile stress D-412

@ 100% elongation MPa 4.3 5.5 7.6 10 12 20 25 32

psi 620 800 1100 1500 1750 2900 3600 4600

@300% elongation MPa 8.3 10 12 1.7 21 30 33 38

psi 1180 1500 1750 2500 3000 4300 4800 5500

Elongation @brk. % D-412 740 600 640 575 490 460 425 350

Tensile set @brk. % D-412 - 45 55 60 65 70 90 90

Compression Set

22 hrs@ 23ºC % 20 25 25 25 30 40 40 50

22 hrs@ 70ºC % 40 45 45 45 45 50 50 55

Tear strength N/mm D-624 80 90 105 125 140 180 220 255

lb./in. DIE C 460 515 600 715 800 1025 1250 1450

Abrasion resistance mg D-1044 2 25 30 45 55 75 55 75

(loss) (Taber)

Test samples were cured 20 hours @ 1OOº C before testing.

* Contains proprietary plasticizer

1

NOTE: These products can only be ordered in minimum quantities. Please contact your sales representative for details.

2

H-18 wheel, 1000 gm weight and 1000 cycles.

Caution: Contact with product dusts from regrinding operations may cause temporary irritation of the eyes and the respiratory tract. Use with local exhaust. Under

hot melt processing conditions (170-230°C), wear personal protective equipment to prevent thermal burns.

First aid: Eyes-Flush eyes with flowing water at least 15 minutes. If irritation develops, consult a physician. Skin-Skin contact with hot melt may cause thermal

burns. Call a physician immediately. Inhalation-If vapors generated from the hot melt process are inhaled, move to fresh air. Aid in breathing. If breathing

difficulties develop, see a physician immediately.

In case of fire: Use water fog, foam, CO2, or dry chemical extinguishing media. Firefighters should be equipped with self-contained breathing apparatus and turnout

gear.

Disposal: Waste material, unused contents and empty containers must be disposed of in accordance with applicable local, state or federal regulations. Refer to our

Material Safety Data Sheet for specific disposal instructions.

In case of chemical emergency: Call CHEMTREC day or night for assistance and information concerning spilled material, fire, exposure and other chemical

accidents. 800-424-9300

Attention: This product is sold solely for use by industrial institutions. Refer to our Material Safety Data Sheet regarding safety, usage, applications, hazards,

procedures and disposal of this product. Consult your supervisor for additional information.

No warranties of any kind, either express or implied, including warranties of merchantability or fitness for a particular purpose, are made regarding products described or designs, data or information set forth or that

the products designs, data or information may be used without infringing the intellectual property rights of others in no case shall the descriptions information, data or designs provided be considered a part of our

terms and conditions of sale. Further, you expressly understand and agree that the descriptions, designs, data and information furnished by BASF hereunder are provided gratis and BASF assumes no obligation or

liability for the description, designs data and information given or results obtained, all such being given and accepted at your risk.

BASF Corporation, 1609 Biddle Avenue, Wyandotte, Michigan 48192 (800) 892-3111 x21, www.basf.com/elastollan

©BASF Corporation 2000

You might also like

- EBOOK Human Services in Contemporary America 10Th Edition Ebook PDF Download Full Chapter PDF KindleDocument61 pagesEBOOK Human Services in Contemporary America 10Th Edition Ebook PDF Download Full Chapter PDF Kindlejames.mcneil99698% (46)

- Shoulder Pain The Solution Prevention Fourth EditionDocument120 pagesShoulder Pain The Solution Prevention Fourth EditionMarko Štambuk97% (33)

- Don Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboFrom EverandDon Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboRating: 4.5 out of 5 stars4.5/5 (12)

- DESMODUR MDQ23165+BAYTEC D22-70MF+BAYTEC XL B (SD6-2) Ang Ind0Document2 pagesDESMODUR MDQ23165+BAYTEC D22-70MF+BAYTEC XL B (SD6-2) Ang Ind0Jorge Miguel Bravo Cardenas100% (1)

- Sigma Fluid PDFDocument2 pagesSigma Fluid PDFHubertt Chacon AntonioNo ratings yet

- New Energy TherapiesDocument202 pagesNew Energy TherapiesFaty LeeNo ratings yet

- Polyurethane Properties PDFDocument1 pagePolyurethane Properties PDFdestroNo ratings yet

