Professional Documents

Culture Documents

SOP-Technical (v1.2)

SOP-Technical (v1.2)

Uploaded by

ABDULOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SOP-Technical (v1.2)

SOP-Technical (v1.2)

Uploaded by

ABDULCopyright:

Available Formats

Table of Contents

Table of Contents……………………………………………………………………………………………………………………………………………………………………………………….……….. 1

1.0 Introduction & Objectives …………………………………………………….. ……………………………………………………………………….………………………………………… 3

1.1 Preface ……………………………………………………………………………………………………………………………………………………………………………………….……….. 4

1.2 Structure of the SOP……………………………………………………………………………………………………………………………………………………………………….………… 5

1.3 Objectives…………………………………………………………………………………………………………………………………………………………………………………………….. 5

1.4 Glossary of the Terms Used………………………………………………………………………………………………………………………………………………………………………… 6

1.5 Process Map Symbols…………………………………………………………………………………………………………………………………………………………………………….…. 7

1.6 Version Control History………………………………………………………………………………………………………………………………………………………………………….…… 7

1.7 Periodicity of Review…………………………………………………………………………………………………………………………………………………………………………….…… 7

1.8 Change Control………………………………………………………………………………………………………………………………………………………………………………….……. 7

2.0 Stadandard Operating Procedure.………………………………………………………………………………………………………………………………………………………….…………….. 8

2.1 Development Process…………………………………………………………………………………………………………………………………………………………………………….….. 9

2.2 Pre-production Process……………………………………………………………………………………………………………………………………………………………………………… 10

2.3 Bulk Production Process……………………...………………………………………………………………………..……………………………………………………………………………. 15

3.0 Process Maps…………………………………………………………………………………………………………………………….………………………………………………………….………….…. 17

3.1 Development Process…………………………………………………………………………………………………………………………………………………………………………….….. 18

3.2 Pre-production Process……………………………………………………………………………………………………………………………………………………………………………… 19

3.3 Bulk Production Process…………………………………………….………………………………………………..……………………………………………………………………………. 26

4.0 Formats/Documents………………………………………………………………………………………………………………………………………………………………………………..…………… 30

TEC001 Style Review Meeting Minutes………………...………................................................................................................................................................................................................ 31

TEC002 Style Changeover Plan............................................................................................................................................................................................................................................... 32

TEC003 Input Control Chart Summary (Next 45 Days Input)…............................................................................................................................................................................................... 33

TEC004 Pilot Run/PP Meeting Schedule for Technical Department………………………………………………………………………………………………………………...……………………. 34

TEC005 Pattern Amendment Sheet ……………………………………………………………………………………………………………………….………………….………..……………………. 36

TEC006 Pilot Run Cutting Requisition……………................................................................................................................................................................................................................... 37

TEC007 New Styles (Pilot/ 1st Bulk) Before Cutting Layer Check List..................................................................................................................................................................................... 38

TEC008 Trims Requisition Slip ................................................................................................................................................................................................................................................ 39

TEC009 Final Pattern Measurement........................................................................................................................................................................................................................................ 40

TEC010 Wash Measurement Check Form............................................................................................................................................................................................................................... 41

Version: 1.1 Technical SOP 1

Table of Contents

4.0 Formats/Documents (Continued….)

TEC010A Non Wash Measurement Check Form……………………………………………………………………………………………………………………………………………………………. 42

TEC011 Wet/Dry/Wrinkle Free Sample Requisition Form...................................................................................................................................................................................................... 43

TEC012 Monthly Style Changeover Responsible Personnel Report…….............................................................................................................................................................................. 44

TEC013 Sewing Operation Bulleting & Thread Consumption Form....................................................................................................................................................................................... 45

TEC014 Pre Production Review Summary…………………………………………………………………………………………………………………………………………………………………. 47

Index…………………………………………………………………………………………………………………………………………………………………………….. 47

Sheet -1 PP Review Summary……………………………………………………………………………………………………………………………………………………….. 48

Annexure - 1 Production Data & TNA…………………………………………………………………………………………………………………………………………………….. 52

Annexure - 2 Sewing Operation Analysis (Operation Control Chart) ………………………………………………………………………………………………………………….. 53

Annexure – 2A Finishing Operation Analysis……………………………………………………………………………………………………………………………………………….. 55

Annexure - 3 Fabric & Trims BOM…………………………………………………………………………………………………………………………………………………………. 56

Annexure - 4 Process Control (Process Checklist) ……………………………………………………………………………………………………………………………………… 59

Annexure - 5 Approvals (Approvals from Merch/Customer)…………………………………………………………………………………………………………………………… 61

