Professional Documents

Culture Documents

Initial Load Test Report

Initial Load Test Report

Uploaded by

arif_rubinCopyright:

Available Formats

You might also like

- PAPER+ +Collapse+of+Soil+in+Pile+Bore+and+Its+Stabilisation+Using+Bentonite+SuspensionDocument9 pagesPAPER+ +Collapse+of+Soil+in+Pile+Bore+and+Its+Stabilisation+Using+Bentonite+SuspensionPrashanth Seshamani Iyer100% (1)

- Methodology of Static Pile Load TestDocument33 pagesMethodology of Static Pile Load Testraju_420034520100% (2)

- Routine Vertical Load Test Report For P-5 Conducted at KMMLDocument8 pagesRoutine Vertical Load Test Report For P-5 Conducted at KMMLshaaz v s mNo ratings yet

- Job Procedure For Pile Load TestDocument30 pagesJob Procedure For Pile Load Testpratimwhite100% (1)

- Pile Load Test ProcedureDocument24 pagesPile Load Test ProcedureRamkumar K100% (4)

- Kentledge of Pile Load TestDocument6 pagesKentledge of Pile Load Testkartick adhikary100% (7)

- Lateral Pile Load Test For PilesDocument8 pagesLateral Pile Load Test For PilesSubrahmanaya S Murthy TATA100% (3)

- (Paper) Launching Girders Risk ChecklistDocument4 pages(Paper) Launching Girders Risk ChecklistRAJENDRA PRASAD100% (2)

- Job Mix Formula For Cement Treated Sub Base: (IRC SP 89-2010)Document1 pageJob Mix Formula For Cement Treated Sub Base: (IRC SP 89-2010)Dwijendra Chanumolu100% (2)

- Methology For Mastic AshphaltDocument6 pagesMethology For Mastic Ashphaltvenkateswara rao PothinaNo ratings yet

- IRC78-2014 B-3 Appendix-9 Bi-Axial Load Testing of Piles - Draft 27-10-2017 PDFDocument22 pagesIRC78-2014 B-3 Appendix-9 Bi-Axial Load Testing of Piles - Draft 27-10-2017 PDFHemant YesajiNo ratings yet

- Vertical Load Test - Design - 2-1Document7 pagesVertical Load Test - Design - 2-1Abir Sengupta100% (1)

- Project On Sugarcane BaggasseDocument26 pagesProject On Sugarcane BaggasseV Deepak Kumar75% (4)

- Dynamic Load Test 1200mm DiaDocument6 pagesDynamic Load Test 1200mm DiaVB665100% (1)

- Pile Load Test Methodology - Kentledge Method - Cyclic-RoutineDocument10 pagesPile Load Test Methodology - Kentledge Method - Cyclic-RoutineHarshit DubeyNo ratings yet

- Test Pile MethodologyDocument7 pagesTest Pile MethodologyCOME TO KNOWNo ratings yet

- Pile Load Test PDFDocument11 pagesPile Load Test PDFAjit P. SinghNo ratings yet

- Lateral Load Test Methodology and Design For Agra-TundlaDocument13 pagesLateral Load Test Methodology and Design For Agra-Tundlabp chaudharuNo ratings yet

- Pile Load Test MethodologyDocument4 pagesPile Load Test MethodologyAkhilesh Dwivedi100% (1)

- Methodology For Verticial Initial Cyclic Load Test by Reaction MethodDocument4 pagesMethodology For Verticial Initial Cyclic Load Test by Reaction MethodvivekNo ratings yet

- Anchor Pile Load Test MethodologyDocument11 pagesAnchor Pile Load Test MethodologyHegdeVenugopal50% (4)

- SOP of Pull Out, Lateral & Compression - REV01Document8 pagesSOP of Pull Out, Lateral & Compression - REV01Prince MittalNo ratings yet

- Kentledge DetailsDocument3 pagesKentledge DetailsAbir Sengupta100% (2)

- Method Statement of Routine Pile Load Test (Dynamic)Document3 pagesMethod Statement of Routine Pile Load Test (Dynamic)Akhilesh Dwivedi100% (2)

