Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 Weld

Saudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 Weld

Uploaded by

MAZHARULCopyright:

Available Formats

You might also like

- Saudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureDocument2 pagesSaudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureMAZHARULNo ratings yet

- Proposed Loctugan Integrated Farm SchoolDocument4 pagesProposed Loctugan Integrated Farm SchoolMariel Pastolero100% (1)

- SATR-W-2006 Rev 6Document1 pageSATR-W-2006 Rev 6Manoj KumarNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldManoj KumarNo ratings yet

- 175 012000Document2 pages175 012000Abu Anas M.SalaheldinNo ratings yet

- SAIC-L-2035 Rev 6Document2 pagesSAIC-L-2035 Rev 6biplabpal2009No ratings yet

- SAIC-W-2006 Rev 0 PDFDocument4 pagesSAIC-W-2006 Rev 0 PDFMidhun K ChandraboseNo ratings yet

- SAIC W 2069 in Process Welding InspectionDocument8 pagesSAIC W 2069 in Process Welding InspectionAbdul Gafoor ShaikhNo ratings yet

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldDocument19 pagesSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldIrshad IqbalNo ratings yet

- Saic L 2139Document9 pagesSaic L 2139Kumar RNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistJoni Carino SuniNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 MechDocument4 pagesSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 Mechkarthi51289No ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- SAIC-A-2008 Rev 6 Verify Test Medium For Hydrostatic Testing and Lay UpDocument2 pagesSAIC-A-2008 Rev 6 Verify Test Medium For Hydrostatic Testing and Lay UpAhdal NoushadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- Saudi Aramco Test ReportDocument4 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Test Report: 25-May-05 Weld-Weekly Weld Status Report SATR-W-2019Document2 pagesSaudi Aramco Test Report: 25-May-05 Weld-Weekly Weld Status Report SATR-W-2019David RodriguesNo ratings yet

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Jul-18 Weldm4metzNo ratings yet

- 175-Ir171300, (850146), 11.30.2015Document2 pages175-Ir171300, (850146), 11.30.2015Rami ELLOUMINo ratings yet

- Saudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-W-2032 24-Jul-18 Weld-Upgrade Aramco JNGLFP Propane System BI-21-00087 MacoDocument7 pagesSaudi Aramco Inspection Checklist: SAIC-W-2032 24-Jul-18 Weld-Upgrade Aramco JNGLFP Propane System BI-21-00087 MacojahaanNo ratings yet

- Saudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportDocument2 pagesSaudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportJoni Carino Suni100% (1)

- Saic e 2002Document10 pagesSaic e 2002jerinNo ratings yet

- Weld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020Document3 pagesWeld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020bishalNo ratings yet

- Saic L 2008 PDFDocument4 pagesSaic L 2008 PDFHesham HelalNo ratings yet

- Saudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 24-Mar-16 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 24-Mar-16 CivilSajid ShaikhNo ratings yet

- Saudi Aramco Inspection Checklist: Review Procedure - Pressure Testing (All Applications) SAIC-A-2001 15-Nov-17 MechDocument27 pagesSaudi Aramco Inspection Checklist: Review Procedure - Pressure Testing (All Applications) SAIC-A-2001 15-Nov-17 MechNaushad AlamNo ratings yet

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocument8 pagesSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurekarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechDocument3 pagesSaudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechHamidNo ratings yet

- SATR-W-2020 Rev 8Document4 pagesSATR-W-2020 Rev 8محمد علي النويصرNo ratings yet

- Saudi Aramco Inspection Checklist: Final Reinstatement After Mechanical & Chem Cleaning SAIC-G-2019 30-Apr-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Final Reinstatement After Mechanical & Chem Cleaning SAIC-G-2019 30-Apr-17 Mechkarthi51289No ratings yet

- Welder Repair Assessment and Tracer Weld Report-Weekly SATR-W-2018 22-Jan-18 WeldDocument2 pagesWelder Repair Assessment and Tracer Weld Report-Weekly SATR-W-2018 22-Jan-18 Weldkarthi51289No ratings yet

- Saic-L-2010 Pmi Testing PDFDocument5 pagesSaic-L-2010 Pmi Testing PDFkarioke mohaNo ratings yet

- Saic L 2007 PDFDocument7 pagesSaic L 2007 PDFHesham HelalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- SAES-W-012 - Google Search3Document1 pageSAES-W-012 - Google Search3fayceal0% (1)