Annexure - 6 Photo Gallery…………………………………………………………………………………………………………………………………………………………………. 62

Annexure - 7 Style Control Chart…………………………………………………………………………………………………………………………………………………………… 63

Style Specific Changeover Responsible Personnel Report…………………………………………………………………………………………………………… 64

TEC015 Style Changeover Layout......................................................................................................................................................................................................................................... 65

TEC016 Line Feeding Plan..................................................................................................................................................................................................................................................... 66

TEC017 Cutter Must………………………………………………………………………………………………………………………………………………………………………………………..…. 67

TEC018 Pilot Review Report……………………………………………………………………………………………………………………………………………..………………………………..…. 68

TEC019 Operation Specification Sheet.................................................................................................................................................................................................................................. 70

TEC020 Pilot Line Manpower Clarification Chart………………………..................................................................................................................................................................................... 71

5.0 Key Performance Indicators (KPIs) and Cockpit Charts…………………………………………………………………………………………………………………………….………… 72

5.1 Technical Process KPI Template……………………………………………………………………………………………………………………………………………………...……......... 73

5.2 Technical Process Charts (Specimen)..…………………….……………………………………………………………….………………………………………………………………..….

5.2.1 Technical Process Cockpit Chart (Specimen)………………………..……………………………………………………………………...…………………………………...… 74

5.2.2 Technical Process Data (Specimen)…………………………………………………………………………………………………………………………………………….…… 75

6.0 Audit Checklist………………………………………………………………………………………………………………………………………………………………………………..……………….… 76

Version: 1.1 Technical SOP 2

Section 1:

Introduction and Objectives

Version: 1.1 Technical SOP 3

1. Introduction

1.1 Preface

1.1.1 It is of paramount important that business processes in an organisation is run in an consistent manner in order to achieve the desired vision, mission, goals and

objectives of an organisation since in consistent processes will derive in consistent results irrespective of how good the inputs to the processes are.

1.1.2 Objective of developing and maintaining Standard Operating Processes (SOPs) are to ensure that any person responsible to run either a part or the entire process

have absolute clarity as to how the process must be run in order to achieve the desired results.

1.1.3 Further SOPs will enable standardization of the way each Strategic Business Unit (SBUs) is run, hence enabling the comparison of results and achievements

between the same. SOPs will enable an organisation to be process driven rather than person driven, which will ensure consistency in the results achieved in terms

of productivity, cost, quality, delivery, safety and morale.

1.1.4 All CEOs/COOs/HOOs will be responsible for adherence to standard operating procedures (SOPs) and will be closely monitored by the country manager of Epic

Group, Bangladesh for compliances with this SOP at these Facilities.

1.1.5 Issues regarding interpretation and modification of this SOP will be decided by Managing Director of Epic Group. Any amendment to this SOP should be approved

by Managing Director of Epic Group.

1.1.6 This SOP is applicable to all the facilities in the EPIC Group, irrespective of the geographical location.

Version: 1.1 Technical SOP 4

1.2 Structure of the SOP

SOP consists of five key areas to be adhered and followed to ensure that the desired result to be achieved.

Section 1 : Introduction & Objectives

Section 2 : Standard Operating Procedures

2.1 – Development Process

2.2 – Pre Production Process

2.3 – Bulk Production Process

Section 3 : Process Maps

3.1 – Development Process

3.2 – Pre Production Process

3.3 – Bulk Production Process

Section 4 : Formats/Documents

Section 5 : Key Performance Indicators (KPIs) and Cockpit Charts

Section 6 : Process Audit Checklist

1.3 Objectives

1.3.1 Standardization of the mode of operating of technical processes in the garment manufacturing facilities across the group, hence to benchmark & continuously

improve the processes to achieve desired results.

1.3.2 To ensure effective and efficient planning of key resources deployed in the technical process such as manpower, machinery, material, space, etc, hence optimum

utilisation of the same throughout the facilities.

Version: 1.1 Technical SOP 5

1.3.3 Direct involvement in driving the style changeover time to the minimum possible level hence ensuring lost time/loss of productivity during the changeover process is

minimised.

1.3.4 To ensure pre production activities are carried out as per the company norms, hence enabling a smooth transition from current style to the new style and achieving

the bulletin targets as planned. Ultimately to ensure overall realisation of the pieces planned for the time period.

1.3.5 To improve the overall performance of garment on time delivery (OTD) by ensuring that the cutting process starts on time as per the time and action plan.

1.3.6 To ensure that the garments output from the sewing lines & finishing lines passes quality inspection right first time.

