Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

7 viewsChilled Beam Product and System-1

Chilled Beam Product and System-1

Uploaded by

belineCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Module 14 US Fire and Life Safety FLSDocument24 pagesModule 14 US Fire and Life Safety FLSbeline100% (2)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hydrothermal and Solvothermal SynthesisDocument19 pagesHydrothermal and Solvothermal SynthesisArcha Unni0% (1)

- Material Balances Design Project Manufacture of Diethyl EtherDocument39 pagesMaterial Balances Design Project Manufacture of Diethyl EthermoheedNo ratings yet

- Aerodynamics - AndersonDocument142 pagesAerodynamics - AndersonbelineNo ratings yet

- Hydraulic Schematic 785C PDFDocument13 pagesHydraulic Schematic 785C PDFDany LeaNo ratings yet

- Flakt Woods Seminar 4Document12 pagesFlakt Woods Seminar 4belineNo ratings yet

- A Simple Method For Determining Kinetic Parameters For Materials in Fire ModelsDocument13 pagesA Simple Method For Determining Kinetic Parameters For Materials in Fire ModelsbelineNo ratings yet

- ,influence of Restraint On Fire Performance of Reinforced Concrete ColumnsDocument10 pages,influence of Restraint On Fire Performance of Reinforced Concrete ColumnsbelineNo ratings yet

- CP Samasta 2020 PDFDocument36 pagesCP Samasta 2020 PDFbelineNo ratings yet

- Midea CAC Product Line Introduction 2017Document52 pagesMidea CAC Product Line Introduction 2017belineNo ratings yet

- EXHIBIT B Part 2 of 2 PDFDocument16 pagesEXHIBIT B Part 2 of 2 PDFbelineNo ratings yet

- Micromax Case History-An Alternative To Brines For Completion & Packer FluidsDocument2 pagesMicromax Case History-An Alternative To Brines For Completion & Packer FluidsilkerkozturkNo ratings yet

- Homeowners Guide To Onsite Sewage SystemsDocument28 pagesHomeowners Guide To Onsite Sewage SystemssolivetoNo ratings yet

- Grain Refining With DDRX by Isothermal MDF of Al-Zn-Mg-Cu AlloyDocument12 pagesGrain Refining With DDRX by Isothermal MDF of Al-Zn-Mg-Cu AlloyAromoNo ratings yet

- Line SizeDocument100 pagesLine SizeBISWAJIT MAJINo ratings yet

- Basic Hydrocyclone OperationDocument23 pagesBasic Hydrocyclone Operationgeo rayfandyNo ratings yet

- A Case Study of High-Pressure, Light-Oil Steam Flooding in A Low-Permeability ReservoirDocument7 pagesA Case Study of High-Pressure, Light-Oil Steam Flooding in A Low-Permeability ReservoirDanna Kornz100% (1)

- Buoyancy-Driven Air Flow in A Closed Half-Scale Stairwell Model - Velocity and Temperature Measurements by Zohrabian Et. AlDocument21 pagesBuoyancy-Driven Air Flow in A Closed Half-Scale Stairwell Model - Velocity and Temperature Measurements by Zohrabian Et. AlzohrabianNo ratings yet

- Catologue Mang MBR LG-KOReD 03.2021Document16 pagesCatologue Mang MBR LG-KOReD 03.2021shjnbe18No ratings yet

- Aft-Catalog s22 SecDocument16 pagesAft-Catalog s22 SecwemersonsrNo ratings yet

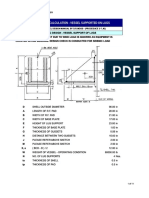

- Sample Design Calculation - Vessel Supported On LugsDocument11 pagesSample Design Calculation - Vessel Supported On LugsinnovativekarthiNo ratings yet

- Heat Transfer Lectures 2 (Convection)Document18 pagesHeat Transfer Lectures 2 (Convection)Haider100% (6)

- Project Standards and Specifications Plant Operating Manuals Rev01Document10 pagesProject Standards and Specifications Plant Operating Manuals Rev01hiyeonNo ratings yet

- (29b) - A User's Guide To The Chemistry, Kinetics and Basic Reactor Engineering of HydroprocessingDocument22 pages(29b) - A User's Guide To The Chemistry, Kinetics and Basic Reactor Engineering of HydroprocessingwoshwoshNo ratings yet