- SATR-A-2009 Rev 2 - System Lay-Up Report (Certificate)Document2 pagesSATR-A-2009 Rev 2 - System Lay-Up Report (Certificate)deepa narayan100% (1)

- Saudi Aramco Inspection Checklist: Selection of Welds For NDE (On-Plot Piping & Structures) SAIC-W-2015 WeldDocument23 pagesSaudi Aramco Inspection Checklist: Selection of Welds For NDE (On-Plot Piping & Structures) SAIC-W-2015 WeldIrshad IqbalNo ratings yet

- Satr-W-2008 Atyb TRDocument6 pagesSatr-W-2008 Atyb TRDeo MNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument1 pageInspection & Testing Requirements Scope:: Test and Inspection PerEagle SpiritNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection - Bolts, Nuts & Washers For Structural ConnectionsDocument6 pagesSaudi Aramco Inspection Checklist: Receiving Inspection - Bolts, Nuts & Washers For Structural ConnectionsAbdul HannanNo ratings yet

- SAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingDocument5 pagesSAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingFiras AlbaweiNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saic-P-3003 Rev 0 PDFDocument4 pagesSaic-P-3003 Rev 0 PDFHesham HelalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument23 pagesSaudi Aramco Inspection ChecklistjahaanNo ratings yet

- 175 030100Document2 pages175 030100Abu Anas M.Salaheldin100% (1)

- QMIS LBE Rev Mech Final OldDocument683 pagesQMIS LBE Rev Mech Final OldprabakaranNo ratings yet

- SATIP-W-011-01 Rev 8Document10 pagesSATIP-W-011-01 Rev 8saravananmenmathiNo ratings yet

- Saic W 2036Document2 pagesSaic W 2036Neelam AhmadNo ratings yet

- Saep 324Document13 pagesSaep 324Up WeldNo ratings yet

- Saudi Aramco Inspection Checklist: Pre Welding Inspection - Offshore Structures SAIC-W-1312 WeldDocument1 pageSaudi Aramco Inspection Checklist: Pre Welding Inspection - Offshore Structures SAIC-W-1312 Weldkartik_harwani4387No ratings yet

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 15-Dec-09 MechDocument6 pagesSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 15-Dec-09 MechEagle SpiritNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 Mechnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistJoni Carino Suni100% (1)

- Satr W 2013Document8 pagesSatr W 2013Rijwan MohammadNo ratings yet

- Satip G 005 01Document11 pagesSatip G 005 01Rijwan MohammadNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportEswari AnandNo ratings yet

- Shieldinggases Aws 5.32 PDFDocument3 pagesShieldinggases Aws 5.32 PDFessnelsonNo ratings yet

- Satip A 004 03Document3 pagesSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- SAEP-379 Quality Issues NotificationDocument4 pagesSAEP-379 Quality Issues NotificationMusic And FunNo ratings yet

- Installation of Main Steel Structure/ Platform & Steam SilencerDocument4 pagesInstallation of Main Steel Structure/ Platform & Steam SilencerzhangNo ratings yet

- Saudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 15-Jul-18 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistMAZHARULNo ratings yet

- Saic L 2003Document9 pagesSaic L 2003MAZHARULNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection ChecklistMAZHARULNo ratings yet

- Saic B 4003 PDFDocument1 pageSaic B 4003 PDFMAZHARULNo ratings yet

- 02.186 - F - Satr-Nde-2008 Revised (003) 010817 SS JointsDocument2 pages02.186 - F - Satr-Nde-2008 Revised (003) 010817 SS JointsMAZHARULNo ratings yet

- Saic B 4006 PDFDocument1 pageSaic B 4006 PDFMAZHARULNo ratings yet

- Saudi Aramco Inspection Checklist: Emergency Eyewash/Shower System Installation SAIC-B-4002 30-Apr-13 PlumbDocument2 pagesSaudi Aramco Inspection Checklist: Emergency Eyewash/Shower System Installation SAIC-B-4002 30-Apr-13 PlumbMAZHARUL100% (1)

- Saudi Aramco Typical Inspection PlanDocument2 pagesSaudi Aramco Typical Inspection PlanMAZHARULNo ratings yet

- Saving Money ThesisDocument8 pagesSaving Money ThesisClaire Webber100% (2)

- IZARSETManual13EN PDFDocument118 pagesIZARSETManual13EN PDFrogerioangelli540No ratings yet