1.4 Glossary of the Terms Used

Term Description Term Description

SOP Standard Operating Procedure PP Pre Production

PR Person Responsible KPI Key Performance Indicator

BFM Basis for Measurement SMV Standard Minute Value

WIPCS Work in Progress Control System PPC Production Planning & Control

MD Managing Director CEO Chief Executive Officer

COO Chief Operating Officer CFO Chief Financial Officer

CPU Central Processing Unit CIMS Commerce Information Management System

CM Cut & Make CB Cost Breakdown

TNA, T&A Time & Action HOO Head Of Operation

WMS Warehouse Management System GRN Goods Received Note

Version: 1.1 Technical SOP 6

1.5 Process Map Symbols

Process Step Rework Connector Process Flow Direction Decision Box

1.6 Version Control History

SOP Serial Number SOP Code Version Description Date Reviewed & Approved By

12 TEC 1.1 Second Review June 2012 Managing Director, Epic Group

1.7 Periodicity of Review

1.7.1 Annually at the end of each financial year.

1.7.2 As and when processes are changed / amended.

1.8 Change Control

1.8.1 All suggestions for changes should be documented in the Change Control Form and sent to Managing Director – Epic Group for consideration for approval.

Section / Chapter Clause Ref. Existing Clause Suggested Clause Initiated by Authorised by

Version: 1.1 Technical SOP 7

Section 2:

Standard Operating Procedures

Version: 1.1 Technical SOP 8

2.1 Development Process

Serial # Process Activity PR Document #

Technical manager must participate in the initial style review meeting conducted by the sample department for a new

style before starting the sample process. Technical manager must study the style and suggest any operational

2.1.1 Head of Technical TEC001

changes required for the style for ease of production, whilst ensuring the buyer’s style specifications. If required

technical manager must submit mock-ups to enable customer to understand the required changes.

Technical manager must ensure the changes requested at the style review meeting which are approved by the

2.1.2 Head of Technical

customer is incorporated in the subsequent samples by reviewing the samples at the sample manufacturing stage.

Version: 1.1 Technical SOP 9

2.2 Pre-Production

Serial # Process Activity PR Document #

Technical manager will receive a copy of the style changeover plan on 1st of every month for the next 3 months

2.2.1 Head of Technical TEC002

from the PPC department.

Technical manager will also receive the input control chart summary (next 45 days input) on 1st of every month for

2.2.2 Technical Manager TEC003

the next 3 months from the PPC department.

Technical manager will also receive the style changeover responsible personnel report from the IE department 4

2.2.3 Technical Manager TEC012

weeks prior to the 1st day of the following month.

Within 2 days of receipt of the above documents technical manager will prepare pilot run/PP meeting schedule for

technical department for the following two months. Immediately after preparation pilot run/PP meeting schedule, it

2.2.4 Head of Technical TEC004

will be circulated to the respective COO, HOO, unit head, merchandiser, head of sample & CAD, cutting manager,

maintenance manager & QC manager for their perusal.

Technical manger must analyze the pre-production sample requirement based on the prepared schedule to identify

2.2.5 any manpower/capacity issues and take necessary actions with the support of the COO/unit head to adjust the Head of Technical TEC004

capacity to cope up with the work load.

Technical manager must obtain the approved PP sample and a technical folder from merchandising before starting

2.2.6 Head of Technical

the pre-production sample process as per the schedule. i.e. 2 weeks prior to the sewing input date.

For stitching of the pilot run technical manager must prepare trims requisition slip based on the trim card received

2.2.7 Technical Manager TEC008

along with the technical folder and send to stores to obtain trims required for the pilot run.

Further technical manager must request adjusted PP patterns & embellishment placement boards (if applicable)

2.2.8 Technical Manager TEC005

from the sample room for the pilot run 2 weeks before the sewing input date.

Version: 1.1 Technical SOP 10

2.2 Pre-Production (Continued…)

Serial # Process Activity PR Document #

Once the adjusted PP patterns are received from the sample room, 1 working day before the pilot run stitching date,

2.2.9 technical manager must ensure that the patterns are checked for the accuracy of the patterns. If patterns are Technical Manager TEC009

incorrect they must be returned to the CAD room for rework.

Technical manager must ensure that the embellishment placement boards are measured for the accuracy. If

2.2.10 embellishment placement boards are correct, same to be sent to the cutting. If incorrect they will be sent send back Technical Manager TEC005

to the sample & CAD room for rework.

In addition to the above items required for the pilot run, technical manager must request pilot cut from the cutting

2.2.11 department 2 weeks before the sewing input date. Cutting of the pilot samples must be done at the cutting Technical Manager

department.

