Professional Documents

Culture Documents

COMEVAL Ball Valves

COMEVAL Ball Valves

Uploaded by

Cardoso MalacaoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

COMEVAL Ball Valves

COMEVAL Ball Valves

Uploaded by

Cardoso MalacaoCopyright:

Available Formats

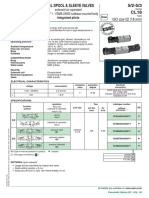

Data Sheets Manual

BV® BALL VALVES

Index

General Design Considerations 5

Attributes of Design - BV26666 6

Parts and Materials - BV26666 7

Dimensions - BV26666 8

Parts and Materials - BV26666 Direct Mounting for actuation 9

Dimensions - BV26666 Direct Mounting for actuation 10

Parts and Materials - BV23V6666 11

Dimensions - BV23V6666 12

Parts and Materials - BV23V6666 Direct Mounting for actuation 13

Dimensions - BV23V6666 Direct Mounting for actuation 14

Attributes of Design - BV36666 15

Parts and Materials - BV36666 16

Dimensions - BV36666 17

Parts and Materials - BV36666 Direct Mounting for actuation 18

Dimensions - BV36666 Direct Mounting for actuation 19

Attributes of Design - BV42263 20

Parts and Materials - BV42263 21

Dimensions - BV42263 22

Attributes of Design - BV46666M / BV42463M 23

Parts and Materials - BV46666M / BV42463M 24

Dimensions - BV46666M / BV42463M 25

Parts and Materials - BV26666 with Electric Actuator 26

Dimensions - BV2 6666 with Electric Actuator 27

Parts and Materials - BV26666 with Pneumatic Actuator 28

Dimensions - BV26666 with Pneumatic Actuator 29

Parts and Materials - BV23V6666 with Electric Actuator 30

Dimensions - BV23V6666 with Electric Actuator 31

Parts and Materials - BV23V6666 with Pneumatic Actuator 32

Dimensions - BV23V6666 with Pneumatic Actuator 33

Parts and Materials - BV36666 with Electric Actuator 34

Dimensions - BV36666 with Electric Actuator 35

Parts and Materials - BV36666 with Pneumatic Actuator 36

Dimensions - BV36666 with Pneumatic Actuator 37

Parts and Materials - BV42263 with Electric Actuator 38

Dimensions - BV42263 with Electric Actuator 39

Parts and Materials - BV42263 with Pneumatic Actuator 40

Dimensions - BV42263 with Pneumatic Actuator 41

Parts and Materials - BV46666M / BV42463M with Electric Actuator 42

Dimensions - BV46666M / BV42463M with Electric Actuator 43

Parts and Materials - BV46666M / BV42463M with Pneumatic Actuator 44

Dimensions - BV46666M / BV42463M with Pneumatic Actuator 45

Hand Lever for Direct Mounting 46

Actuation and Accessories 47-50

Data subject to change without prior notice 3

Data Sheets Manual

BV® BALL VALVES

General Design Considerations

Rotary Isolating Valves are featured by a 90º stem

rotation as full stroke. Open and close movements

are rapid, they are normally utilized to flow non

compressible fluids in liquid state and low pressure

ranges. The operating device is usually a handle

although there are diverse actuation possibilities as

assembly is non costly and very feasible thanks to

the advantages offered by the international stan-

dardization ISO 5211.

Balls are both ends perforated and are used to block

the fluid passage across the valve. The ball is open

by turning the stem which is linked to the top part of

the ball, being the valve open when both perforated

ends are aligned to the valve ends. When the ball

perforation is perpendicular to the valve inlet and

outlet ends, the valve is closed and no fluid is allow

to come across the valve. The valve handle indica-

tes the valve position (open or closed).

There are diverse kinds of constructive designs,

however, the most common category is being go-

verned by the combination of the valve stem and

ball linkage: Floating Ball Type and Trunnion Moun-

ted Ball Type.

Floating type ball valves are the most common

ones, on these the stem turns the ball by the top

part only.

TRUNNION mounted ball valves are featured by

a stem which guides the ball stem entirely. This is

the most commonly used design on the large size

valves.

The COMEVAL – BV range of ball valves is featu-

red by its diversity both in materials and styles and

suit to the most common international standards

(DIN / EN and ANSI). This Engineering Handbook

illustrates the typical models manufactured and de-

livered on a short notice, other styles featuring hig-

her grade applications may be provided on request

within a reasonable time frame.

Data subject to change without prior notice 5

Data Sheets Manual

BV® BALL VALVES

Attributes of Design - BV26666

Vinyl sleeved, quick and comfortable handling. Locking device and padlock arrangement

for unauthorized operations.

Full and unrestricted bore.

Stroke limiter to 90º, secure valve opening

and shutting.

Polished mirror ball surface, fully made

out of stainless steel.

Material and Design Pressure engraved in the valve

body. Low valve surface porosity and roughness, thanks

to lost wax casting technology, better Aesthetic and less

prone to corrosion attack.

Precision machined components for

optimal valve performance. Threaded end cap, hexagonal profiled.

No union bolting.

Ball Valves are quick closing valves that are operated by hand lever in a quarter turn operation. They are full bore valves, light

and of rugged construction being suitable for general duties thanks to its fully stainless steel construction. A perforated ends

ball permits the fluid closing when the ball ends are perpendicular to the fluid stream and allow the fluid passage when the

ends are aligned with the fluid stream. They are valves for 90º operation mainly used along non compressible fluids.

Data subject to change without prior notice 6

Data Sheets Manual

BV® BALL VALVES

Parts and Materials - BV26666

N0. PART MATERIAL

1 BODY St. Steel CF8M

2 CAP St. Steel CF8M

3 GASKET PTFE

4 BALL St. Steel CF8M

5 SEAT PTFE

6 THRUST WASHER PTFE

7 STEM PACKING PTFE

8 GLAND NUT St. Steel SS304

9 SPRING WASHER St. Steel SS304

10 STEM NUT St. Steel SS304

11 STEM St. Steel SS316

12 LOCKING DEVICE St. Steel SS304

13 HANDLE St. Steel SS304

14 PLASTIC COVER Plastic

Data subject to change without prior notice 7

Data Sheets Manual

BV® BALL VALVES

Dimensions - BV26666

Weight

NPS mm L Ød H W (kg)

1/4” 6 48 11,6 48 100 0,5

3/8” 10 48 11,6 48 100 0,5

1/2” 15 58 15 52 100 0,5

3/4” 20 65,7 20 61 127 1.0

1” 25 77 25 65 127 1.0

1.1/4” 32 90 32 79 154 1.0

1.1/2” 40 98 38 83 154 1,5

2” 50 121 50 97 192 2,5

2.1/2” 65 145 65 135 244 5.0

3” 80 166 80 144 244 7,5

4” 100 240 100 159 275 16,5

Dimensions are expressed in mm, and subjected to manufacturing tolerances. Data can be altered without

notice by our Design Department for the product benefit.

Manufacture Design Standards:

2 pieces, floating ball design

Pipe thread in acc. to DIN259, DIN2999, ISO228 CLASS A

Optional screwed end: NPT, BSPT

Blow-out proof stem

Full port

Locking device

Investment casting body

QA certified to ISO 9001:2000

In compliance with Pressure Equipment Directive PED 97/23/EC

Testing to EN12266-1 (DIN3230 part 3) or API598

Marking to EN19

Operating Parameters:

Working pressure: 0...63 bar-g

Working temperature: -20ºC ... +200ºC

Main Applications:Water, oil, compressed air, low pressure steam, etc.

Data subject to change without prior notice 8

Data Sheets Manual

BV® BALL VALVES

Parts and Materials - BV26666 Direct Mounting for actuation

N0. PART MATERIAL

1 BODY St. Steel CFBM

2 CAP St. Steel CFBM

3 BALL St. Steel CFBM

4 SEAT RPTFE

5 STEM St. Steel SS316

6 GASKET PTFE

7 THRUST WASHER RPTFE

8 O-RING VITON

9 STEM PACKING PTFE

10 GLAND St. Steel SS304

11 BELLEVILLE WASHER St. Steel SS304

12 STEM NUT St. Steel SS304

13 STOP WASHER St. Steel SS304

Please refer to our Data Sheet Manuals: “Quarter Turn Rotary Actuators“.

Data subject to change without prior notice 9

Data Sheets Manual

BV® BALL VALVES

Dimensions - BV26666 Direct Mounting for actuation

Weight

NPS mm L Ød H1 H2 ØE Ta Tb R (kg)

1/4” 6 52 11,6 38,8 9 Ø36/Ø42 R3 R3 9 0,5

3/8” 10 52 12,7 38,8 9 Ø36/Ø42 R3 R3 9 0,5

1/2” 15 58 15 38,8 9 Ø36/Ø42 R3 R3 9 0,5

3/4” 20 67 20 45,4 9 Ø36/Ø42 R3 R3 9 1.0

1” 25 78 25 55,8 11 Ø42/Ø50 R3 R3,5 11 1.0

1.1/4” 32 90 32 60,2 11 Ø42/Ø50 R3 R3,5 11 1,5

1.1/2” 40 104 38 75,5 14 Ø50/Ø70 R3,5 R4,5 14 2,5

2” 50 126 50 83,3 14 Ø50/Ø70 R3,5 R4,5 14 4.0

2.1/2” 65 158 65 107,9 17 Ø50/Ø102 R4,5 R5,5 17 7,5

3” 80 186 80 116,6 17 Ø50/Ø102 R4,5 R5,5 17 12.0

Dimensions are expressed in mm, and subjected to manufacturing tolerances. Data can be altered without

notice by our Design Department for the product benefit.

