Professional Documents

Culture Documents

Technical Equipment Ramsey

Technical Equipment Ramsey

Uploaded by

Sangram KendreCopyright:

Available Formats

You might also like

- Edu Jacob Atmchem Problems Jan 2021Document77 pagesEdu Jacob Atmchem Problems Jan 2021Elle WoodsNo ratings yet

- ASTM D 1193-2011, Standard Specification For Reagent Water PDFDocument6 pagesASTM D 1193-2011, Standard Specification For Reagent Water PDFvanitaNo ratings yet

- Equipment VA Consumption ReferenceDocument5 pagesEquipment VA Consumption ReferenceFerdinand Ramos EspirituNo ratings yet

- MEGA CatalogueDocument8 pagesMEGA CatalogueSumitBhaumik69% (13)

- Technical Equipment RamseyDocument2 pagesTechnical Equipment RamseythuNo ratings yet

- 3000 LPH Quotation Tender No 34235090Document7 pages3000 LPH Quotation Tender No 34235090Thomas BLOOMNo ratings yet

- Pack RYTDocument41 pagesPack RYTGonzalo Alonso QuintanaNo ratings yet

- GPP - Oil, Chemical, Grease List, 17.06.2023Document8 pagesGPP - Oil, Chemical, Grease List, 17.06.2023dilip matalNo ratings yet

- Brochure Filters S2O PDFDocument5 pagesBrochure Filters S2O PDFRabindranath Hendy TagoreNo ratings yet

- Brochure Filters YFODocument5 pagesBrochure Filters YFOHabib Yahia CherifNo ratings yet

- Especificaciones Técnicas Reveladora Raptor + ThermalDocument2 pagesEspecificaciones Técnicas Reveladora Raptor + ThermalyoanacgwNo ratings yet

- Rivulis F6150 English Metric 20190909 WebDocument6 pagesRivulis F6150 English Metric 20190909 WebMehdi BassouNo ratings yet

- Plant and Machinery DetailDocument2 pagesPlant and Machinery DetailShrinath AnbalaganNo ratings yet

- HGSXDocument1 pageHGSXmktg2No ratings yet

- 3000 LPH QuotationDocument7 pages3000 LPH QuotationThomas BLOOMNo ratings yet

- Hyster H5.00XLDocument8 pagesHyster H5.00XLAurel TurcNo ratings yet

- York Check and Foot Valves: Technical CatalogueDocument14 pagesYork Check and Foot Valves: Technical CatalogueWilliam OeyNo ratings yet

- DATA SHEET BLOWER FRAIJANES - URAI-33-Blower-Data-SheetDocument2 pagesDATA SHEET BLOWER FRAIJANES - URAI-33-Blower-Data-SheetOscar SteigerNo ratings yet

- Separator Sizing SpreadsheetDocument40 pagesSeparator Sizing SpreadsheetRidho MuhtadiNo ratings yet

- HWYH-1178 Mud Report - 7530073 - 01Document5 pagesHWYH-1178 Mud Report - 7530073 - 01KHALEDFEKAIRNo ratings yet

- 1000 LPH Ro Plant-1Document1 page1000 LPH Ro Plant-1Suranjan BhattacharyyaNo ratings yet

- RTC Leaflet Micro Nano-Bubble-Generator enDocument2 pagesRTC Leaflet Micro Nano-Bubble-Generator ensudarji subagyoNo ratings yet

- Eco-Friendly: Ruian Zhenjing Machinery. PVT - LTDDocument8 pagesEco-Friendly: Ruian Zhenjing Machinery. PVT - LTDBikash NayakNo ratings yet

- Semi Automatic Blowing Machine 1 With 2 by Cherrydou 202105828Document12 pagesSemi Automatic Blowing Machine 1 With 2 by Cherrydou 202105828adm.moh121No ratings yet

- 019 - Concept Note - Jordan ProjectDocument3 pages019 - Concept Note - Jordan ProjectAhmad AlayeshNo ratings yet

- Chemical Material Preparation ListDocument3 pagesChemical Material Preparation ListYip DavidNo ratings yet

- Vdocuments - MX Separator Sizing SpreadsheetDocument31 pagesVdocuments - MX Separator Sizing SpreadsheetYustianNo ratings yet

- Series Pds Pms H2o FPT EngDocument2 pagesSeries Pds Pms H2o FPT EngtongaiNo ratings yet

- Air Chiller CL-2200 DatasheetDocument3 pagesAir Chiller CL-2200 Datasheetteddy tavaresNo ratings yet

- Sika - AG GroutDocument4 pagesSika - AG GroutBill MurrayNo ratings yet

- Type DA 33 DA 66 DA 118 DA 186 DA-267: Test EquipmentDocument4 pagesType DA 33 DA 66 DA 118 DA 186 DA-267: Test EquipmentBobby Jacob [Lead Manager, Minimac]No ratings yet

- Essmart Dealer Catalogue 2020Document12 pagesEssmart Dealer Catalogue 2020Vinay Bahadur KulshreshthaNo ratings yet

- Cartridge and Bag Filter UnitDocument6 pagesCartridge and Bag Filter UnitDoni KurniawanNo ratings yet