It is the responsibility of the technical manager to ensure that the pilot cut markers are checked for the accuracy

before cutting the pilot run in the cutting department.

Pilot should consist of garments representing each colour in the order in full size range. If a colour has more than

2.2.12 one body pattern due to shrinkage, a full size range for each shrinkage pattern must be included in the pilot. Technical Manager TEC007

If there are 5 colours for an order, 6 sizes in the size range and 2 shrinkage ranges for each colour, pilot should

have total minimum pilot qty of 05 x 02 x 06 = 60 pieces.

If markers are accurate approval will be given to the cutting and if markers need reworking, technical manager will

2.2.13

inform the CAD room manager to make necessary adjustments.

Technical manager is responsible for checking the pilot cut immediately after cutting to verify the accuracy of the cut

2.2.14 panels. If the cut panels are not correct as per the buyer’s quality requirements, they will be returned to the cutting Technical Manager TEC007

department for rework.

Version: 1.1 Technical SOP 11

2.2 Pre-Production (Continued…)

Serial # Process Activity PR Document #

Further technical manager will receive the tentative bulletin from IE dept. Upon receipt of the tentative bulletin

technical manager must ensure machines, folders, presser foots & attachments required for the pilot run are

prepared by the garment maintenance dept 1 working day prior to stitching the pilot run.

A manpower clarification chart must be filled for each pilot run with the operator name, ID number and the pilot Technical

operations each operator has to carry out. Manager/Unit

2.2.15 TEC013, TEC020

Maintenance

Technical manager must ensure that pilot line consists of operators who are not sample men but tailors who are

experienced from the floor. Manager

Further technical manager must ensure all pilot machines equipped with all the required folders / attachments /

guides as correctly used in the lines.

Once pilot run cut panels, actual trims & accessories are received, technical manager will instruct the technical

team to start stitching the pilot run. Technical TEC018, TEC010,

2.2.16 Manager/ QC TEC010A

It is the responsibility of the Technical manager to educate each pilot run operator on the machine operations to be

Manager

carried out and the expected quality requirement. Technical manager must monitor the performance of each pilot

operator during pilot production.

Pilot operator must be advised to record any technical difficulties faced during the manufacture of the pilot samples.

Further pilot operator must suggest easy production ideas or any attachment requirements which may help increase

the productivity, which were to be identified while the sample are being made. Technical

2.2.17

Manager

Technical manager must note all pilot operator comments and incorporate the suggestion in the pattern amendment

sheet to the CAD department, while giving the bulk cutting approval.

Version: 1.1 Technical SOP 12

2.2 Pre-Production (Continued…)

Serial # Process Activity PR Document #

Once stitching is completed garments will be picked-up at random from the pilot run, 100% quality checking and

2.2.18 measurements checking of key measurements points will carried out by the technical team and the QC team.

Technical manager is responsible to rework garments if quality is not as per the expected standard by the buyer.

In case of non wash garments, garments to be finished as per the buyers specifications. 100% quality checking of Technical

2.2.19 the pilot run garments and measurement checking of key measurements points of the garments picked-up at Manager/ QC TEC010A

random will be carried out subsequently. Manager

In case garments needs processing in wet/dry/wrinkle free process (es),send pilot run garments to wet/dry/wrinkle

free process (es) for processing as per buyer's specifications. Upon receipt of the garments after processing in the Technical

2.2.20 TEC010, TEC011

respective areas, technical manager will instruct the technical team to conduct 100% quality checking of the Manager

garments and measurement checking of key measurements points of the garments picked-up at random.

Based on the pilot run results, pattern adjustments required for the bulk production should be sent to the CAD room.

Pilot run review meeting to be held with all concerned departments immediately after stitching and finishing. Pilot

run review meeting minutes prepared and shared with the meeting participants following the pilot run review Technical

2.2.21 meeting. TEC005, TEC018

Manager

Concerned departments to participate in the pilot run review meeting are production general manager, QC manager,

merchandising manager, maintenance manager, cutting manager, technical manager, finishing manager and CAD

room manager.

Subsequently, technical manager will call all concerned parties for the PP meeting. PP meeting to be held 1 week

prior to the sewing input date.

Concerned parties to attend the PP meeting are Head of Technical, Technical Manager, Unit Head, Production Technical

2.2.22

General Manager, Merchandising Manager, QC Manager, Audit Manager, IE Manager, Maintenance Manager, Manager

Head of Sample & CAD, Head of Washing & Wrinkle Free, QC Manager – Washing & Wrinkle Free, Fabric & Trims

Quality Manager and Stores Manager.