- WMM Mix DesignDocument23 pagesWMM Mix DesignjanardangaurNo ratings yet

- Initial Pile Load Test Report Anchor MethodDocument8 pagesInitial Pile Load Test Report Anchor MethodShakti SharmaNo ratings yet

- Plate Load Test at InaruwaDocument34 pagesPlate Load Test at InaruwaSushant Giri100% (1)

- Method Statement For Conducting High Strain Dynamic Pile Testing of 1200Mm Dia R.C. Bored PilesDocument6 pagesMethod Statement For Conducting High Strain Dynamic Pile Testing of 1200Mm Dia R.C. Bored PilesFaisal RizwanNo ratings yet

- Pile Load Test Procedure-2Document9 pagesPile Load Test Procedure-2S GoudaNo ratings yet

- Methodology For PQC (00) Toll Plaza L&TDocument4 pagesMethodology For PQC (00) Toll Plaza L&TDeven PatleNo ratings yet

- Checklist For Bored Cast In-Situ Piles ReniforcmentDocument4 pagesChecklist For Bored Cast In-Situ Piles ReniforcmentSureshKumarNo ratings yet

- Methodology Well Foundation (R3)Document14 pagesMethodology Well Foundation (R3)jitendra100% (3)

- BBS For Test Pile-03 at OMG - 1000mm DiaDocument5 pagesBBS For Test Pile-03 at OMG - 1000mm DiaAjay MalikNo ratings yet

- What Are The Requirements of Bentonite (Powder and Suspension) Used in Piling Work As Per IS-2911Document2 pagesWhat Are The Requirements of Bentonite (Powder and Suspension) Used in Piling Work As Per IS-2911Pritha DasNo ratings yet

- Cast-In-Situ Bored Piling Works by ConventionalMethod1Document11 pagesCast-In-Situ Bored Piling Works by ConventionalMethod1jitendraNo ratings yet

- Load Test Load Calculations & ChartDocument12 pagesLoad Test Load Calculations & ChartHegdeVenugopalNo ratings yet

- Precast Pier Cap 01Document1 pagePrecast Pier Cap 01Gajendra Bisht100% (1)

- Pile Load Test Procedure-1Document5 pagesPile Load Test Procedure-1S GoudaNo ratings yet

- Indian HighwaysDocument95 pagesIndian HighwaysTLOFFICE PATNANo ratings yet

- Vertical Pile Load Test (Sabarmati Station Building)Document9 pagesVertical Pile Load Test (Sabarmati Station Building)Vipin Kumar ParasharNo ratings yet

- Method Statement For Construction of PilesDocument27 pagesMethod Statement For Construction of PilesShakti Sharma100% (1)

- Report On Vertical Pile Load TestDocument39 pagesReport On Vertical Pile Load TestTest EngineerNo ratings yet

- Directorate General Border Roads Directorate General Border Roads Directorate General Border RoadsDocument14 pagesDirectorate General Border Roads Directorate General Border Roads Directorate General Border RoadsAaron WilsonNo ratings yet

- 26.05.2021-METHOD STATEMENT - VERTICAL LOAD TEST by Anchor MethodDocument16 pages26.05.2021-METHOD STATEMENT - VERTICAL LOAD TEST by Anchor MethodpdksubudhiNo ratings yet

- Danta - Lateral Load Test Report Final-05.01.24Document18 pagesDanta - Lateral Load Test Report Final-05.01.24Deepak avinashNo ratings yet

- Launching Girder Assembly ChecklistDocument3 pagesLaunching Girder Assembly ChecklistWan Noor AzirahNo ratings yet

- SOP Pile Load Test PDFDocument5 pagesSOP Pile Load Test PDFSoigne Consultants100% (2)

- MBIU Report Gorakhpur BypassDocument167 pagesMBIU Report Gorakhpur BypassRaghav SharmaNo ratings yet

- 51) CASE STUDY - Design and Installation of Driven Piles For High Rise Building PDFDocument134 pages51) CASE STUDY - Design and Installation of Driven Piles For High Rise Building PDFGV RamasubbaraoNo ratings yet

