Professional Documents

Culture Documents

C6B Force Trandusers

C6B Force Trandusers

Uploaded by

Эдуард КеллертOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C6B Force Trandusers

C6B Force Trandusers

Uploaded by

Эдуард КеллертCopyright:

Available Formats

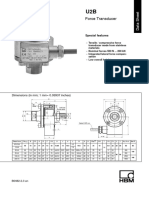

C6B

Force transducers

Special features

- Rugged compressive force transducers

- Nominal (rated) force 200 kN ... 10 MN

Data sheet

- Hermetically welded, versions with IP68

available

- Extensive range of mounting aids, flexibly

configurable

Connection options

Rmin = 30 mm

20

Rmin = 30 mm approx. 60

Rmin = 30 mm

20

approx. 80

B04978_01_E00_05 HBM: public

Dimensions (in mm)

Bottom view Top view

Nominal A B C±0.1 D D1 E±0.1 F G H J K L1) L2) M H11 N1) N2) O P Q±0.1 R S±0.1

(rated)

force

200 kN 80 60 40.4 1 1 32 16.25 42 0.75 M8x 26 12 14 6 100 106 - 35 48 M6 64

8 x8

500 kN 80 60 52 1 1 32 16.25 42 0.75 26 12 14 6 100 106 - - 42 64

1 MN 159 100 88 2 3 68 35.5 44 17.5 M12 31 12 14 8 184 186 - 75 98 M8 130

x15 x15

2 MN 159 100 106 2 3 68 35.5 44 17.5 31 12 14 8 184 186 100 80 90 130

1) Fixed cable option

2) Plug option

Nominal A B C D F G H J K L1) L2) N1) N2) O F7 P S

(rated)

