Professional Documents

Culture Documents

Deviated Well Kill Sheet 6.125 SECTION 08-Sep-2020.

Deviated Well Kill Sheet 6.125 SECTION 08-Sep-2020.

Uploaded by

yousef nOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Deviated Well Kill Sheet 6.125 SECTION 08-Sep-2020.

Deviated Well Kill Sheet 6.125 SECTION 08-Sep-2020.

Uploaded by

yousef nCopyright:

Available Formats

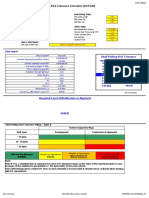

PRERECORDED WELL DATA

KEEP THIS DATA SHEET CURRENT AT ALL TIMES

(Highly Deviated and Horizontal Wells)

Well Name ANDR 740 Field ANDR Rig 68

HOLE DATA

Size(avg) 6.1250 Hole MD 9,100 ft. Hole TVD 7,177 ft.

Hole Capacity: No pipe in hole 0.0365 bbls/ft x 9,100 ft. = 331.8 bbl

(from BOP to MD) *Use

DP PUMP DATA Liners (in.) Stroke(in.) Rod(in. ) % Eff. bbl./stk For Kill?

CSG No. 1 6 12 97 0.1018 X

No. 2 6 12 97 0.1018

* X if used, empty if not

CASING (LAST SET) DATA

9.6250 by 8.8350 Shoe MD 2,960 Shoe TVD 2,960

(in. OD) (in. Avg ID) (feet) (feet)

WELLHEAD OR CASING PRESSURE LIMITATION

The lessor of: 100% BOP Rating 10,000 psi.

100% Wellhead Rating 3,000 psi. Limitation = 2,456 psi.

80% Casing Burst 2,456 psi.

LINER CASING DATA

7.0000 by 6.2150 Top @ 2,960 Shoe @ 8266 7177

(in. OD) (in. Avg ID) MD(feet) MD(feet) TVD(feet)

DRILL STRING DATA DRILL COLLARS

Drill Pipe 1 5.0000 in. (OD) 19.5 lb./ft. OD(in.) ID(in.)

Drill Pipe 2 4.0000 in. (OD) 0.0103 lb./ft. by

HW Drill Pipe 4.0000 in. (OD) 0.0064 lb./ft. by

INTERNAL CAPACITIES (Section 1 - Surface to Kickoff Point)

Drill Pipe 1 385 ft. x 0.0178 bbl./ft. = 6.8 bbl.

Drill Pipe 2 4,615 ft. x 0.0103 bbl./ft. = 47.5 bbl.

HW Drill Pipe ft. x 0.0064 bbl./ft. = 0.0 bbl.

Drill Collars 0 ft. x 0.0000 bbl./ft. = 0.0 bbl.

Drill Collars ft. x 0.0000 bbl./ft. = 0.0 bbl.

Section 1 Subtotal Internal Capacities = 54.4 bbl.

Kickoff MD 5,000 534 Strokes

Kickoff TVD 5,000

INTERNAL CAPACITIES (Section 2 - Kickoff Point to Start of Hold)

Drill Pipe 1 ft. x 0.01776 bbl./ft. = 0.0 bbl.

Drill Pipe 2 1171 ft. x 0.0103 bbl./ft. = 12.1 bbl.

HW Drill Pipe ft. x 0.0064 bbl./ft. = 0.0 bbl.

Drill Collars ft. x 0.0000 bbl./ft. = 0.0 bbl.

Drill Collars ft. x 0.0000 bbl./ft. = 0.0 bbl.

Section 2 Subtotal Internal Capacities = 12.1 bbl.

Start of Hold MD 6,171 118 Strokes

Start of Hold TVD 6,171

Kickoff Point

Start of Hold (continued on next page) Version 2.0 (4/15/00)

DP PRERECORDED WELL DATA

CSG (Highly Deviated and Horizontal Wells)

(page 2)

INTERNAL CAPACITIES (Section 3 - Start of Hold to TD of Bit)

Drill Pipe 1 ft. x 0.01776 bbl./ft. = 0.0 bbl.

