Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

68 viewsNA 625 Data Sheet

NA 625 Data Sheet

Uploaded by

andresrojas25Inweld Nickel 625 is a filler metal used for welding nickel-chromium-molybdenum alloys to themselves or other materials like steel. It has a nominal composition of 61% nickel, 22% chromium, 9% molybdenum, and 3.5% niobium plus tantalum. It can be used for welding applications between cryogenic and 1000°F temperatures. Typical weld metal properties include a tensile strength of 110,000 psi, yield strength of 60,000 psi, and 30% elongation. Recommended parameters are provided for gas metal arc welding and gas tungsten arc welding processes.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- 1100 Data SheetDocument1 page1100 Data SheetMuhammad Whisnu NugrahaNo ratings yet

- 4340 Wire For Low Alloy SteelsDocument1 page4340 Wire For Low Alloy SteelsPankaj KumbhareNo ratings yet

- Filler Metal 70s-6Document1 pageFiller Metal 70s-6Hugo RodriguezNo ratings yet

- 230 Broadway Huntington Station, NY 11746 P: 631.547.5470 - F: 631.547.5475 100 Commerce Way Aliquippa, PA 15001 P: 724.378.6351 - F: 724.378.2505Document1 page230 Broadway Huntington Station, NY 11746 P: 631.547.5470 - F: 631.547.5475 100 Commerce Way Aliquippa, PA 15001 P: 724.378.6351 - F: 724.378.2505mohamed AdelNo ratings yet

- 312-16 Data SheetDocument1 page312-16 Data Sheetmuhi salehNo ratings yet

- Bavaria en BA-TIG 310Document1 pageBavaria en BA-TIG 310cocoNo ratings yet

- 71t 1cDocument1 page71t 1cSuthan M RNo ratings yet

- ER90S-B9 Electrode SpecDocument1 pageER90S-B9 Electrode SpecfaizalzolNo ratings yet

- Arc Welding Electrodes (Product Catalogue)Document28 pagesArc Welding Electrodes (Product Catalogue)ddprt123No ratings yet

- NI-182 Victory ENICRFE-3 Electrode Data SheetDocument1 pageNI-182 Victory ENICRFE-3 Electrode Data SheetgianNo ratings yet

- Pinnacle Alloys ENiCrFe 3 12.16Document2 pagesPinnacle Alloys ENiCrFe 3 12.16satnamNo ratings yet

- SO18. 222369 - Sockolet3.4 - CA1293Document2 pagesSO18. 222369 - Sockolet3.4 - CA1293Jhonatan GonzalezNo ratings yet

- Spring Materials (Round Wire)Document6 pagesSpring Materials (Round Wire)Kishore BhatNo ratings yet

- 007 Welding Duplex and Superduplex Stainless Steel Industry Guide Rev0Document11 pages007 Welding Duplex and Superduplex Stainless Steel Industry Guide Rev0carlonewmannNo ratings yet

- E7018 PDFDocument3 pagesE7018 PDFPrakash RajNo ratings yet

- Tecnofil Catalogo2022Document8 pagesTecnofil Catalogo2022Cesar OteroNo ratings yet

- Stainless Steel Flux Cored Tig: Alloy Description and ApplicationDocument1 pageStainless Steel Flux Cored Tig: Alloy Description and ApplicationNGUYEN VINHNo ratings yet

- Mill Test & Inspection Certificate: According To en 10204 3.1Document2 pagesMill Test & Inspection Certificate: According To en 10204 3.1Jeisson BotiaNo ratings yet

- E7018 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE7018 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- Bavaria en BA-TIG 309LSiDocument1 pageBavaria en BA-TIG 309LSicocoNo ratings yet

- ER70S-2 Mild SteelDocument1 pageER70S-2 Mild SteelNadeemNo ratings yet

- USA 110S-1 Welding Wire and Rod: Cert # 05-R0925Document1 pageUSA 110S-1 Welding Wire and Rod: Cert # 05-R0925javadmohammadiNo ratings yet

- Class: Er410 Aws: A5.9: Request A Quotedata Sheetmaterial Safety Sheetback To Products PageDocument2 pagesClass: Er410 Aws: A5.9: Request A Quotedata Sheetmaterial Safety Sheetback To Products PageAditya PrajasNo ratings yet