Manufacture Design Standards:

Harmonised Standard EN 593

QA certified to ISO 9001:2000

According to Pressure Equipment Directive PED 97/23/EC by a recognised Notify body

Testing standards EN12266-1 / API 598

Marking according to EN 19

Face to face dimensions according to EN558-1 Series 20

Body end connections wafer type to be installed between flanges

DN32-600: EN 1092-1/2 PN10/16 and ASA150; other connections available on request

Epoxy painted Blue RAL5002

Operating Parameters:

Working pressure: 0...16 bar-g DN25-300; 0...10 bar-g DN350-600

Working temperature: according to sealing material

See Engineering Data for complete overview of operating parameters

Main Applications:Water, oil, compressed air, low pressure steam, etc.

Please refer to our Data Sheet Manuals: “Quarter Turn Rotary Actuators“.

Data subject to change without prior notice 10

Data Sheets Manual

BV® BALL VALVES

Parts and Materials - BV23V6666

N0. PART MATERIAL

1 BODY St. Steel CFBM

2 CAP-B St. Steel CFBM

3 CAP-A St. Steel CFBM

4 BALL St. SteelCFBM

5 SEAT PTFE

6 STEM St. Steel SS316

7 GASKET-B PTFE

8 THRUST WASHER RPTFE

9 O-RING VITON

10 STEM PACKING PTFE

11 GLAND St. Steel SS304

12 BELLEVILLE WASHER St. Steel SS304

13 STEM NUT St. Steel SS304

14 STOP WASHER St. Steel SS304

15 HANDLE WASHER St. Steel SS304

16 LOCKING DEVICE St. Steel SS304

17 HANDLE St. Steel SS304

18 PLASTIC COVER PLASTIC

19 GASKET-A PTFE

20 STOP PIN (BOLT & NUT) St. Steel SS304

Data subject to change without prior notice 11

Data Sheets Manual

BV® BALL VALVES

Dimensions - BV23V6666

DN Weight/

NPS mm L Ød F H W H1 H2 ØE R (kg)

1/4” 6 76 11,6 58,5 73 124 41 9 Ø36/Ø42 9 1.0

3/8” 10 76 12,5 58,5 73 124 41 9 Ø36/Ø42 9 1.0

1/2” 15 76 12,5 58,5 73 124 41 9 Ø36/Ø42 9 1.0

3/4” 20 86 16 72,1 74,3 124 44,3 9 Ø36/Ø42 9 1,5

1” 25 99,1 20 81,8 87 152 53,5 11 Ø42/Ø50 11 2.0

1.1/4” 32 117,4 25 94,7 92,7 152 59,2 11 Ø42/Ø50 11 3.0

1.1/2” 40 123,8 32 103,9 110,4 182 75,9 15 Ø50/Ø70 14 4.0

2” 50 148 38 125,5 118,6 182 84,1 15 Ø50/Ø70 14 6.0

Dimensions are expressed in mm, and subjected to manufacturing tolerances. Data can be altered without notice by our Design Department for the product benefit.

Manufacture Design Standards:

Harmonised Standard EN 593

QA certified to ISO 9001:2000

According to Pressure Equipment Directive PED 97/23/EC by a recognised Notify body

Testing standards EN12266-1 / API 598

Marking according to EN 19

Face to face dimensions according to EN558-1 Series 20

Body end connections wafer type to be installed between flanges

DN32-600: EN 1092-1/2 PN10/16 and ASA150; other connections available on request

Epoxy painted Blue RAL5002

Operating Parameters:

Working pressure: 0...16 bar-g DN25-300; 0...10 bar-g DN350-600

Working temperature: according to sealing material

See Engineering Data for complete overview of operating parameters

Main Applications:Water, oil, compressed air, low pressure steam, etc.

Data subject to change without prior notice 12

Data Sheets Manual

BV® BALL VALVES

Parts and Materials - BV23V6666 Direct Mounting for actuation

N0. PART MATERIAL

1 BODY St. Steel CFBM

2 CAP-B St. Steel CFBM

3 CAP-A St. Steel CFBM

4 BALL St. SteelCFBM

5 SEAT PTFE

6 STEM St. Steel SS316

7 GASKET-B PTFE

8 THRUST WASHER RPTFE

9 O-RING VITON

10 STEM PACKING PTFE

11 GLAND St. Steel SS304

12 BELLEVILLE WASHER St. Steel SS304

13 STEM NUT St. Steel SS304

14 STOP WASHER St. Steel SS304

19 GASKET-A PTFE

Please refer to our Data Sheet Manuals: “Quarter Turn Rotary Actuators“.

Data subject to change without prior notice 13

Data Sheets Manual

BV® BALL VALVES

Dimensions - BV23V6666 Direct Mounting for actuation

DN Weight/

NPS mm L Ød F H W H1 H2 ØE R (kg)

1/4” 6 76 11,6 58,5 73 124 41 9 Ø36/Ø42 9 1.0

3/8” 10 76 12,5 58,5 73 124 41 9 Ø36/Ø42 9 1.0

1/2” 15 76 12,5 58,5 73 124 41 9 Ø36/Ø42 9 1.0

3/4” 20 86 16 72,1 74,3 124 44,3 9 Ø36/Ø42 9 1,5

1” 25 99,1 20 81,8 87 152 53,5 11 Ø42/Ø50 11 2.0

1.1/4” 32 117,4 25 94,7 92,7 152 59,2 11 Ø42/Ø50 11 3.0

1.1/2” 40 123,8 32 103,9 110,4 182 75,9 15 Ø50/Ø70 14 4.0

2” 50 148 38 125,5 118,6 182 84,1 15 Ø50/Ø70 14 6.0

Dimensions are expressed in mm, and subjected to manufacturing tolerances. Data can be altered without notice by our Design Department for the product benefit.

Manufacture Design Standards:

Harmonised Standard EN 593

QA certified to ISO 9001:2000

According to Pressure Equipment Directive PED 97/23/EC by a recognised Notify body

Testing standards EN12266-1 / API 598

Marking according to EN 19

Face to face dimensions according to EN558-1 Series 20

Body end connections wafer type to be installed between flanges

DN32-600: EN 1092-1/2 PN10/16 and ASA150; other connections available on request

Epoxy painted Blue RAL5002

Operating Parameters:

Working pressure: 0...16 bar-g DN25-300; 0...10 bar-g DN350-600

Working temperature: according to sealing material

See Engineering Data for complete overview of operating parameters

Main Applications:Water, oil, compressed air, low pressure steam, etc.

Please refer to our Data Sheet Manuals: “Quarter Turn Rotary Actuators“.

Data subject to change without prior notice 14

Data Sheets Manual

BV® BALL VALVES

Attributes of Design - BV36666

Locking device and padlock arrangement for Interchangeable ends by means of studs, other

unauthorized operations. valve ends can be accommodated.

Vinyl sleeved, quick and comfortable handling.

In line maintenance, no need to dismantle

the valve from the pipe work.

Size, Material and Design Pressure engraved in the valve

body. CE marking according to PED 97/23/CE is visible in

the valve body.

Full bore in Series BV2 and BV3, in line

maintenance and less pressure drop.

Ball Valves are quick closing valves that are operated by hand lever in a quarter turn operation. They are full bore valves, light

and of rugged construction being suitable for general duties thanks to its fully stainless steel construction. A perforated ends

ball permits the fluid closing when the ball ends are perpendicular to the fluid stream and allow the fluid passage when the

ends are aligned with the fluid stream. They are valves for 90º operation mainly used along non compressible fluids.

Data subject to change without prior notice 15

Data Sheets Manual

BV® BALL VALVES

Parts and Materials - BV36666

N0. PART MATERIAL

1 BODY St. Steel SS316

2 CAP St. Steel SS316

3 SEAT PTFE

4 BALL St. Steel SS316

5 BOLT St. Steel SS304

6 WASHER St. Steel SS304

7 NUT St. Steel SS304

8 THRUST WASHER PTFE

9 STEM PACKING PTFE

10 GLAND NUT St. Steel SS304

11 STEM WASHER St. Steel SS304

12 STEM NUT St. Steel SS304

13 STEM St. Steel SS316

14 LOCKING DEVICE St. Steel SS304

15 HANDLE St. Steel SS304

16 PLASTIC COVER Plastic

Data subject to change without prior notice 16

Data Sheets Manual

BV® BALL VALVES

Dimensions - BV36666

DN SW BW Weight

NPS mm L Ød H W ØD I T1 L1 ØD1 Ød1 T2 (kg)

1/4” 6 58 11,6 52 102 14,1 14 3,9 70 17 10 3,5 0,5

3/8” 10 58 12,7 54 102 17,6 15,5 2,2 70 17 12,5 2,25 0,5

1/2” 15 63 15 62 123 21,7 16 2,5 75 21,3 16 2,65 0,5

3/4” 20 73 20 66 123 27,1 16,5 2,9 90 26,7 20 3,35 1.0

1” 25 85 25 77 153 33,8 19 2,6 100 33,6 25 4,3 1.0

1.1/4” 32 96 32 80 153 42,6 22 3,3 110 42,4 33,8 4,3 1.5

1.1/2” 40 114 38 91 183 48,7 22 3,6 125 48 39,5 4,25 2,5

2” 50 134 50 98 183 61,1 25 4,5 150 60,5 50,8 4,85 3,5

2.1/2” 65 180 65 138 246 76,9 38 4,1 190 76,1 62,7 6,7 7.0

3” 80 200 80 149 246 89,8 41 6,85 220 88,9 77,9 5,5 12,5

4” 100 228 100 175 246 115,5 26 5,5 270 114,2 100 7,1 20,5

Dimensions are expressed in mm, and subjected to manufacturing tolerances. Data can be altered without notice by our Design Department for the product benefit.

