Professional Documents

Culture Documents

0%(1)0% found this document useful (1 vote)

305 viewsWelding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used Position

Welding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used Position

Uploaded by

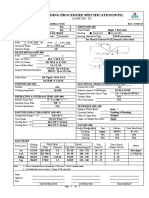

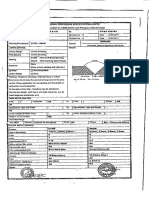

TrudieThis document provides a welding procedure specification for gas metal arc welding pipe to plate using three stringer passes. Key details include welding 6mm pipe to 200x200mm plate using ER70S-6 filler metal with a 0.9mm diameter. The joint is a tee joint with a 4.2mm root face. Welding parameters include a short circuit transfer mode with a DCEP polarity at 340-375 amps and 12-18L/min gas flow.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityNo ratings yet

- NES M 2020 2009-N Cold Rolled C & Steel & StripsDocument13 pagesNES M 2020 2009-N Cold Rolled C & Steel & Stripssalvador hernandezNo ratings yet

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Preliminary Welding Procedure Specification: Code: EN ISO 15609-1Document2 pagesPreliminary Welding Procedure Specification: Code: EN ISO 15609-1wentropremNo ratings yet

- Ferrite Content ReportDocument2 pagesFerrite Content ReportJawad MunirNo ratings yet

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Hot Dip GalvanizingDocument110 pagesHot Dip GalvanizingCandy KendeeNo ratings yet

- Weldbrite MSDSDocument3 pagesWeldbrite MSDSTan Chee Ming50% (2)

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- WPS Format For AWS D1.1 - WPS - FCAWDocument1 pageWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

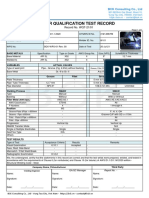

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan VelNo ratings yet

- Welding Procedure Welding Procedure Specification SpecificationDocument2 pagesWelding Procedure Welding Procedure Specification SpecificationHamid MansouriNo ratings yet

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Document2 pagesWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajNo ratings yet

- WPS 84281 R06Document1 pageWPS 84281 R06Ritesh kumarNo ratings yet

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Document1 pageWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- HHHHHHHHJJJJJJ: O O O ODocument1 pageHHHHHHHHJJJJJJ: O O O OAli MoosaviNo ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- WPS 19Document15 pagesWPS 19Avishek Gupta100% (1)

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- Wps PQR Spec IndexDocument1 pageWps PQR Spec IndexTridib DeyNo ratings yet

- Wps Mma PipeDocument2 pagesWps Mma PipeDimitris NikouNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- WPS List For Piping: (Asme Section Ix)Document2 pagesWPS List For Piping: (Asme Section Ix)Ali MoosaviNo ratings yet

- Electrofusion Calibration Report IPlast105 - 1462Document1 pageElectrofusion Calibration Report IPlast105 - 1462Alicia Lizbeth Cutipa LaymeNo ratings yet

- PQR WPS RequirementDocument2 pagesPQR WPS RequirementRameshBaskaranNo ratings yet

- Sample Wps Carbon Steel GTAW SMAW PDFDocument2 pagesSample Wps Carbon Steel GTAW SMAW PDFirwanNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- WPS 1aDocument2 pagesWPS 1aPrasenjit BhanjaNo ratings yet

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 pagesN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNo ratings yet

- WPS & PQR (E Co Cr-E)Document3 pagesWPS & PQR (E Co Cr-E)HossamSAshourNo ratings yet

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104No ratings yet

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

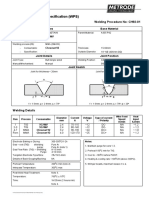

- Metrode - P92 WPS PDFDocument3 pagesMetrode - P92 WPS PDFXing ChenNo ratings yet

- 1 5 1Document5 pages1 5 1daemsalNo ratings yet

- Pipe Welding Traceability Record (Rev 01) As On 1st June 2018Document1,913 pagesPipe Welding Traceability Record (Rev 01) As On 1st June 2018gomathyselvi100% (1)