Drill Pipe 2 2,591.00 ft. x 0.0103 bbl./ft. = 26.7 bbl.

HW Drill Pipe 338 ft. x 0.0064 bbl./ft. = 2.2 bbl.

Drill Collars ft. x 0.0000 bbl./ft. = 0.0 bbl.

Drill Collars ft. x 0.0000 bbl./ft. = 0.0 bbl.

Section 3 Subtotal Internal Capacities = 28.9 bbl.

Total MD 9,100 283 Strokes

Total TVD 7,177

TOTAL INTERNAL CAPACITY

Msrd. Depth(Bit) 9,100 ft. Total Internal = 95.3 bbl. = 936 Strokes

ANNULUS CAPACITIES

DP1 x Csg. 385 ft. x 0.0516 bbl./ft. = 19.9 bbl.

DP1 x Liner ft. x 0.0132 bbl./ft. = 0.0 bbl.

DP1 x Hole ft. x 0.0122 bbl./ft. = 0.0 bbl.

DP2 x Csg. 2,575 ft. x 0.0603 bbl./ft. = 155.3 bbl.

DP2 x Liner 5,202 ft. x 0.0220 bbl./ft. = 114.4 bbl.

DP2 x Hole 600 ft. x 0.0209 bbl./ft. = 12.5 bbl.

HW DP x Csg. ft. x 0.0603 bbl./ft. = 0.0 bbl.

HW DP x Liner 0 ft. x 0.0220 bbl./ft. = 0.0 bbl.

HW DP x Hole 338 ft. x 0.0209 bbl./ft. = 7.1 bbl.

DC1 x Csg ft. x 0.0000 bbl./ft. = 0.0 bbl.

DC1 x Liner ft. x 0.0000 bbl./ft. = 0.0 bbl.

DC1 x Hole ft. x 0.0000 bbl./ft. = 0.0 bbl.

DC2 x Csg ft. x 0.0000 bbl./ft. = 0.0 bbl.

DC2 x Liner ft. x 0.0000 bbl./ft. = 0.0 bbl.

DC2 x Hole ft. x 0.0000 bbl./ft. = 0.0 bbl.

Msrd Depth(bit) 9,100 ft. Total Annulus = 309.1 bbl. = 3,037 Strokes

System Volume = 404.4 bbl. = 3,972 Strokes

(Internal + Annulus)

Active Pit Volume bbl.

Kickoff Point

Start of Hold

MAX INITIAL SICP TO FRACTURE FORMATION AT SHOE

Max. SICP = (Shoe Test - Present Mud Wt.) x Shoe TVD x 0.007

= 0 pcf EMW - pcf MW] x 7,177 ft. x 0.007 = 0 psi

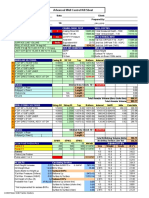

DRILLER'S METHOD WORKSHEET

(Highly Deviated and Horizontal Wells)

PRERECORDED INFORMATION SPM psi bbl/stk bbl/min

A. Slow Pump Rate Data Pump #1 30 775 0.1018 3.1

( Use SPR Pressure through Riser for Subsea ) Pump #2 40 1190 0.1018 4.1

INFORMATION RECORDED WHEN WELL KICKS Time of Kick:

B. Old Mud Weight B 0 pcf

C. Initial Shut-In Drill Pipe Pressure (SIDP) C 0 psi

D. Initial Shut-In Casing Pressure (SICP) D 0 psi

E. Initial Pit Volume Increase E 0 bbl

F. True Vertical Depth of Hole F 7,177 ft (TVD)

Measured Depth of Hole (for Capacity Calculations ONLY) 9,100 ft (MD)

FIRST CIRCULATION TO CLEAR WELL OF INFLUX

Bring Pumps up to Speed While Holding Casing Pressure Constant 30 SPM

{Account for Choke Line Friction if Subsea}

Read and Record Initial Circulating Pressure on Drill Pipe 775 psi

[Should Approximately = Slow Pump Rate Pressure (A) + SIDP (C)]

Maintain Constant DP Pressure Until Influx is Circulated Out. Then Shut Down

Pumps While Holding Casing Pressure Constant. {Remember CLF for Subsea}. If Drill

Pipe and Casing Shut-In Pressures are not Equal, Continue to Circulate Out Influx.