Manufacture Design Standards:

Harmonised Standard EN 593

QA certified to ISO 9001:2000

According to Pressure Equipment Directive PED 97/23/EC by a recognised Notify body

Testing standards EN12266-1 / API 598

Marking according to EN 19

Face to face dimensions according to EN558-1 Series 20

Body end connections wafer type to be installed between flanges

DN32-600: EN 1092-1/2 PN10/16 and ASA150; other connections available on request

Epoxy painted Blue RAL5002

Operating Parameters:

Working pressure: 0...16 bar-g DN25-300; 0...10 bar-g DN350-600

Working temperature: according to sealing material

See Engineering Data for complete overview of operating parameters

Main Applications:Water, oil, compressed air, low pressure steam, etc.

Data subject to change without prior notice 17

Data Sheets Manual

BV® BALL VALVES

Parts and Materials - BV36666 Direct Mounting for actuation

N0. PART MATERIAL

1 BODY St. Steel CFBM

2 CAP St. Steel CFBM

3 BALL St. Steel CFBM

4 SEAT PTFE

5 STEM St. Steel SS316

6 THRUST WASHER RPTFE

7 O-RING VITON

8 STEM PACKING PTFE

9 GLAND St. Steel SS304

10 BELLEVILLE WASHER St. Steel SS304

11 STEM NUT St. Steel SS304

12 STOP WASHER St. Steel SS304

13 BOLT St. Steel SS304

14 NUT St. Steel SS304

15 WASHER St. Steel SS304

Please refer to our Data Sheet Manuals: “Quarter Turn Rotary Actuators“.

Data subject to change without prior notice 18

Data Sheets Manual

BV® BALL VALVES

Dimensions - BV36666 Direct Mounting for actuation

DN MAIN DIMENSIONS SW BW Weight

NPS mm L Ød H1 H2 ØC ØE Ta Tb R ØD I T1 L1 ØD1 Ød T2 (kg)

1/4” 6 63 11,6 38,8 9 52 Ø36/Ø42 R3 R3 9 14,1 14 3,9 70 17 10 3,5 1.0

3/8” 10 63 12,7 38,8 9 52 Ø36/Ø42 R3 R3 9 17,6 15,5 2,2 70 17 12,5 2,25 1.0

1/2” 15 63 15 38,8 9 52 Ø36/Ø42 R3 R3 9 21,7 16 2,5 75 21,3 16 2,65 1.0

3/4” 20 73 20 45,4 9 54,5 Ø36/Ø42 R3 R3 9 27,1 16,5 2,9 90 26,7 20 3,35 1.0

1” 25 85 25 55,8 11 63,5 Ø42/Ø50 R3 R3,5 11 33,8 19 2,6 100 33,6 25 4,3 1,5

1.1/4” 32 96 32 60,2 11 74,4 Ø42/Ø50 R3 R3,5 11 42,6 22 3,3 110 42,4 33,8 4,3 2.0

1.1/2” 40 114 38 75,5 14 84 Ø50/Ø70 R3,5 R4,5 14 48,7 22 3,6 125 48 39,5 4,25 3.0

2” 50 134 50 83,3 14 101 Ø50/Ø70 R3,5 R4,5 14 61,1 25 4,5 150 60,5 50,8 4,85 5.0

2.1/2” 65 180 65 107,9 17 132 Ø50/Ø102 R4,5 R5,5 17 76,9 38 4,1 190 76,1 62,7 6,7 9.0

3” 80 200 80 116,6 17 161,5 Ø50/Ø102 R4,5 R5,5 17 89,8 41 6,85 220 88,9 77,9 5,5 14.0

4” 100 228 100 131,7 22 191 Ø102/Ø125 R5,75 R6,75 22 115,5 36 5,5 270 114,2 100 7,1 22.0

Dimensions are expressed in mm, and subjected to manufacturing tolerances. Data can be altered without notice by our Design Department for the product benefit.

Manufacture Design Standards:

Harmonised Standard EN 593

QA certified to ISO 9001:2000

According to Pressure Equipment Directive PED 97/23/EC by a recognised Notify body

Testing standards EN12266-1 / API 598

Marking according to EN 19

Face to face dimensions according to EN558-1 Series 20

Body end connections wafer type to be installed between flanges

DN32-600: EN 1092-1/2 PN10/16 and ASA150; other connections available on request

Epoxy painted Blue RAL5002

Operating Parameters:

Working pressure: 0...16 bar-g DN25-300; 0...10 bar-g DN350-600

Working temperature: according to sealing material

See Engineering Data for complete overview of operating parameters

Main Applications:Water, oil, compressed air, low pressure steam, etc.

Please refer to our Data Sheet Manuals: “Quarter Turn Rotary Actuators“.

Data subject to change without prior notice 19

Data Sheets Manual

BV® BALL VALVES

Attributes of Design - BV42263

Chrome plated rugged hand lever, ergonomic design

Top flange drilled to ISO 5211 a complete range of

brackets available for easy and quick automation

Mirror polished stainless steel ball, solid

type up to DN100. Reduced operating

torque and optimal seat tightness

Precision machined components, for

optimal valve performance

Inside and outside black matt glossy

body paint protection

Live loaded stem packing,

belleville washers automatically

adjusting for thermal effects

Blow out proof stem

Floating ball, full bore, split body design, integral

flanges with union studs in stainless steel

Cast Iron material with oversized thickness,

to increase valve life

Data subject to change without prior notice 20

Data Sheets Manual

BV® BALL VALVES

Parts and Materials - BV42263

Nº Part Material

1 BODY Cast Iron EN-JL1040

2 STUD St. Steel 1.4408

3 BALL St. Steel SS304

4 CAP Cast Iron EN-JL1040

5 GASKET PTFE

6 STEM St. Steel SS304

7 SEAT PTFE

8 THRUST WASHER PTFE

9 PACKING PTFE

10 GLAND RING St. Steel SS304

11 BELLEVILLE DISC Steel

12 NUT St. Steel SS304

13 BOLT St. Steel SS304

14 NUT St. Steel SS304

15 COVER Steel

16 COVER RING PTFE

17 STUD BOLT St. Steel SS304

18 HANDLE DN15-100 Steel / DN125-200 Ductile Iron

Data subject to change without prior notice 21

Data Sheets Manual

BV® BALL VALVES

Dimensions - BV42263

TOP VIEW DETAIL

DN L H W ØD ØK nxØd ØC ØE F H1 ØG M ØP R Weight (kg)

15 115 120 175 95 65 4x14 47 35 16 52 50 M6 12 8 3,5

20 120 120 175 105 75 4x14 57 35 16 54 50 M6 12 8 4,0

25 125 130 175 115 85 4x14 67 35 21 60 50 M6 16 10 5,0

32 130 135 175 140 100 4x18 78 35 21 65 50 M6 16 10 6,5

40 140 170 240 150 110 4x18 88 55 25 75 70 M8 20 14 9,0

50 150 175 240 165 125 4x18 102 55 25 83 70 M8 20 14 11,5

65 170 190 240 185 145 4x18 123 55 25 97 70 M8 20 14 16,5

80 180 220 330 200 160 8x18 135 70 27 114 102 M10 25 19 21,0

100 190 235 330 220 180 8x18 158 70 27 127 102 M10 25 19 27,5

125 325 290 690 250 210 8x18 187 85 38 158 125 M12 34 26 56,5

150 350 310 690 285 240 8x22 213 85 38 175 125 M12 34 26 76,5

200 400 -- -- 340 295 12x22 268 100 43 245 140 M16 42 32 135,0

Dimensions are expressed in mm, and subjected to manufacturing tolerances. Data can be altered without notice by our Design Department for the product benefit.

Manufacturing Design Standards:

Split body, Full Bore, Floating Ball design

Harmonised Construction Standard DIN3357

QA certified to ISO 9001:2000

In compliance with Pressure Equipment Directive PED 97/23/EC Art.3, Parr.3

Testing to EN12266-1 (DIN3230 part 3)

Marking to EN19

Face to face dimension: DN15-100 DIN3202 F4 (EN558-1 Series 14 & 27)

DN125-200 DIN3202 F5 (EN558-1 Series 15 & 27)

Body end connections: flanged EN1092-2 PN16 integral flanges (type 21), raised face (type B)

Top flange drilled to ISO5211 for actuators mounting with standard brackets

Black matt inside and outside paint protection.

Operating Parameters:

Working Pressure: 0…16 bar-g / Working Temperature –10ºC…+200ºC

(see Engineering Data for complete overview of Pressure-Temperature limits)

Main Applications: Water, oil, compressed air, low pressure steam, etc. depending on materials of construction