- Shreya Singhal Vs Union of IndiaDocument3 pagesShreya Singhal Vs Union of IndiaShivang SharmaNo ratings yet

- Assignment 1 - Roles and ResponsibilitiesDocument12 pagesAssignment 1 - Roles and ResponsibilitiesericmcnarteyNo ratings yet

- 807 Karnataka Yantradhare 2015Document25 pages807 Karnataka Yantradhare 2015MALLIKARJUN BIRADARNo ratings yet

- Mvule Trust Annual Report, 2010Document24 pagesMvule Trust Annual Report, 2010Straight Talk FoundationNo ratings yet

- Kinco CV100 VFD User Manual-En20130617Document109 pagesKinco CV100 VFD User Manual-En20130617alibuchy100% (1)

- Normal 5f5fc792e6de4Document66 pagesNormal 5f5fc792e6de4AbdulmalekNo ratings yet

- Economics and EmigrationDocument24 pagesEconomics and EmigrationMarius ComperNo ratings yet

- Auditing - RF-12 Quiz BowlDocument12 pagesAuditing - RF-12 Quiz BowlAngel TumamaoNo ratings yet

- Computer Vision: Models, Learning and InferenceDocument59 pagesComputer Vision: Models, Learning and InferencePREM KUMAR MNo ratings yet

- Knimbus and Jgate ComparisonDocument3 pagesKnimbus and Jgate ComparisonMahesh Wagh100% (1)

- CNC Overview PDFDocument16 pagesCNC Overview PDFQuoc HuyNo ratings yet

- COM 226 - Computer Troubleshooting Handout PrintDocument68 pagesCOM 226 - Computer Troubleshooting Handout PrintOluwafisayo B. AyoadeNo ratings yet

- CS8611 MINI PROJECT Validation of Facebook Login PageDocument14 pagesCS8611 MINI PROJECT Validation of Facebook Login PageaddssdfaNo ratings yet

- Dislocations and Plastic DeformationDocument6 pagesDislocations and Plastic DeformationPrashanth VantimittaNo ratings yet

- Servo SystemDocument2 pagesServo SystemJoseGarciaRuizNo ratings yet

- DGI300 Manual 4.1Document154 pagesDGI300 Manual 4.1Caraiane Catalin100% (2)

- Naplan 2013 Final Test Numeracy Year 9 (Calculator)Document13 pagesNaplan 2013 Final Test Numeracy Year 9 (Calculator)Mohammad AliNo ratings yet

- Nato Unclassified: Declassified/Declassifié - Public Disclosed/Mise en Lecture PubliqueDocument55 pagesNato Unclassified: Declassified/Declassifié - Public Disclosed/Mise en Lecture PubliqueDamonta HenryNo ratings yet

- Medidores Rotativos Série FMRDocument3 pagesMedidores Rotativos Série FMRmateuNo ratings yet

- Marketing PlanDocument51 pagesMarketing PlanS.m.Rasel100% (2)

- Company & Mill Presentation - Mining-And-Wet-GrindingDocument28 pagesCompany & Mill Presentation - Mining-And-Wet-GrindingTecnoExpress CHILENo ratings yet

- 2019 49 59 Ford Big CarDocument172 pages2019 49 59 Ford Big CarJanneLaukkanenNo ratings yet

- MicroShield ManualDocument130 pagesMicroShield Manualagus waluyoNo ratings yet

- Syllabus For All SemsDocument115 pagesSyllabus For All SemsMisbah JahanNo ratings yet

- The CPV Valley Energy Center - 2013 RFPDocument103 pagesThe CPV Valley Energy Center - 2013 RFP2rQiTPh4KnNo ratings yet

- Herbal Gram Index v1-67Document86 pagesHerbal Gram Index v1-67terryvnd50% (2)

- Channel List 20210427Document13 pagesChannel List 20210427drpnnreddyNo ratings yet

Saudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 Weld

Saudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 Weld

Uploaded by

MAZHARULOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 Weld

Saudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 Weld

Uploaded by

MAZHARULCopyright:

Available Formats

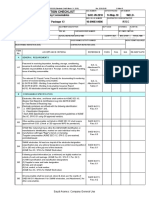

SAUDI ARAMCO ID/PIEU-30-September-2018 - REV.2018.09.00 (Standards Cutoff - September 30,2018) Rev.2018.09.