- Introduction Letter: Subject: Company ProfileDocument21 pagesIntroduction Letter: Subject: Company ProfilePritam JadhavNo ratings yet

- HD 5/12 C PlusDocument16 pagesHD 5/12 C PlusSaiful FatoniNo ratings yet

- RPF Data Sheet Logo Revised 1Document3 pagesRPF Data Sheet Logo Revised 1Thomas ThommanNo ratings yet

- BX Series Hydraulic Breaker Spec Sheet EnglishDocument2 pagesBX Series Hydraulic Breaker Spec Sheet EnglishAloysius GlassNo ratings yet

- HTTP WWW - FrymasterDocument2 pagesHTTP WWW - Frymasterdaygo21No ratings yet

- Model # Description Sand Required (LBS.) PriceDocument22 pagesModel # Description Sand Required (LBS.) PriceLuisNo ratings yet

- GTR 20Document2 pagesGTR 20Rahul AgarwalNo ratings yet

- BM-S25L 3-5gallon Bottle Blow Molding MachineDocument11 pagesBM-S25L 3-5gallon Bottle Blow Molding MachineMohamed BayoumiNo ratings yet

- BX SeriesDocument2 pagesBX Seriesaaron mufukNo ratings yet

- List AlatDocument3 pagesList AlatLutfi wahyuNo ratings yet

- Groz - Lube Price List 2014 AprilDocument7 pagesGroz - Lube Price List 2014 AprilPhox IndiaNo ratings yet

- Filters and CapacitiesDocument3 pagesFilters and CapacitiesbrunofernandesdacostNo ratings yet

- NKC Projects - Mobile Workshop VanDocument3 pagesNKC Projects - Mobile Workshop Vanfaisal begNo ratings yet

- Graco PumpDocument12 pagesGraco PumpRudi Abu ZahraNo ratings yet

- How To Stabilize and Strengthen The Wellbore During Drilling Operations" by DR Fred GrowcockDocument16 pagesHow To Stabilize and Strengthen The Wellbore During Drilling Operations" by DR Fred Growcockrıdvan duranNo ratings yet

- Spill Response and Control EquipmentDocument13 pagesSpill Response and Control EquipmentsinghajitbNo ratings yet

- Bom of 150 KLD Etp: SR - No Description Width (MM) Length /dia (MM) Hight (MM) Thikness (MM) F.B & Nos. Flow Rate /capDocument12 pagesBom of 150 KLD Etp: SR - No Description Width (MM) Length /dia (MM) Hight (MM) Thikness (MM) F.B & Nos. Flow Rate /capRajdeepsinhNo ratings yet

- Machinery List, Customer List, Product Details, Org Chart - BoschDocument8 pagesMachinery List, Customer List, Product Details, Org Chart - BoschDanish931No ratings yet

- Product DetailsDocument6 pagesProduct DetailsAHMED391 GAMESNo ratings yet

- Avanti: Model BS 100P BS 200PDocument7 pagesAvanti: Model BS 100P BS 200PItstanweerkhanNo ratings yet

- High Pressure Washer STG G 2Document1 pageHigh Pressure Washer STG G 2Vũ Nguyễn MinhNo ratings yet

- High Flow Series Filter CartridgesDocument2 pagesHigh Flow Series Filter CartridgesCarlos BarriosNo ratings yet

- HPW-DUST Data Sheet v1 5Document6 pagesHPW-DUST Data Sheet v1 5Miguel CNo ratings yet

- 813 - Consumables For Engine RoomDocument1 page813 - Consumables For Engine RoomAhmed HamdyNo ratings yet

- Catalog For CleaningDocument10 pagesCatalog For CleaningHaktuiiNo ratings yet

- ACFrOgDsDANBTTyLEGW5xT3C9NIyC1B5iGGKV0jcOJsf8evmI1FzmFCjq0MroJYugbF9u4pMdAVF Jyf2a9xLUyUbtGIZ OnqgqZ8hY OI5yC2K9cJA69ioTIgwFido PDFDocument4 pagesACFrOgDsDANBTTyLEGW5xT3C9NIyC1B5iGGKV0jcOJsf8evmI1FzmFCjq0MroJYugbF9u4pMdAVF Jyf2a9xLUyUbtGIZ OnqgqZ8hY OI5yC2K9cJA69ioTIgwFido PDFRati Ranjan SahooNo ratings yet

- Raptor EnglishDocument2 pagesRaptor EnglishLe Thanh HuyNo ratings yet

- HS 2K Primer (High Build)Document5 pagesHS 2K Primer (High Build)tietkop20No ratings yet

- Dosing Disc Thickness Calculation For Capsule Filling Machine - SaintyTecDocument4 pagesDosing Disc Thickness Calculation For Capsule Filling Machine - SaintyTecSangram KendreNo ratings yet

- Questions&Answers GeneralDocument23 pagesQuestions&Answers GeneralSangram KendreNo ratings yet

- Efficiency Shared Containment Knowledge Capsules at Full SpeedDocument17 pagesEfficiency Shared Containment Knowledge Capsules at Full SpeedSangram KendreNo ratings yet