Data subject to change without prior notice 22

Data Sheets Manual

BV® BALL VALVES

Attributes of Design - BV46666M / BV42463M

Direct mounting pad, top flange to suit actuators

as per ISO 5211 standard, and square stem with

bevelled edges. Easy and inexpensive automa-

tion with no need for brackets

Rugged and light hand lever¸ ergonomic design

Mirror polished stainless steel ball,

solid type up to DN100. Reduced

operating torque and optimal seat

tightness

Marking according to EN19, with Precision machined components,

name plate including CE marking for optimal valve performance

Live loaded stem packing, belleville

washers automatically adjusting for

thermal effects. Lock washer avoids

stem nut back off. PTFE bushings

help to precise stem guiding

Blow out proof stem

Low valve surface porosity and roughness,

thanks to lost wax casting technology, better

aesthetic and less prone to corrosion attack

Floating ball, full bore, split body design, integral

flanges with union studs in stainless steel

O-ring safety shaft sealing, ensure atmospheric

tightness with liquids and gases

Double Antistatic Device

Data subject to change without prior notice 23

Data Sheets Manual

BV® BALL VALVES

Parts and Materials - BV46666M / BV42463M

Nº Part Material

BV46666M BV42463M

1 BODY Stainless Steel 1.4408 Carbon Steel 1.0619

2 CAP Stainless Steel 1.4408 Carbon Steel 1.0619

3 BALL Stainless Steel 1.4408 Stainless Steel SS316

4 STEM Stainless Steel SS316 Stainless Steel SS316

5 SEAT PTFE PTFE + 20% Glass Fiber

6 GASKET PTFE PTFE

7 THRUST WASHER PTFE PTFE

8 PACKING PTFE PTFE

9 GLAND RING Stainless Steel SS304 Stainless Steel SS304

10 BELLEVILLE DISC Stainless Steel SS301 Stainless Steel SS301

11 O-RING Viton Viton

12 STEM NUT Stainless Steel SS304 Stainless Steel SS304

13 BLOCKING WASHER Stainless Steel SS304 Stainless Steel SS304

14 BOLTS NUTS Stainless Steel SS304 Stainless Steel SS304

15 HANDLE Stainless Steel SS304 Stainless Steel SS304

16 HANDLE SLEEVE Plastic Plastic

17 STOP PIN Stainless Steel SS304 Stainless Steel SS304

18 LOCKING DEVICE Stainless Steel SS304 Stainless Steel SS304

19 HANDLE HEAD Stainless Steel 1.4308 Stainless Steel 1.4308

20 HANDLE BOLT Stainless Steel SS304 Stainless Steel SS304

Data subject to change without prior notice 24

Data Sheets Manual

BV® BALL VALVES

Dimensions - BV46666M / BV42463M

BV46666M

BV42463M

DN L H H2 W ØD ØK nxØd ØC T f R ISO-5211 Weight (kg)

15 115 55 9 125 95 65 4x14 45 14 2 9 F04 3,0

20 120 66.5 11 125 105 75 4x14 58 16 2 9 F04 3,5

25 125 66.5 11 160 115 85 4x14 68 16 2 11 F04-F05 4,0

32 130 74 11 160 140 100 4x18 78 16 2 11 F04-F05 5,5

40 140 85.5 15 190 150 110 4x18 88 16 3 14 F05-F07 7,5

50 150 92.5 15 190 165 125 4x18 102 18 3 14 F05-F07 11,0

65 170 113 18 355 185 145 4x18 122 18 3 17 F07-F10 16,0

80 180 124.5 18 355 200 160 8x18 138 20 3 17 F07-F10 20,5

100 190 142.5 23 400 220 180 8x18 158 20 3 22 F10-F12 26,5

125 325 182 28 770 250 210 8x18 188 22 3 27 F10-F12 50,5

150 350 201 28 770 285 240 8x22 212 22 3 27 F10-F12 71,5

200 400 259 35 1100 340 295 12x22 268 24 3 36 F14 115,0

Dimensions are expressed in mm, and subjected to manufacturing tolerances. Data can be altered without notice by our Design Department for the product benefit.

Manufacturing Design Standards:

Split body, Full Bore, Floating Ball design

Harmonised Construction Standard DIN3357

QA certified to ISO 9001:2000

In compliance with Pressure Equipment Directive PED 97/23/EC Module D1

Testing to EN12266-1 (DIN3230 part 3) or API598

Marking to EN19

Face to face dimension: DN15-100 DIN3202 F4 (EN558-1 Series 14 & 27)

DN125-200 DIN3202 F5 (EN558-1 Series15 & 27)

Body end connections: flanged EN1092-1 PN16 integral flanges (type 21), raised face (type B)

Direct Mounting Pad ISO5211 for actuators mounting

Black matt inside and outside paint protection.

Operating Parameters:

Working Pressure: DN15-50: 0…40 bar-g / DN65-200: 0…16 bar-g

Working Temperature –40ºC…+200ºC

(see Engineering Data for complete overview of Pressure-Temperature limits)

Main Applications: Water, oil, compressed air, low pressure steam, etc. depending on materials of construction

Data subject to change without prior notice 25

Data Sheets Manual

BV® BALL VALVES

Parts and Materials - BV26666 with Electric Actuator

N0. PART MATERIAL

1 BODY St. Steel CFBM

2 CAP St. Steel CFBM

3 BALL St. Steel CFBM

4 SEAT PTFE

5 STEM St. Steel SS316

6 GASKET PTFE

7 THRUST WASHER RPTFE

8 O-RING VITON

9 STEM PACKING PTFE

10 GLAND St. Steel SS304

11 BELLEVILLE WASHER St. Steel SS304

12 STEM NUT St. Steel SS304

13 STOP WASHER St. Steel SS304

14 ELECTRIC ACTUATOR

Data subject to change without prior notice 26

Data Sheets Manual

BV® BALL VALVES

Dimensions - BV26666 with Electric Actuator

DN MAIN DIMENSIONS ELECTRIC ACTUATOR Weight.

NPS mm L Ød Type H U W V (kg)

1/4” 6 52 11,6 CMVLUO 205 169 122 104 2.0

3/8” 10 52 12,7 CMVLUO 205 169 122 104 2.0

1/2” 15 58 15 CMVLUO 205 169 122 104 2.5

3/4” 20 67 20 CMVLUO 210 169 122 104 2,5

1” 25 78 25 CMVLH20 220 169 122 104 3.0

1.1/4” 32 90 32 CMVLH55 275 169 122 105 4.0

1.1/2” 40 104 38 CMVLH55 290 169 122 105 6.0

2” 50 126 50 CMVLH55 300 169 122 105 6.5

2.1/2” 65 158 65 CMVLH140 380 235 128 214 13,5

3” 80 186 80 CMVLH140 390 235 128 214 17,5

Dimensions are expressed in mm, and subjected to manufacturing tolerances.

Data can be altered without notice by our Design Department for the product benefit.

Manufacture Design Standards:

Harmonised Standard EN 593

QA certified to ISO 9001:2000

According to Pressure Equipment Directive PED 97/23/EC by a recognised Notify body

Testing standards EN12266-1 / API 598

Marking according to EN 19

Face to face dimensions according to EN558-1 Series 20

Body end connections wafer type to be installed between flanges

DN32-600: EN 1092-1/2 PN10/16 and ASA150; other connections available on request

Epoxy painted Blue RAL5002

Operating Parameters:

Working pressure: 0...16 bar-g DN25-300; 0...10 bar-g DN350-600

Working temperature: according to sealing material

See Engineering Data for complete overview of operating parameters

Main Applications:Water, oil, compressed air, low pressure steam, etc.

Data subject to change without prior notice 27

Data Sheets Manual

BV® BALL VALVES

Parts and Materials - BV26666 with Pneumatic Actuator

N0. PART MATERIAL

1 BODY St. Steel CFBM

2 CAP St. Steel CFBM

3 BALL St. Steel CFBM

4 SEAT PTFE

5 STEM St. Steel SS316

6 GASKET PTFE

7 THRUST WASHER RPTFE

8 O-RING VITON

9 STEM PACKING PTFE

10 GLAND St. Steel SS304

11 BELLEVILLE WASHER St. Steel SS304

12 STEM NUT St. Steel SS304

13 STOP WASHER St. Steel SS304

14 PNEUMATIC ACTATOR

Data subject to change without prior notice 28

Data Sheets Manual

BV® BALL VALVES

Dimensions - BV26666 with Pneumatic Actuator

MAIN

DN DIMENSIONS DOUBLE ACTING SINGLE ACTING

Weight.

NPS mm L Ød Type H U V Type H U V (kg)

CMVLB CMVLB

1/4” 6 52 11,6 D032 120 142 45 S045 140 146 58 2.0

CMVLB CMVLB

3/8” 10 52 12,7 D032 120 142 45 S045 140 146 58 2.0

CMVLB CMVLB

1/2” 15 58 15 D045 140 146 58 S052 150 146 59 2.0

CMVLB CMVLB

3/4” 20 67 20 D045 145 146 58 S052 155 146 59 2,5

CMVLB CMVLB

1” 25 78 25 D052 165 146 59 S063 180 168 72 3,5

CMVLB CMVLB

1.1/4” 32 90 32 D052 170 146 59 S075 195 184 83 4,5

CMVLB CMVLB

1.1/2” 40 104 38 D063 200 168 72 S083 220 204 90 6,5

CMVLB CMVLB

2” 50 126 50 D075 220 184 83 S092 240 260 104 9.5

CMVLB CMVLB

2.1/2” 65 158 65 D083 255 204 90 S092 265 260 104 13,5

CMVLB CMVLB

3” 80 186 80 D092 275 260 104 S092 275 260 104 17,5

Dimensions are expressed in mm, and subjected to manufacturing tolerances. Data can be altered without notice by our Design Department for the product benefit.

Manufacture Design Standards:

Harmonised Standard EN 593

QA certified to ISO 9001:2000

According to Pressure Equipment Directive PED 97/23/EC by a recognised Notify body

Testing standards EN12266-1 / API 598

Marking according to EN 19

Face to face dimensions according to EN558-1 Series 20

Body end connections wafer type to be installed between flanges

DN32-600: EN 1092-1/2 PN10/16 and ASA150; other connections available on request

Epoxy painted Blue RAL5002

Operating Parameters:

Working pressure: 0...16 bar-g DN25-300; 0...10 bar-g DN350-600

Working temperature: according to sealing material

See Engineering Data for complete overview of operating parameters

Main Applications:Water, oil, compressed air, low pressure steam, etc.