- Methodology of UPVDocument3 pagesMethodology of UPVAnonymous eKt1FCDNo ratings yet

- Method Statement For Construction of Bored Cast In-Situ Piles Using Mechanical Rotary RigDocument5 pagesMethod Statement For Construction of Bored Cast In-Situ Piles Using Mechanical Rotary RigVijay Jamadar100% (2)

- Larsen & Toubro Limited - Ecc Division: Page 1 of 4Document4 pagesLarsen & Toubro Limited - Ecc Division: Page 1 of 4Akhilesh DwivediNo ratings yet

- Pile Dynamic Test MethodologyDocument3 pagesPile Dynamic Test Methodologykom1984No ratings yet

- Irc 78 2014 PDFDocument100 pagesIrc 78 2014 PDFRajen KoleyNo ratings yet

- Bridge Load TestDocument4 pagesBridge Load Testvivek100% (1)

- CC Road PDFDocument222 pagesCC Road PDFPhani PitchikaNo ratings yet

- Pile Load TestDocument4 pagesPile Load TestRitesh Dahiya100% (1)

- A Revolution To Stop Punching of Anchor Cone in PSC Girder 1659263632Document13 pagesA Revolution To Stop Punching of Anchor Cone in PSC Girder 1659263632Sanjay MishraNo ratings yet

- Bridge Evaluation Report - 87m - R1Document15 pagesBridge Evaluation Report - 87m - R1hari om sharmaNo ratings yet

- JV of Shirish Patel & Associates Consultants PVT Limited & Indus Consultrans PVT LTDDocument540 pagesJV of Shirish Patel & Associates Consultants PVT Limited & Indus Consultrans PVT LTDarif_rubin100% (1)

- WMS-002 Pile Driving by Pile-Driving Barge REV.ADocument136 pagesWMS-002 Pile Driving by Pile-Driving Barge REV.AVan Cuong PhamNo ratings yet

- DBR VupDocument15 pagesDBR Vuparif_rubinNo ratings yet

- Costing - 2021-2022 - 28.072023Document804 pagesCosting - 2021-2022 - 28.072023arif_rubinNo ratings yet

- Design of 4L 31.25m SpanDocument1 pageDesign of 4L 31.25m Spanarif_rubinNo ratings yet

- AASHTO Hook DetailDocument1 pageAASHTO Hook Detailarif_rubinNo ratings yet

- Yfc Project PVT Ltd. DMRC: JV of Shirish Patel & Associates Consultants PVT Limited & Indus Consultrans PVT LTDDocument2 pagesYfc Project PVT Ltd. DMRC: JV of Shirish Patel & Associates Consultants PVT Limited & Indus Consultrans PVT LTDarif_rubinNo ratings yet

- Schedule of Bearing Load (31M Span & R 420M)Document1 pageSchedule of Bearing Load (31M Span & R 420M)arif_rubinNo ratings yet

- JV of Shirish Patel & Associates Consultants PVT Limited & Indus Consultrans PVT LTDDocument540 pagesJV of Shirish Patel & Associates Consultants PVT Limited & Indus Consultrans PVT LTDarif_rubin100% (1)

- 31.25m 4L Concrete Dime DRG - 1Document1 page31.25m 4L Concrete Dime DRG - 1arif_rubinNo ratings yet

- 31.25m 4L Concrete Dime DRG - 1Document1 page31.25m 4L Concrete Dime DRG - 1arif_rubinNo ratings yet

- Nagpur Metro Rail Project: Systra-Aecom-Egis-RitesDocument1 pageNagpur Metro Rail Project: Systra-Aecom-Egis-Ritesarif_rubinNo ratings yet

- Nagpur Metro Rail Project: Systra-Aecom-Egis-RitesDocument1 pageNagpur Metro Rail Project: Systra-Aecom-Egis-Ritesarif_rubinNo ratings yet

- 4L BOx Girder Concrete Dimension DRGDocument1 page4L BOx Girder Concrete Dimension DRGarif_rubinNo ratings yet

- Appendix A: Dead Load & Sidl Load Calculation: SPAN-1 SPAN-2Document2 pagesAppendix A: Dead Load & Sidl Load Calculation: SPAN-1 SPAN-2arif_rubin50% (2)