- Geotextiles DatasheetDocument1 pageGeotextiles DatasheetMohammad TalalNo ratings yet

- Bontec Non-Woven Geotextiles - TDSDocument11 pagesBontec Non-Woven Geotextiles - TDSAnang BagusNo ratings yet

- Nylon Materials ChartDocument1 pageNylon Materials ChartPrabhat SharmaNo ratings yet

- Techgeo Nonwoven Geotextiles Technical Data SheetDocument1 pageTechgeo Nonwoven Geotextiles Technical Data Sheetakkieuap100% (1)

- Tecothane TPU ClearDocument3 pagesTecothane TPU ClearKhoa HuynhdangNo ratings yet

- High Impact Polystyrene: Product InformationDocument1 pageHigh Impact Polystyrene: Product InformationOswald SolorzanoNo ratings yet

- Summary of Fluoropolymer Properties - 1Document1 pageSummary of Fluoropolymer Properties - 1Amir KhanNo ratings yet

- 1 Wa-Catalog9Document1 page1 Wa-Catalog9johnNo ratings yet

- Ficha Tecnica de Geotextil Tejido de BaunovoDocument1 pageFicha Tecnica de Geotextil Tejido de BaunovoJose ReyesNo ratings yet

- 01.03.03.101 Spesifikasi-BPM HDPE SmoothDocument1 page01.03.03.101 Spesifikasi-BPM HDPE SmoothRezky BaskoroNo ratings yet

- FRPC Properties EN-RUDocument1 pageFRPC Properties EN-RUVahNo ratings yet

- PDS - GulfSea Hydraulic AW Series-1Document2 pagesPDS - GulfSea Hydraulic AW Series-1Zaini YaakubNo ratings yet

- Operation Manual: Pile Driver DPD 350Document31 pagesOperation Manual: Pile Driver DPD 350Joseph Emmanuel ParedesNo ratings yet

- PDS - GulfSea Hydraulic HVI Plus 68Document2 pagesPDS - GulfSea Hydraulic HVI Plus 68Obydur Rahman100% (1)

- DESMODUR MTX6076BAYTEC D24BAYTEC XL B SD2 4MF 2 60A 76D Ang Ind1Document2 pagesDESMODUR MTX6076BAYTEC D24BAYTEC XL B SD2 4MF 2 60A 76D Ang Ind1Алексей ПанасюгинNo ratings yet

- Hydraulic Torque Wrench Operation ManualDocument18 pagesHydraulic Torque Wrench Operation Manualahmad fahmeyNo ratings yet

- Property of Polyfelt TS Nonwoven GeotextilesDocument1 pageProperty of Polyfelt TS Nonwoven GeotextilesAgis Satryo Falck100% (1)

- Cpi 4600 F Series TdsDocument2 pagesCpi 4600 F Series TdsNguyễn ThưNo ratings yet

- Desmodur MAX-T MOCADocument2 pagesDesmodur MAX-T MOCAFrench CorvetteNo ratings yet

- Gulf Oil Marine - Product Data SheetDocument10 pagesGulf Oil Marine - Product Data SheetObydur RahmanNo ratings yet

- StaripDocument2 pagesStaripTahir FadhilNo ratings yet

- Desmodur TDL6xx XL1705Document2 pagesDesmodur TDL6xx XL1705French CorvetteNo ratings yet

- Matrix EP and TK TDS 2035Document1 pageMatrix EP and TK TDS 2035Don HowardNo ratings yet

- 42 CR Mo 4Document2 pages42 CR Mo 4ElMacheteDelHuesoNo ratings yet

- Okada Hydraulic Breakers: Introduction MaterialDocument3 pagesOkada Hydraulic Breakers: Introduction MaterialHarol MendozaNo ratings yet

- Daphne Super Hydro A Series: Lubricant Product InformationDocument2 pagesDaphne Super Hydro A Series: Lubricant Product InformationGayuh Wahyu Eska NegaraNo ratings yet

- DD Series Guide Rod Diesel Pile Hammer D Series Diesel Pile HammerDocument7 pagesDD Series Guide Rod Diesel Pile Hammer D Series Diesel Pile HammerMuqorobinNo ratings yet

- Estizulia PSAI-4150 PDFDocument1 pageEstizulia PSAI-4150 PDFOriana Gudiño GaliñoNo ratings yet