Data subject to change without prior notice 29

Data Sheets Manual

BV® BALL VALVES

Parts and Materials - BV23V6666 with Electric Actuator

N0. PART MATERIAL

1 BODY St. Steel CFBM

2 CAP-B St. Steel CFBM

3 CAP-A St. Steel CFBM

4 BALL St. SteelCFBM

5 SEAT PTFE

6 STEM St. Steel SS316

7 GASKET-B PTFE

8 THRUST WASHER RPTFE

9 O-RING VITON

10 STEM PACKING PTFE

11 GLAND St. Steel SS304

12 BELLEVILLE WASHER St. Steel SS304

13 STEM NUT St. Steel SS304

14 STOP WASHER St. Steel SS304

19 GASKET-A PTFE

21 ELECTRIC ACTUATOR

Data subject to change without prior notice 30

Data Sheets Manual

BV® BALL VALVES

Dimensions - BV23V6666 with Electric Actuator

DN MAIN DIMENSIONS ELECTRIC ACTUATOR Weight

NPS mm L L L1 Ød Type H U W W V (kg)

1/4” 6 76 76 58,5 11,6 CMVLH20 205 169 122 122 104 2,5

3/8” 10 76 76 58,5 12,5 CMVLH20 205 169 122 122 104 2,5

1/2” 15 76 76 58,5 12,5 CMVLH20 205 169 122 122 104 2,5

3/4” 20 86 86 72,1 16 CMVLH20 210 169 122 122 104 3.0

1” 25 99,1 99,1 81,8 20 CMVLH20 220 169 122 122 104 3,5

1.1/4” 32 117,4 117,4 94,7 25 CMVLH55 275 169 122 122 105 5,5

1.1/2” 40 123,8 123.8 103,9 32 CMVLH140 345 235 128 128 214 9,5

2” 50 148 148 125,5 38 CMVLH140 355 235 128 128 214 11,5

Dimensions are expressed in mm, and subjected to manufacturing tolerances. Data can be altered without notice by our Design Department for the product benefit.

Manufacture Design Standards:

Harmonised Standard EN 593

QA certified to ISO 9001:2000

According to Pressure Equipment Directive PED 97/23/EC by a recognised Notify body

Testing standards EN12266-1 / API 598

Marking according to EN 19

Face to face dimensions according to EN558-1 Series 20

Body end connections wafer type to be installed between flanges

DN32-600: EN 1092-1/2 PN10/16 and ASA150; other connections available on request

Epoxy painted Blue RAL5002

Operating Parameters:

Working pressure: 0...16 bar-g DN25-300; 0...10 bar-g DN350-600

Working temperature: according to sealing material

See Engineering Data for complete overview of operating parameters

Main Applications:Water, oil, compressed air, low pressure steam, etc.

Data subject to change without prior notice 31

Data Sheets Manual

BV® BALL VALVES

Parts and Materials - BV23V6666 with Pneumatic Actuator

N0. PART MATERIAL

1 BODY St. Steel CFBM

2 CAP-B St. Steel CFBM

3 CAP-A St. Steel CFBM

4 BALL St. SteelCFBM

5 SEAT PTFE

6 STEM St. Steel SS316

7 GASKET-B PTFE

8 THRUST WASHER RPTFE

9 O-RING VITON

10 STEM PACKING PTFE

11 GLAND St. Steel SS304

12 BELLEVILLE WASHER St. Steel SS304

13 STEM NUT St. Steel SS304

14 STOP WASHER St. Steel SS304

19 GASKET-A PTFE

21 PNEUMATIC ACTUATOR

Data subject to change without prior notice 32

Data Sheets Manual

BV® BALL VALVES

Dimensions - BV23V6666 with Pneumatic Actuator

DN MAIN DIMENSIONS DOUBLE ACTING SINGLE ACTING Weight

NPS mm L L1 Ød Type H U V Type H U V (kg)

CMVLB CMVLB

1/4” 6 76 58,5 11,6 D045 140 146 58 S052 150 146 59 2.5

CMVLB CMVLB

3/8” 10 76 58,5 12,5 D045 140 146 58 S052 150 146 59 2.5

CMVLB CMVLB

1/2” 15 76 58,5 12,5 D045 140 146 58 S052 150 146 59 2.5

CMVLB CMVLB

3/4” 20 86 72,1 16 D045 145 146 58 S063 175 168 72 4.0

CMVLB CMVLB

1” 25 99,1 81,8 20 D045 155 146 58 S063 180 168 72 4.0

CMVLB CMVLB

1.1/4” 32 117,4 94,7 25 D063 185 168 72 S083 205 204 90 6,5

CMVLB CMVLB

1.1/2” 40 123,8 103,9 32 D075 210 184 83 S092 230 260 104 10.0

CMVLB CMVLB

2” 50 148 125,5 38 D083 230 204 90 S105 255 268 115 13.0

Dimensions are expressed in mm, and subjected to manufacturing tolerances. Data can be altered without notice by our Design Department for the product benefit.

Manufacture Design Standards:

Harmonised Standard EN 593

QA certified to ISO 9001:2000

According to Pressure Equipment Directive PED 97/23/EC by a recognised Notify body

Testing standards EN12266-1 / API 598

Marking according to EN 19

Face to face dimensions according to EN558-1 Series 20

Body end connections wafer type to be installed between flanges

DN32-600: EN 1092-1/2 PN10/16 and ASA150; other connections available on request

Epoxy painted Blue RAL5002

Operating Parameters:

Working pressure: 0...16 bar-g DN25-300; 0...10 bar-g DN350-600

Working temperature: according to sealing material

See Engineering Data for complete overview of operating parameters

Main Applications:Water, oil, compressed air, low pressure steam, etc.

Data subject to change without prior notice 33

Data Sheets Manual

BV® BALL VALVES

Parts and Materials - BV36666 with Electric Actuator

N0. PART MATERIAL

1 BODY St. Steel CFBM

2 CAP St. Steel CFBM

3 BALL St. Steel CFBM

4 SEAT PTFE

5 STEM St. Steel SS316

6 THRUST WASHER RPTFE

7 O-RING VITON

8 STEM PACKING PTFE

9 GLAND St. Steel SS304

10 BELLEVILLE WASHER St. Steel SS304

11 STEM NUT St. Steel SS304

12 STOP WASHER St. Steel SS304

16 ELECTRIC ACTUATOR

Data subject to change without prior notice 34

Data Sheets Manual

BV® BALL VALVES

Dimensions - BV36666 with Electric Actuator

DN MAIN DIMENSIONS ELECTRIC ACTUATOR Weight

NPS mm L Ød ØC Type H U W V (kg)

1/4” 6 64 11,6 52 CMVLUO 205 169 122 104 2.5

3/8” 10 64 12,7 52 CMVLUO 205 169 122 104 2.5

1/2” 15 64 15 52 CMVLUO 205 169 122 104 2.5

3/4” 20 73 20 54,5 CMVLUO 210 169 122 104 2,5

1” 25 85 25 63,5 CMVLH20 220 169 122 104 3.5

1.1/4” 32 96 32 74,4 CMVLH55 275 169 122 105 4.5

1.1/2” 40 114 38 84 CMVLH55 290 169 122 105 5,5

2” 50 134 50 101 CMVLH55 300 169 122 105 7,5

2.1/2” 65 180 65 132 CMVLH140 380 235 128 214 13,5

3” 80 200 80 161,5 CMVLH140 390 235 128 214 19,5

4” 100 228 100 191 CMVLH300 405 235 128 214 28.0

Dimensions are expressed in mm, and subjected to manufacturing tolerances. Data can be altered without notice by our Design Department for the product benefit.

Manufacture Design Standards:

Harmonised Standard EN 593

QA certified to ISO 9001:2000

According to Pressure Equipment Directive PED 97/23/EC by a recognised Notify body

Testing standards EN12266-1 / API 598

Marking according to EN 19

Face to face dimensions according to EN558-1 Series 20

Body end connections wafer type to be installed between flanges

DN32-600: EN 1092-1/2 PN10/16 and ASA150; other connections available on request

Epoxy painted Blue RAL5002

Operating Parameters:

Working pressure: 0...16 bar-g DN25-300; 0...10 bar-g DN350-600

Working temperature: according to sealing material

See Engineering Data for complete overview of operating parameters

Main Applications:Water, oil, compressed air, low pressure steam, etc.

Data subject to change without prior notice 35

Data Sheets Manual

BV® BALL VALVES

Parts and Materials - BV36666 with Pneumatic Actuator

N0. PART/PARTE MATERIAL

1 BODY St. Steel CFBM

2 CAP St. Steel CFBM

3 BALL St. Steel CFBM

4 SEAT PTFE

5 STEM St. Steel SS316

6 THRUST WASHER RPTFE

7 O-RING VITON

8 STEM PACKING PTFE

9 GLAND St. Steel SS304

10 BELLEVILLE WASHER St. Steel SS304

11 STEM NUT St. Steel SS304

12 STOP WASHER St. Steel SS304

16 PNEUMATIC ACTUATOR

Data subject to change without prior notice 36

Data Sheets Manual

BV® BALL VALVES

Dimensions - BV36666 with Pneumatic Actuator

DN MAIN DIMENSIONS DOUBLE ACTING SINGLE ACTING

Weight

NPS mm L Ød ØC Type H U V Type H U V (kg)

CMVLB CMVLB

1/4” 6 64 11,6 52 D032 120 142 45 S045 140 146 58 2.5

CMVLB CMVLB

3/8” 10 64 12,7 52 D032 120 142 45 S045 140 146 58 2.5

CMVLB CMVLB

1/2” 15 64 15 52 D045 140 146 58 S052 150 146 59 2.5

CMVLB CMVLB

3/4” 20 73 20 54,5 D045 145 146 58 S052 155 146 59 2,5

CMVLB CMVLB

1” 25 85 25 63,5 D052 165 146 59 S063 180 168 72 4.0

CMVLB CMVLB

1.1/4” 32 96 32 74,4 D052 170 146 59 S075 195 184 83 5.0

CMVLB CMVLB

1.1/2” 40 114 38 84 D063 200 168 72 S083 220 204 90 7.0

CMVLB CMVLB

2” 50 134 50 101 D075 220 184 83 S092 240 260 104 10,5

CMVLB CMVLB

2.1/2” 65 180 65 132 D083 255 204 90 S092 280 268 115 16,5

CMVLB CMVLB

3” 80 200 80 161,5 D092 275 260 104 S092 310 298 140 24,5

CMVLB CMVLB

4” 100 228 100 191 D125 325 298 140 S140 340 390 152 38.0

Dimensions are expressed in mm, and subjected to manufacturing tolerances. Data can be altered without notice by our Design Department for the product benefit.