G. Increase in Mud Weight required to Balance Kick

G=Initial SIDP= C = G 0 pcf

0.007´ TVD 0.007´ F

H. New Mud Weight H=B+G= H 0 pcf

I. Total Volume to Weight up I = Active Pit Vol + System Vol = I 404 bbl

J. Barite Required J =I ´

( 30 ´ G ) =

( 262 - H ) J 0 50#

sacks

SECOND CIRCULATION TO BALANCE WELL

Bring Pumps up to Speed While Holding

Casing Pressure Constant. {Account for » SIDP(C) Casing Pressure 0 psi

CLF if Subsea} Maintain Constant Casing

Pressure Until New Mud Reaches the Bit. Drill String Internal Capacity 936 strokes

Read and Record Drill Pipe Pressure

When New Mud Reaches the Bit KWM(H) Final Circulating Pressure 0 psi

» SPRP (A) ´

Maintain Constant Drill Pipe Pressure Old MW (B)

Until the System is Displaced. System Volume 3,972 strokes

Version 2.0 (4/15/00)

DRILLER'S METHOD WORKSHEET

(page 2)

RESERVOIR PRESSURE (Pr)

K 0 psi

P. Pr =0.007´ New MW ´ TVD=0.007´ H´ F

HEIGHT OF GAS BUBBLE AROUND DRILL PIPE (KH)

L. Annulus Capacity Factor (DP x Casing) Right Below Wellhead L 0.0516 bbls/ft

Initial Pit Vol Increase ( E )

M. Height = = M 0 ft.

Annulus Capacity Factor ( L )

MAXIMUM CASING PRESSURE (Pcmax) WHEN GAS GETS TO SURFACE

N. Mud Weight Gradient

N 0.00 psi/ft.

= MW (B) ´ 0.007 =

O. Pc max,Part1 = SIDP ¸ 2 = ( C ) ¸ 2 = O 0 psi

P. TZ= Compressibility and Temperature Effects (Fig 11P.5) P 0.00

or Tz = 4.03 - (0.38 ´ ln(Pr)) = 4.03 - (0.38 ´ ln(K))

Q. Pcmax, Part2 (Figure 11P.1)

= (O)2 + (K )(M)(N)(P) Q 0 psi

R. Maximum Casing Pressure,

R 0 psi

PcMAX = (Part 1 ) + (Part 2) = O + Q =

S. Does Pcmax Exceed the Wellhead or Casing Pressure Limitation?

YES NO

VOLUME GAIN WHILE CIRCULATING OUT GAS BUBBLE

T. Volume of Gas at Surface (from Fig. 11P.4 or Formula below)

T 0 bbl

Pit Increase ´ Pr ´ TZ E ´ K ´ P

Vg , Volume of gas at surface , bbl = = =

Pcmax R

U. Volume Gain While Circulating Out Gas Kick U =T - E = U 0 bbl

STROKES TO MAXIMUM CASING PRESSURE AND VOLUME

Maximum Casing Pressure and Excess Volume Occur When the Pumped Volume Equals

Total Annulus Capacity - Volume of Gas at Surface

bbl strokes

= Annulus Cap {prerecorded } - T = 309.1 3037

ENGINEER'S METHOD WORKSHEET

(Highly Deviated and Horizontal Wells)