Version: 1.1 Technical SOP 13

2.2 Pre-Production (Continued…)

Serial # Process Activity PR Document #

Conduct PP meeting & discuss, order details, buyer's special comments, all process details include technical,

quality, etc. Receive approved sample, approved shade band, internal fabric shade segregation report, colour wise Technical

2.2.23 garment cut plan, in-depth orientation of the buyer's standards and expectations of the garment from the respective TEC014

Manager

responsible department personnel.

Circulate PP review summary to the meeting participants within 2 working days of holding the meeting.

Version: 1.1 Technical SOP 14

2.3 Bulk Production Process

Process Activity PR Document #

Technical

2.3.1 Technical manager must ensure that the bulk markers are checked and approved before bulk cutting. TEC007, TEC017

Manager

It is the responsibility of the technical manager to ensure the suitability of special m/c, folders, presser foots, jigs & Technical

2.3.2 attachments given by garment maintenance for bulk production before starting the bulk production.

Manager

Further technical manager is responsible for the preparation of templates & finished boards required for sewing.

Subsequently technical manager will receive the finalized and duly approved sewing operation bulletin, style Technical TEC013, TEC015,

2.3.3 changeover layout & line feeding plan from IE department, which will be used as the base documents in feeding the

Manager TEC016

new style.

Upon receipt of all documents mentioned above technical manager will start feeding line as per the bulletin, style

changeover layout, line feeding plan and the approved sample. Mock-ups required for all operations must be prepared Technical

2.3.4 TEC019

with the involvement of the quality department. Technical manager must ensure timely completion of the line feeding Manager

and also must ensure that quality pass garments are coming as output from the line.

First output garments from the line will be submitted to the technical manager by the line QC supervisor & technician

responsible for line feeding for first time approval. Technical team is responsible for 100% quality checking of the

garments along with the QC dept to ensure line output meets the buyer specified standards. Technical

2.3.5 If the garments meet buyer requirements, technical manager will grant approval to proceed with the bulk production. Manager/ QC

If issues are identified with the output, cutting, sewing, technical and quality teams must get together and make a Manager

team effort to resolve the issues at the earliest possible time to ensure that minimum amount of time is lost from the

process.

Technical manager is responsible to review the first bulk garments output from the finishing and issue final FTA to Technical

2.3.6 proceed with finishing of the bulk garments. A collective decision to be taken with the head of QA on the standard to

Manager

be approved as the FTA.

Version: 1.1 Technical SOP 15

2.3 Bulk Production Process (Continued….)

Process Activity PR Document #

Technical manager is responsible to improve style ramp-up time & monitor IE build-up plan after feeding the line and Technical

2.3.7

troubleshoot day to day technical issues in the garment production. Manager

Version: 1.1 Technical SOP 16

Section 3:

Process Map

Version: 1.1 Technical SOP 17

Version: 1.1 Technical SOP 18

Version: 1.1 Technical SOP 19

Version: 1.1 Technical SOP 20

Version: 1.1 Technical SOP 21

Version: 1.1 Technical SOP 22

Version: 1.1 Technical SOP 23

Version: 1.1 Technical SOP 24

Version: 1.1 Technical SOP 25

Version: 1.1 Technical SOP 26

Version: 1.1 Technical SOP 27

Version: 1.1 Technical SOP 28

Version: 1.1 Technical SOP 29

Section 4:

Formats/Documents

Version: 1.1 Technical SOP 30

Version: 1.1 Technical SOP 31

Version: 1.1 Technical SOP 32

Version: 1.1 Technical SOP 33

Version: 1.1 Technical SOP 34

Version: 1.1 Technical SOP 35

Version: 1.1 Technical SOP 36

Version: 1.1 Technical SOP 37

Version: 1.1 Technical SOP 38

Version: 1.1 Technical SOP 39

Version: 1.1 Technical SOP 40

Version: 1.1 Technical SOP 41

TEC010A (Stationery)

Version: 1.1 Technical SOP 42

Version: 1.1 Technical SOP 43

Version: 1.1 Technical SOP 44

Version: 1.1 Technical SOP 45

Version: 1.1 Technical SOP 46

Version: 1.1 Technical SOP 47

Version: 1.1 Technical SOP 48

Version: 1.1 Technical SOP 49

Version: 1.1 Technical SOP 50

Version: 1.1 Technical SOP 51

Version: 1.1 Technical SOP 52

Version: 1.1 Technical SOP 53

Version: 1.1 Technical SOP 54

Version: 1.1 Technical SOP 55

Version: 1.1 Technical SOP 56

Version: 1.1 Technical SOP 57

Version: 1.1 Technical SOP 58

Version: 1.1 Technical SOP 59

Version: 1.1 Technical SOP 60

Version: 1.1 Technical SOP 61

Version: 1.1 Technical SOP 62

Version: 1.1 Technical SOP 63

Version: 1.1 Technical SOP 64

Version: 1.1 Technical SOP 65

Version: 1.1 Technical SOP 66

Version: 1.1 Technical SOP 67

Version: 1.1 Technical SOP 68

Version: 1.1 Technical SOP 69

Version: 1.1 Technical SOP 70

Version: 1.1 Technical SOP 71

Section 5:

Key Performance Indicators (KPIs) and

Cockpit Charts

Version: 1.1 Technical SOP 72

Version: 1.1 Technical SOP 73

Version: 1.1 Technical SOP 74

Version: 1.1 Technical SOP 75

Section 6:

Process Audit Checklist

Version: 1.1 Technical SOP 76

Version: 1.1 Technical SOP 77

Version: 1.1 Technical SOP 78

You might also like

- BUCU004 Entreprenuership Lecture Notes From Mount Kenya University BUCU004 Entreprenuership Lecture Notes From Mount Kenya UniversityDocument149 pagesBUCU004 Entreprenuership Lecture Notes From Mount Kenya University BUCU004 Entreprenuership Lecture Notes From Mount Kenya Universitybetty KemNo ratings yet

- En 16432-1 - EN - Ballastless Track Systems - General RequirementsDocument35 pagesEn 16432-1 - EN - Ballastless Track Systems - General RequirementsBaptiste RochetteNo ratings yet

- Fundamental of Apparel ProductionDocument11 pagesFundamental of Apparel ProductionAnilNo ratings yet

- AMH - Q1201 - Fashion DesignerDocument27 pagesAMH - Q1201 - Fashion DesignerRahul RanjanNo ratings yet

- Logistics Problem 19 - Shipping, Storage, & DistributionDocument35 pagesLogistics Problem 19 - Shipping, Storage, & DistributionJose F. MaestreNo ratings yet

- Project Profile Dairy Farm Management PDFDocument57 pagesProject Profile Dairy Farm Management PDFBharat Patel100% (1)

- Abb Technical Training Booklet WebDocument78 pagesAbb Technical Training Booklet WebAkoKhalediNo ratings yet

- Busbar CatalogueDocument8 pagesBusbar CatalogueSalmanNo ratings yet

- Retail Geography (Shuguang Wang, Paul Du)Document255 pagesRetail Geography (Shuguang Wang, Paul Du)RasmusEriksson100% (1)

- 19 Departments and Its Functions at A Garment FactoryDocument11 pages19 Departments and Its Functions at A Garment FactoryLiaqut Ali KhanNo ratings yet

- IS3223 Zara Case Study: Zara: IT For Fast FashionDocument27 pagesIS3223 Zara Case Study: Zara: IT For Fast FashionAlex NguyenNo ratings yet

- Garment Industry DepartmentsDocument61 pagesGarment Industry DepartmentsDeepthi SonuNo ratings yet

- Topic 9 - Tendering ProcedureDocument36 pagesTopic 9 - Tendering ProcedureKen MutuiNo ratings yet

- Cannington Court, SomersetDocument95 pagesCannington Court, SomersetWessex ArchaeologyNo ratings yet

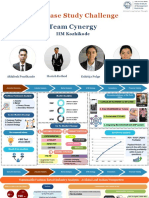

- PWC Case Study Challenge: Team CynergyDocument16 pagesPWC Case Study Challenge: Team CynergyDeepakbalajiNo ratings yet

- 2939-1000-45EG-0006 - C - Technical Specification - Compressed Air PackageDocument23 pages2939-1000-45EG-0006 - C - Technical Specification - Compressed Air PackageAloysius WongNo ratings yet

- New Crew Handbook FinalDocument30 pagesNew Crew Handbook Finalr tNo ratings yet

- RoadshowsDocument10 pagesRoadshowssiewspahNo ratings yet

- Bhavik Yadav Internship ReportDocument24 pagesBhavik Yadav Internship ReportAnita AhlawatNo ratings yet

- Green Banking ActivitiesDocument37 pagesGreen Banking ActivitiesShoumik MahmudNo ratings yet

- 5 Seams 02Document27 pages5 Seams 02Mital AnjariaNo ratings yet

- Determination of Machine Requirements For A New FactoryDocument25 pagesDetermination of Machine Requirements For A New FactorySivakumar KNo ratings yet

- 3 Module Merchandise ManagementDocument50 pages3 Module Merchandise ManagementSamNo ratings yet

- Establishment Manual NiftDocument311 pagesEstablishment Manual Niftsoumojitg86100% (1)