- Dresser Mooney Regulators Flowgrid PCVDocument12 pagesDresser Mooney Regulators Flowgrid PCVElias ElHossariNo ratings yet

- Numerical Fluid MechanicsDocument4 pagesNumerical Fluid MechanicsAkira TamashiroNo ratings yet

- Difference Between Pipe and TubeDocument3 pagesDifference Between Pipe and TubeAnonymous fQAeGFNo ratings yet

- Plasma Atomized Spherical Metal Powders: Inventor of The Plasma Atomization ProcessDocument2 pagesPlasma Atomized Spherical Metal Powders: Inventor of The Plasma Atomization ProcesssafNo ratings yet

- Self-Assessment Exercise 1Document3 pagesSelf-Assessment Exercise 1Deniz YiğitNo ratings yet

- 13B-2 E5 PADocument4 pages13B-2 E5 PAMichel Dorian VargasNo ratings yet

- Catalogo PedrolloDocument100 pagesCatalogo Pedrolloluimg100% (1)

- SPE8352 Dstanalysis Withpressure Dependent Rockandfluid PropertiesDocument9 pagesSPE8352 Dstanalysis Withpressure Dependent Rockandfluid PropertiesSofiaNo ratings yet

- Calculation of Flow From PinholeDocument6 pagesCalculation of Flow From PinholeSubrata MukherjeeNo ratings yet

- High Rise StructuresPlumbing Design GuidelinesDocument6 pagesHigh Rise StructuresPlumbing Design GuidelinesjituplanojrNo ratings yet

- Commissioning Report - FILTERDocument9 pagesCommissioning Report - FILTERGrace PentinioNo ratings yet

- Batch Reactor Equations and Sample ProblemsDocument9 pagesBatch Reactor Equations and Sample ProblemsARIANA NICOLE RELIGIOSONo ratings yet

- Ellipsoidal Tip Pitot Tube: Designed To Meet British Standard 1042Document1 pageEllipsoidal Tip Pitot Tube: Designed To Meet British Standard 1042Khoiruman AssyaidanieyNo ratings yet

- A Mechanistic Heat Transfer Correlation For Non-Boiling Two Phase Flow in Horizontal, Inclined and Vertical PipesDocument9 pagesA Mechanistic Heat Transfer Correlation For Non-Boiling Two Phase Flow in Horizontal, Inclined and Vertical Pipesmostafa shahrabiNo ratings yet

Chilled Beam Product and System-1

Chilled Beam Product and System-1

Uploaded by

beline0 ratings0% found this document useful (0 votes)

7 views14 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

7 views14 pagesChilled Beam Product and System-1

Chilled Beam Product and System-1

Uploaded by

belineCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 14

Chilled beam - iQ Star Wega-1

Sustainable chilled beam system for flexible utilization

Air Climate Systems

Introduction of chilled beam

Requirements of the market

IQ Star range and new WEGA beam

Wega beam – Variable airflow

Static pressure control

Controls for WEGA, STRA-14

Documentation

References

Air Climate Systems

Induction (Active) Beams - Flush Mounted

Air Climate Systems

Principle

Supply air temp. 15-18°C

(from TERS/PAU)

Inlet water temp. 14-15°C

20~22°C

23°C Induce warm

air

1,8m

from space

26°C

air velocity 0,15 - 0,25 m/s

0,50m

Room temp. 25.6°C

(summer)

Occupied zone

Air Climate Systems

Induction (Active) Chilled Beams

Primary air supply Concrete soffit

Suspended

Ceiling

Air Climate Systems

Induction (Active) Beams - Flush Mounted

Coanda effect holds the air against the ceiling

Air Climate Systems

Flakt Woods Integrated Chilled Beams Systems Solution

Important advantages of chilled beam system :

1.Energy savings :

•Chiller energy costs can be reduced 15%~20% with

Chilled Beams vs. VAV due to higher operating water

temps (14~16 ºC) with beams . More saving if

separate chiller system is used

•Up to 75% of the total cooling capacity will be

handled by the water. Reduced air requirements

means less ductwork for air, smaller AHU, lower

noise and related fan motor operating costs.

•No fan energy compared to FCU system

Air Climate Systems

Why water?