PRERECORDED INFORMATION SPM psi bbl/stk bbl/min

A. Slow Pump Rate Data Pump #1 40 700 0.1018 4.1

( Use SPR Pressure thru Riser for Subsea ) Pump #2 50 1060 0.1018 5.1

INFORMATION RECORDED WHEN WELL KICKS Time of Kick:

B. Old Mud Weight B 0 pcf

C. Initial Shut-In Drill Pipe Pressure (SIDP) C psi

D. Initial Shut-In Casing Pressure (SICP) D psi

E. Initial Pit Volume Increase E bbl

F. True Vertical Depth of Hole F 7,177 ft (TVD)

Measured Depth of Hole (for Capacity Calculations ONLY) 9,100 ft (MD)

MUD WEIGHT TO BALANCE KICK

G. Increase in Mud Weight required to Balance Kick

Initial SIDP C

G= = = G 0 pcf

0 .007 x TVD 0 .007 x F

H. New Mud Weight H=B+G= H 0 pcf

I. Total Volume to Weight up I = Active Pit Vol + System Vol = I 404 bbl

J. Barite Required

J =I ´

(30 ´ G) =

(262 - H) J 0 50# sacks

INITIAL CIRCULATING PRESSURE

K. Slow Pump Rate Pressure + SIDP K =A+C= K 700 psi

FINAL CIRCULATING PRESSURE

L. Slow Pump Rate Pressure X (New Mud Wt / Old Mud Wt) H L 0 psi

L =A ´ =

B

CIRCULATING PRESSURE AT KICKOFF POINT

M. Total Internal Capacity (from Prerecorded Well Data) M 936 strokes

N. Surface to Kickoff Point Strokes (from Prerecorded Data) N 534 strokes

O. Hydrostatic Pressure Increase Due to KWM at Kickoff Pt.

O 0 psi

( )

O = H - B ´ 0.007 ´ TVD at Kickoff Point =

P. Friction Pressure Increase Due to KWM at Kickoff Pt.

(L - A) P -399 psi

P = ´ N =

M

Q. Circulating Pressure at Kickoff Point

Q=K-O+P Q 301 psi

CIRCULATING PRESSURE AT START OF HOLD

R. Strokes from Kickoff Point to Start of Hold (from Prerecorded Well Data) R 118 strokes

S. Hydrostatic Pressure Increase Due to KWM at Start of Hold

S 0 psi

( )

S = H- B ´ 0.007´ TVD at Start of Hold =

T. Friction Pressure Increase Due to KWM at Start of Hold

(L - A) T -488 psi

T = ´ (N + R) =

M

Version 2.0 (4/15/00)

ENGINEER'S METHOD WORKSHEET

(page 2)

U. Circulating Pressure at Start of Hold

U=K-S +T= U 212 psi

V. Strokes from Hold Point to TD (from Prerecorded Well Data) V 283 strokes

DRILL PIPE PRESSURE PROFILE

W. Pressure Drop Per Stroke to Kickoff Point

W=

( Initial Circ Press (K) - Final Circ Press (Q)) = W 0.7479 psi per stroke

( Internal Capacity Strokes (N))

X. Pressure Drop Per Stroke from Kickoff to Start of Hold

X=

( Starting Pressure (Q) - Ending Pressure (U)) = X 0.7479 psi per stroke

( Internal Capacity Strokes (R))

Y. Pressure Drop Per Stroke from Hold Point to TD

(note: for a horizontal well this will be negative, meaning the pressure will increase each stroke increment)

Y=

( Starting Pressure (U) - FCP (L)) = Y 0.7479 psi per stroke

( Internal Capacity Strokes (V))

Strokes Pressure (psi)

0 700 = Initial Circ. Press. (K)

40 670

80 640

120 610

160 580

200 550

240 520

280 491

320 461

360 431

Kickoff Pt. (N) 534 301 = Kickoff Pt. Circ. Press. (Q)

550 289

570 274

590 259

610 244

630 229

0 0

0 0

0 0

Start of Hold (R+N) 653 212 =Circ Press. @ Start of Hold(U)