00 30-Sep-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 WELD-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

WELDING EQUIPMENT CALIBRATION

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

1/13/21 2:30 PM 1/13/21 2:30 PM SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SATIP-W-011-01 2.2

SAUDI ARAMCO INSPECTION LEVEL

W

CONTRACTOR INSPECTION LEVEL

H

NO

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A General Requirements

Welding power supplies shall be validated in accordance with BS EN 50504

SAES-W-011,

A1 or an approved equivalent if impact toughness test is reqd by the applicable

Para. 19.2

company or industry specifications or codes.

The welding equipment should be validated or calibrated at yearly intervals. SAES-W-011,

A2

(BS EN 50504 section 6). Para. 19.2

Welding equipment is validated by an 'expert', using equipment which has

calibration traceable to national standards. SAES-W-011,

A3

NOTE: Welding equipment manufacturer, repairer, validation agent or the Para. 19.2

user can carry out the validation. (BS EN 50504 Para. section 7).

Measuring instruments used in validation should conform to following:

1) They are in good condition.

2) They should be calibrated by a recognized calibrator with standards

SAES-W-011,

A4 traceable to a national standard.

Para. 19.2

3) They should be at least twice and preferably five times more accurate,

than the accuracy required for the validation grade.

(BS EN 50504 Section 9.3)

Ambient temperature is measured to ensure it is within the limits specified for

SAES-W-011,

A5 the power source, and the instrument rating tested. Ambient temperature is

Para. 19.2

recorded on validation certificate. (BS EN 50504 Para. 9.5.1.1)

Input voltage is measured to ensure compliance with the specified value for

the power source. This measurement is recorded on the validation

SAES-W-011,

A6 certificate.

Para. 19.2

NOTE: Correct tappings have been connected within the power source if

relevant. Refer (BS EN 50504 Para. 9.5.1.2)

For engine driven power sources, check rated load speed and no-load speed

SAES-W-011,

A7 to ensure that the power source meets the rated values (BS EN 50504 Para.

Para. 19.2

9.5.1.3)

The resistive load across the output terminals of the power source, is

connected as far as practical. The instrumentation used for the validation of SAES-W-011,

A8

the voltage across the resistive load & the transducer in the circuit, is Para. 19.2

connected.(BS EN 50504 Para. 9.5.1.4)

Saudi Aramco: Company General Use

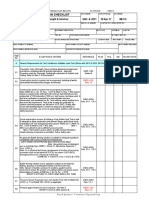

Power Source for each welding process are subjected to the following loads:

a. TIG - is loaded with a conventional load of drooping

characteristics{(U₂ = (10 + 0,04 I2) V up to I₂ = 600 A},

after which it remains constant at 34V.

b. SMAW- is loaded with a conventional load of Drooping

characteristic {U₂ = (20 + 0,04 I2) V up to I₂ = 600 A}, after

which U₂ remains constant at 44 V.

c. MIG/MAG/FCAW- loaded with Flat characteristic

{U₂ = (14 + 0,05 I2) V up to I₂ = 600 A}, after which U₂ SAES-W-011,

A9

remains constant at 44 V. Para. 19.2

d. SAW - loaded with a conventional load U₂ = (20 + 0,04 I2) V

up to I₂ = 600 A, after which U₂ remains constant at 44 V.

(BS EN 50504 Para. 9.4)

The wire feed unit being validated, is connected to the source of power SAES-W-011,

A10

supply normally used during welding. (BS EN 50504 Para. 9.5.1.5) Para. 19.2

The wire feeder is assembled and adjusted according to the manufacturer's SAES-W-011,

A11

instructions.(BS EN 50504 Para. 9.5.1.6) Para. 19.2

The wire feeder shall not be driven at speeds or loaded with filler wire

SAES-W-011,

A12 diameters, in excess of that shown on the rating plate. (BS EN 50504.Para.

Para. 19.2

9.5.1.7)

Use terminals, cables and wires of high quality to connect the welding

equipment during validation and make all joints sound. Make all crimped and SAES-W-011,

A13

soldered joints free from any signs of overheating (BS EN 50504.Para. Para. 19.2

9.5.1.8)

The validation/calibration range of the control or meter fitted to the power

source, is selected from one of the following:

a) the full range of the control or meter;

SAES-W-011,

A14 b) a partial range of the control or meter;

Para. 19.2

c) selected points over the range of the control or meter.