force

5 MN 190 180 130 3 44 55 20 M12 31 12 14 216 218 16 6 100±0.2

10 MN 267 240 180 3 44 96 30 M20 31 12 14 293 295 25 10 140

1) Fixed cable option

2) Plug option

HBM 2 B04978_01_E00_05 HBM: public

Mounting aids

Spherical cap ZK

E

b

d

S

ØM

3x offset by 120°

a

200 kN - 2 MN 5 MN & 10 MN

Nominal (rated) ZK ordering Weight in B E±0.1 G M H11 O F7 P S a b d

force number kg

200 kN …500 kN 1-C6/50T/ZK 1.7 60 32 82 6 - - 64±0.1 112 52 28

1 MN 1-C6/100T/ZK 3.8 100 68 121 8 - - 130±0.1 174.5 75.3 40

2 MN 1-C6/200T/ZK 11.6 100 68 159 8 - - 130±0.1 195 95.5 50

5 MN 1-C6/500T/ZK 20.6 180 - 178 - 16 8 284 104 61

10 MN 1-C6/10MN/ZK 50.2 240 - 240 - 25 12 385 145 88

Load but

ton ZL

200 kN - 2 MN 5 MN & 10 MN

Nominal ZL ordering Weight in kg G H-0.1 J R U-0.2 K F7 M b c d

(rated) force number

200 kN 1-C6/20T/ZL 0.8 60 31.9 M5 300 32 - - 50 5 30

500 kN 1-C6/50T/ZL 0.8 60 31.9 M5 300 44 - - 50 5 30

1 MN 1-C6/100T/ZL 6.4 120 67.9 M6 600 64 - - 85 5 60

2 MN 1-C6/200T/ZL 6.8 120 67.9 M6 600 85 - - 85 5 60

5 MN 1-C6/500T/ZL 6.5 - - M12 600 129.8 16 8 60 - 35

10 MN 1-C6/10MN/ZL 30.1 - - M20 1000 219.8 25 12 110 - 67

B04978_01_E00_05 HBM: public 3 HBM

Thrust piece

EPO3

200 kN - 2 MN 5 MN & 10 MN

Nominal EPO3 ordering Weight in kg C D E F N O P Q S U-0.2 a

(rated) force number

200 kN 1-EPO3R/20T 1.2 47.8 27.5 20 58 14 110 90 13 90 32 125

500 kN 1-EPO3/50T 3.4 81.8 50 39.5 89 10 147 120 18 130 44 144.5

1 MN 1-EPO3/100T 3.2 81.9 50 39.5 89 10 147 120 18 130 64 219.5

2 MN 1-EPO3/250T 13 139.8 80 67.5 150 25 225 190 22 200 85 247.5

5 MN 1-EPO3/500T 27 169.8 103 90 188 33 270 220 28 250 130 250

10 MN1) 1-EPO3/10MN 55 260 140 120 290 - - - - - 220 430

1) Version with nominal (rated) force 10 MN is supplied without clamping ring

HBM 4 B04978_01_E00_05 HBM: public

Specifications

kN 200 500

Nominal (rated) force Fnom

MN 1 2 5 10

Accuracy

Accuracy class 0.5

Relative reproducibility and repeatability errors with

unchanging mounting position

When hardened compression plates are used 0.2 0.1 0.06

brg %

If load button ZL is used, or with load button ZL and thrust

0.1 0.06

piece EPO

When used with spherical cap ZK 0.2 0.1 0.06

Relative reversibility error (hysteresis) at 0.5Fnom

When hardened compression plates are used 0.5

If load button ZL is used, or with load button ZL and thrust v0.5 %

0.5 0.3

piece EPO

When used with spherical cap ZK 0.5

Non-linearity

When hardened compression plates are used 1

If load button ZL is used, or with load button ZL and thrust dlin %

0.4

piece EPO

When used with spherical cap ZK 1

Relative creep dcrF+E % 0.06

Effect of eccentricity dE %/mm 0.2 0.06

Temperature coefficient of sensitivity TCS %/10 K 0.1

Temperature coefficient of zero signal TC0 %/10 K 0.05

Rated electrical output

Rated output (nominal) Cnom mV/V 2

Relative zero signal error ds,0 % 1

Deviation of the characteristic value with optional

"adjusted rated output"

When hardened compression plates are used 2.5

dc %

If load button ZL is used, or with load button ZL and thrust

0.5

piece EPO

When used with spherical cap ZK 0.5

Rated output range (without rated output adjustment) C mV/V 2 … 2.48 mV/V

Input resistance Ri Ω 380 … 420

Output resistance Ro Ω 280 … 360

Output resistance with "adjusted rated output" option Ro Ω 365

Tolerance of the output resistance with "adjusted rated

dRa Ω 1.5

output" option

Insulation resistance Ris GΩ >5

Operating range of the excitation voltage BU,G V 0.5 … 20

Reference excitation voltage Uref V 5

Connection 6-wire

Temperature

Reference temperature Tref °C 23

Nominal (rated) temperature range BT,nom °C -10 … +70

Operating temperature range BT,g °C -30 … +85

Storage temperature range BT,S °C -50 … +85

B04978_01_E00_05 HBM: public 5 HBM

kN 200 500

Nominal (rated) force Fnom

MN 1 2 5 10

Characteristic mechanical quantities

Maximum operating force FG 150

Force limit FL % of Fnom 150

Breaking force FB >200 >180

Static lateral force limit

When hardened compression plates are used No specification possible

If load button ZL is used, or with load button ZL and thrust FQ % of Fnom

20 10

piece EPO

When used with spherical cap ZK 3

Permissible eccentricity eG mm 5 6 11 12 10 10

Nominal (rated) displacement snom mm 0.13 0.15 0.2 0.2 0.5 0.7

Fundamental frequency fG kHz 11.6 14.4 6.1 6.9 5.3 4

Relative permissible oscillatory stress frb % of Fnom 70

Stiffness F/S 106 N/mm 1538 3333 5000 10000 14286

General information

Degree of protection per EN 60529 with"fixed cable" (standard version) IP681)