690 184

730 154

770 124

810 94

850 64

890 34

930 4

0 0

0 0

Total Int. Cap. (M) 936 0 =Final Circ. Press. (L)

ENGINEER'S METHOD WORKSHEET

(page 3)

RESERVOIR PRESSURE (Pr)

Z 0 psi

Z. Pr = New MW xTVDx0.007 = H x F x0.007 =

MAXIMUM CASING PRESSURE (Pcmax) WHEN GAS GETS TO SURFACE

AA. Drill String Capacity from Prerecorded Data AA 95 bbl

BB. Annulus Capacity Factor DP x Casing Right Below Wellhead BB 0.0516 bbl/ft

CC. Temperature and Compression Effects. (TZ from Figure 11P.5 or Formula below)

CC =4.03 - (0.38 ´ ln(Z)) CC 0.00

DD . New MW Gradient, psi/ft DD 0.000 psi/ft

= H x 0.007 =

EE. PcMAX , Part 1 (from Figure 11P.2 or Formula below)

EE 0 psi

= G ´ AA x 0.007 =

2 ´ BB

FF. PcMAX , Part 2 (from Fig. 11P.3 or Formula below)

2 æ ö

=

æ

EE

ç

ç

ç

ç

ö

÷

÷

÷

÷ + çç Z ´ E ´ CC ´ DD ÷

÷ = FF 0 psi

ç

ç

ç

è

÷

÷

÷

ø

ç

ç

è

BB ÷

÷

ø

GG. Maximum Casing Pressure,

PCmax=(Part1) + (Part2) = EE + FF = GG 0 psi

Does Pcmax Exceed the Wellhead or Casing Pressure Limitation?

YES NO

VOLUME GAIN WHILE CIRCULATING OUT GAS BUBBLE

HH. Volume of Gas at Surface (From Fig 11P.4 or From Formula Below)

E ´ Z ´ CC

Vg , Vol gas at surf, bbl = = HH 0 bbl

GG

II. Volume Gain While Circulating Out Gas Kick II = HH - E II 0 bbl

JJ. Volume Gain due to Barite Addition JJ = J = JJ 0 bbl

30sacks/bbl

Total Volume Gain While Circulating Out Gas = II + JJ 0 bbl

STROKES TO MAXIMUM CASING PRESSURE AND VOLUME

Maximum Casing Pressure and Excess Volume Occur When the Pumped Volume Equals

Total Annulus Capacity - Volume of Gas at Surface bbl strokes

= Annulus Capacity (from Prerecorded) - HH 309 3037

You might also like

- PayslipDocument1 pagePayslipAshish Agarwal67% (3)

- 5008S Fresenuis Service ManualDocument318 pages5008S Fresenuis Service ManualEslam Karam100% (10)

- MACP and Well Control RecordDocument6 pagesMACP and Well Control RecordSudish BhatNo ratings yet

- (Highly Deviated and Horizontal Wells) : Pre-Recorded Sheet Keep This Data Sheet Current at All TimesDocument7 pages(Highly Deviated and Horizontal Wells) : Pre-Recorded Sheet Keep This Data Sheet Current at All TimesSasan AbbasiNo ratings yet

- Swab and Surge Pressures SHBDocument1 pageSwab and Surge Pressures SHBstevebeardsleyNo ratings yet

- Subsea Bop SpaceoutDocument1 pageSubsea Bop SpaceoutWell ControlNo ratings yet

- Ilker Drilling ProgrammeDocument71 pagesIlker Drilling Programmerıdvan duranNo ratings yet

- Hydrolysis of Nucleic AcidsDocument7 pagesHydrolysis of Nucleic Acidskeepersake81% (16)

- (Vertical and Deviated Wells) : Casing (Last Set) DataDocument7 pages(Vertical and Deviated Wells) : Casing (Last Set) Datac PjNo ratings yet