Either b) or c) is agreed on BEFORE performing validation/calibration

Refer.BS EN 50504.Para. 9.5.1.9

Measurements are taken at the minimum setting, the maximum setting, and

SAES-W-011,

A15 3 other points nominally equally spaced between minimum and maximum,

Para. 19.2

over the full or partial range. (BS EN 50504.Para. 9.5.1.9)

B Validation (Calibration) Process

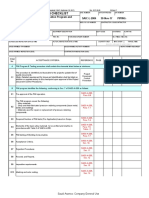

The equipment is switched on 5 minutes before any calibration requirements. SAES-W-011,

B1

(BS EN 50504.Para. 9.5.2.1) Para. 19.2

Validation starts at the minimum output setting. The power source output is

energized and stabilized for 10 seconds, and a reading is taken. The SAES-W-011,

B2

procedure is repeated for each of the measurement points up to the Para. 19.2

maximum, (BS EN 50504 .Para. 9.5.2.2)

After a further 10 seconds a second reading is taken at the max. setting. This

SAES-W-011,

B3 procedure is repeated for each of the measurement points down to the

Para. 19.2

minimum,(BS EN 50504 .Para. 9.5.2.3)

The power source ishould not be loaded in excess of that shown on the SAES-W-011,

B4

rating plate, (BS EN 50504.Para. 9.5.2.4) Para. 19.2

If validation at a particular current and or voltage is required, but the nature

of the load does not permit that current or voltage at the corresponding load

SAES-W-011,

B5 voltage or current to be achieved, points are taken above and below the

Para. 19.2

desired values, and the required value calculated, (BS EN 50504 .Para.

9.5.2.5)

At each validation point selected, record on to SATR-W-2011:

a) Current and/or voltage control setting

b) Power source meter readings.

c) Two values of the true measurement of current and/or voltage from the

SAES-W-011,

B6 test instrumentation.

Para. 19.2

d) The mean value of the two measurements.

Results of measurements are systematically recorded and supplied on, or

with validation certificate. (SATR-W-2011).

(BSEN 50504 .Para. 9.5.2.6)

If the power source has a slope control, the setting is noted. If it is necessary

SAES-W-011,

B7 to validate the power source at different settings of the slope control, this is

Para. 19.2

agreed prior to the validation.(BS EN 50504. Para. 9.5.2.7)

Saudi Aramco: Company General Use

Consistency of the equipment is important and consistency test are

recommended during validation

A consistency test should be carried out on controls, which are not

graduated in absolute units.

NOTE:

1) consistency test determine the repeatability of the equipment output over SAES-W-011,

B8

a period of time. The results obtained from the present validation are Para. 19.2

compared to the results of the initial tests. The

repeatability/consistency is the difference between these readings.

2) Percentage values of accuracy specified in Table 1, should be used in the

consistency test as for standard or precision grade as appropriate.(BS EN

50504- Para 3.4 & Section 5)

On completion of a validation the results are compared with the Accuracy set SAES-W-011,

B9

in Table 1 of section 4 (BS EN 50504.Para. 9.5.2.8 See Attachment 1) Para. 19.2

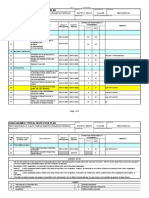

Equipment that meets the accuracy in (Table 1) are labeled with the

following information:

A) "PASSED"

B) Date the label is valid (Date of Passed); SAES-W-011,

B10

C) Date of expiry of the validation (As per schedule Q) Para. 19.2

D) Name of the authority issuing the label

E) Make, model and serial number of the equipment (Unique ID #) (BS EN

50504 .Para. 10.1.2)

For Equipment that does not meet accuracy recommended in Table 1, label

bearing the following information is attached:

a) "FAILED"

b) Date the label was issued;

c) Name of the authority issuing the label; SAES-W-011,

B11

d) Make, model and serial number of the equipment. Para. 19.2

All equipment in shops or in the field

shall have a label. A tag for rejected equipment with a reason for rejection is

an acceptable identifier (needs repair, etc.). See SAIC-L-2031.(BS EN 50504

.Para. 10.1.3)

Avalidation certificate shall be issued, indicating that the equipment has SAES-W-011,

B12

passed or failed.(BS EN 50504 .Para.10.2) Para. 19.2

REMARKS:

ATTACHMENTS:

Attachment 1 - BS EN 50504-2008 Table 1 (Validation/Calibration Tolerances)

REFERENCE DOCUMENTS:

1. SAES-W-011, Welding Requirements for On-Plot Piping, (1 January 2018)

2. BS EN 50504-2008, Code of practice for Validation of arc welding equipment

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

S.PARSAD/MANSOOR MR. IBRAHIM

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

MAZHARULHAQ MR.ABDUL KAREEM

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU-30-September-2018 - REV.2018.09.00 (Standards Cutoff - September 30,2018) Rev.2018.09.00 30-Sep-18

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 WELD-

Attachment 1 - BS EN 50504-2008- Table 1 (Validation/Calibration Tolerances)

Saudi Aramco: Company General Use

You might also like

- Saudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureDocument2 pagesSaudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureMAZHARULNo ratings yet

- Proposed Loctugan Integrated Farm SchoolDocument4 pagesProposed Loctugan Integrated Farm SchoolMariel Pastolero100% (1)

- SATR-W-2006 Rev 6Document1 pageSATR-W-2006 Rev 6Manoj KumarNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldManoj KumarNo ratings yet

- 175 012000Document2 pages175 012000Abu Anas M.SalaheldinNo ratings yet

- SAIC-L-2035 Rev 6Document2 pagesSAIC-L-2035 Rev 6biplabpal2009No ratings yet

- SAIC-W-2006 Rev 0 PDFDocument4 pagesSAIC-W-2006 Rev 0 PDFMidhun K ChandraboseNo ratings yet

- SAIC W 2069 in Process Welding InspectionDocument8 pagesSAIC W 2069 in Process Welding InspectionAbdul Gafoor ShaikhNo ratings yet

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldDocument19 pagesSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldIrshad IqbalNo ratings yet

- Saic L 2139Document9 pagesSaic L 2139Kumar RNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistJoni Carino SuniNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 MechDocument4 pagesSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 Mechkarthi51289No ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- SAIC-A-2008 Rev 6 Verify Test Medium For Hydrostatic Testing and Lay UpDocument2 pagesSAIC-A-2008 Rev 6 Verify Test Medium For Hydrostatic Testing and Lay UpAhdal NoushadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- Saudi Aramco Test ReportDocument4 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Test Report: 25-May-05 Weld-Weekly Weld Status Report SATR-W-2019Document2 pagesSaudi Aramco Test Report: 25-May-05 Weld-Weekly Weld Status Report SATR-W-2019David RodriguesNo ratings yet

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Jul-18 Weldm4metzNo ratings yet

- 175-Ir171300, (850146), 11.30.2015Document2 pages175-Ir171300, (850146), 11.30.2015Rami ELLOUMINo ratings yet

- Saudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-W-2032 24-Jul-18 Weld-Upgrade Aramco JNGLFP Propane System BI-21-00087 MacoDocument7 pagesSaudi Aramco Inspection Checklist: SAIC-W-2032 24-Jul-18 Weld-Upgrade Aramco JNGLFP Propane System BI-21-00087 MacojahaanNo ratings yet

- Saudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportDocument2 pagesSaudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportJoni Carino Suni100% (1)

- Saic e 2002Document10 pagesSaic e 2002jerinNo ratings yet

- Weld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020Document3 pagesWeld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020bishalNo ratings yet

- Saic L 2008 PDFDocument4 pagesSaic L 2008 PDFHesham HelalNo ratings yet

- Saudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 24-Mar-16 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 24-Mar-16 CivilSajid ShaikhNo ratings yet

- Saudi Aramco Inspection Checklist: Review Procedure - Pressure Testing (All Applications) SAIC-A-2001 15-Nov-17 MechDocument27 pagesSaudi Aramco Inspection Checklist: Review Procedure - Pressure Testing (All Applications) SAIC-A-2001 15-Nov-17 MechNaushad AlamNo ratings yet

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocument8 pagesSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurekarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechDocument3 pagesSaudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechHamidNo ratings yet

- SATR-W-2020 Rev 8Document4 pagesSATR-W-2020 Rev 8محمد علي النويصرNo ratings yet

- Saudi Aramco Inspection Checklist: Final Reinstatement After Mechanical & Chem Cleaning SAIC-G-2019 30-Apr-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Final Reinstatement After Mechanical & Chem Cleaning SAIC-G-2019 30-Apr-17 Mechkarthi51289No ratings yet