- Limak - Sawaed WpsDocument1 pageLimak - Sawaed WpsAlam MD SazidNo ratings yet

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Template BUTTDocument1 pageTemplate BUTTDylan TriggNo ratings yet

- VP16 PDFDocument13 pagesVP16 PDFKara WhiteNo ratings yet

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- 1662 15Document117 pages1662 15RajamanikkamNo ratings yet

- PQR WPQ Witness Report LatestDocument1 pagePQR WPQ Witness Report LatestSatish KeskarNo ratings yet

- Juta Bumi Kapital Sdn. BHD: Doc. No. Revision NoDocument2 pagesJuta Bumi Kapital Sdn. BHD: Doc. No. Revision NoSong Kiet ChooNo ratings yet

- EFR-190719-PQR-01 - Shell Vertical-Horizontal PDFDocument11 pagesEFR-190719-PQR-01 - Shell Vertical-Horizontal PDFIonut FloricaNo ratings yet

- WQT Aws D1.1Document1 pageWQT Aws D1.1Ali HammoudaNo ratings yet

- PQR For 32 MM PlateDocument1 pagePQR For 32 MM PlateMuhammed MubeenNo ratings yet

- Pipe Fit Up ReportDocument2 pagesPipe Fit Up ReportnguyenquanghiepNo ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- Wqt-Visual-Mag - BS 2Document24 pagesWqt-Visual-Mag - BS 2KyNo ratings yet

- 002 - Anexo Et - P8bep17Document3 pages002 - Anexo Et - P8bep17Laudos GuindautecNo ratings yet

- Welding Prosedur Specification Wps Pre QualifiedDocument8 pagesWelding Prosedur Specification Wps Pre QualifiedryanonedNo ratings yet

- Welding Procedure Specification (WPS) Yes Prequalified X Qualified by Testing or Procedure Qualification Records (PQR) YesDocument2 pagesWelding Procedure Specification (WPS) Yes Prequalified X Qualified by Testing or Procedure Qualification Records (PQR) YessdgshhNo ratings yet

- Draf WPSDocument2 pagesDraf WPSMj EdinNo ratings yet

- Catalog Industrial Supply TyrolitDocument316 pagesCatalog Industrial Supply TyrolitgtibicjNo ratings yet

- Ironmaking - Part 2Document42 pagesIronmaking - Part 2Aryan MishraNo ratings yet

- Fabrication CostDocument4 pagesFabrication CostVasudev BhanajiNo ratings yet

- 6 - Carpentry Shop1Document11 pages6 - Carpentry Shop1Monster DarkNo ratings yet

- TMT Bar Research ReportDocument13 pagesTMT Bar Research ReportAmrinder SinghNo ratings yet

- Quiz Answer Key WeldingDocument2 pagesQuiz Answer Key WeldingKawan kawankaanNo ratings yet

- PHILMETAL PRODUCT 0.50mm TDocument1 pagePHILMETAL PRODUCT 0.50mm TKerwin Jay CondorNo ratings yet

- Workshop Practice Series 02 Vertical Milling in The Home WorkshopDocument49 pagesWorkshop Practice Series 02 Vertical Milling in The Home WorkshopParaschiv DariusNo ratings yet

- Gear Cutters 01 PDFDocument4 pagesGear Cutters 01 PDFFabio Gilii100% (1)

- Status Quo Mapping of Hydrogen Production and Consumption in IndiaDocument46 pagesStatus Quo Mapping of Hydrogen Production and Consumption in IndiaHariharan SNo ratings yet

- Day 5 Welding Process, Electrode - SMAW & GMAWDocument32 pagesDay 5 Welding Process, Electrode - SMAW & GMAWRohit KambleNo ratings yet

- 3 601 H55 100 Spares For Bosch Angle Grinder GWS 26-180 H (Angle Grinders) - Power Tool SparesDocument6 pages3 601 H55 100 Spares For Bosch Angle Grinder GWS 26-180 H (Angle Grinders) - Power Tool SparesCTRL ENGENHARIA E MANUTENÇÃO ComprasNo ratings yet