Degree of protection per EN 60529, with "bayonet connector" option, socket

IP67

connected to sensor

Degree of protection per EN 60529, with "threaded connector" option IP64

Spring element material Stainless steel

Measuring point protection hermetically welded measuring body

Cable (standard version) Outside diameter 5.4 mm

Cable length m 6 or 15

Mechanical shock resistance as per IEC 60068‐2‐6

Number n 1000

Duration ms 2

Acceleration m/s2 650

Vibrational stress per IEC 60068‐2‐27

Frequency range Hz 5 … 65

Duration min 30

Acceleration m/s2 150

Weight m kg 1.6 1.8 10.1 10.7 32 84

m lbs 3.5 4.0 22.3 23.6 70.5 185.2

1) Test condition: 1 m water column, 100 hours

HBM 6 B04978_01_E00_05 HBM: public

Versions and ordering numbers

Code Measurement Ordering number

range

200K 200 kN 1-C6B/200KN

500K 500 kN 1-C6B/500KN

1M00 1 MN 1-C6B/1 MN

2M00 2 MN 1-C6B/2MN

5M00 5 MN 1-C6B/5MN

10M0 10 MN 1-C6B/10MN

The ordering numbers shown in gray are preferred types. They can be delivered rapidly.

The ordering number for the preferred types is 1‐C6B…, the ordering number for the customized versions is

K‐C6B‐…

Rated Transducer Mechanical design Plug Electrical Plug version for the

output identification protection connection "permanently attached

adjustment cable" option

Not Without Without load Without plug With permanently Free ends

adjusted TEDS chip application protection attached cable, 6 m Y

N S OO U K

Adjusted With TEDS With spherical cap ZK With plug With permanently D-sub-HD15, 15-pin

J chip ZK protection attached cable, 15 m F

T P V

With the ZL load With bayonet D-sub-HD15, 15-pin

button and EPO thrust connector Q

piece B

EZ

With threaded Male connector

connector ME3106PEMV

G N

ODU male connector, 14-pin

P

M12 male connector, 8-pin

M

Rated output adjustment The exact rated output is specified on the type plate. The sensor can be adjusted to an exact

rated output of 2 mV/V. Then the relative tolerance of the rated output is dependent on the

selected loading fittings. (see specifications, section "Rated electrical outputs"). You can con

nect the C6B in parallel if you order the sensor with adjusted rated output.

Transducer identification Integration of TEDS chip (integrated electronic data sheet) as per IEEE 1451.4.

If the relevant amplifier electronics are provided, the measurement chain will parameterize

itself automatically.

Mechanical design Standard delivery does not include load application parts.

The C6B is optionally available with the appropriate load application parts and calibrated or

adjusted.

Plug protection A square profile is installed around the plug for mechanical protection.

Dimensions WxHxD: 30 x 30 x 20 mm

Electrical connection Permanently attached cable, 6 m is standard; options: Permanently attached cable, 15 m;

bayonet connection (PT02E10-P-compatible); threaded connector (PT02E10-P-compatible)

Connector assembly Mounted and verified plugs for direct use on HBM amplifiers.

(Only in combination with permanently attached cable)

B04978_01_E00_05 HBM: public 7 HBM

Cables/plugs Ordering number

Configurable cable, available in different lengths and on request with plug mounted for connecting di K-CAB-F

rectly to the amplifier

Connection cable KAB157-3; IP67 (with bayonet connector); 3 m long, TPE outer sheath; 6 x 0.25 mm2; 1-KAB157-3

free ends, shielded, outside diameter 6.5 mm

Connection cable KAB158-3; IP54 (with threaded connector); 3 m long, TPE outer sheath; 6 x 0.25 mm2; 1-KAB158-3

free ends, shielded, outside diameter 6.5 mm

Loose cable socket (bayonet connection) 3-3312.0382

Loose cable socket (screw connection) 3-3312.0354

Ground cable, 400 mm 1-EEK4

Ground cable, 600 mm 1-EEK6

Ground cable, 800 mm 1-EEK8

B04978_01_E00_05 HBM: public

Subject to modifications. Hottinger Baldwin Messtechnik GmbH

All product descriptions are for general information Im Tiefen See 45 ⋅ 64293 Darmstadt ⋅ Germany

only. They are not to be understood as a guarantee Tel. +49 6151 803‐0 ⋅ Fax +49 6151 803‐9100

of quality or durability. E-mail: info@hbm.com ⋅ www.hbm.com

measure and predict with confidence

HBM 8 B04978_01_E00_05 HBM: public

You might also like

- Swiggy Case Study - DE RejectDocument2 pagesSwiggy Case Study - DE RejectNirmal Kumawat0% (1)