- Double Deck Substructure Design ReportDocument280 pagesDouble Deck Substructure Design Reportarif_rubin100% (4)

- Ground Water Table Value As Per CGWB Data: (Refer Appendix A)Document1 pageGround Water Table Value As Per CGWB Data: (Refer Appendix A)arif_rubinNo ratings yet

- Appendix A: Dead Load & Sidl Load Calculation: SPAN-1 SPAN-2Document2 pagesAppendix A: Dead Load & Sidl Load Calculation: SPAN-1 SPAN-2arif_rubin50% (2)

- Pile Capacity in Granular SoilDocument7 pagesPile Capacity in Granular Soilarif_rubinNo ratings yet

- Appendix EDocument51 pagesAppendix Earif_rubinNo ratings yet

- Pres Tress I-Girder Design SheetDocument70 pagesPres Tress I-Girder Design Sheetarif_rubinNo ratings yet

- Appendix G PDFDocument1 pageAppendix G PDFarif_rubinNo ratings yet

- Appendix DDocument63 pagesAppendix Darif_rubinNo ratings yet

- Appendix H PDFDocument59 pagesAppendix H PDFarif_rubinNo ratings yet

- Spine Girder - Prestress DesignDocument109 pagesSpine Girder - Prestress Designarif_rubinNo ratings yet

- Appendix H PDFDocument59 pagesAppendix H PDFarif_rubinNo ratings yet

- BuildTech - Development of Construction TechnologiesDocument10 pagesBuildTech - Development of Construction TechnologiesSheena BasmayorNo ratings yet

- Concrete Morter Cube QC 452 - 2, 7, 28 D - Strength 15-10-2020 PDFDocument1 pageConcrete Morter Cube QC 452 - 2, 7, 28 D - Strength 15-10-2020 PDFjajajajNo ratings yet

- Lifting EquipmentDocument82 pagesLifting Equipmentchandrahas reddyNo ratings yet

- Selecting Non-Metallic Com-Ponents For API Separators: Water SolutionsDocument1 pageSelecting Non-Metallic Com-Ponents For API Separators: Water SolutionsGladys Gabriela Quispe RamosNo ratings yet

- Solar Chimney: AbstractDocument1 pageSolar Chimney: AbstractRikki RevsNo ratings yet

- The Nickel Advantage in Duplex Stainless SteelsDocument15 pagesThe Nickel Advantage in Duplex Stainless SteelsgullenariNo ratings yet

- An Experimental and Characteristic Study of Abaca Fiber ConcreteDocument10 pagesAn Experimental and Characteristic Study of Abaca Fiber ConcreteAika LorenNo ratings yet

- RX Screw CataloguesDocument2 pagesRX Screw CataloguesPuppala Laxmana PrasadNo ratings yet

- Comment - EEP Procurement Manual - Mgmt-Aa - RevisedDocument150 pagesComment - EEP Procurement Manual - Mgmt-Aa - RevisedBelay TadesseNo ratings yet

- Upah Borongan Civil Gudang KCP GCMDocument6 pagesUpah Borongan Civil Gudang KCP GCMRahardi HardNo ratings yet

- Anatomy of Boiler FailureDocument19 pagesAnatomy of Boiler Failureکاشف ساقیNo ratings yet

- Environmental and Social Action Plan (ESAP) (Draft)Document24 pagesEnvironmental and Social Action Plan (ESAP) (Draft)GeoVakNo ratings yet

- PLATE 01 Design 04Document3 pagesPLATE 01 Design 04Jerame BruceNo ratings yet

- Fire Pump Shut Off Operation 1682811247Document11 pagesFire Pump Shut Off Operation 1682811247Faisal AlotaibiNo ratings yet

- Tipolo WH Gantt ChartDocument15 pagesTipolo WH Gantt ChartMayeterisk RNo ratings yet

- Cob, A Vernacular Earth Construction Process in The Context of Modern Sustainable BuildingDocument17 pagesCob, A Vernacular Earth Construction Process in The Context of Modern Sustainable BuildingMilena Vallone PottNo ratings yet