- KickDocument2 pagesKickChung NguyenNo ratings yet

- IWCF Surface BOP: Kill SheetDocument6 pagesIWCF Surface BOP: Kill SheetMrSebollini0% (1)

- Kill Sheet IWCFDocument2 pagesKill Sheet IWCFMaria FernandaNo ratings yet

- Kill Sheet IWCFDocument2 pagesKill Sheet IWCFGourav RanaNo ratings yet

- Blank Well Control Toolbox SheetDocument8 pagesBlank Well Control Toolbox SheetAhmedNo ratings yet

- Matts Advanced Well Control Kill Sheet Ra 07261Document21 pagesMatts Advanced Well Control Kill Sheet Ra 07261CARLOS RODRIGUEZNo ratings yet

- Drilling Calculations Mindmap-2Document1 pageDrilling Calculations Mindmap-2Mario A. OrtizNo ratings yet

- Surface BOP Stack Operations API - Deviated Well Kill SheetDocument0 pagesSurface BOP Stack Operations API - Deviated Well Kill Sheetjosesito_amoroso2005No ratings yet

- Final Diagram Fanny 18b-164 Wo1Document8 pagesFinal Diagram Fanny 18b-164 Wo1MANUEL ASTUDILLONo ratings yet

- Drilling Application: Hole Diameter, In? Mud WT? Hole Diameter, In? Mud WT?Document1 pageDrilling Application: Hole Diameter, In? Mud WT? Hole Diameter, In? Mud WT?Abdul Hameed OmarNo ratings yet

- 14b-Kill Sheet PreparationDocument10 pages14b-Kill Sheet PreparationLorenaStămulescuNo ratings yet

- LOT & Kill SheetDocument1 pageLOT & Kill SheetBaniNo ratings yet

- Kill SheetDocument4 pagesKill SheetAnwar FauzenNo ratings yet

- Tut-126 ProgramDocument28 pagesTut-126 Programhamdi1000No ratings yet

- Hosan 1 EWOR Final CheckDocument40 pagesHosan 1 EWOR Final CheckvengurionNo ratings yet

- Maximum Overpull Worksheet: Well:Grenadier EDC - 90Document1 pageMaximum Overpull Worksheet: Well:Grenadier EDC - 90islam atifNo ratings yet

- FINAL DP # 5 - 9 5-8 Casing TallyDocument5 pagesFINAL DP # 5 - 9 5-8 Casing TallydavoodazNo ratings yet

- 29 - Well Control Data Sheet For Directional Wells Wt. & Wt. MethodDocument1 page29 - Well Control Data Sheet For Directional Wells Wt. & Wt. MethodJunaid MateenNo ratings yet

- 07 Circulation Times and Volumes - QuartzDocument1 page07 Circulation Times and Volumes - QuartzRebarNo ratings yet

- Pre Recorded Imformation: Davis Family 1-42Document10 pagesPre Recorded Imformation: Davis Family 1-42scrbdgharaviNo ratings yet

- Drilling CalculationsDocument7 pagesDrilling CalculationsBrahim LetaiefNo ratings yet

- Drilling 12 1.4 in HoleDocument1 pageDrilling 12 1.4 in HoleMohamed AbozeimaNo ratings yet

- Well Control Worksheet For A Surface Bop Stack: CANNON 1-21Document2 pagesWell Control Worksheet For A Surface Bop Stack: CANNON 1-21scrbdgharaviNo ratings yet

- Field Measurements of Annular Pressure and Temperature During Primary CementingDocument5 pagesField Measurements of Annular Pressure and Temperature During Primary CementingDoni KurniawanNo ratings yet

- Bha# 4 Fishing With Spear Assy 1227 Grapple 3032Document1 pageBha# 4 Fishing With Spear Assy 1227 Grapple 3032Ivan Dario Benavides BonillaNo ratings yet

- Kick Tolerance2Document4 pagesKick Tolerance2fisco4rilNo ratings yet

- Workover Daily Report WQ1-039Document3 pagesWorkover Daily Report WQ1-039kareem100% (1)