- RCT-ConGrout GPDocument3 pagesRCT-ConGrout GPfahadNo ratings yet

- Coagulant PolyelectrolyteDocument2 pagesCoagulant PolyelectrolyteChillerCNo ratings yet

- Shell Crack Repair Procedure - Short EDocument2 pagesShell Crack Repair Procedure - Short Etricky7770% (1)

- Summary of Cutting Data For Plain Surface: DegrosareDocument4 pagesSummary of Cutting Data For Plain Surface: DegrosareAndrei MihaiNo ratings yet

- Aluminium in Building ConstructionDocument18 pagesAluminium in Building ConstructionRithas Mohammad PKNo ratings yet

- Jigs and Fixtures Design PTB41002: Cost Calculation Raja Aziz Raja Ma'arofDocument18 pagesJigs and Fixtures Design PTB41002: Cost Calculation Raja Aziz Raja Ma'arofazizmaarof100% (5)

- KLIPPON POK 122209 enDocument4 pagesKLIPPON POK 122209 enGoran MladenovicNo ratings yet

- Fórmulas Mandrilhamento MétricaDocument1 pageFórmulas Mandrilhamento MétricaJunior GuedesNo ratings yet

- RAMP & STAIRS DETAILS-Model - pdf3Document1 pageRAMP & STAIRS DETAILS-Model - pdf3Ahmed Reda KamelNo ratings yet

- Carpentry and Masonry Tabay AssignmentDocument18 pagesCarpentry and Masonry Tabay AssignmentAijunful TabayNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- No. Jenis Plate Size Coating Material Coating Thickness One Sides Surface Finish Chemical Treatment Vendor StandardDocument3 pagesNo. Jenis Plate Size Coating Material Coating Thickness One Sides Surface Finish Chemical Treatment Vendor StandardDimas A PrakosoNo ratings yet

- Chapter ViiiDocument13 pagesChapter ViiiBrielle Shai CruzNo ratings yet

- Welding Procedure Specification: WPS For Low Yeild Streght Carbon Steel With PWHT (SMAW)Document1 pageWelding Procedure Specification: WPS For Low Yeild Streght Carbon Steel With PWHT (SMAW)Lipika GayenNo ratings yet

- Liquid Metal Embrittlement (LME)Document13 pagesLiquid Metal Embrittlement (LME)a_omar_iitmNo ratings yet

Welding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used Position

Welding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used Position

Uploaded by

Trudie0%(1)0% found this document useful (1 vote)

305 views2 pagesThis document provides a welding procedure specification for gas metal arc welding pipe to plate using three stringer passes. Key details include welding 6mm pipe to 200x200mm plate using ER70S-6 filler metal with a 0.9mm diameter. The joint is a tee joint with a 4.2mm root face. Welding parameters include a short circuit transfer mode with a DCEP polarity at 340-375 amps and 12-18L/min gas flow.

Original Description:

Original Title

5F pipe to plate

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a welding procedure specification for gas metal arc welding pipe to plate using three stringer passes. Key details include welding 6mm pipe to 200x200mm plate using ER70S-6 filler metal with a 0.9mm diameter. The joint is a tee joint with a 4.2mm root face. Welding parameters include a short circuit transfer mode with a DCEP polarity at 340-375 amps and 12-18L/min gas flow.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0%(1)0% found this document useful (1 vote)

305 views2 pagesWelding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used Position

Welding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used Position

Uploaded by

TrudieThis document provides a welding procedure specification for gas metal arc welding pipe to plate using three stringer passes. Key details include welding 6mm pipe to 200x200mm plate using ER70S-6 filler metal with a 0.9mm diameter. The joint is a tee joint with a 4.2mm root face. Welding parameters include a short circuit transfer mode with a DCEP polarity at 340-375 amps and 12-18L/min gas flow.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