- TechnofourDocument2 pagesTechnofourSangram KendreNo ratings yet

- Generate Making Tablets Tcm11 42308Document1 pageGenerate Making Tablets Tcm11 42308Sangram KendreNo ratings yet

- US FDA Inspections Resume in IndiaDocument7 pagesUS FDA Inspections Resume in IndiaSangram KendreNo ratings yet

- Compression of Schedule M To Proposed Schedule M: Part I-ADocument2 pagesCompression of Schedule M To Proposed Schedule M: Part I-ASangram Kendre100% (1)

- Performance Update - Q2FY 22Document12 pagesPerformance Update - Q2FY 22Sangram KendreNo ratings yet

- Scaleup of Wet Granulation Processes Science Not Art CompressDocument6 pagesScaleup of Wet Granulation Processes Science Not Art CompressSangram KendreNo ratings yet

- Pharma Water SystemDocument75 pagesPharma Water SystemSangram KendreNo ratings yet

- OOS Investigation and Where You Are Going Wrong: Page 1 of 3Document3 pagesOOS Investigation and Where You Are Going Wrong: Page 1 of 3Sangram KendreNo ratings yet

- Considerations For The Use of Real-World Data and Real-World Evidence To Support Regulatory Decision-Making For Drug and Biological ProductsDocument12 pagesConsiderations For The Use of Real-World Data and Real-World Evidence To Support Regulatory Decision-Making For Drug and Biological ProductsSangram KendreNo ratings yet

- Date: 19 October 2021: Shilpa Medicare LimitedDocument30 pagesDate: 19 October 2021: Shilpa Medicare LimitedSangram KendreNo ratings yet

- Risk AcceptabilityDocument8 pagesRisk AcceptabilitySangram KendreNo ratings yet

- Optimization and Validation of Process For Formulation of Duloxetinehydrochloride CapsulesDocument8 pagesOptimization and Validation of Process For Formulation of Duloxetinehydrochloride CapsulesSangram KendreNo ratings yet

- Strategies For Improving Capsule Filling EfficiencyDocument4 pagesStrategies For Improving Capsule Filling EfficiencySangram KendreNo ratings yet

- f2 Chemistry TopicalsDocument36 pagesf2 Chemistry TopicalsEvansOmoiNo ratings yet

- Laboratory Evaluation of Concrete Thin Repair Materials MERL-2009-36Document15 pagesLaboratory Evaluation of Concrete Thin Repair Materials MERL-2009-36chutton681No ratings yet

- Ceramics International: Junfeng Chen, Nan Li, Yaowu Wei, Bingqiang Han, Wen YanDocument9 pagesCeramics International: Junfeng Chen, Nan Li, Yaowu Wei, Bingqiang Han, Wen YanJunfeng ChenNo ratings yet

- Chemical BondingDocument26 pagesChemical BondingDipin Preet SinghNo ratings yet

- Thomas1999 PDFDocument2 pagesThomas1999 PDFD.C.No ratings yet

- Kimia Pertemuan 1Document36 pagesKimia Pertemuan 1sabtun ismi khasanahNo ratings yet

- 10 ch05.2.1 Carboxylic Acids and Their Derivatives 29Document29 pages10 ch05.2.1 Carboxylic Acids and Their Derivatives 29NH Khánh NhiiNo ratings yet

- Exercise - II: (One or More Than One Option Correct)Document3 pagesExercise - II: (One or More Than One Option Correct)mehul pantNo ratings yet

- Typical Sections - Editable (Autosaved)Document157 pagesTypical Sections - Editable (Autosaved)sandeepNo ratings yet

- Hfi5110 300516Document2 pagesHfi5110 300516李万福No ratings yet

- Manual Therm Tran ChemDocument35 pagesManual Therm Tran ChemNam DanhNo ratings yet

- ASTM D1856 092015 Aug 2019Document4 pagesASTM D1856 092015 Aug 2019karenmerino94No ratings yet

- CIR - Propanediol (1,3-Propandeiol)Document73 pagesCIR - Propanediol (1,3-Propandeiol)Darlene LabuguenNo ratings yet

- Biology PPT Group 5Document15 pagesBiology PPT Group 5Air ConditionerNo ratings yet

- Kla Gard BDocument2 pagesKla Gard BSudkate BoonthawornNo ratings yet

- 4th Sem Old Papers PCMBZDocument79 pages4th Sem Old Papers PCMBZPrince SharmaNo ratings yet

- Lab Policies Sodium Potassium Chloride ISE Cobas c501 Lab 4007Document5 pagesLab Policies Sodium Potassium Chloride ISE Cobas c501 Lab 4007Ghaith MaaniNo ratings yet

- Aircraft Surface Protection and Paint CoatingsDocument2 pagesAircraft Surface Protection and Paint CoatingsSarah SNo ratings yet

- ATP - ADP Cycle WorksheetDocument3 pagesATP - ADP Cycle Worksheetlionstudio214No ratings yet

- 5243 Heterogeneous Catalysis1Document7 pages5243 Heterogeneous Catalysis1Mohit PatelNo ratings yet