- 10 - Drilling 12 1.4 in HoleDocument1 page10 - Drilling 12 1.4 in HoleMohamed Abozeima100% (1)

- Hole Problem Data PackageDocument154 pagesHole Problem Data PackageAhmed Mamdouh100% (2)

- Stuck Point WorksheetDocument5 pagesStuck Point Worksheetjose perozoNo ratings yet

- Appendix-25 Sole-2 Wireline ReportDocument8 pagesAppendix-25 Sole-2 Wireline ReportAustinNo ratings yet

- Formulas Charts and TablesDocument56 pagesFormulas Charts and TablesRodolfo MendezNo ratings yet

- IWCF Theory & AnswersDocument81 pagesIWCF Theory & Answersmohnadjib03 mohnadjibNo ratings yet

- 09 Spotting LCM Pill in The Annulus - QuartzDocument1 page09 Spotting LCM Pill in The Annulus - QuartzRebarNo ratings yet

- AD-0024 Surface Vertical Kill SheetDocument2 pagesAD-0024 Surface Vertical Kill SheetMelnapsterDsouzaNo ratings yet

- 12 Casing Running Speed - QuartzDocument1 page12 Casing Running Speed - QuartzRebarNo ratings yet

- Surface & Production Casing DesignDocument11 pagesSurface & Production Casing DesignscrbdgharaviNo ratings yet

- Plugback Sidetracks - Off Cement PlugsDocument4 pagesPlugback Sidetracks - Off Cement PlugsAdel Ahmed AlkhaligyNo ratings yet

- Halliburton TallybookDocument40 pagesHalliburton TallybookmimostarNo ratings yet

- Drilling Fluid Calculations Archives - Drilling Formulas and Drilling Calculations PDFDocument10 pagesDrilling Fluid Calculations Archives - Drilling Formulas and Drilling Calculations PDFAmine MimoNo ratings yet

- Job Sheet For 11-7/8" Intermediate Casing: 12.5 4,000' Low PH Desco 1,527.33' 9,850 4.276Document1 pageJob Sheet For 11-7/8" Intermediate Casing: 12.5 4,000' Low PH Desco 1,527.33' 9,850 4.276scrbdgharaviNo ratings yet

- Chapter One: Diverter SystemDocument29 pagesChapter One: Diverter SystemsyedainahmadNo ratings yet

- Well Control EquationsDocument13 pagesWell Control EquationsShaho Abdulqader Mohamedali100% (1)

- Surface BOP Stack Operations SI - Deviated Well Kill SheetDocument0 pagesSurface BOP Stack Operations SI - Deviated Well Kill Sheetjosesito_amoroso2005No ratings yet

- Well Control Worksheet - Surface BOPDocument2 pagesWell Control Worksheet - Surface BOPstevebeardsleyNo ratings yet

- Assortment of Mini ApplicationsDocument1 pageAssortment of Mini ApplicationsAbdul Hameed OmarNo ratings yet

- 2010 Workover Completion Practice Test2Document12 pages2010 Workover Completion Practice Test2Boedi SyafiqNo ratings yet

- Dir PlanDocument2 pagesDir PlanscrbdgharaviNo ratings yet

- Drilling Engineering NotesDocument28 pagesDrilling Engineering NotesshanecarlNo ratings yet

- Example BHA Tally Directional Drilling 8.5 SectionDocument2 pagesExample BHA Tally Directional Drilling 8.5 Sectionfauzanhaq1602No ratings yet

- Casing DesignDocument8 pagesCasing DesignJason Bash100% (1)

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Simple Kill SheetDocument32 pagesSimple Kill SheetDiego AraqueNo ratings yet

- Health The Basics 11th Edition Donatelle Test BankDocument19 pagesHealth The Basics 11th Edition Donatelle Test BankJosephWilliamsinaom100% (6)