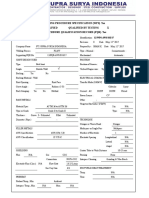

Welding Procedure Specification (pWPS) – 5FPipe to plate

Company name: Cosmo Training Academy Identification # GMAW

Welding process: GMAW Revision: 1 Date: By:

Type: X Manual Semi-automatic Authorized by: Date:

Machine Automatic

Supporting PQR No.(s)

JOINT DESIGN USED POSITION

Type: Lap X Tee Butt Groove: 1G Fillet: Flat surfacing:

Corner Edge Vertical progression: Up Down

Single weld X Double weld ELECTRICAL CHARACTERSTICS

Backing: Yes X No Transfer: X Short circuit Globular

Root opening: N/A Mode: Spray Pulse

Root face dimension: a 4.2mm Other:

Groove angle: N/A Current: AC X DCEP DCEN

Back Gouging: Yes No Power source: CC X CV

Method: GRINDING Tungsten Electrode (GTAW): N/A

BASE MATERIAL Size: Type:

Material spec: MILD STEEL / CARBON STEEL TECHNIQUE

Type or grade: Stringer, weave bead, other: STRINGER

Thickness :6MM PIPE TO PLATE Multi- or single-pass (per side): MUTLTIPASS

PIPE 80 NB SCHED 40 AND PLATE 200 X 200

FILLER METALS Number of electrodes:

AWS specifications: AWS A5.18 Contact tip to work distance:

AWS classifications ER70S-6 LINCOLN Peening: Yes X No

SHIELDING Interpass cleaning: X Yes No

Electrode flux (class): Gas: Cleaning method: X Chipping hammer

Compossition: MAG MIX 3 X Wire brush / Grinding

Flux: Flow rate: 12-18L/MIN TECHNIQUE

Gas cup size:

Preheat temp: Min: N/A Max: N/A

Interpass temp: Min: N/A Max: N/A

WELDING PROCEDURE

Pass or Weld Filler Metals Current

Layer(s) Technique Class Diamete Polarity Amps (A) Travel Speed Joint Details

r

1 Stringer ER70S-6 0.9MM DCEP 340-375

2 Stringer ER70S-6 0.9MM DCEP 340-375

a 4.2mm

3 Stringer ER70S-6 0.9MM DCEP 340-375

Welding Procedure Specification (WPS) - Template The Lincoln Electric Company

Welding Procedure Specification (WPS) - Template The Lincoln Electric Company

You might also like

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityNo ratings yet

- NES M 2020 2009-N Cold Rolled C & Steel & StripsDocument13 pagesNES M 2020 2009-N Cold Rolled C & Steel & Stripssalvador hernandezNo ratings yet

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Preliminary Welding Procedure Specification: Code: EN ISO 15609-1Document2 pagesPreliminary Welding Procedure Specification: Code: EN ISO 15609-1wentropremNo ratings yet

- Ferrite Content ReportDocument2 pagesFerrite Content ReportJawad MunirNo ratings yet

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Hot Dip GalvanizingDocument110 pagesHot Dip GalvanizingCandy KendeeNo ratings yet

- Weldbrite MSDSDocument3 pagesWeldbrite MSDSTan Chee Ming50% (2)

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- WPS Format For AWS D1.1 - WPS - FCAWDocument1 pageWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan VelNo ratings yet

- Welding Procedure Welding Procedure Specification SpecificationDocument2 pagesWelding Procedure Welding Procedure Specification SpecificationHamid MansouriNo ratings yet

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Document2 pagesWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajNo ratings yet

- WPS 84281 R06Document1 pageWPS 84281 R06Ritesh kumarNo ratings yet

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Document1 pageWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- HHHHHHHHJJJJJJ: O O O ODocument1 pageHHHHHHHHJJJJJJ: O O O OAli MoosaviNo ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- WPS 19Document15 pagesWPS 19Avishek Gupta100% (1)