- Appendix-A EPM-SPD-PC-P-007 QC Dossier Index PDFDocument14 pagesAppendix-A EPM-SPD-PC-P-007 QC Dossier Index PDFStudent Foreign100% (1)

- Nabh Project Planner Title: QualitykonnectDocument2 pagesNabh Project Planner Title: QualitykonnectQualityKonnect ConsultantsNo ratings yet

- 3 Properties of Sea WaterDocument73 pages3 Properties of Sea WaterMarissa RamonNo ratings yet

- Instrumental Analytical Methods Experiment 1 - Flame-Photometric AnalysisDocument3 pagesInstrumental Analytical Methods Experiment 1 - Flame-Photometric Analysisapi-23518718950% (2)

- Durability and Strength Evaluation of High-Performance Concrete in Marine StructuresDocument7 pagesDurability and Strength Evaluation of High-Performance Concrete in Marine StructuresCarlos GarridoNo ratings yet

- Sensepoint DS01069 V6 0912 EMEAIDocument6 pagesSensepoint DS01069 V6 0912 EMEAIadito junandaNo ratings yet

- BiomoleculesDocument48 pagesBiomoleculesOliric FabiolasNo ratings yet

- 04-200-R1 Silicon Iron AnodesDocument2 pages04-200-R1 Silicon Iron Anodessams1101No ratings yet

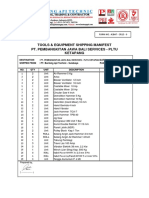

Technical Equipment Ramsey

Technical Equipment Ramsey

Uploaded by

Sangram KendreCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Equipment Ramsey

Technical Equipment Ramsey

Uploaded by

Sangram KendreCopyright:

Available Formats

Glatt Air Techniques Inc.

20 Spear Road

Ramsey, NJ 07446 USA

Tel +1 201 825 8700

Fax +1 201 825 0389

info@glattair.com

www.glatt.com

Organic Solvent Processing – IPA, Acetone, Methanol, Ethanol DEA Registration: Schedule I – V

DEA Vault: Commercial scale

DEA Import License

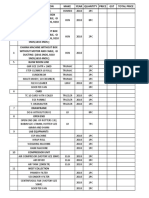

FLUID BED PROCESSORS

Equipment Processing Inserts Recommended Working Volume (Max WV)

PROCESSING EQUIPMENT

GPCG 1 3.5 inch Wurster 0.4 – 1.3L (1.6)

6 inch Wurster 0.7 – 2.8 L (3.5)

2-liter Granulator/Dryer/Coater 0.6 – 1.6 L

295 mm Rotor 0.9 – 3.6 L

GPCG 1.1 6 inch Wurster 0.7 – 2.8 L (3.5)

2-liter Granulator/Dryer/Coater 0.6 – 1.6 L

CPS™ Insert, CPS-3 1–3L

GPCG 3.1 6 inch Wurster 0.7 – 2.8 L (3.5)

(Aqueous & Organic 7 inch Wurster 1.3 – 5 L (6.25)

Solvent Processing 10-liter Granulator/Dryer/Coater 3–8L

Capabilities) CPS™ Insert, CPS-3 1–3L

GPCG 5 7 inch Wurster HS 1.7 – 6.6 L (8.25)

(Aqueous & Organic 9 inch Wurster HS 2.8 – 11 L (14)

Solvent Processing 22-liter Granulator/Dryer/Coater 6.6 – 18 L

up to 26g/min. pure 485 mm Rotor 4.5 – 24 L

GPCG 10 9 inch Wurster HS 4 – 22 L (27.4)

(Aqueous & Organic 12 inch Wurster HS 9.5 – 38 L (47.5)

Solvent Processing 50-liter Granulator/Dryer/Coater 5 – 40 L

Capabilities) 60 liter Granulator/Dryer/Coater 8 – 47 L

GPCG 60 18 inch Wurster HS 20 – 82 L (102)

32 inch Wurster HS 84 – 325 L (406)

220-liter Granulator/ Dryer/Coater 60 – 176 L

CPS™ Insert, CPS-30 18 – 56 L

GPCG 120 18 inch Wurster HS 20 – 81 L (102)

(Aqueous & Organic 32 inch Wurster HS 84 – 325 L (406)

Solvent Processing 290-liter Granulator/Dryer/Coater 88 – 240 L

Capabilities) 525-liter Granulator/Dryer/Coater 158– 420 L

CPS™ Insert, CPS-100 60 – 100 L

GPCG 300 1020-liter Granulator/Dryer/Coater 306 – 816 L

HIGH SHEAR GRANULATORS

VG 25 (2) Main Blade Mixing 25, 35 & 45 degree blade Working capacity - 15 L

VG 200 Main Blade Mixing 35 degree blade Working capacity - 120 liters

PAN COATERS

Equipment Pan Size Volume

BLENDERS

GMPC II Multi Pan Drum Insert 16 inch Pan 2L

20 inch Pan 9L

Equipment Bin Volume Recommended

24 inch Pan 24 L

30 inch Pan 56 L Glatt CML 10 Bin Blender 1.0 L 150 g – 400 g

2.0 L 300 g – 800 g

GCS-500 Perforated Pan 60 inch Pan 500 L 10 L 1.5 kg – 4.0 kg

TABLET PRESSES PK 8 qt V Blender 7.5 L 1.0 kg – 2.0 kg

PK 2 ft ³ V Blender 56 L 7.0 kg – 17.0 kg

Equipment Output

PK 5 ft ³ V Blender 142 L 18.0 kg – 40.0 kg

Carver Single Station Tablet Press Manual

CM-1200 Bin Blender 35 L 5.0 kg – 14.0 kg

Korsch PH 100 6 station Rotary Press 180 – 420 tablets/minute 250 L 37.5 kg – 100 kg