- General Revision For Treasury Management (Please See That You Can Answer The Following 32 Questions and The MCQS)Document14 pagesGeneral Revision For Treasury Management (Please See That You Can Answer The Following 32 Questions and The MCQS)RoelienNo ratings yet

- Indu Lagna - For Waelth and FinanceDocument7 pagesIndu Lagna - For Waelth and Financeybbvvprasada raoNo ratings yet

- Bar Bending Schedule: Title: Commercial BLDG Cutting ListDocument22 pagesBar Bending Schedule: Title: Commercial BLDG Cutting ListJet ArcaNo ratings yet

- Japanese Quality Tools and TechniquesDocument36 pagesJapanese Quality Tools and TechniquesNab JiNo ratings yet

- Alere G1 Glucose Meter ManualDocument55 pagesAlere G1 Glucose Meter ManualSundar Rajan33% (6)

- Safety Manual (B-80687EN 10)Document35 pagesSafety Manual (B-80687EN 10)Jander Luiz TomaziNo ratings yet

- Jambajuicelv-Application-0618 1Document2 pagesJambajuicelv-Application-0618 1api-526082107No ratings yet

- Fallas VenezuelaDocument20 pagesFallas VenezuelaDaniel Quintana GaviriaNo ratings yet

- Maximo Training Material Day 2Document41 pagesMaximo Training Material Day 2ckombo9912100% (2)

- Local Winds: Land and Sea BreezesDocument8 pagesLocal Winds: Land and Sea Breezesravi rathodNo ratings yet

- 9de13c0f0c009828f703d0103efa820b.xlsDocument70 pages9de13c0f0c009828f703d0103efa820b.xlsPreeti JaiswalNo ratings yet

- HD Consumer Behavior AssignmentDocument9 pagesHD Consumer Behavior AssignmentAishwaryaNo ratings yet

- Jyotish - Hindu Panchangam & MuhurtasDocument40 pagesJyotish - Hindu Panchangam & MuhurtasSamir Kadiya100% (1)

- A Picture Is Worth A Thousand Words: The Benefit of Medical Illustration in Medical PublishingDocument6 pagesA Picture Is Worth A Thousand Words: The Benefit of Medical Illustration in Medical PublishingSinisa RisticNo ratings yet

- About BITS CmdletsDocument3 pagesAbout BITS CmdletsvashsauNo ratings yet

- WhatsApp v. Union of India Filing VersionDocument224 pagesWhatsApp v. Union of India Filing VersionVinayNo ratings yet

- Overview: Module 4: Main Aim Subsidiary Aims Personal AimsDocument28 pagesOverview: Module 4: Main Aim Subsidiary Aims Personal AimsIslam TahaNo ratings yet

- Experiencing Postsocialist CapitalismDocument251 pagesExperiencing Postsocialist CapitalismjelisNo ratings yet

- Rope PDFDocument19 pagesRope PDFBenjamin van DierenNo ratings yet

- The-Impact-On-Load-balancing-In-Cloud-Computing 2020Document5 pagesThe-Impact-On-Load-balancing-In-Cloud-Computing 2020Nikola JovanovicNo ratings yet

- Alcantara - Module 10 - 2ged SS-03Document2 pagesAlcantara - Module 10 - 2ged SS-03Janine AlcantaraNo ratings yet

- Английская грамматика в тестах - РомановаDocument152 pagesАнглийская грамматика в тестах - РомановаLi FeNo ratings yet

- Characterising Roof Ventilators: P 2 A Q CDocument4 pagesCharacterising Roof Ventilators: P 2 A Q CDhirendra Singh RathoreNo ratings yet

- Genuine Eaton Vicker HidrauDocument28 pagesGenuine Eaton Vicker HidrauJenner Volnney Quispe ChataNo ratings yet

- 01 02 BDocument453 pages01 02 BJose VieraNo ratings yet

- Bus Bar SolutionsDocument3 pagesBus Bar SolutionsSanjay MehtaNo ratings yet