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- Wps PQR Spec IndexDocument1 pageWps PQR Spec IndexTridib DeyNo ratings yet

- Wps Mma PipeDocument2 pagesWps Mma PipeDimitris NikouNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- WPS List For Piping: (Asme Section Ix)Document2 pagesWPS List For Piping: (Asme Section Ix)Ali MoosaviNo ratings yet

- Electrofusion Calibration Report IPlast105 - 1462Document1 pageElectrofusion Calibration Report IPlast105 - 1462Alicia Lizbeth Cutipa LaymeNo ratings yet

- PQR WPS RequirementDocument2 pagesPQR WPS RequirementRameshBaskaranNo ratings yet

- Sample Wps Carbon Steel GTAW SMAW PDFDocument2 pagesSample Wps Carbon Steel GTAW SMAW PDFirwanNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- WPS 1aDocument2 pagesWPS 1aPrasenjit BhanjaNo ratings yet

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 pagesN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNo ratings yet

- WPS & PQR (E Co Cr-E)Document3 pagesWPS & PQR (E Co Cr-E)HossamSAshourNo ratings yet

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104No ratings yet

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- Metrode - P92 WPS PDFDocument3 pagesMetrode - P92 WPS PDFXing ChenNo ratings yet

- 1 5 1Document5 pages1 5 1daemsalNo ratings yet

- Pipe Welding Traceability Record (Rev 01) As On 1st June 2018Document1,913 pagesPipe Welding Traceability Record (Rev 01) As On 1st June 2018gomathyselvi100% (1)

- Limak - Sawaed WpsDocument1 pageLimak - Sawaed WpsAlam MD SazidNo ratings yet

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Template BUTTDocument1 pageTemplate BUTTDylan TriggNo ratings yet

- VP16 PDFDocument13 pagesVP16 PDFKara WhiteNo ratings yet

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- 1662 15Document117 pages1662 15RajamanikkamNo ratings yet

- PQR WPQ Witness Report LatestDocument1 pagePQR WPQ Witness Report LatestSatish KeskarNo ratings yet

- Juta Bumi Kapital Sdn. BHD: Doc. No. Revision NoDocument2 pagesJuta Bumi Kapital Sdn. BHD: Doc. No. Revision NoSong Kiet ChooNo ratings yet

- EFR-190719-PQR-01 - Shell Vertical-Horizontal PDFDocument11 pagesEFR-190719-PQR-01 - Shell Vertical-Horizontal PDFIonut FloricaNo ratings yet

- WQT Aws D1.1Document1 pageWQT Aws D1.1Ali HammoudaNo ratings yet

- PQR For 32 MM PlateDocument1 pagePQR For 32 MM PlateMuhammed MubeenNo ratings yet

- Pipe Fit Up ReportDocument2 pagesPipe Fit Up ReportnguyenquanghiepNo ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- Wqt-Visual-Mag - BS 2Document24 pagesWqt-Visual-Mag - BS 2KyNo ratings yet

- 002 - Anexo Et - P8bep17Document3 pages002 - Anexo Et - P8bep17Laudos GuindautecNo ratings yet

- Welding Prosedur Specification Wps Pre QualifiedDocument8 pagesWelding Prosedur Specification Wps Pre QualifiedryanonedNo ratings yet

- Welding Procedure Specification (WPS) Yes Prequalified X Qualified by Testing or Procedure Qualification Records (PQR) YesDocument2 pagesWelding Procedure Specification (WPS) Yes Prequalified X Qualified by Testing or Procedure Qualification Records (PQR) YessdgshhNo ratings yet

- Draf WPSDocument2 pagesDraf WPSMj EdinNo ratings yet

- Catalog Industrial Supply TyrolitDocument316 pagesCatalog Industrial Supply TyrolitgtibicjNo ratings yet

- Ironmaking - Part 2Document42 pagesIronmaking - Part 2Aryan MishraNo ratings yet