- ST7Document4 pagesST7marcelonieto761No ratings yet

- Free Pdms Piping Tutorial PDFDocument2 pagesFree Pdms Piping Tutorial PDFBrianNo ratings yet

- KNDocument42 pagesKNtalibanindonesiaNo ratings yet

- U2BDocument9 pagesU2BROLAND GONZALEZNo ratings yet

- Force Transducer: Special FeaturesDocument6 pagesForce Transducer: Special FeaturesSoup PongsakornNo ratings yet

- Fixadores BWF - Series-SDocument6 pagesFixadores BWF - Series-Scaio.gassnerNo ratings yet

- 4 - Spur GearsDocument8 pages4 - Spur GearsAnil YildizNo ratings yet

- CM-9CB TG-S9Cb US-9CbDocument3 pagesCM-9CB TG-S9Cb US-9Cbamit singhNo ratings yet

- 006 - Design of Tension MemberDocument5 pages006 - Design of Tension MemberVAIBHAVNo ratings yet

- Beam Design LRFD Aci 318-14Document6 pagesBeam Design LRFD Aci 318-14Usman AfzalNo ratings yet

- Force Transducer: Special FeaturesDocument4 pagesForce Transducer: Special FeaturesFrancisco BoteroNo ratings yet

- ETABS 2016 Concrete Frame Design: ACI 318-14 Beam Section DesignDocument2 pagesETABS 2016 Concrete Frame Design: ACI 318-14 Beam Section DesignLulu Danur MayasinNo ratings yet

- C6A Force TransducerDocument4 pagesC6A Force TransducerlelixNo ratings yet

- 7tc1 Top FixedDocument2 pages7tc1 Top FixedEmily ShumNo ratings yet

- Soplador 0.75 KW SCL K04 MS FPZ Escaldador de Pollo PDFDocument2 pagesSoplador 0.75 KW SCL K04 MS FPZ Escaldador de Pollo PDFPablo CastilloNo ratings yet

- Data Sheet - Núcleo - 00K6527E060Document1 pageData Sheet - Núcleo - 00K6527E060pauloNo ratings yet

- EC2-BE-dubble Reinforced Beams SLS-crackwidth Rev6Document7 pagesEC2-BE-dubble Reinforced Beams SLS-crackwidth Rev6Dong LINo ratings yet

- TCI-link FittingsDocument24 pagesTCI-link FittingsOresteHernandezNo ratings yet

- Boq-Anchor 0810Document1 pageBoq-Anchor 0810indra syifaiNo ratings yet

- Major Axis Bending Minor Axis BendingDocument26 pagesMajor Axis Bending Minor Axis Bendingarunkumar.mgsNo ratings yet

- ABC Combinepdf 1Document20 pagesABC Combinepdf 1myraoswandaaNo ratings yet

- DYWIDAG Flat Multiplane Anchorage: Technical DataDocument1 pageDYWIDAG Flat Multiplane Anchorage: Technical DataAhmed Mostafa AL-AboudyNo ratings yet

- CM B108Document1 pageCM B108amit singhNo ratings yet

- Beam Design: Planning and Design Section Design byDocument1 pageBeam Design: Planning and Design Section Design byking taugNo ratings yet

- Flexural Analysis of Singly Reinforced Section (Final)Document4 pagesFlexural Analysis of Singly Reinforced Section (Final)Alvaro CaravantesNo ratings yet

- Rebar CalculatorDocument11 pagesRebar CalculatorMahindaNo ratings yet

- Reinforcement Concrete: HomeworkDocument14 pagesReinforcement Concrete: HomeworkPiseth HengNo ratings yet

- Reinforced Concrete Column Design: B 250mm H 250mmDocument7 pagesReinforced Concrete Column Design: B 250mm H 250mmAli Al-BashaNo ratings yet

- ETABS 2015 15.1.0-Design DetailsDocument2 pagesETABS 2015 15.1.0-Design DetailsdenyfateNo ratings yet