- Columbia Sportswear Quality ManualDocument108 pagesColumbia Sportswear Quality Manualsapna maheshwariNo ratings yet

- Subject: Corporate Finance - II Ramodhan Gupta Case Solution by Group B. MembersDocument5 pagesSubject: Corporate Finance - II Ramodhan Gupta Case Solution by Group B. MembersRohit RahangdaleNo ratings yet

- Apparel Quality ManagementDocument14 pagesApparel Quality ManagementPratik RajNo ratings yet

- Quality Control - Nike Inc.Document7 pagesQuality Control - Nike Inc.Bhavya DiddeeNo ratings yet

- 11 Chapter 4Document61 pages11 Chapter 4Nigussie GodanaNo ratings yet

- Business Skills in E CommerceDocument78 pagesBusiness Skills in E Commerceshaid AhamedNo ratings yet

- Production Process and Material Handling of Jeans.Document26 pagesProduction Process and Material Handling of Jeans.Sandeep Guneshwar100% (1)

- I4 Implementation in IndiaDocument131 pagesI4 Implementation in IndiaMariya NowrinNo ratings yet

- Danish Javed - 3405403 - Frameworks Project ReportDocument36 pagesDanish Javed - 3405403 - Frameworks Project ReportDanish JavedNo ratings yet

- Spinning MillDocument6 pagesSpinning MillAnand Arumugam0% (1)

- Textile Design Internship DocumentDocument96 pagesTextile Design Internship DocumentswathiNo ratings yet

- Presentation On Shoppers StopDocument28 pagesPresentation On Shoppers Stopabhishek_sinhaNo ratings yet

- Textiles: Hosiery/ Knitwear ProcessingDocument20 pagesTextiles: Hosiery/ Knitwear ProcessingShripadNo ratings yet

- H&M Group Requirements For Quality System: Textile ProductsDocument30 pagesH&M Group Requirements For Quality System: Textile Productssaidurtex100% (1)

- Bullwhip Effect in Supply Chain: Solution Suggested/available Leveraging On ICTDocument13 pagesBullwhip Effect in Supply Chain: Solution Suggested/available Leveraging On ICTali_awaisNo ratings yet

- Unit 8 Documentation in Cutting Room: StructureDocument11 pagesUnit 8 Documentation in Cutting Room: StructureHarry AryanNo ratings yet

- Tenant GuidelinesDocument90 pagesTenant Guidelinessheryl himocNo ratings yet

- Introduction To Clothing MaterialDocument21 pagesIntroduction To Clothing MaterialMd. Samin Ahmed SaminNo ratings yet

- RASCI Qualifications Pack 0103 - Retail Trainee AssociateDocument72 pagesRASCI Qualifications Pack 0103 - Retail Trainee AssociateAbhijit DasNo ratings yet

- Hipo INKJET Plotter ManualDocument32 pagesHipo INKJET Plotter ManualJorge MonsalveNo ratings yet

- ReportDocument67 pagesReporthrithika100% (1)

- ALEC GarmentsDocument16 pagesALEC GarmentsAlecNo ratings yet

- Apparel Industrial EngineeringDocument4 pagesApparel Industrial EngineeringkbalabalaNo ratings yet

- Richa Global DocumentDocument60 pagesRicha Global DocumentPrachi JaiswalNo ratings yet

- What Is Conventional TextileDocument3 pagesWhat Is Conventional TextileTehseen Marwat Sunny100% (2)

- TenderingDocument38 pagesTenderingSsebowa AmosNo ratings yet

- Priorities For Planning Reform in England: Rtpi Policy PaperDocument24 pagesPriorities For Planning Reform in England: Rtpi Policy PaperA. ChengNo ratings yet

- Design and Implementation ofDocument5 pagesDesign and Implementation ofalexNo ratings yet

- Garment Plant LayoutDocument66 pagesGarment Plant LayoutsprakashsalemNo ratings yet

- Internship @naharDocument26 pagesInternship @naharGourab Mondal100% (1)

- Basic Product AdministrationDocument488 pagesBasic Product Administrationkaviguna12345No ratings yet

- Study of Knitting Process of at Kalash Private LimitedDocument36 pagesStudy of Knitting Process of at Kalash Private LimitedAhmad HassanNo ratings yet

- Nazmul Islam Final Internship ReportDocument48 pagesNazmul Islam Final Internship Reportsaleh shehamNo ratings yet

- BIONICEYEORGIGINALDocument52 pagesBIONICEYEORGIGINALakshatjain0099No ratings yet

- Quality Manual - Simba Fashions Ltd.Document143 pagesQuality Manual - Simba Fashions Ltd.ABDULNo ratings yet