• Water holds ~ 3400 x more energy than air

• Pumps more efficient than fans

Note: Ventilation air still required

Air Climate Systems

Flakt Woods Integrated Chilled Beams Systems Solution

2. Very quiet operation

•Maximum alllowable noise noise level for offices is

35-40 dB(A). Active chilled beam noise level around

30-35 dB(A)

3. Optinum occupant comfort and indoor air

quality (IAQ)

•Effective controls of both room temperature and

humidity

More air (due to induced room air)can be evenly

distributed throughout the space, reduced draft or

dumping of cold air vs VAV system at peak

conditions.

Air Climate Systems

Flakt Woods Integrated Chilled Beams Systems Solution

4. Simple controls:

•Chilled Beams are most often controlled by

simply opening and closing a chilled water valve,

based on a call for cooling from the wall

thermostat. These valves are configured to fail

closed and are commonly fitted with a anti-

condensation sensor.

Air Climate Systems

Flakt Woods Integrated Chilled Beams Systems Solution

5. Low maintenance :

•Unlike fan coil unit Chilled Beam has no fan, fan

motor, electrical wiring, condensate drain pan &

pipes and filters to be maintained.

•Low velocity associated with induced air across dry

cooling coil limits the collection of airborne dust.

6. Less building skin height

•Low Chilled Beam height (250mm) and

less installation space allow building

ceiling height for each floor to be

reduced up to 460mm.

Air Climate Systems

Easy Maintenance No filters,

No fan motors

No condensate

drain pan

Easy

maintenance

Low operating

cost

Air Climate Systems

Fan Coil Units vs. Chilled Beams

• Require electrical connections and

high service cost

• Fans are inefficient and require

maintenance – high noise

• Filter maintenance – Carrier

recommends monthly filter

changes – at each unit

• Deep coils required to handle

latent load in space

• Condensate management and

microbial challenge

• Low cost but high maintenance

and energy consumption

Air Climate Systems

Thank you!

Air Climate Systems

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Module 14 US Fire and Life Safety FLSDocument24 pagesModule 14 US Fire and Life Safety FLSbeline100% (2)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hydrothermal and Solvothermal SynthesisDocument19 pagesHydrothermal and Solvothermal SynthesisArcha Unni0% (1)

- Material Balances Design Project Manufacture of Diethyl EtherDocument39 pagesMaterial Balances Design Project Manufacture of Diethyl EthermoheedNo ratings yet

- Aerodynamics - AndersonDocument142 pagesAerodynamics - AndersonbelineNo ratings yet

- Hydraulic Schematic 785C PDFDocument13 pagesHydraulic Schematic 785C PDFDany LeaNo ratings yet

- Flakt Woods Seminar 4Document12 pagesFlakt Woods Seminar 4belineNo ratings yet

- A Simple Method For Determining Kinetic Parameters For Materials in Fire ModelsDocument13 pagesA Simple Method For Determining Kinetic Parameters For Materials in Fire ModelsbelineNo ratings yet

- ,influence of Restraint On Fire Performance of Reinforced Concrete ColumnsDocument10 pages,influence of Restraint On Fire Performance of Reinforced Concrete ColumnsbelineNo ratings yet

- CP Samasta 2020 PDFDocument36 pagesCP Samasta 2020 PDFbelineNo ratings yet

- Midea CAC Product Line Introduction 2017Document52 pagesMidea CAC Product Line Introduction 2017belineNo ratings yet

- EXHIBIT B Part 2 of 2 PDFDocument16 pagesEXHIBIT B Part 2 of 2 PDFbelineNo ratings yet

- Micromax Case History-An Alternative To Brines For Completion & Packer FluidsDocument2 pagesMicromax Case History-An Alternative To Brines For Completion & Packer FluidsilkerkozturkNo ratings yet

- Homeowners Guide To Onsite Sewage SystemsDocument28 pagesHomeowners Guide To Onsite Sewage SystemssolivetoNo ratings yet

- Grain Refining With DDRX by Isothermal MDF of Al-Zn-Mg-Cu AlloyDocument12 pagesGrain Refining With DDRX by Isothermal MDF of Al-Zn-Mg-Cu AlloyAromoNo ratings yet