- Welder Repair Assessment and Tracer Weld Report-Weekly SATR-W-2018 22-Jan-18 WeldDocument2 pagesWelder Repair Assessment and Tracer Weld Report-Weekly SATR-W-2018 22-Jan-18 Weldkarthi51289No ratings yet

- Saic-L-2010 Pmi Testing PDFDocument5 pagesSaic-L-2010 Pmi Testing PDFkarioke mohaNo ratings yet

- Saic L 2007 PDFDocument7 pagesSaic L 2007 PDFHesham HelalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- SAES-W-012 - Google Search3Document1 pageSAES-W-012 - Google Search3fayceal0% (1)

- SATR-A-2009 Rev 2 - System Lay-Up Report (Certificate)Document2 pagesSATR-A-2009 Rev 2 - System Lay-Up Report (Certificate)deepa narayan100% (1)

- Saudi Aramco Inspection Checklist: Selection of Welds For NDE (On-Plot Piping & Structures) SAIC-W-2015 WeldDocument23 pagesSaudi Aramco Inspection Checklist: Selection of Welds For NDE (On-Plot Piping & Structures) SAIC-W-2015 WeldIrshad IqbalNo ratings yet

- Satr-W-2008 Atyb TRDocument6 pagesSatr-W-2008 Atyb TRDeo MNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument1 pageInspection & Testing Requirements Scope:: Test and Inspection PerEagle SpiritNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection - Bolts, Nuts & Washers For Structural ConnectionsDocument6 pagesSaudi Aramco Inspection Checklist: Receiving Inspection - Bolts, Nuts & Washers For Structural ConnectionsAbdul HannanNo ratings yet

- SAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingDocument5 pagesSAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingFiras AlbaweiNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saic-P-3003 Rev 0 PDFDocument4 pagesSaic-P-3003 Rev 0 PDFHesham HelalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument23 pagesSaudi Aramco Inspection ChecklistjahaanNo ratings yet

- 175 030100Document2 pages175 030100Abu Anas M.Salaheldin100% (1)

- QMIS LBE Rev Mech Final OldDocument683 pagesQMIS LBE Rev Mech Final OldprabakaranNo ratings yet

- SATIP-W-011-01 Rev 8Document10 pagesSATIP-W-011-01 Rev 8saravananmenmathiNo ratings yet

- Saic W 2036Document2 pagesSaic W 2036Neelam AhmadNo ratings yet

- Saep 324Document13 pagesSaep 324Up WeldNo ratings yet

- Saudi Aramco Inspection Checklist: Pre Welding Inspection - Offshore Structures SAIC-W-1312 WeldDocument1 pageSaudi Aramco Inspection Checklist: Pre Welding Inspection - Offshore Structures SAIC-W-1312 Weldkartik_harwani4387No ratings yet

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 15-Dec-09 MechDocument6 pagesSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 15-Dec-09 MechEagle SpiritNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 Mechnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistJoni Carino Suni100% (1)

- Satr W 2013Document8 pagesSatr W 2013Rijwan MohammadNo ratings yet

- Satip G 005 01Document11 pagesSatip G 005 01Rijwan MohammadNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportEswari AnandNo ratings yet

- Shieldinggases Aws 5.32 PDFDocument3 pagesShieldinggases Aws 5.32 PDFessnelsonNo ratings yet

- Satip A 004 03Document3 pagesSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- SAEP-379 Quality Issues NotificationDocument4 pagesSAEP-379 Quality Issues NotificationMusic And FunNo ratings yet

- Installation of Main Steel Structure/ Platform & Steam SilencerDocument4 pagesInstallation of Main Steel Structure/ Platform & Steam SilencerzhangNo ratings yet

- Saudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 15-Jul-18 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistMAZHARULNo ratings yet

- Saic L 2003Document9 pagesSaic L 2003MAZHARULNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection ChecklistMAZHARULNo ratings yet

- Saic B 4003 PDFDocument1 pageSaic B 4003 PDFMAZHARULNo ratings yet

- 02.186 - F - Satr-Nde-2008 Revised (003) 010817 SS JointsDocument2 pages02.186 - F - Satr-Nde-2008 Revised (003) 010817 SS JointsMAZHARULNo ratings yet

- Saic B 4006 PDFDocument1 pageSaic B 4006 PDFMAZHARULNo ratings yet

- Saudi Aramco Inspection Checklist: Emergency Eyewash/Shower System Installation SAIC-B-4002 30-Apr-13 PlumbDocument2 pagesSaudi Aramco Inspection Checklist: Emergency Eyewash/Shower System Installation SAIC-B-4002 30-Apr-13 PlumbMAZHARUL100% (1)