- Pulley DetailsDocument2 pagesPulley DetailsKristin FitzpatrickNo ratings yet

- New DPD350T ManualDocument36 pagesNew DPD350T Manualequipadojacob796No ratings yet

- Silicone Rubber Compounds, Curing Agent Dicumyl Peroxide, 40-75 Shore A, Q, Peroxide Cure (M 608 - 5 DCP)Document2 pagesSilicone Rubber Compounds, Curing Agent Dicumyl Peroxide, 40-75 Shore A, Q, Peroxide Cure (M 608 - 5 DCP)sunitaNo ratings yet

- 102 CR 6Document2 pages102 CR 6ceca nikolicNo ratings yet

- VCMO140Document3 pagesVCMO140samsul hudaNo ratings yet

- 1 Wa-Catalog7Document1 page1 Wa-Catalog7johnNo ratings yet

- Guia Codigos Astm D2000Document19 pagesGuia Codigos Astm D2000Federico PayáNo ratings yet

- Pebax Product Range and PropertiesDocument2 pagesPebax Product Range and Propertiesabhishek_negi_41No ratings yet

- Hongruntong Marine Co., Ltd.Document27 pagesHongruntong Marine Co., Ltd.HONGRUNTONG MARINENo ratings yet

- Teflon® FEP (Fluorinated Ethylene Propylene)Document1 pageTeflon® FEP (Fluorinated Ethylene Propylene)mohammed goudaNo ratings yet

- Desmodur TD6xx Based SystemsDocument2 pagesDesmodur TD6xx Based SystemsKris SzongNo ratings yet

- TITANIA 1717en-4Document4 pagesTITANIA 1717en-4bre brilianNo ratings yet

- DESMODUR - MDQ75164+BAYTEC - D75+BAYTEC - XL - AL32 (SD25.1 or SD25.2) - Ang - Ind4Document2 pagesDESMODUR - MDQ75164+BAYTEC - D75+BAYTEC - XL - AL32 (SD25.1 or SD25.2) - Ang - Ind4N ThulasiramanNo ratings yet

- Novec Heat Transfer Product Line CardDocument2 pagesNovec Heat Transfer Product Line CardJimilShahNo ratings yet

- DN Turbine OilDocument2 pagesDN Turbine OilPrapat SabsinthaweelapNo ratings yet

- GeotextleDocument2 pagesGeotextleShashwati DobaiNo ratings yet

- Physical and Piezoelectric Properties of APC MaterialsDocument2 pagesPhysical and Piezoelectric Properties of APC MaterialsTrương Anh DuyNo ratings yet

- UPVC Pipe DIN 8062 TdsDocument3 pagesUPVC Pipe DIN 8062 TdsAdany AdenNo ratings yet

- Huskey: Hi-Lo Series OilsDocument1 pageHuskey: Hi-Lo Series OilsMuhammad FauziNo ratings yet

- Dayamas Rotational Molded PE Tank Brochures-09Document4 pagesDayamas Rotational Molded PE Tank Brochures-09Koay Chee WaiNo ratings yet

- Data Sheet: Scrd-Ut SeriesDocument2 pagesData Sheet: Scrd-Ut SeriesMustafa PardawalaNo ratings yet

- Submersible Agitator Pumps: Toyo DPDocument2 pagesSubmersible Agitator Pumps: Toyo DPBasit Edu0% (1)

- 13-Polyethylene RollDocument2 pages13-Polyethylene RollAkramNo ratings yet

- Gulf EP Lubricant SY - PAODocument1 pageGulf EP Lubricant SY - PAOatripathi2009No ratings yet

- Catalog - Maxbrio Ripper Seires - Ver.1504 - Eng (1M)Document6 pagesCatalog - Maxbrio Ripper Seires - Ver.1504 - Eng (1M)henry vegaNo ratings yet

- DESMODUR MDQ45163+BAYTEC D45MF+BDO Ang Ind0 BUK OnlyDocument2 pagesDESMODUR MDQ45163+BAYTEC D45MF+BDO Ang Ind0 BUK OnlyJagdish Patel100% (1)

- Single Core Oil Filled Cable 60-36-kvDocument2 pagesSingle Core Oil Filled Cable 60-36-kvRazvan DonciuNo ratings yet

- Kavanagh3e LN17 Styled 17Document17 pagesKavanagh3e LN17 Styled 17InciaNo ratings yet