- Line SizeDocument100 pagesLine SizeBISWAJIT MAJINo ratings yet

- Basic Hydrocyclone OperationDocument23 pagesBasic Hydrocyclone Operationgeo rayfandyNo ratings yet

- A Case Study of High-Pressure, Light-Oil Steam Flooding in A Low-Permeability ReservoirDocument7 pagesA Case Study of High-Pressure, Light-Oil Steam Flooding in A Low-Permeability ReservoirDanna Kornz100% (1)

- Buoyancy-Driven Air Flow in A Closed Half-Scale Stairwell Model - Velocity and Temperature Measurements by Zohrabian Et. AlDocument21 pagesBuoyancy-Driven Air Flow in A Closed Half-Scale Stairwell Model - Velocity and Temperature Measurements by Zohrabian Et. AlzohrabianNo ratings yet

- Catologue Mang MBR LG-KOReD 03.2021Document16 pagesCatologue Mang MBR LG-KOReD 03.2021shjnbe18No ratings yet

- Aft-Catalog s22 SecDocument16 pagesAft-Catalog s22 SecwemersonsrNo ratings yet

- Sample Design Calculation - Vessel Supported On LugsDocument11 pagesSample Design Calculation - Vessel Supported On LugsinnovativekarthiNo ratings yet

- Heat Transfer Lectures 2 (Convection)Document18 pagesHeat Transfer Lectures 2 (Convection)Haider100% (6)

- Project Standards and Specifications Plant Operating Manuals Rev01Document10 pagesProject Standards and Specifications Plant Operating Manuals Rev01hiyeonNo ratings yet

- (29b) - A User's Guide To The Chemistry, Kinetics and Basic Reactor Engineering of HydroprocessingDocument22 pages(29b) - A User's Guide To The Chemistry, Kinetics and Basic Reactor Engineering of HydroprocessingwoshwoshNo ratings yet

- Dresser Mooney Regulators Flowgrid PCVDocument12 pagesDresser Mooney Regulators Flowgrid PCVElias ElHossariNo ratings yet

- Numerical Fluid MechanicsDocument4 pagesNumerical Fluid MechanicsAkira TamashiroNo ratings yet

- Difference Between Pipe and TubeDocument3 pagesDifference Between Pipe and TubeAnonymous fQAeGFNo ratings yet

- Plasma Atomized Spherical Metal Powders: Inventor of The Plasma Atomization ProcessDocument2 pagesPlasma Atomized Spherical Metal Powders: Inventor of The Plasma Atomization ProcesssafNo ratings yet

- Self-Assessment Exercise 1Document3 pagesSelf-Assessment Exercise 1Deniz YiğitNo ratings yet

- 13B-2 E5 PADocument4 pages13B-2 E5 PAMichel Dorian VargasNo ratings yet

- Catalogo PedrolloDocument100 pagesCatalogo Pedrolloluimg100% (1)

- SPE8352 Dstanalysis Withpressure Dependent Rockandfluid PropertiesDocument9 pagesSPE8352 Dstanalysis Withpressure Dependent Rockandfluid PropertiesSofiaNo ratings yet

- Calculation of Flow From PinholeDocument6 pagesCalculation of Flow From PinholeSubrata MukherjeeNo ratings yet

- High Rise StructuresPlumbing Design GuidelinesDocument6 pagesHigh Rise StructuresPlumbing Design GuidelinesjituplanojrNo ratings yet

- Commissioning Report - FILTERDocument9 pagesCommissioning Report - FILTERGrace PentinioNo ratings yet

- Batch Reactor Equations and Sample ProblemsDocument9 pagesBatch Reactor Equations and Sample ProblemsARIANA NICOLE RELIGIOSONo ratings yet

- Ellipsoidal Tip Pitot Tube: Designed To Meet British Standard 1042Document1 pageEllipsoidal Tip Pitot Tube: Designed To Meet British Standard 1042Khoiruman AssyaidanieyNo ratings yet

- A Mechanistic Heat Transfer Correlation For Non-Boiling Two Phase Flow in Horizontal, Inclined and Vertical PipesDocument9 pagesA Mechanistic Heat Transfer Correlation For Non-Boiling Two Phase Flow in Horizontal, Inclined and Vertical Pipesmostafa shahrabiNo ratings yet