Manufacture Design Standards:

Harmonised Standard EN 593

QA certified to ISO 9001:2000

According to Pressure Equipment Directive PED 97/23/EC by a recognised Notify body

Testing standards EN12266-1 / API 598

Marking according to EN 19

Face to face dimensions according to EN558-1 Series 20

Body end connections wafer type to be installed between flanges

DN32-600: EN 1092-1/2 PN10/16 and ASA150; other connections available on request

Epoxy painted Blue RAL5002

Operating Parameters:

Working pressure: 0...16 bar-g DN25-300; 0...10 bar-g DN350-600

Working temperature: according to sealing material

See Engineering Data for complete overview of operating parameters

Main Applications:Water, oil, compressed air, low pressure steam, etc.

Data subject to change without prior notice 37

Data Sheets Manual

BV® BALL VALVES

Parts and Materials - BV42263 with Electric Actuator

Nº Part Material

1 BODY Cast Iron EN-JL1040

2 STUD St. Steel 1.4408

3 BALL St. Steel SS304

4 CAP Cast Iron EN-JL1040

5 GASKET PTFE

6 STEM St. Steel SS304

7 SEAT PTFE

8 THRUST WASHER PTFE

9 PACKING PTFE

10 GLAND RING St. Steel SS304

11 BELLEVILLE DISC Steel

12 NUT St. Steel SS304

15 COVER Steel

16 COVER RING PTFE

17 STUD BOLT St. Steel SS304

19 COUPLING KIT

20 ELECTRIC ACTUATOR

Data subject to change without prior notice 38

Data Sheets Manual

BV® BALL VALVES

Dimensions - BV42263 with Electric Actuator

DN MAIN DIMENSIONS ELECTRIC ACTUATOR Weight

mm L ØD ØK nxØd Type H U W (kg)

15 115 95 65 4x14 CMVLH20 265 169 122 5.0

20 120 105 75 4x14 CMVLH20 270 169 122 5.0

25 125 115 85 4x14 CMVLH20 325 169 122 7.0

32 130 140 100 4x18 CMVLH55 330 169 122 9.0

40 140 150 110 4x18 CMVLH55 415 235 128 14.0

50 150 165 125 4x18 CMVLH55 425 235 128 17.0

65 170 185 145 4x18 CMVLH140 440 235 128 21.0

80 180 200 160 8x18 CMVLH140 455 235 128 26.0

100 190 220 180 8x18 CMVLH300 470 235 128 35.0

125 325 250 210 8x18 .-. .-. .-. .-. .-.

150 350 285 240 8x22 .-. .-. .-. .-. .-.

200 400 340 295 12x22 .-. .-. .-. .-. .-.

Dimensions are expressed in mm, and subjected to manufacturing tolerances. Data can be altered without notice by our Design Department for the product benefit.

Manufacturing Design Standards:

Split body, Full Bore, Floating Ball design

Harmonised Construction Standard DIN3357

QA certified to ISO 9001:2000

In compliance with Pressure Equipment Directive PED 97/23/EC Art.3, Parr.3

Testing to EN12266-1 (DIN3230 part 3)

Marking to EN19

Face to face dimension: DN15-100 DIN3202 F4 (EN558-1 Series 14 & 27)

DN125-200 DIN3202 F5 (EN558-1 Series 15 & 27)

Body end connections: flanged EN1092-2 PN16 integral flanges (type 21), raised face (type B)

Top flange drilled to ISO5211 for actuators mounting with standard brackets

Black matt inside and outside paint protection.

Operating Parameters:

Working Pressure: 0…16 bar-g / Working Temperature –10ºC…+200ºC

(see Engineering Data for complete overview of Pressure-Temperature limits)

Main Applications: Water, oil, compressed air, low pressure steam, etc. depending on materials of construction

Data subject to change without prior notice 39

Data Sheets Manual

BV® BALL VALVES

Parts and Materials - BV42263 with Pneumatic Actuator

Nº Part Material

1 BODY Cast Iron EN-JL1040

2 STUD St. Steel 1.4408

3 BALL St. Steel SS304

4 CAP Cast Iron EN-JL1040

5 GASKET PTFE

6 STEM St. Steel SS304

7 SEAT PTFE

8 THRUST WASHER PTFE

9 PACKING PTFE

10 GLAND RING St. Steel SS304

11 BELLEVILLE DISC Steel

12 NUT St. Steel SS304

15 COVER Steel

16 COVER RING PTFE

17 STUD BOLT St. Steel SS304

19 COUPLING KIT

20 PNEUMATIC ACTUATOR

Data subject to change without prior notice 40

Data Sheets Manual

BV® BALL VALVES

Dimensions - BV42263 with Pneumatic Actuator

DN MAIN DIMENSIONS DOUBLE ACTING SINGLE ACTING Weight

mm L ØD ØK nxØd Type H U Type H U (kg)

15 115 95 65 4x14 CMVLB 205 146 CMVLB 225 168 5.5

D045 S063

20 120 105 75 4x14 CMVLB 210 146 CMVLB 230 168 5,5

D045 S063

25 125 115 85 4x14 CMVLB 235 168 CMVLB 245 184 7.0

D045 S075

32 130 140 100 4x18 CMVLB 240 168 CMVLB 260 204 10.0

D063 S083

40 140 150 110 4x18 CMVLB 270 204 CMVLB 280 260 14.0

D063 S083

50 150 165 125 4x18 CMVLB 280 204 CMVLB 305 268 18,5

D075 S092

65 170 185 145 4x18 CMVLB 305 260 CMVLB 340 298 26.0

D092 S105

80 180 200 160 8x18 CMVLB 355 268 CMVLB 375 298 31.0

D092 S125

100 190 220 180 8x18 CMVLB 365 268 CMVLB 405 390 45,5

D125 S140

125 325 250 210 8x18 CMVLB 435 390 CMVLB or CMVLB .-.

D140 S160 S160

150 350 285 240 8x22 CMVLB or CMVLB CMVLB or CMVLB .-.

D140 D160 S190 S160

200 400 340 295 12x22 CMVLB 620 532 CMVLB 685 722 .-.

D210 D240

Dimensions are expressed in mm, and subjected to manufacturing tolerances. Data can be altered without notice by our Design Department for the product benefit.

Manufacturing Design Standards:

Split body, Full Bore, Floating Ball design

Harmonised Construction Standard DIN3357

QA certified to ISO 9001:2000

In compliance with Pressure Equipment Directive PED 97/23/EC Art.3, Parr.3

Testing to EN12266-1 (DIN3230 part 3)

Marking to EN19

Face to face dimension: DN15-100 DIN3202 F4 (EN558-1 Series 14 & 27)

DN125-200 DIN3202 F5 (EN558-1 Series 15 & 27)

Body end connections: flanged EN1092-2 PN16 integral flanges (type 21), raised face (type B)

Top flange drilled to ISO5211 for actuators mounting with standard brackets

Black matt inside and outside paint protection.

Operating Parameters:

Working Pressure: 0…16 bar-g / Working Temperature –10ºC…+200ºC

(see Engineering Data for complete overview of Pressure-Temperature limits)

Main Applications: Water, oil, compressed air, low pressure steam, etc. depending on materials of construction

Data subject to change without prior notice 41

Data Sheets Manual

BV® BALL VALVES

Parts and Materials - BV46666M / BV42463M with Electric Actuator

Nº Part Material

BV46666M BV42463M

1 BODY Stainless Steel 1.4408 Carbon Steel 1.0619

2 CAP Stainless Steel 1.4408 Carbon Steel 1.0619

3 BALL Stainless Steel 1.4408 Stainless Steel SS316

4 STEM Stainless Steel SS316 Stainless Steel SS316

5 SEAT PTFE PTFE + 20% Glass Fiber

6 GASKET PTFE PTFE

7 THRUST WASHER PTFE PTFE

8 PACKING PTFE PTFE

9 GLAND RING Stainless Steel SS304 Stainless Steel SS304

10 BELLEVILLE DISC Stainless Steel SS301 Stainless Steel SS301

11 O-RING Viton Viton

12 STEM NUT Stainless Steel SS304 Stainless Steel SS304

14 BOLTS NUTS Stainless Steel SS304 Stainless Steel SS304

21 ELECTRIC ACTUATOR

Data subject to change without prior notice 42

Data Sheets Manual

BV® BALL VALVES

Dimensions - BV46666M / BV42463M with Electric Actuator

BV42463M BV46666M

DN MAIN DIMENSIONS ELECTRIC ACTUATOR Weight

mm L ØD ØK nxØd Type H U W (kg)

15 115 95 65 4x14 CMVLH20 220 169 122 4,5

20 120 105 75 4x14 CMVLH20 230 169 122 5.0

25 125 115 85 4x14 CMVLH20 230 169 122 6.0

32 130 140 100 4x18 CMVLH55 290 169 122 8.0

40 140 150 110 4x18 CMVLH55 300 169 122 10.0

50 150 165 125 4x18 CMVLH55 310 169 122 13,5

65 170 185 145 4x18 CMVLH140 385 235 128 22.0

80 180 200 160 8x18 CMVLH140 395 235 128 26.0

100 190 220 180 8x18 CMVLH300 415 235 128 32.0

125 325 250 210 8x18 .-. .-. .-. .-. .-.