- Case Study: COVID-19 Impact On Diversity & Inclusion (DEI)Document11 pagesCase Study: COVID-19 Impact On Diversity & Inclusion (DEI)ALEX kinstonNo ratings yet

- Price List Rapid SD Bioline 2021Document2 pagesPrice List Rapid SD Bioline 2021adiajahcNo ratings yet

- FL 382Document24 pagesFL 382Dany GunawanNo ratings yet

- Gut Rebuilding Protocol : Standard Process Supplements Lunch DinnerDocument1 pageGut Rebuilding Protocol : Standard Process Supplements Lunch DinnerSteve KellerNo ratings yet

- Dissertation On Food Security in IndiaDocument7 pagesDissertation On Food Security in IndiaPaperWritingServiceReviewsSingapore100% (1)

- Bhanu Reddy CVDocument3 pagesBhanu Reddy CVpamisetty ramNo ratings yet

- Teaching Resume For MedailleDocument3 pagesTeaching Resume For Medailleapi-579167947No ratings yet

- Brochure - 26th World Congress On Pediatrics, Neonatology & Primary CareDocument6 pagesBrochure - 26th World Congress On Pediatrics, Neonatology & Primary CareSpandana RoyNo ratings yet

- Calf Rumen DevelopmentDocument5 pagesCalf Rumen DevelopmentWaqas NawazNo ratings yet

- Spaq CoDocument7 pagesSpaq Cofadila mohammedNo ratings yet

- Action Plan of Activities LuponDocument7 pagesAction Plan of Activities LuponMaria RinaNo ratings yet

- Decent Work Employment Transcultural Nursing SAS Session 6Document10 pagesDecent Work Employment Transcultural Nursing SAS Session 6King NavsunNo ratings yet

- Jean Piaget ReflectionDocument2 pagesJean Piaget Reflectionapi-236351635100% (3)

- Fowler, Gasiorek, & Giles (2015) - Don't Talk Yourself Into An Early Grave! The Role of Communication in Aging WellDocument2 pagesFowler, Gasiorek, & Giles (2015) - Don't Talk Yourself Into An Early Grave! The Role of Communication in Aging WellCraig FowlerNo ratings yet

- Developing A Civic Action Plan WorksheetDocument3 pagesDeveloping A Civic Action Plan WorksheetMirella CostaNo ratings yet

- University Malaysia Sabah School of Food Science & Nutriton NP20303 Human Nutrition Lap Report Anthropometry'Document4 pagesUniversity Malaysia Sabah School of Food Science & Nutriton NP20303 Human Nutrition Lap Report Anthropometry'fengmanNo ratings yet

- GI Bleeding Case 2Document4 pagesGI Bleeding Case 2Imah ArmildezNo ratings yet

- module-LTM 2019-3Document97 pagesmodule-LTM 2019-3Ed SandanNo ratings yet

- Physical Education: Quarter 2 - Module 1: Physical Activities Related To Team SportsDocument26 pagesPhysical Education: Quarter 2 - Module 1: Physical Activities Related To Team SportsEvelyn SuNo ratings yet

- हिंदी प्रश्न कोशDocument80 pagesहिंदी प्रश्न कोशNithin krishnaNo ratings yet

- Radiology of Acute Mastoiditis and Its Complications: A Pictorial Review and Interpretation ChecklistDocument6 pagesRadiology of Acute Mastoiditis and Its Complications: A Pictorial Review and Interpretation ChecklistSalma Nurisna UfairohNo ratings yet

- CBTP Research PaperDocument67 pagesCBTP Research PaperEskindir Solomon100% (2)

- Lesson Plan Mapeh 8Document52 pagesLesson Plan Mapeh 8Jean Dee Marie DanucopNo ratings yet

- Update On The Management of Symptoms in Schizophrenia: Focus On AmisulprideDocument11 pagesUpdate On The Management of Symptoms in Schizophrenia: Focus On AmisulpridepaulNo ratings yet

- Imaging Tables: Instruction/Maintenance ManualDocument48 pagesImaging Tables: Instruction/Maintenance ManualJamalBazziNo ratings yet

- SIP Annex 1B Child Mapping ToolDocument8 pagesSIP Annex 1B Child Mapping ToolLawrence RolluquiNo ratings yet