400 L 60 kg – 160 kg

Fette 1200i 24 station Rotary Press 72,000 tablets/hour

500 L 75 kg – 200 kg

Fette 2200i 36 station Rotary Press 240,000 tablets/hour 1200 L 180 kg – 480 kg

Glatt. Pharmaceutical Services.

Glatt Air Techniques Inc.

20 Spear Road

Ramsey, NJ 07446 USA

Tel +1 201 825 8700

Fax +1 201 825 0389

info@glattair.com

www.glatt.com

Organic Solvent Processing – IPA, Acetone, Methanol, Ethanol DEA Registration: Schedule I – V

DEA Vault: Commercial scale

DEA Import License

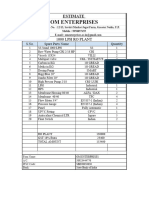

ENCAPSULATORS

Equipment Capabilities Output

PROCESSING EQUIPMENT

H/H Encapsulator Modu C LS Pellets / Powder / Mini Tabs Capsule Change parts: 13K – 25K capsules / hour

00, 0, 0el, 1, 2, 3, 4

H/H Encapsulator Modu C MS Pellets, 00, 0, 1, 2, 3, 4 100k/hour

Torpac Manual Encapsulator 0,2 NA

IN-CAP Capsule Filler Pellets: 00, 0, 1 all change parts 1500 and 3000 capsules / hour

Powder: 0, 1 all change parts

Anritsu Capsule Weight Checker Capsules Sizes: 00, 0, 1, 2, 3, 4 (supports elongated capsules) 40 – 60 K/hour

MILLS AND SIEVES

Equipment Capabilities

GS Sieve – Conical Mill Array of change parts

Fitzmill Various screen sizes all change parts

Sweco Sieves (5) 24”, 30” and 48”, various screen sizes

Quick Sieves Array of change parts

Dynomill Zirconium milling medium

Sturtevant Micronizer Model SDM4

MISCELLANEOUS EQUIPMENT

Solution Vessels - Jacketed and non jacketed. Various sizes up to - 500 liters

Lydon Oven – Tray drying oven, 80 trays (400 kilos)

Vertical Axis Centrifuge – Volume : 5.5 liters

PACKAGING EQUIPMENT: (submission batch size)

Dietz TC4 Electronic tablet/capsule counter

AutoMate AM-74 Induction Foil Cap Sealer/Lepak Cap Sealer

Imaje ink jet printer, Torque Tester

ANALYTICAL EQUIPMENT

HPLC Systems Empower 3 software; PDA detectors

Dissolution Baths Transfer modules to HPLC; on line capabilities

directly to UV/Vis

UV/Vis Diode-Array Spectrophotometer Manual analysis; single or multi-bath dissolution

analysis

Total Organic Carbon (TOC) Analyzer Water testing

Infrared Spectrophotometer (FT) Raw material ID testing

Gas Chromatograph Head space and direct injection capability

Scanning Electron Microscope Newly purchased JEOL unit

Stability Chambers 25ºC/60% RH; 40ºC/75% RH; 30ºC/65% RH

Malvern Particle Size Analyzer Mastersizer 2000

Eyecon Particle Analyzer Innopharma Technology

Glatt. Pharmaceutical Services.

You might also like

- Edu Jacob Atmchem Problems Jan 2021Document77 pagesEdu Jacob Atmchem Problems Jan 2021Elle WoodsNo ratings yet

- ASTM D 1193-2011, Standard Specification For Reagent Water PDFDocument6 pagesASTM D 1193-2011, Standard Specification For Reagent Water PDFvanitaNo ratings yet

- Equipment VA Consumption ReferenceDocument5 pagesEquipment VA Consumption ReferenceFerdinand Ramos EspirituNo ratings yet

- MEGA CatalogueDocument8 pagesMEGA CatalogueSumitBhaumik69% (13)

- Technical Equipment RamseyDocument2 pagesTechnical Equipment RamseythuNo ratings yet

- 3000 LPH Quotation Tender No 34235090Document7 pages3000 LPH Quotation Tender No 34235090Thomas BLOOMNo ratings yet

- Pack RYTDocument41 pagesPack RYTGonzalo Alonso QuintanaNo ratings yet

- GPP - Oil, Chemical, Grease List, 17.06.2023Document8 pagesGPP - Oil, Chemical, Grease List, 17.06.2023dilip matalNo ratings yet