- Soal 2 - XLSXDocument4 pagesSoal 2 - XLSXCVCP PROPERTINo ratings yet

- Industrial Low Voltage Cables: Construction: ResistanceDocument2 pagesIndustrial Low Voltage Cables: Construction: ResistanceFer F. Rodriguez CNo ratings yet

- ETABS 2016 Shear Wall DesignDocument2 pagesETABS 2016 Shear Wall DesignSuneesh PNo ratings yet

- ETABS Concrete Frame Design: Eurocode 2-2004 Beam Section DesignDocument1 pageETABS Concrete Frame Design: Eurocode 2-2004 Beam Section DesignCSEC Uganda Ltd.No ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1L4NYHW6GDTZBRADocument2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1L4NYHW6GDTZBRARajib MaharjanNo ratings yet

- Shear Wall DesignDocument6 pagesShear Wall DesignSreehari Ashok100% (1)

- Etabs 18.1 PDFDocument2 pagesEtabs 18.1 PDFBißék ŚílwàlNo ratings yet

- EC - RC Beam Shear DesignDocument1 pageEC - RC Beam Shear DesignMyat Thu Zar KhineNo ratings yet

- Ready Reference BOLTSDocument1 pageReady Reference BOLTSManjiri DhondNo ratings yet

- ABC428201544125PM1Document15 pagesABC428201544125PM1deborahNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 1SRAL4HSLYXM7Q8Document2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 1SRAL4HSLYXM7Q8er.praveenraj30No ratings yet

- CLC 18-10ti: A Ti Stabilized 18Cr-10Ni Austenitic Stainless Steel (321 Grade)Document4 pagesCLC 18-10ti: A Ti Stabilized 18Cr-10Ni Austenitic Stainless Steel (321 Grade)PeterWayNo ratings yet

- Creep and ShrinkageDocument3 pagesCreep and ShrinkageYaselaNo ratings yet

- BEAMDocument2 pagesBEAMraserafica07No ratings yet

- Beam Design IS800 2007Document10 pagesBeam Design IS800 2007ER Deepak SutharNo ratings yet

- General Information: 2.1. ConcreteDocument3 pagesGeneral Information: 2.1. ConcreteGeloNo ratings yet

- Grade Beam DesignDocument2 pagesGrade Beam Designjohnstruct archNo ratings yet

- Design of R.C.C Column Footing: Input DetailsDocument15 pagesDesign of R.C.C Column Footing: Input DetailsAbilaash VelumaniNo ratings yet

- ETABS 2016 Concrete Frame Design: ACI 318-14 Beam Section DesignDocument2 pagesETABS 2016 Concrete Frame Design: ACI 318-14 Beam Section DesignkennysawegNo ratings yet

- ETABS 2016 Concrete Frame Design: ACI 318-14 Beam Section DesignDocument2 pagesETABS 2016 Concrete Frame Design: ACI 318-14 Beam Section DesignkennysawegNo ratings yet

- Kiepe DG EnglischDocument4 pagesKiepe DG EnglischIvan Mario VillcaNo ratings yet

- ETABS 19.1.0-Design Details sloofDocument3 pagesETABS 19.1.0-Design Details sloofrobbiNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1L4NYHW6GDTZBRADocument2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.0.0 License # 1L4NYHW6GDTZBRARajib MaharjanNo ratings yet

- Volt Drop Calc Paul SonbergDocument15 pagesVolt Drop Calc Paul SonbergNikolai YenkoNo ratings yet

- Erp-Reinf Shearwall R1Document6 pagesErp-Reinf Shearwall R1Gunawan Prc2020No ratings yet

- Design of Selender ColumnDocument16 pagesDesign of Selender ColumnTalha UmarNo ratings yet

- RE.0444N - Normal: Direct Current Tachometer GeneratorDocument3 pagesRE.0444N - Normal: Direct Current Tachometer GeneratorJUANJAUNNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.0.3 Gilang Ramadhan Andaluna License # 1S5LLY67BDQYHLRDocument2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.0.3 Gilang Ramadhan Andaluna License # 1S5LLY67BDQYHLRbudifreadnoNo ratings yet