- Weldwire Company, Inc. Technical InformationDocument1 pageWeldwire Company, Inc. Technical InformationdfmolinaNo ratings yet

- USA 70S-B2L Welding Wire and Rod: Cert # 05-R0925Document1 pageUSA 70S-B2L Welding Wire and Rod: Cert # 05-R0925Nhien ManNo ratings yet

- ENiFe CIDocument1 pageENiFe CIakashmalayiNo ratings yet

- Certificado Bothwell Ca1469Document1 pageCertificado Bothwell Ca1469erssonNo ratings yet

- ASTM A335 Pipe Specification1Document8 pagesASTM A335 Pipe Specification1Rupam BaruahNo ratings yet

- ASTM A335 Pipe Specification1 PDFDocument8 pagesASTM A335 Pipe Specification1 PDFRoberto EliasNo ratings yet

- E6011 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE6011 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- Your Reliable Welding Business Partner Worldwide"Document70 pagesYour Reliable Welding Business Partner Worldwide"Anonymous SLI4aGNo ratings yet

- FCD45 Ductile Iron: Common NameDocument1 pageFCD45 Ductile Iron: Common NameHimindra ChaaubeNo ratings yet

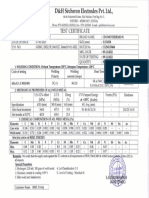

- S6cheron Electrodes PVT.: CertificateDocument1 pageS6cheron Electrodes PVT.: CertificateMetal EraNo ratings yet

- 309-16 Data SheetDocument1 page309-16 Data Sheetdapp.70No ratings yet

- E7014 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE7014 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- Hycast Alloys PDFDocument3 pagesHycast Alloys PDFMark JackamanNo ratings yet

- SmawDocument56 pagesSmawFakhar WindratamaNo ratings yet

- WeldingDocument1 pageWeldingNNo ratings yet

- Perno A325 HDG 5-8 X 2 (Rel+66215280)Document1 pagePerno A325 HDG 5-8 X 2 (Rel+66215280)Alexander Ortiz CarrionNo ratings yet

- 6010P (E6010)Document1 page6010P (E6010)brunizzaNo ratings yet

- Alloy 4047 Weld Data Sheet: Typical ApplicationsDocument2 pagesAlloy 4047 Weld Data Sheet: Typical ApplicationsMarcoAntonioNo ratings yet

- E6013 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE6013 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- Tetra S 316L-G: Technical Data Sheet Cored Welding WireDocument1 pageTetra S 316L-G: Technical Data Sheet Cored Welding WirePeter TvardzíkNo ratings yet

- USA 309L-16 Coated Electrode: Alloy Description and ApplicationDocument1 pageUSA 309L-16 Coated Electrode: Alloy Description and ApplicationRaju ChaudharyNo ratings yet

- Norma Aws Er70s6Document2 pagesNorma Aws Er70s6Nathan CantelliNo ratings yet

- Specifications For PlatesDocument4 pagesSpecifications For PlatesRv VaghasiaNo ratings yet

- TWI Article On Super Duplex Welding - 1Document4 pagesTWI Article On Super Duplex Welding - 1kapsarcNo ratings yet

- Data Sheet For BRASS SPECIFICATIONS PDFDocument5 pagesData Sheet For BRASS SPECIFICATIONS PDFvkmsNo ratings yet

- Chemical Composition: Si Fe Cu MN MG Ni ZN SN Ti PB CRDocument2 pagesChemical Composition: Si Fe Cu MN MG Ni ZN SN Ti PB CRQuality teamNo ratings yet

- Weldwire Company, Inc. Technical InformationDocument1 pageWeldwire Company, Inc. Technical InformationchepurthiNo ratings yet

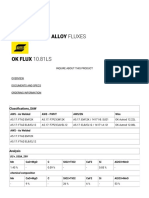

- Ok Flux 10.81LS PDFDocument2 pagesOk Flux 10.81LS PDFDeepak BhatiNo ratings yet

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel Weldingkdsenipah6667No ratings yet

- GB5310 2008 Pipe SpecificationDocument5 pagesGB5310 2008 Pipe SpecificationRio EstikaNo ratings yet