- Brochure Filters S2O PDFDocument5 pagesBrochure Filters S2O PDFRabindranath Hendy TagoreNo ratings yet

- Brochure Filters YFODocument5 pagesBrochure Filters YFOHabib Yahia CherifNo ratings yet

- Especificaciones Técnicas Reveladora Raptor + ThermalDocument2 pagesEspecificaciones Técnicas Reveladora Raptor + ThermalyoanacgwNo ratings yet

- Rivulis F6150 English Metric 20190909 WebDocument6 pagesRivulis F6150 English Metric 20190909 WebMehdi BassouNo ratings yet

- Plant and Machinery DetailDocument2 pagesPlant and Machinery DetailShrinath AnbalaganNo ratings yet

- HGSXDocument1 pageHGSXmktg2No ratings yet

- 3000 LPH QuotationDocument7 pages3000 LPH QuotationThomas BLOOMNo ratings yet

- Hyster H5.00XLDocument8 pagesHyster H5.00XLAurel TurcNo ratings yet

- York Check and Foot Valves: Technical CatalogueDocument14 pagesYork Check and Foot Valves: Technical CatalogueWilliam OeyNo ratings yet

- DATA SHEET BLOWER FRAIJANES - URAI-33-Blower-Data-SheetDocument2 pagesDATA SHEET BLOWER FRAIJANES - URAI-33-Blower-Data-SheetOscar SteigerNo ratings yet

- Separator Sizing SpreadsheetDocument40 pagesSeparator Sizing SpreadsheetRidho MuhtadiNo ratings yet

- HWYH-1178 Mud Report - 7530073 - 01Document5 pagesHWYH-1178 Mud Report - 7530073 - 01KHALEDFEKAIRNo ratings yet

- 1000 LPH Ro Plant-1Document1 page1000 LPH Ro Plant-1Suranjan BhattacharyyaNo ratings yet

- RTC Leaflet Micro Nano-Bubble-Generator enDocument2 pagesRTC Leaflet Micro Nano-Bubble-Generator ensudarji subagyoNo ratings yet

- Eco-Friendly: Ruian Zhenjing Machinery. PVT - LTDDocument8 pagesEco-Friendly: Ruian Zhenjing Machinery. PVT - LTDBikash NayakNo ratings yet

- Semi Automatic Blowing Machine 1 With 2 by Cherrydou 202105828Document12 pagesSemi Automatic Blowing Machine 1 With 2 by Cherrydou 202105828adm.moh121No ratings yet

- 019 - Concept Note - Jordan ProjectDocument3 pages019 - Concept Note - Jordan ProjectAhmad AlayeshNo ratings yet

- Chemical Material Preparation ListDocument3 pagesChemical Material Preparation ListYip DavidNo ratings yet

- Vdocuments - MX Separator Sizing SpreadsheetDocument31 pagesVdocuments - MX Separator Sizing SpreadsheetYustianNo ratings yet

- Series Pds Pms H2o FPT EngDocument2 pagesSeries Pds Pms H2o FPT EngtongaiNo ratings yet

- Air Chiller CL-2200 DatasheetDocument3 pagesAir Chiller CL-2200 Datasheetteddy tavaresNo ratings yet

- Sika - AG GroutDocument4 pagesSika - AG GroutBill MurrayNo ratings yet

- Type DA 33 DA 66 DA 118 DA 186 DA-267: Test EquipmentDocument4 pagesType DA 33 DA 66 DA 118 DA 186 DA-267: Test EquipmentBobby Jacob [Lead Manager, Minimac]No ratings yet

- Essmart Dealer Catalogue 2020Document12 pagesEssmart Dealer Catalogue 2020Vinay Bahadur KulshreshthaNo ratings yet

- Cartridge and Bag Filter UnitDocument6 pagesCartridge and Bag Filter UnitDoni KurniawanNo ratings yet

- Introduction Letter: Subject: Company ProfileDocument21 pagesIntroduction Letter: Subject: Company ProfilePritam JadhavNo ratings yet

- HD 5/12 C PlusDocument16 pagesHD 5/12 C PlusSaiful FatoniNo ratings yet

- RPF Data Sheet Logo Revised 1Document3 pagesRPF Data Sheet Logo Revised 1Thomas ThommanNo ratings yet

- BX Series Hydraulic Breaker Spec Sheet EnglishDocument2 pagesBX Series Hydraulic Breaker Spec Sheet EnglishAloysius GlassNo ratings yet

- HTTP WWW - FrymasterDocument2 pagesHTTP WWW - Frymasterdaygo21No ratings yet

- Model # Description Sand Required (LBS.) PriceDocument22 pagesModel # Description Sand Required (LBS.) PriceLuisNo ratings yet

- GTR 20Document2 pagesGTR 20Rahul AgarwalNo ratings yet

- BM-S25L 3-5gallon Bottle Blow Molding MachineDocument11 pagesBM-S25L 3-5gallon Bottle Blow Molding MachineMohamed BayoumiNo ratings yet