- Saudi Aramco Typical Inspection PlanDocument2 pagesSaudi Aramco Typical Inspection PlanMAZHARULNo ratings yet

- Saving Money ThesisDocument8 pagesSaving Money ThesisClaire Webber100% (2)

- IZARSETManual13EN PDFDocument118 pagesIZARSETManual13EN PDFrogerioangelli540No ratings yet

- Shreya Singhal Vs Union of IndiaDocument3 pagesShreya Singhal Vs Union of IndiaShivang SharmaNo ratings yet

- Assignment 1 - Roles and ResponsibilitiesDocument12 pagesAssignment 1 - Roles and ResponsibilitiesericmcnarteyNo ratings yet

- 807 Karnataka Yantradhare 2015Document25 pages807 Karnataka Yantradhare 2015MALLIKARJUN BIRADARNo ratings yet

- Mvule Trust Annual Report, 2010Document24 pagesMvule Trust Annual Report, 2010Straight Talk FoundationNo ratings yet

- Kinco CV100 VFD User Manual-En20130617Document109 pagesKinco CV100 VFD User Manual-En20130617alibuchy100% (1)

- Normal 5f5fc792e6de4Document66 pagesNormal 5f5fc792e6de4AbdulmalekNo ratings yet

- Economics and EmigrationDocument24 pagesEconomics and EmigrationMarius ComperNo ratings yet

- Auditing - RF-12 Quiz BowlDocument12 pagesAuditing - RF-12 Quiz BowlAngel TumamaoNo ratings yet

- Computer Vision: Models, Learning and InferenceDocument59 pagesComputer Vision: Models, Learning and InferencePREM KUMAR MNo ratings yet

- Knimbus and Jgate ComparisonDocument3 pagesKnimbus and Jgate ComparisonMahesh Wagh100% (1)

- CNC Overview PDFDocument16 pagesCNC Overview PDFQuoc HuyNo ratings yet

- COM 226 - Computer Troubleshooting Handout PrintDocument68 pagesCOM 226 - Computer Troubleshooting Handout PrintOluwafisayo B. AyoadeNo ratings yet

- CS8611 MINI PROJECT Validation of Facebook Login PageDocument14 pagesCS8611 MINI PROJECT Validation of Facebook Login PageaddssdfaNo ratings yet

- Dislocations and Plastic DeformationDocument6 pagesDislocations and Plastic DeformationPrashanth VantimittaNo ratings yet

- Servo SystemDocument2 pagesServo SystemJoseGarciaRuizNo ratings yet

- DGI300 Manual 4.1Document154 pagesDGI300 Manual 4.1Caraiane Catalin100% (2)

- Naplan 2013 Final Test Numeracy Year 9 (Calculator)Document13 pagesNaplan 2013 Final Test Numeracy Year 9 (Calculator)Mohammad AliNo ratings yet

- Nato Unclassified: Declassified/Declassifié - Public Disclosed/Mise en Lecture PubliqueDocument55 pagesNato Unclassified: Declassified/Declassifié - Public Disclosed/Mise en Lecture PubliqueDamonta HenryNo ratings yet

- Medidores Rotativos Série FMRDocument3 pagesMedidores Rotativos Série FMRmateuNo ratings yet

- Marketing PlanDocument51 pagesMarketing PlanS.m.Rasel100% (2)

- Company & Mill Presentation - Mining-And-Wet-GrindingDocument28 pagesCompany & Mill Presentation - Mining-And-Wet-GrindingTecnoExpress CHILENo ratings yet

- 2019 49 59 Ford Big CarDocument172 pages2019 49 59 Ford Big CarJanneLaukkanenNo ratings yet

- MicroShield ManualDocument130 pagesMicroShield Manualagus waluyoNo ratings yet

- Syllabus For All SemsDocument115 pagesSyllabus For All SemsMisbah JahanNo ratings yet

- The CPV Valley Energy Center - 2013 RFPDocument103 pagesThe CPV Valley Energy Center - 2013 RFP2rQiTPh4KnNo ratings yet

- Herbal Gram Index v1-67Document86 pagesHerbal Gram Index v1-67terryvnd50% (2)

- Channel List 20210427Document13 pagesChannel List 20210427drpnnreddyNo ratings yet