- ERCUDocument1 pageERCURogério JuniorNo ratings yet

- CM-9CB TG-S9Cb US-9CbDocument3 pagesCM-9CB TG-S9Cb US-9Cbamit singhNo ratings yet

- ROYAL-S (E 6013) : ApplicationsDocument1 pageROYAL-S (E 6013) : Applicationsxbs17No ratings yet

- Electric Gas Lighting How to Install Electric Gas Ignition ApparatusFrom EverandElectric Gas Lighting How to Install Electric Gas Ignition ApparatusRating: 3 out of 5 stars3/5 (1)

NA 625 Data Sheet

NA 625 Data Sheet

Uploaded by

andresrojas250 ratings0% found this document useful (0 votes)

68 views1 pageInweld Nickel 625 is a filler metal used for welding nickel-chromium-molybdenum alloys to themselves or other materials like steel. It has a nominal composition of 61% nickel, 22% chromium, 9% molybdenum, and 3.5% niobium plus tantalum. It can be used for welding applications between cryogenic and 1000°F temperatures. Typical weld metal properties include a tensile strength of 110,000 psi, yield strength of 60,000 psi, and 30% elongation. Recommended parameters are provided for gas metal arc welding and gas tungsten arc welding processes.

Original Description:

625

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentInweld Nickel 625 is a filler metal used for welding nickel-chromium-molybdenum alloys to themselves or other materials like steel. It has a nominal composition of 61% nickel, 22% chromium, 9% molybdenum, and 3.5% niobium plus tantalum. It can be used for welding applications between cryogenic and 1000°F temperatures. Typical weld metal properties include a tensile strength of 110,000 psi, yield strength of 60,000 psi, and 30% elongation. Recommended parameters are provided for gas metal arc welding and gas tungsten arc welding processes.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

68 views1 pageNA 625 Data Sheet

NA 625 Data Sheet

Uploaded by

andresrojas25Inweld Nickel 625 is a filler metal used for welding nickel-chromium-molybdenum alloys to themselves or other materials like steel. It has a nominal composition of 61% nickel, 22% chromium, 9% molybdenum, and 3.5% niobium plus tantalum. It can be used for welding applications between cryogenic and 1000°F temperatures. Typical weld metal properties include a tensile strength of 110,000 psi, yield strength of 60,000 psi, and 30% elongation. Recommended parameters are provided for gas metal arc welding and gas tungsten arc welding processes.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Inweld Nickel 625

AWS A5.14 ERNiCrMo-3

Chemical Composition of Inweld Nickel 625

Nb (Cb)

Fe C Cr Ni Mo Mn Si P Al & Ta S Ti Cu Other

0.5 0.10 20.0- 58.0 8.0- 0.50 0.50 0.02 0.40 3.15- 0.015 0.40 0.50 0.50

23.0 min 10.0 4.15

Single values are maximum unless otherwise specified.

Description and Applications

The nominal composition (wt.-%) of NA625 is 61 Ni, 22 Cr, 9 Mo, 3.5 Nb plus Ta. Filler metal of this classifi-

cation is used for welding nickel-chromium-molybdenum alloy (ASTM B 443, B 444, and B 446 having UNS

number N06625) to itself, to steel, to other nickel-base alloys, for cladding steel with nickel-chromium-molyb-

denum weld metal, and for welding the clad side of joints in steel with nickel-chromium-molybdenum alloy

using the GTAW, GMAW, SAW, and PAW processes. This filler metal is recommended for applications where

the operating temp ranges from cryogenic to 1,000˚ F [540˚C].