- BX SeriesDocument2 pagesBX Seriesaaron mufukNo ratings yet

- List AlatDocument3 pagesList AlatLutfi wahyuNo ratings yet

- Groz - Lube Price List 2014 AprilDocument7 pagesGroz - Lube Price List 2014 AprilPhox IndiaNo ratings yet

- Filters and CapacitiesDocument3 pagesFilters and CapacitiesbrunofernandesdacostNo ratings yet

- NKC Projects - Mobile Workshop VanDocument3 pagesNKC Projects - Mobile Workshop Vanfaisal begNo ratings yet

- Graco PumpDocument12 pagesGraco PumpRudi Abu ZahraNo ratings yet

- How To Stabilize and Strengthen The Wellbore During Drilling Operations" by DR Fred GrowcockDocument16 pagesHow To Stabilize and Strengthen The Wellbore During Drilling Operations" by DR Fred Growcockrıdvan duranNo ratings yet

- Spill Response and Control EquipmentDocument13 pagesSpill Response and Control EquipmentsinghajitbNo ratings yet

- Bom of 150 KLD Etp: SR - No Description Width (MM) Length /dia (MM) Hight (MM) Thikness (MM) F.B & Nos. Flow Rate /capDocument12 pagesBom of 150 KLD Etp: SR - No Description Width (MM) Length /dia (MM) Hight (MM) Thikness (MM) F.B & Nos. Flow Rate /capRajdeepsinhNo ratings yet

- Machinery List, Customer List, Product Details, Org Chart - BoschDocument8 pagesMachinery List, Customer List, Product Details, Org Chart - BoschDanish931No ratings yet

- Product DetailsDocument6 pagesProduct DetailsAHMED391 GAMESNo ratings yet

- Avanti: Model BS 100P BS 200PDocument7 pagesAvanti: Model BS 100P BS 200PItstanweerkhanNo ratings yet

- High Pressure Washer STG G 2Document1 pageHigh Pressure Washer STG G 2Vũ Nguyễn MinhNo ratings yet

- High Flow Series Filter CartridgesDocument2 pagesHigh Flow Series Filter CartridgesCarlos BarriosNo ratings yet

- HPW-DUST Data Sheet v1 5Document6 pagesHPW-DUST Data Sheet v1 5Miguel CNo ratings yet

- 813 - Consumables For Engine RoomDocument1 page813 - Consumables For Engine RoomAhmed HamdyNo ratings yet

- Catalog For CleaningDocument10 pagesCatalog For CleaningHaktuiiNo ratings yet

- ACFrOgDsDANBTTyLEGW5xT3C9NIyC1B5iGGKV0jcOJsf8evmI1FzmFCjq0MroJYugbF9u4pMdAVF Jyf2a9xLUyUbtGIZ OnqgqZ8hY OI5yC2K9cJA69ioTIgwFido PDFDocument4 pagesACFrOgDsDANBTTyLEGW5xT3C9NIyC1B5iGGKV0jcOJsf8evmI1FzmFCjq0MroJYugbF9u4pMdAVF Jyf2a9xLUyUbtGIZ OnqgqZ8hY OI5yC2K9cJA69ioTIgwFido PDFRati Ranjan SahooNo ratings yet

- Raptor EnglishDocument2 pagesRaptor EnglishLe Thanh HuyNo ratings yet

- HS 2K Primer (High Build)Document5 pagesHS 2K Primer (High Build)tietkop20No ratings yet

- Dosing Disc Thickness Calculation For Capsule Filling Machine - SaintyTecDocument4 pagesDosing Disc Thickness Calculation For Capsule Filling Machine - SaintyTecSangram KendreNo ratings yet

- Questions&Answers GeneralDocument23 pagesQuestions&Answers GeneralSangram KendreNo ratings yet

- Efficiency Shared Containment Knowledge Capsules at Full SpeedDocument17 pagesEfficiency Shared Containment Knowledge Capsules at Full SpeedSangram KendreNo ratings yet

- TechnofourDocument2 pagesTechnofourSangram KendreNo ratings yet

- Generate Making Tablets Tcm11 42308Document1 pageGenerate Making Tablets Tcm11 42308Sangram KendreNo ratings yet

- US FDA Inspections Resume in IndiaDocument7 pagesUS FDA Inspections Resume in IndiaSangram KendreNo ratings yet

- Compression of Schedule M To Proposed Schedule M: Part I-ADocument2 pagesCompression of Schedule M To Proposed Schedule M: Part I-ASangram Kendre100% (1)

- Performance Update - Q2FY 22Document12 pagesPerformance Update - Q2FY 22Sangram KendreNo ratings yet

- Scaleup of Wet Granulation Processes Science Not Art CompressDocument6 pagesScaleup of Wet Granulation Processes Science Not Art CompressSangram KendreNo ratings yet

- Pharma Water SystemDocument75 pagesPharma Water SystemSangram KendreNo ratings yet

- OOS Investigation and Where You Are Going Wrong: Page 1 of 3Document3 pagesOOS Investigation and Where You Are Going Wrong: Page 1 of 3Sangram KendreNo ratings yet