150 350 285 240 8x22 .-. .-. .-. .-. .-.

200 400 340 295 12x22 .-. .-. .-. .-. .-.

Dimensions are expressed in mm, and subjected to manufacturing tolerances. Data can be altered without notice by our Design Department for the product benefit.

Manufacturing Design Standards:

Split body, Full Bore, Floating Ball design

Harmonised Construction Standard DIN3357

QA certified to ISO 9001:2000

In compliance with Pressure Equipment Directive PED 97/23/EC Module D1

Testing to EN12266-1 (DIN3230 part 3) or API598

Marking to EN19

Face to face dimension: DN15-100 DIN3202 F4 (EN558-1 Series 14 & 27)

DN125-200 DIN3202 F5 (EN558-1 Series15 & 27)

Body end connections: flanged EN1092-1 PN16 integral flanges (type 21), raised face (type B)

Direct Mounting Pad ISO5211 for actuators mounting

Black matt inside and outside paint protection.

Operating Parameters:

Working Pressure: DN15-50: 0…40 bar-g / DN65-200: 0…16 bar-g

Working Temperature –40ºC…+200ºC

(see Engineering Data for complete overview of Pressure-Temperature limits)

Main Applications: Water, oil, compressed air, low pressure steam, etc. depending on materials of construction

Data subject to change without prior notice 43

Data Sheets Manual

BV® BALL VALVES

Parts and Materials - BV46666M / BV42463M with Pneumatic Actuator

Nº Part Material

BV46666M BV42463M

1 BODY Stainless Steel 1.4408 Carbon Steel 1.0619

2 CAP Stainless Steel 1.4408 Carbon Steel 1.0619

3 BALL Stainless Steel 1.4408 Stainless Steel SS316

4 STEM Stainless Steel SS316 Stainless Steel SS316

5 SEAT PTFE PTFE + 20% Glass Fiber

6 GASKET PTFE PTFE

7 THRUST WASHER PTFE PTFE

8 PACKING PTFE PTFE

9 GLAND RING Stainless Steel SS304 Stainless Steel SS304

10 BELLEVILLE DISC Stainless Steel SS301 Stainless Steel SS301

11 O-RING Viton Viton

12 STEM NUT Stainless Steel SS304 Stainless Steel SS304

14 BOLTS NUTS Stainless Steel SS304 Stainless Steel SS304

21 PNEUMATIC ACTUATOR

Data subject to change without prior notice 44

Data Sheets Manual

BV® BALL VALVES

Dimensions - BV46666M / BV42463M with Pneumatic Actuator

BV42463M BV46666M

MAIN DIMENSIONS DOUBLE ACTING SINGLE ACTING

DN Weight

mm L ØD ØK nxØd Type H U Type/Modelo H U (kg)

15 115 95 65 4x14 CMVLB 155 146 CMVLB 180 168 5.0

D045 S063

20 120 105 75 4x14 CMVLB 170 146 CMVLB 190 168 5,5

D045 S063

25 125 115 85 4x14 CMVLB 170 146 CMVLB 205 184 7.0

D045 S075

32 130 140 100 4x18 CMVLB 200 168 CMVLB 220 204 9,5

D063 S083

40 140 150 110 4x18 CMVLB 210 168 CMVLB 230 204 11,5

D063 S083

50 150 165 125 4x18 CMVLB 230 184 CMVLB 250 260 17.0

D075 S092

65 170 185 145 4x18 CMVLB 270 260 CMVLB 285 268 23,5

D092 S105

80 180 200 160 8x18 CMVLB 280 260 CMVLB 315 298 31.0

D092 S125

100 190 220 180 8x18 CMVLB 325 298 CMVLB 350 390 42,5

D125 S140

125 325 250 210 8x18 CMVLB 390 390 CMVLB 415 458 90,5

D140 S160

150 350 285 240 8x22 CMVLB or CMVLB CMVLB 480 525 118.0

D140 D160 S190

200 400 340 295 12x22 CMVLB or CMVLB CMVLB or CMVLB .-.

D190 D210 D240 D270

Dimensions are expressed in mm, and subjected to manufacturing tolerances. Data can be altered without notice by our Design Department for the product benefit.

Manufacturing Design Standards:

Split body, Full Bore, Floating Ball design

Harmonised Construction Standard DIN3357

QA certified to ISO 9001:2000

In compliance with Pressure Equipment Directive PED 97/23/EC Module D1

Testing to EN12266-1 (DIN3230 part 3) or API598

Marking to EN19

Face to face dimension: DN15-100 DIN3202 F4 (EN558-1 Series 14 & 27)

DN125-200 DIN3202 F5 (EN558-1 Series15 & 27)

Body end connections: flanged EN1092-1 PN16 integral flanges (type 21), raised face (type B)

Direct Mounting Pad ISO5211 for actuators mounting

Black matt inside and outside paint protection.

Operating Parameters:

Working Pressure: DN15-50: 0…40 bar-g / DN65-200: 0…16 bar-g

Working Temperature –40ºC…+200ºC

(see Engineering Data for complete overview of Pressure-Temperature limits)

Main Applications: Water, oil, compressed air, low pressure steam, etc. depending on materials of construction

Data subject to change without prior notice 45

Data Sheets Manual

BV® BALL VALVES

Hand Lever for Direct Mounting

DN MAIN DIMENSIONS

NPS mm H W

Nº PART MATERIAL ¼” 6 38 125

01 HANDLE St. Steel SS304 3/8” 10 38 125

02 PLASTIC COVER Plastic ½” 15 38 125

03 LOCKING DEVICE St. Steel SS304 ¾” 20 35 125

04 STEM NUT St. Steel SS304 1” 25 36,5 160

05 HANDLE WASHER St. Steel SS304 1-1/4” 32 36,5 160

1.1/2” 40 37,5 190

2” 50 37,5 190

2.1/2” 65 57,5 355

3” 80 57,5 355

4” 100 75 400

Data subject to change without prior notice 46

Data Sheets Manual

BV® BALL VALVES

Actuation and Accessories

BV® ball valves can be provided with a wide range of solutions on actuation and control accessories which is all pac-

kaged at our works according to customer specifications. The modular system permits to distributors and plant users

to assemble or replace the diverse options in site. Virtually most applications that may be encountered on the industry

today are covered with the standard range of actuation and accessories, nevertheless, other customer tailored solu-

tions can be provided by our R&D Section.

OVERALL VALVE ACTUATION

Hand lever; made in Aluminium, light and

resistant to ruptures, ergonomically design

for a quick operation either in 90º or partial

stroke thanks to its notch plate offering in-

termediate locking positions. The lever can

be operated by pulling the trigger and gets

blocked by releasing it.

Worm Gear; declutchable Gear operated by

Hand Wheel, providing a smooth and slow

valve operation on valves and specially on

the larger sizes. It is provided with visual po-

Hand Lever Worm Gear sition indicator.

Electric Actuators; a wide range of actuators available

for diverse duties; from the L&H Series (standard light

and single phase actuators, plastic cased for low torque

and standard duty requirements) to the most power-

ful and high performance known brands. They can be

provided for On / Off services or throttling by means of

electronic positioners. As a standard feature they are all

provided with emergency manual override.

Electric Actuators

Pneumatic Actuators; of rack and pinion type,

available in single and double acting versions, the

standard casing is Aluminium and can also be provi-

ded with special coatings on request. As a standard

feature they are all provided with visual position in-

dicator.

Pneumatic Actuators

Data subject to change without prior notice 47

Data Sheets Manual

BV® BALL VALVES

Actuation and Accessories

POSITION INDICATION ARRANGEMENTS ON MANUAL VALVES

Special designs of proven reliability have been engineered by our R&D section to provide BV® users with more

service options.

Valve with hand lever Valve with hand lever

with electromechanical with inductive proximity

limit switches limit switches

Valve with worm gear Valve with worm gear

with electromechanical with inductive proximity

limit switches limit switches

Valve with hand lever with

limit switches box (metal or plastic)

Valve with worm gear with

limit switches box (metal or plastic)

Data subject to change without prior notice 48

Data Sheets Manual

BV® BALL VALVES

Actuation and Accessories

CONTROL ACCESSORIES ON PNEUMATIC ACTUATED VALVES

Valve position indication can be provided by some arrangements such as Limit Switches that can be mounted

either onto the actuator shell or cased into plastic or metal boxes.

Inductive proximity limit switches

Metal or plastic limit switches boxes

Solenoid Valves in diverse materials and configurations can be provided as the most common accessories on

pneumatic actuators. For throttling services a range of standard or smart Positionners can be adapted onto the

actuators. Intermediate Gear Boxes can be fitted in all cases for emergency manual actuation.

Solenoid Valves for On/Off control

Pneumatic or Electropneumatic,

Standard or Intelligent Positionners

Intermediate Gear Box for

emergency manual actuation

Data subject to change without prior notice 49

Data Sheets Manual

BV® BALL VALVES

Actuation and Accessories

CONTROL ACCESSORIES ON ELECTRIC ACTUATED VALVES

On our lighter duty L&H Series actuators some options can be provided as follows:

Volt Free contacts for indication

Positionner 4-20 mA / 0-10 V

Remote control

Battery for safety position at air failure

For any other electric actuator, options and accessories can be found on the corresponding manufacturer’s Web Site

or data sheets.

OTHER OPTIONS

Stem extensions Pad Locked lever

Stem Extensions; either for manual operated valves or actuated ones. The length of extension is made to the

customer specification, and provides bolting arrangement on both sides: valve stem and actuator stem side with

upper part according to ISO 5211 standard.