Typical Weld Metal Properties

AWS Spec

Tensile Strength: 110,000 psi

Yield Strength: 60,000 psi

Elongation: 30%

Recommended Parameters

GMAW (DCEP – Electrode+) Spray, 75%Ar/25%He

Wire Diameter Voltage Amperage

0.035” 26-32 175-240

0.045” 26-32 225-300

1/16” 27-33 250-330

GTAW (DCEN – Electrode-), 100% Argon

Wire Diameter Voltage Amperage

1/16” 70-150

3/32” 140-230

1/8” 225-320

5/32” 175-300

INWELDCORPORATION.COM

Pennsylvania North Carolina Texas California

3962 Portland Street 1029 S. Marietta St. 9300 Lawndale St. 6201 Coliseum Way, Unit A

Coplay, PA 18037 Gastonia, NC 28054 Houston, TX 77012 Oakland, CA 94621

You might also like

- 1100 Data SheetDocument1 page1100 Data SheetMuhammad Whisnu NugrahaNo ratings yet

- 4340 Wire For Low Alloy SteelsDocument1 page4340 Wire For Low Alloy SteelsPankaj KumbhareNo ratings yet

- Filler Metal 70s-6Document1 pageFiller Metal 70s-6Hugo RodriguezNo ratings yet

- 230 Broadway Huntington Station, NY 11746 P: 631.547.5470 - F: 631.547.5475 100 Commerce Way Aliquippa, PA 15001 P: 724.378.6351 - F: 724.378.2505Document1 page230 Broadway Huntington Station, NY 11746 P: 631.547.5470 - F: 631.547.5475 100 Commerce Way Aliquippa, PA 15001 P: 724.378.6351 - F: 724.378.2505mohamed AdelNo ratings yet

- 312-16 Data SheetDocument1 page312-16 Data Sheetmuhi salehNo ratings yet

- Bavaria en BA-TIG 310Document1 pageBavaria en BA-TIG 310cocoNo ratings yet

- 71t 1cDocument1 page71t 1cSuthan M RNo ratings yet

- ER90S-B9 Electrode SpecDocument1 pageER90S-B9 Electrode SpecfaizalzolNo ratings yet

- Arc Welding Electrodes (Product Catalogue)Document28 pagesArc Welding Electrodes (Product Catalogue)ddprt123No ratings yet

- NI-182 Victory ENICRFE-3 Electrode Data SheetDocument1 pageNI-182 Victory ENICRFE-3 Electrode Data SheetgianNo ratings yet

- Pinnacle Alloys ENiCrFe 3 12.16Document2 pagesPinnacle Alloys ENiCrFe 3 12.16satnamNo ratings yet

- SO18. 222369 - Sockolet3.4 - CA1293Document2 pagesSO18. 222369 - Sockolet3.4 - CA1293Jhonatan GonzalezNo ratings yet

- Spring Materials (Round Wire)Document6 pagesSpring Materials (Round Wire)Kishore BhatNo ratings yet

- 007 Welding Duplex and Superduplex Stainless Steel Industry Guide Rev0Document11 pages007 Welding Duplex and Superduplex Stainless Steel Industry Guide Rev0carlonewmannNo ratings yet

- E7018 PDFDocument3 pagesE7018 PDFPrakash RajNo ratings yet

- Tecnofil Catalogo2022Document8 pagesTecnofil Catalogo2022Cesar OteroNo ratings yet

- Stainless Steel Flux Cored Tig: Alloy Description and ApplicationDocument1 pageStainless Steel Flux Cored Tig: Alloy Description and ApplicationNGUYEN VINHNo ratings yet

- Mill Test & Inspection Certificate: According To en 10204 3.1Document2 pagesMill Test & Inspection Certificate: According To en 10204 3.1Jeisson BotiaNo ratings yet

- E7018 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE7018 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- Bavaria en BA-TIG 309LSiDocument1 pageBavaria en BA-TIG 309LSicocoNo ratings yet

- ER70S-2 Mild SteelDocument1 pageER70S-2 Mild SteelNadeemNo ratings yet

- USA 110S-1 Welding Wire and Rod: Cert # 05-R0925Document1 pageUSA 110S-1 Welding Wire and Rod: Cert # 05-R0925javadmohammadiNo ratings yet

- Class: Er410 Aws: A5.9: Request A Quotedata Sheetmaterial Safety Sheetback To Products PageDocument2 pagesClass: Er410 Aws: A5.9: Request A Quotedata Sheetmaterial Safety Sheetback To Products PageAditya PrajasNo ratings yet

- Weldwire Company, Inc. Technical InformationDocument1 pageWeldwire Company, Inc. Technical InformationdfmolinaNo ratings yet

- USA 70S-B2L Welding Wire and Rod: Cert # 05-R0925Document1 pageUSA 70S-B2L Welding Wire and Rod: Cert # 05-R0925Nhien ManNo ratings yet