- Agap2 Group OverviewDocument15 pagesAgap2 Group OverviewharidileepNo ratings yet

- Road Map For Digital Design and ConstructionDocument20 pagesRoad Map For Digital Design and ConstructionSyl Vain RissNo ratings yet

- Structural Design and Detailed Drawing of A Steel Industrial Building - 510418108 - Debayan GhoshDocument67 pagesStructural Design and Detailed Drawing of A Steel Industrial Building - 510418108 - Debayan GhoshhelloNo ratings yet

- Notes Api650Document6 pagesNotes Api650MasoodMiyanNo ratings yet

- Final Draft Report of Building Bye-Laws FrameworkDocument58 pagesFinal Draft Report of Building Bye-Laws FrameworkRabindra Dawadi100% (6)

- 13 Tooling, Screws and ConsumablesDocument39 pages13 Tooling, Screws and ConsumablesngotiensiNo ratings yet

- Math PTDocument17 pagesMath PT• C O L E •No ratings yet

- Data Schedule - 12CX2.5MM2 - XVC7VDocument5 pagesData Schedule - 12CX2.5MM2 - XVC7VBurhan SharafNo ratings yet

- Section Iii Design Criteria FOR Potable Water Distribution SystemsDocument10 pagesSection Iii Design Criteria FOR Potable Water Distribution SystemsRamces SolimanNo ratings yet

- Diploma in Construction and Real Estate Project ManagementDocument1 pageDiploma in Construction and Real Estate Project ManagementberrezegNo ratings yet

- HARDWAREDocument32 pagesHARDWARE20021155567% (3)

- P O R T F O L I O: Manthan ManoharDocument29 pagesP O R T F O L I O: Manthan ManoharManthan ManoharNo ratings yet

Initial Load Test Report

Initial Load Test Report

Uploaded by

arif_rubinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Initial Load Test Report

Initial Load Test Report

Uploaded by

arif_rubinCopyright:

Available Formats

JV OF SHIRISH PATEL & ASSOCIATES

CONSULTANTS PVT LIMITED & INDUS

CONSULTRANS PVT LTD.

CLIENT: CONTRACTOR:

YFC PROJECTS PVT LTD.

PROJECT :

DESIGN & CONSTRUCTION OF INTEGRATED STRUCTURE CONSISTING OF ELEVATED VIADUCT AND 6

LANE FLYOVER (DOUBLE DECK SYSTEM), VIADUCT, ELEVATED RAMPS FOR VIADUCT AND FLYOVER,

SIDING LINES, UNDERPASS AT SAKET-G, ELEVATED RAMP FROM BRT CORRIDOR TO FLYOVER , 2 LANE

UNDERPASS AND 4 ELEVATED STATIONS FROM CHAINAGE +14480 to +18760 m OF AEROCITY TO

TUGLAKABAD CORRIDOR OF PHASE-IV FOR DELHI MRTS.

SUBJECT CODE

REPORT ON RESULT INTERPRETATION OF

INITIAL LOAD TEST PLT 1 & PLT2 DOCUMENT NO : 30.TA.DCL.203

REV

(PAGES) 0 0 1 To 0 1 4

R0

This document is the property of Shirish Patel & REF. DRAWING NO

Associates Private Limited & Indus Consultrans Pvt

Ltd (JV) and is not to be reproduced, copied, handed

over to a third party or used for any purpose other

than that for which it has been loaned.

COMMENTS

R0 FIRST ISSUE AMM ARIF 03-09-2020

PREPARED CHECKED Date

REV PARTICULARS

Tuglakabad Corridor of Phase-IV of Delhi MRTS

CONTENTS

1. General

2. Scope

3. Design Parameters

4. Pile load test and preparation

5. Results

6. Proposal

Annexure A

Annexure B

QAP (DDC-Structures) Page 2

Tuglakabad Corridor of Phase-IV of Delhi MRTS

1. GENERAL:

DMRC has appointed YFC Projects Pvt. Ltd for the construction of Metro viaduct, Integrated

double deck viaduct and four elevated stations along Tughlakabad MRTS corridor. The initial

load test was performed by YFC projects Pvt. Ltd to proceed for the working piles of the

viaducts.