- Beam Design - 1 6mm Thick 14tk FlangeDocument7 pagesBeam Design - 1 6mm Thick 14tk Flangevrajan1988No ratings yet

- Last Updated: Jan 27, 2006Document2 pagesLast Updated: Jan 27, 2006박준용No ratings yet

- Etabs 20.3 Segmented GRDocument2 pagesEtabs 20.3 Segmented GRHjshj ShjhjNo ratings yet

- EE364a Homework 4 SolutionsDocument21 pagesEE364a Homework 4 SolutionsSakshi SharmaNo ratings yet

- Maquinaria Naval Parte A-DDocument185 pagesMaquinaria Naval Parte A-DraulbrlunaNo ratings yet

- ALD Management (SRAN15.1 02)Document160 pagesALD Management (SRAN15.1 02)waelq20030% (1)

- Transport Across The Cell MembraneDocument14 pagesTransport Across The Cell Membraneapi-292439032No ratings yet

- Online Grievance Reddressal System (Mini Project) Guided By: R.Nitesh Asst - ProfessorDocument35 pagesOnline Grievance Reddressal System (Mini Project) Guided By: R.Nitesh Asst - ProfessorharshithaNo ratings yet

- Assignment 1Document10 pagesAssignment 1karthik r100% (1)

- Quiz No. 4Document1 pageQuiz No. 4Cristina SarmientoNo ratings yet

- A Priori Bealer (1999) PDFDocument27 pagesA Priori Bealer (1999) PDFDiego MontoyaNo ratings yet

- Difference Between RAM and ROMDocument7 pagesDifference Between RAM and ROMJan Carlo Balatan Pablo100% (2)

- Jntuh SCTDocument3 pagesJntuh SCTGowthamUcekNo ratings yet

- Building BlocksDocument3 pagesBuilding BlocksivoryspudNo ratings yet

- Quantum Information Theory Chapter 1Document12 pagesQuantum Information Theory Chapter 1juanNo ratings yet

- Setup Sheet Report: Mill DefaultDocument5 pagesSetup Sheet Report: Mill DefaultGandi SaputraNo ratings yet

- Vdtuev FLEETWELD 5P PLUS enDocument1 pageVdtuev FLEETWELD 5P PLUS enfsasas asfaasNo ratings yet

- FutureDocument37 pagesFutureBT20EEE052 KhushalNo ratings yet

- Determination of Negative Permittivity and PermeabDocument6 pagesDetermination of Negative Permittivity and PermeabNewton GomesNo ratings yet

- Ec 1015 Satellite Communication Anna University Question Paper MayDocument2 pagesEc 1015 Satellite Communication Anna University Question Paper Maysanth_213No ratings yet

- CH 17 SolutionsDocument63 pagesCH 17 Solutions전민욱No ratings yet

- Most Repeated Concepts & QuestionsDocument44 pagesMost Repeated Concepts & Questionsanshika tembhareNo ratings yet

- LED FLOOD LIGHT 100 - SMD NewDocument1 pageLED FLOOD LIGHT 100 - SMD NewAlvin RejisNo ratings yet

- SDL 700 DataDocument1 pageSDL 700 DataPetinggi TElektroNo ratings yet

- A Four Leg Shunt Active Power Filter Predictive Fuzzy Logic Controller For Low-Voltage Unbalanced-Load Distribution NetworksDocument15 pagesA Four Leg Shunt Active Power Filter Predictive Fuzzy Logic Controller For Low-Voltage Unbalanced-Load Distribution NetworksEdsonNo ratings yet

- Radiometrik KalibrasiDocument38 pagesRadiometrik KalibrasiAhmad SholehNo ratings yet

- C - Fakepathsyllabus Linear Algebra2023 2Document6 pagesC - Fakepathsyllabus Linear Algebra2023 2ywgf4q7hkkNo ratings yet

- Interpreting Topographical MapsDocument20 pagesInterpreting Topographical MapsBinu Kumar SNo ratings yet

- DTC b0012 or b0013Document15 pagesDTC b0012 or b0013Masmas MasNo ratings yet

- Cronin 1992Document15 pagesCronin 1992Alangelico Ortiz San PascualNo ratings yet