- ENiFe CIDocument1 pageENiFe CIakashmalayiNo ratings yet

- Certificado Bothwell Ca1469Document1 pageCertificado Bothwell Ca1469erssonNo ratings yet

- ASTM A335 Pipe Specification1Document8 pagesASTM A335 Pipe Specification1Rupam BaruahNo ratings yet

- ASTM A335 Pipe Specification1 PDFDocument8 pagesASTM A335 Pipe Specification1 PDFRoberto EliasNo ratings yet

- E6011 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE6011 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- Your Reliable Welding Business Partner Worldwide"Document70 pagesYour Reliable Welding Business Partner Worldwide"Anonymous SLI4aGNo ratings yet

- FCD45 Ductile Iron: Common NameDocument1 pageFCD45 Ductile Iron: Common NameHimindra ChaaubeNo ratings yet

- S6cheron Electrodes PVT.: CertificateDocument1 pageS6cheron Electrodes PVT.: CertificateMetal EraNo ratings yet

- 309-16 Data SheetDocument1 page309-16 Data Sheetdapp.70No ratings yet

- E7014 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE7014 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- Hycast Alloys PDFDocument3 pagesHycast Alloys PDFMark JackamanNo ratings yet

- SmawDocument56 pagesSmawFakhar WindratamaNo ratings yet

- WeldingDocument1 pageWeldingNNo ratings yet

- Perno A325 HDG 5-8 X 2 (Rel+66215280)Document1 pagePerno A325 HDG 5-8 X 2 (Rel+66215280)Alexander Ortiz CarrionNo ratings yet

- 6010P (E6010)Document1 page6010P (E6010)brunizzaNo ratings yet

- Alloy 4047 Weld Data Sheet: Typical ApplicationsDocument2 pagesAlloy 4047 Weld Data Sheet: Typical ApplicationsMarcoAntonioNo ratings yet

- E6013 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE6013 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- Tetra S 316L-G: Technical Data Sheet Cored Welding WireDocument1 pageTetra S 316L-G: Technical Data Sheet Cored Welding WirePeter TvardzíkNo ratings yet

- USA 309L-16 Coated Electrode: Alloy Description and ApplicationDocument1 pageUSA 309L-16 Coated Electrode: Alloy Description and ApplicationRaju ChaudharyNo ratings yet

- Norma Aws Er70s6Document2 pagesNorma Aws Er70s6Nathan CantelliNo ratings yet

- Specifications For PlatesDocument4 pagesSpecifications For PlatesRv VaghasiaNo ratings yet

- TWI Article On Super Duplex Welding - 1Document4 pagesTWI Article On Super Duplex Welding - 1kapsarcNo ratings yet

- Data Sheet For BRASS SPECIFICATIONS PDFDocument5 pagesData Sheet For BRASS SPECIFICATIONS PDFvkmsNo ratings yet

- Chemical Composition: Si Fe Cu MN MG Ni ZN SN Ti PB CRDocument2 pagesChemical Composition: Si Fe Cu MN MG Ni ZN SN Ti PB CRQuality teamNo ratings yet

- Weldwire Company, Inc. Technical InformationDocument1 pageWeldwire Company, Inc. Technical InformationchepurthiNo ratings yet

- Ok Flux 10.81LS PDFDocument2 pagesOk Flux 10.81LS PDFDeepak BhatiNo ratings yet

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel Weldingkdsenipah6667No ratings yet

- GB5310 2008 Pipe SpecificationDocument5 pagesGB5310 2008 Pipe SpecificationRio EstikaNo ratings yet

- ERCUDocument1 pageERCURogério JuniorNo ratings yet

- CM-9CB TG-S9Cb US-9CbDocument3 pagesCM-9CB TG-S9Cb US-9Cbamit singhNo ratings yet

- ROYAL-S (E 6013) : ApplicationsDocument1 pageROYAL-S (E 6013) : Applicationsxbs17No ratings yet

- Electric Gas Lighting How to Install Electric Gas Ignition ApparatusFrom EverandElectric Gas Lighting How to Install Electric Gas Ignition ApparatusRating: 3 out of 5 stars3/5 (1)