- Fabrication CostDocument4 pagesFabrication CostVasudev BhanajiNo ratings yet

- 6 - Carpentry Shop1Document11 pages6 - Carpentry Shop1Monster DarkNo ratings yet

- TMT Bar Research ReportDocument13 pagesTMT Bar Research ReportAmrinder SinghNo ratings yet

- Quiz Answer Key WeldingDocument2 pagesQuiz Answer Key WeldingKawan kawankaanNo ratings yet

- PHILMETAL PRODUCT 0.50mm TDocument1 pagePHILMETAL PRODUCT 0.50mm TKerwin Jay CondorNo ratings yet

- Workshop Practice Series 02 Vertical Milling in The Home WorkshopDocument49 pagesWorkshop Practice Series 02 Vertical Milling in The Home WorkshopParaschiv DariusNo ratings yet

- Gear Cutters 01 PDFDocument4 pagesGear Cutters 01 PDFFabio Gilii100% (1)

- Status Quo Mapping of Hydrogen Production and Consumption in IndiaDocument46 pagesStatus Quo Mapping of Hydrogen Production and Consumption in IndiaHariharan SNo ratings yet

- Day 5 Welding Process, Electrode - SMAW & GMAWDocument32 pagesDay 5 Welding Process, Electrode - SMAW & GMAWRohit KambleNo ratings yet

- 3 601 H55 100 Spares For Bosch Angle Grinder GWS 26-180 H (Angle Grinders) - Power Tool SparesDocument6 pages3 601 H55 100 Spares For Bosch Angle Grinder GWS 26-180 H (Angle Grinders) - Power Tool SparesCTRL ENGENHARIA E MANUTENÇÃO ComprasNo ratings yet

- RCT-ConGrout GPDocument3 pagesRCT-ConGrout GPfahadNo ratings yet

- Coagulant PolyelectrolyteDocument2 pagesCoagulant PolyelectrolyteChillerCNo ratings yet

- Shell Crack Repair Procedure - Short EDocument2 pagesShell Crack Repair Procedure - Short Etricky7770% (1)

- Summary of Cutting Data For Plain Surface: DegrosareDocument4 pagesSummary of Cutting Data For Plain Surface: DegrosareAndrei MihaiNo ratings yet

- Aluminium in Building ConstructionDocument18 pagesAluminium in Building ConstructionRithas Mohammad PKNo ratings yet

- Jigs and Fixtures Design PTB41002: Cost Calculation Raja Aziz Raja Ma'arofDocument18 pagesJigs and Fixtures Design PTB41002: Cost Calculation Raja Aziz Raja Ma'arofazizmaarof100% (5)

- KLIPPON POK 122209 enDocument4 pagesKLIPPON POK 122209 enGoran MladenovicNo ratings yet

- Fórmulas Mandrilhamento MétricaDocument1 pageFórmulas Mandrilhamento MétricaJunior GuedesNo ratings yet

- RAMP & STAIRS DETAILS-Model - pdf3Document1 pageRAMP & STAIRS DETAILS-Model - pdf3Ahmed Reda KamelNo ratings yet

- Carpentry and Masonry Tabay AssignmentDocument18 pagesCarpentry and Masonry Tabay AssignmentAijunful TabayNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- No. Jenis Plate Size Coating Material Coating Thickness One Sides Surface Finish Chemical Treatment Vendor StandardDocument3 pagesNo. Jenis Plate Size Coating Material Coating Thickness One Sides Surface Finish Chemical Treatment Vendor StandardDimas A PrakosoNo ratings yet

- Chapter ViiiDocument13 pagesChapter ViiiBrielle Shai CruzNo ratings yet

- Welding Procedure Specification: WPS For Low Yeild Streght Carbon Steel With PWHT (SMAW)Document1 pageWelding Procedure Specification: WPS For Low Yeild Streght Carbon Steel With PWHT (SMAW)Lipika GayenNo ratings yet

- Liquid Metal Embrittlement (LME)Document13 pagesLiquid Metal Embrittlement (LME)a_omar_iitmNo ratings yet