Pad Locked lever; this simple system prevents unauthorized operation at the plant. It is arranged on request.

Data subject to change without prior notice 50

www.comeval.es

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Manual Reparacion Stereo TiidaDocument32 pagesManual Reparacion Stereo TiidaRicardo Rangel Posadas100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- IMBIL Slurry Pumps General Technical CatalogueDocument39 pagesIMBIL Slurry Pumps General Technical CatalogueCardoso MalacaoNo ratings yet

- Normal DistributionDocument43 pagesNormal Distributionkrystel basaNo ratings yet

- KSB Acto ActuatorsDocument16 pagesKSB Acto ActuatorsCardoso MalacaoNo ratings yet

- KOBOLD AQUA XL Technical Data SheetDocument1 pageKOBOLD AQUA XL Technical Data SheetCardoso MalacaoNo ratings yet

- Lowara 22SV06F075T Pumps DatasheetDocument3 pagesLowara 22SV06F075T Pumps DatasheetCardoso MalacaoNo ratings yet

- IMBIL INI32125.1 Data-SheetDocument4 pagesIMBIL INI32125.1 Data-SheetCardoso MalacaoNo ratings yet

- Solenoid Air Operated ISO 15407-1 - VDMA 24563 Subbase-Mounted BodyDocument4 pagesSolenoid Air Operated ISO 15407-1 - VDMA 24563 Subbase-Mounted BodyCardoso MalacaoNo ratings yet

- JAPY Pump HT0Document1 pageJAPY Pump HT0Cardoso MalacaoNo ratings yet

- ASCO ConnectorsDocument4 pagesASCO ConnectorsCardoso MalacaoNo ratings yet

- WKM Valves (Codes How To Order)Document1 pageWKM Valves (Codes How To Order)Cardoso MalacaoNo ratings yet

- ISO Size 02 (18 MM) : Air Operated ISO 15407-1 - VDMA 24563 Subbase-Mounted BodyDocument2 pagesISO Size 02 (18 MM) : Air Operated ISO 15407-1 - VDMA 24563 Subbase-Mounted BodyCardoso MalacaoNo ratings yet

- LP 30 Self Monitoring Level ProbeDocument2 pagesLP 30 Self Monitoring Level ProbeCardoso MalacaoNo ratings yet

- Threaded Protection Tube Design Per DIN 43772 Form 5, 8 Model TW45Document7 pagesThreaded Protection Tube Design Per DIN 43772 Form 5, 8 Model TW45Cardoso MalacaoNo ratings yet

- Monitoring Relays True RMS 3-Phase, 3-Phase+N, Multi-Function Types DPB01, PPB01Document5 pagesMonitoring Relays True RMS 3-Phase, 3-Phase+N, Multi-Function Types DPB01, PPB01Cardoso MalacaoNo ratings yet

- ABB Electronic Timer CT-SDS.22Document11 pagesABB Electronic Timer CT-SDS.22Cardoso MalacaoNo ratings yet

- Castrol Tribol 800Document2 pagesCastrol Tribol 800Cardoso Malacao0% (1)

- Sulzer-Moret 121 NFDDocument89 pagesSulzer-Moret 121 NFDCardoso MalacaoNo ratings yet

- BS5467 Copper Conductor Single Core 1.9-3.3 KVDocument2 pagesBS5467 Copper Conductor Single Core 1.9-3.3 KVCardoso MalacaoNo ratings yet

- ATLAS COPCO Air Compressors GA30-90 GA37 110VSDDocument9 pagesATLAS COPCO Air Compressors GA30-90 GA37 110VSDCardoso MalacaoNo ratings yet

- IMBIL Slurry Pumps Model IS ME 50 X 38 Performance CurveDocument2 pagesIMBIL Slurry Pumps Model IS ME 50 X 38 Performance CurveCardoso MalacaoNo ratings yet

- HARRIS Shipbuilding-CatalogDocument76 pagesHARRIS Shipbuilding-CatalogCardoso MalacaoNo ratings yet

- KONECRANES SMV 45 GC4S Technical Data-Sheet + Machine Drawing + Features Included in Our Offer (Maequi Lda)Document4 pagesKONECRANES SMV 45 GC4S Technical Data-Sheet + Machine Drawing + Features Included in Our Offer (Maequi Lda)Cardoso Malacao0% (1)

- Krohne TD Optitemp Tra TcaDocument60 pagesKrohne TD Optitemp Tra TcaCardoso MalacaoNo ratings yet

- Plate Heat Exchanger Model M15-MFG - ASTM B265 Gr1 TitaniumDocument1 pagePlate Heat Exchanger Model M15-MFG - ASTM B265 Gr1 TitaniumCardoso MalacaoNo ratings yet

- Avery Tronix Load Cell T302Document4 pagesAvery Tronix Load Cell T302Cardoso MalacaoNo ratings yet

- SAUER - DAFOSS Series 20 - 27Document12 pagesSAUER - DAFOSS Series 20 - 27Cardoso Malacao100% (1)

- Hardox 550 Uk Data SheetDocument2 pagesHardox 550 Uk Data SheetCardoso MalacaoNo ratings yet

- CAPRARI Pumps Mec-ADocument46 pagesCAPRARI Pumps Mec-ACardoso Malacao100% (1)

- ATOSs Valves DHI-0711Document4 pagesATOSs Valves DHI-0711Cardoso MalacaoNo ratings yet

- Mobrey 9000 Series Pressure TransmittersDocument6 pagesMobrey 9000 Series Pressure TransmittersCardoso MalacaoNo ratings yet

- PARKER PS1-E11 Technical Datasheet PDFDocument1 pagePARKER PS1-E11 Technical Datasheet PDFCardoso MalacaoNo ratings yet

- E-Gold Secrets: Free)Document19 pagesE-Gold Secrets: Free)Mohamed WahidNo ratings yet

- Commercial Law Review 2023Document21 pagesCommercial Law Review 2023David Dumaluan IVNo ratings yet

- HMXDocument9 pagesHMXMarco Alfieri100% (2)

- Nigeria: Author: DR Roland IgbinobaDocument4 pagesNigeria: Author: DR Roland IgbinobaTihitna GezahegnNo ratings yet

- Assignment #2Document38 pagesAssignment #2edson vicenteNo ratings yet

- Training Memorandum of Agreement/Waiver: Polytechnic University of The Philippines Quezon City BranchDocument3 pagesTraining Memorandum of Agreement/Waiver: Polytechnic University of The Philippines Quezon City BranchAnton ArponNo ratings yet

- Securitizing SuburbiaDocument105 pagesSecuritizing SuburbiaForeclosure FraudNo ratings yet

- Finale Manuscript1 3.1Document14 pagesFinale Manuscript1 3.1Emmanuel BaccarayNo ratings yet

- mtb2 Quarter 4 Week 1 2Document3 pagesmtb2 Quarter 4 Week 1 2Carino ArleneNo ratings yet

- Experiment #4 Title: Testing of Reinforcing Steel BarsDocument9 pagesExperiment #4 Title: Testing of Reinforcing Steel BarsAnne Kristel Dela RosaNo ratings yet

- 36 Lansang vs. Court of AppealsDocument1 page36 Lansang vs. Court of AppealsRoushael Cient MontealtoNo ratings yet

- Exam 2018 s1 Op2 NewDocument12 pagesExam 2018 s1 Op2 NewmakgethwawhitneyNo ratings yet

- Corrosion in MetalsDocument5 pagesCorrosion in MetalsJitendra KumarNo ratings yet

- Entrainment Losses in Barometric TowersDocument5 pagesEntrainment Losses in Barometric TowersGeorge Isaac McQuilesNo ratings yet

- Electrical Power Distribution Part 1 Fundamentals For Every EngineerDocument25 pagesElectrical Power Distribution Part 1 Fundamentals For Every EngineerFlooriNo ratings yet

- Unit 5 Air CompressorDocument15 pagesUnit 5 Air Compressormadhume01No ratings yet

- Mary Oneill Resume - LatestDocument2 pagesMary Oneill Resume - Latestapi-237173493No ratings yet

- Using A ComputerDocument30 pagesUsing A ComputerJEEHANDSOME RANDOMNo ratings yet

- Burj DubaiDocument27 pagesBurj DubaiInche Helmi Dori DoriNo ratings yet

- Service DM Kalibrierung Tab Dienstleistungen enDocument2 pagesService DM Kalibrierung Tab Dienstleistungen enrcnexyNo ratings yet

- Vesda Laser Focus 250Document2 pagesVesda Laser Focus 250WERMERMNo ratings yet

- International Emergency Nursing: Yong Eun Kwon, Miyoung Kim, Sujin ChoiDocument7 pagesInternational Emergency Nursing: Yong Eun Kwon, Miyoung Kim, Sujin ChoiAmrinder RandhawaNo ratings yet

- A Thesis Presented To The Faculty of Senior High School in Asian Institute of Computer Studies Batangas Batangas CityDocument10 pagesA Thesis Presented To The Faculty of Senior High School in Asian Institute of Computer Studies Batangas Batangas Citylilibeth garciaNo ratings yet

- Concrete Discharge Time (ASCC)Document1 pageConcrete Discharge Time (ASCC)V. ManilalNo ratings yet

- Lab - Manual LP V (2019PATERN)Document39 pagesLab - Manual LP V (2019PATERN)Vaishnavi DhimateNo ratings yet

- The Rise of Judicial Governance in The Supreme Court of IndiaDocument56 pagesThe Rise of Judicial Governance in The Supreme Court of IndiaMAHANTESH GNo ratings yet

- Industrial Marketing 5-6Document2 pagesIndustrial Marketing 5-6Mary Grace Ygot ParachaNo ratings yet

- Vood 100 200 ConfigDocument118 pagesVood 100 200 ConfigasgariNo ratings yet