- Considerations For The Use of Real-World Data and Real-World Evidence To Support Regulatory Decision-Making For Drug and Biological ProductsDocument12 pagesConsiderations For The Use of Real-World Data and Real-World Evidence To Support Regulatory Decision-Making For Drug and Biological ProductsSangram KendreNo ratings yet

- Date: 19 October 2021: Shilpa Medicare LimitedDocument30 pagesDate: 19 October 2021: Shilpa Medicare LimitedSangram KendreNo ratings yet

- Risk AcceptabilityDocument8 pagesRisk AcceptabilitySangram KendreNo ratings yet

- Optimization and Validation of Process For Formulation of Duloxetinehydrochloride CapsulesDocument8 pagesOptimization and Validation of Process For Formulation of Duloxetinehydrochloride CapsulesSangram KendreNo ratings yet

- Strategies For Improving Capsule Filling EfficiencyDocument4 pagesStrategies For Improving Capsule Filling EfficiencySangram KendreNo ratings yet

- f2 Chemistry TopicalsDocument36 pagesf2 Chemistry TopicalsEvansOmoiNo ratings yet

- Laboratory Evaluation of Concrete Thin Repair Materials MERL-2009-36Document15 pagesLaboratory Evaluation of Concrete Thin Repair Materials MERL-2009-36chutton681No ratings yet

- Ceramics International: Junfeng Chen, Nan Li, Yaowu Wei, Bingqiang Han, Wen YanDocument9 pagesCeramics International: Junfeng Chen, Nan Li, Yaowu Wei, Bingqiang Han, Wen YanJunfeng ChenNo ratings yet

- Chemical BondingDocument26 pagesChemical BondingDipin Preet SinghNo ratings yet

- Thomas1999 PDFDocument2 pagesThomas1999 PDFD.C.No ratings yet

- Kimia Pertemuan 1Document36 pagesKimia Pertemuan 1sabtun ismi khasanahNo ratings yet

- 10 ch05.2.1 Carboxylic Acids and Their Derivatives 29Document29 pages10 ch05.2.1 Carboxylic Acids and Their Derivatives 29NH Khánh NhiiNo ratings yet

- Exercise - II: (One or More Than One Option Correct)Document3 pagesExercise - II: (One or More Than One Option Correct)mehul pantNo ratings yet

- Typical Sections - Editable (Autosaved)Document157 pagesTypical Sections - Editable (Autosaved)sandeepNo ratings yet

- Hfi5110 300516Document2 pagesHfi5110 300516李万福No ratings yet

- Manual Therm Tran ChemDocument35 pagesManual Therm Tran ChemNam DanhNo ratings yet

- ASTM D1856 092015 Aug 2019Document4 pagesASTM D1856 092015 Aug 2019karenmerino94No ratings yet

- CIR - Propanediol (1,3-Propandeiol)Document73 pagesCIR - Propanediol (1,3-Propandeiol)Darlene LabuguenNo ratings yet

- Biology PPT Group 5Document15 pagesBiology PPT Group 5Air ConditionerNo ratings yet

- Kla Gard BDocument2 pagesKla Gard BSudkate BoonthawornNo ratings yet

- 4th Sem Old Papers PCMBZDocument79 pages4th Sem Old Papers PCMBZPrince SharmaNo ratings yet

- Lab Policies Sodium Potassium Chloride ISE Cobas c501 Lab 4007Document5 pagesLab Policies Sodium Potassium Chloride ISE Cobas c501 Lab 4007Ghaith MaaniNo ratings yet

- Aircraft Surface Protection and Paint CoatingsDocument2 pagesAircraft Surface Protection and Paint CoatingsSarah SNo ratings yet

- ATP - ADP Cycle WorksheetDocument3 pagesATP - ADP Cycle Worksheetlionstudio214No ratings yet

- 5243 Heterogeneous Catalysis1Document7 pages5243 Heterogeneous Catalysis1Mohit PatelNo ratings yet

- Appendix-A EPM-SPD-PC-P-007 QC Dossier Index PDFDocument14 pagesAppendix-A EPM-SPD-PC-P-007 QC Dossier Index PDFStudent Foreign100% (1)

- Nabh Project Planner Title: QualitykonnectDocument2 pagesNabh Project Planner Title: QualitykonnectQualityKonnect ConsultantsNo ratings yet

- 3 Properties of Sea WaterDocument73 pages3 Properties of Sea WaterMarissa RamonNo ratings yet

- Instrumental Analytical Methods Experiment 1 - Flame-Photometric AnalysisDocument3 pagesInstrumental Analytical Methods Experiment 1 - Flame-Photometric Analysisapi-23518718950% (2)

- Durability and Strength Evaluation of High-Performance Concrete in Marine StructuresDocument7 pagesDurability and Strength Evaluation of High-Performance Concrete in Marine StructuresCarlos GarridoNo ratings yet

- Sensepoint DS01069 V6 0912 EMEAIDocument6 pagesSensepoint DS01069 V6 0912 EMEAIadito junandaNo ratings yet

- BiomoleculesDocument48 pagesBiomoleculesOliric FabiolasNo ratings yet

- 04-200-R1 Silicon Iron AnodesDocument2 pages04-200-R1 Silicon Iron Anodessams1101No ratings yet