- Situational LeadershipDocument14 pagesSituational LeadershipABDULNo ratings yet

- 1.quality Policy - SewingDocument1 page1.quality Policy - SewingABDULNo ratings yet

- Defects Library For Customer ClaimDocument55 pagesDefects Library For Customer ClaimABDULNo ratings yet

- For Line QC GPQ Training 1682907711Document9 pagesFor Line QC GPQ Training 1682907711ABDULNo ratings yet

- Karuppuchamy OriginalDocument3 pagesKaruppuchamy Originalkaruppuchamy becivilNo ratings yet

- ReferensiDocument4 pagesReferensiyusri polimengoNo ratings yet

- SSVM Institutions Periodic Test 2 Mathematics: (Each Question Carries 1 Mark)Document3 pagesSSVM Institutions Periodic Test 2 Mathematics: (Each Question Carries 1 Mark)MidhunBhuvaneshB RWSNo ratings yet

- Acadamic StressDocument23 pagesAcadamic Stressalene100% (1)

- Revised Bloom's TaxonomyDocument29 pagesRevised Bloom's Taxonomymariel floresNo ratings yet

- Full Chapter Repetition and Creation Poetics of Autotextuality 1St Edition Radosvet Kolarov PDFDocument53 pagesFull Chapter Repetition and Creation Poetics of Autotextuality 1St Edition Radosvet Kolarov PDFclarence.nance336100% (8)

- Klendathu Invasion (W/ Bookmarks & Errata) - Starship Troopers Miniatures GameDocument52 pagesKlendathu Invasion (W/ Bookmarks & Errata) - Starship Troopers Miniatures GameBanjoRower100% (2)

- Crack Width Cal-T Beam-Euro CodeDocument10 pagesCrack Width Cal-T Beam-Euro CodeGautham AllimuthuNo ratings yet

- PHP 8 BasicsDocument335 pagesPHP 8 BasicsIklan Buana Prima Mulia100% (2)

- IA Sample 2Document27 pagesIA Sample 2FffNo ratings yet

- Tender Recommendation Report ContentDocument2 pagesTender Recommendation Report ContentIslam HamdyNo ratings yet

- Microeconomic Analysis NotesDocument23 pagesMicroeconomic Analysis NotesMinira JafarovaNo ratings yet

- Urban MorphologyDocument4 pagesUrban Morphologyariya saranNo ratings yet

- C, PNP 8 Foundation InitiativesDocument1 pageC, PNP 8 Foundation InitiativesLakan DulaNo ratings yet

- Fungi: Candida Auris: A Review of Recommendations For Detection and Control in Healthcare SettingsDocument11 pagesFungi: Candida Auris: A Review of Recommendations For Detection and Control in Healthcare SettingschiralicNo ratings yet

- R20 MECH SyllabusDocument264 pagesR20 MECH SyllabusSujitha SunilNo ratings yet

- MuseoModerno - Google FontsDocument4 pagesMuseoModerno - Google Fontsjune142020No ratings yet

- Curriculum Development ModelsDocument4 pagesCurriculum Development Modelsjoan arreolaNo ratings yet

- Salwico IC21 WP: Indication Control UnitDocument5 pagesSalwico IC21 WP: Indication Control UnitrolandseNo ratings yet

- Ax 100Document25 pagesAx 100Oscar Caetano FontNo ratings yet

- Task 2 Writing Task Yasneidy ContrerasDocument3 pagesTask 2 Writing Task Yasneidy ContrerasDaniela santanderNo ratings yet

- Social Theory As Habitus (OCR)Document10 pagesSocial Theory As Habitus (OCR)vcvc vcvcNo ratings yet

- 12 Questions To Help You Make Sense of Economic EvaluationsDocument6 pages12 Questions To Help You Make Sense of Economic EvaluationsHaNo ratings yet

- Andrew Zago, Awkward Position, 2010Document15 pagesAndrew Zago, Awkward Position, 2010Davide Tommaso FerrandoNo ratings yet

- Rational FunctionDocument34 pagesRational FunctionJames Marck BabieraNo ratings yet

- Consultadd ServicesDocument56 pagesConsultadd ServicesRatan SrivastavaNo ratings yet

- Score SheetsDocument6 pagesScore SheetsErika Bose CantoriaNo ratings yet

- English Code Phonics Book 2Document51 pagesEnglish Code Phonics Book 2Jezabel Escobar100% (1)

- Business English Useful Phrases For Leading A MeetingDocument10 pagesBusiness English Useful Phrases For Leading A MeetingEstherPoboSerradillaNo ratings yet