2. SCOPE:

The Geotechnical investigation of various bore holes proposed along the length of the

viaduct has been carried out. It was envisaged to use 1.0m and 1.2m diameter bored cast

in situ piles for the viaduct. From the soil properties arrived from the geotechnical

investigation, it was envisaged to use 1.0m diameter pile of 530 MT capacity for normal

metro viaduct and 1.2m dia bored cast in situ pile of 827 MT capacity for double deck

(Integrated) viaduct.

Before proceeding for working pile it is necessary to conduct the Initial Load test. The main

purpose of the load test is to determine ultimate load capacity of the pile. The scope of this

report is to discuss about the results of the initial load test PLT-1 & PLT-2 conducted and

decide on the further course of action to be taken to proceed for the construction of working

piles.

3. DESIGN PARAMETERS

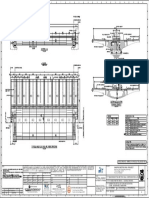

As per the IS:2911 Part-IV and the Employer’s requirement, 2 Nos of pile load tests within

2.1 km length of double Deck (Integrated) viaduct is envisaged. Based on the available

space at site, the initial load test PLT-1 for 1.2m dia pile was conducted near P77 (Between

Ch 16580 to 16600). PLT-2 was conducted at pier CP154 of 1.0m diameter for capacity of

530 Mton. The GT investigation of the relevant bore hole BH-26 and BH-50 respectively

was performed by Design Consortium and Indian Geotechnical Services. The bore hole

details are attached with this report as Annexure-A.

QAP (DDC-Structures) Page 3

Tuglakabad Corridor of Phase-IV of Delhi MRTS

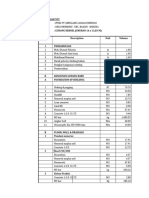

Basic parameters.

Sr. No Pile Load Water table Pile founding Soil classification

test depth

01 PLT-1 Not 24m below Silty clay with low to

Encountered cut off level medium plasticity (CL)

02 PLT-2 Not 25m below Stiff to hard Sandy Silt

Encountered cut off level of low plasticity (CL)

Although GWT is considered 11m below GL for all working piles, test pile is designed for

dry soil condition as the water table is not encountered in the bore holes.

Following are the design capacities calculated by the DDC and Design Consortium of 1.0m

dia and 1.2m dia test pile for 25m and 24m length, respectively.

Sr. Pile Pile GT Agency Pile capacity Pile Pile

No test dia recommended capacity capacity

by GT Agency calculated excluding

by DDC Selfweight

01 PLT-1 1.20 m Designer 827 MT 827 MT 796 MtT

Consortium

02 PLT-2 1.00 m Indian 532 MT 530 MT 508 MT

Geotechnical

Services

QAP (DDC-Structures) Page 4

Tuglakabad Corridor of Phase-IV of Delhi MRTS

4. PILE LOAD TEST AND PREPARATIONS

Initial pile load test has been performed as per the requirements of IS:2911 Part-IV. The

test pile was installed using the same technique as proposed for the working pile.

PLT-1:

Before starting the load test PLT-1, Pile Integrity test of the test pile was done on

21.08.2020 to ensure that the pile shaft is uniform and there are defects in the pile cross

section. The shaft is also checked for Cross Hole Analyser logging as an additional NDT on

pile. The results of PIT and sonic logging was satisfactory. Copy of the PIT, Sonic logging

tests and pour card is attached with this report.

Since the test pile is to be tested for 2.5x design pile capacity, it is ensured that the test

set up can withstand load of 1.25 x the test load. The test is carried out at the cut off level

of the pile. The load test was prepared for the load of 827 x 2.5 = 2068 tons.

It is to be noted that the capacity 827 MT includes self-weight of pile.

PLT-2:

The test pile of 1.0m diameter is to be tested for 2.5x 530MT = 1325 MT. It is ensured that

the test set up can withstand load of 1.25 x the test load. The test is carried out at the cut

off level of the pile.

Load to both the test pile is applied as per Maintained Load Method given in IS:2911 Part-

IV. Rate of application of load and measurement of settlement of loads is strictly observed

as per the IS code.

5. RESULTS

The pile load test was commenced on 23 August 2020 and completed on 24 August 2020.

IS:2911 has stipulated two criteria to arrive at the capacity of the pile. The safe load on

single pile for the initial load test should be least of the following:

a) Two-thirds of the final load at which the total displacement attains a value of 18mm for

pile dia greater than 0.6 m unless otherwise required in a given case on the basis of nature

QAP (DDC-Structures) Page 5

Tuglakabad Corridor of Phase-IV of Delhi MRTS

& type of structure in which case the safe load should be corresponding to the stated total

displacement.

b) 50 percent of the final load at which the total displacement equal to 10% of the pile

diameter in case of uniform pile diameter.

PLT-1:

As per the report submitted by Pinnacle Piling India (Pvt) Ltd, the allowable safe load on

1.2m dia pile for 24m length is 617 ton. This is lesser than the design pile capacity of 796

Mton (without selfweight). The load test report is submitted to DMRC for their reference.

The rebound of the pile was observed to be 9.46mm.

The NDT on test pile performed before the commencement of the initial load test was

satisfactory. The pour card submitted also confirms the volume of concrete as per the

drilled length of the shaft. The pile was also concreted continuously without a break. Hence

the reason for arriving lower capacity of pile is not ascertained.

The recommended load capacity of 617 ton will be adopted for the relevant foundations to

PLT-1.

PLT-2:

The initial load test on PLT-2 of 1.0m dia pile was conducted on 06 August 2020 and it was

completed on the same day.

Parameters discussed in the beginning of the same clause are also applicable for the safe

load of 1.0m dia initial load test. It was observed that the displacement of 7.64mm was

achieved at 40% (212 ton) of the working load of 530 Mton. On further increase in test

load to 41.85% (221.8 ton), there was a sudden increase in displacement of 90.65mm. The

test was continued till 109.52mm of settlement.

The PIT was carried out to the test pile. It was observed that Shaft cross section is not

uniform. The pile is found defected.

The failure of the test is mainly due to the improper casting of pile.

QAP (DDC-Structures) Page 6

Tuglakabad Corridor of Phase-IV of Delhi MRTS

It was decided to carry out new initial load test PLT-2A at between pier location CP155 for

530 MT. Borehole applicable will be same.

6. PROPOSAL

PLT-1:

The initial load test result suggests the pile capacity of 617 MT against design capacity of

796 MT. It is therefore felt necessary to conduct additional initial load test near P95 to

validate the design pile capacity.

The matter was discussed with DMRC and AECOM vide video conference dated 28-08-2020.

DMRC/AECOM agreed for additional load test. But also suggested to include additional tests

to maintain the consistency of the proposal for the length of integrated viaduct. Piers to be

divided into number of tests.

The additional pile locations are identified after visiting the site and checking the feasibility.

The statement showing the new load tests, its locations, and applicable piers for the design

of the sub structure is given in Annexure-B.

It was broadly discussed that;

Test results of PLT-1 will be extrapolated keeping maximum pile toe level (founding level

of pile) at 2 times the Dia of pile above bore investigation tip of 40.0m below GL. The

correction factor of 617/796 will be applied on the theoretical capacity calculation. These

results shall be applicable for sub structure of pier P72 to P92.

A new initial load test PLT-9 and PLT-10 is proposed at P95 and P53 respectively for 1.2m

dia pile. Results of PLT-9 shall be applicable for sub structure of pier P93 to P114. Whereas

results of PLT-10 shall be applicable for sub structure of pier P43 to P71.

Location of test pile PLT-3 proposed at Pier P123. Results of PLT-3 shall be applicable for

pier P115 to P131.

The maximum reaction will be restricted to 750 MT on 1.20 m dia pile.

QAP (DDC-Structures) Page 7

Tuglakabad Corridor of Phase-IV of Delhi MRTS

PLT-2:

Since the pile load test PLT-2 has failed at substantially lower settlement values, it is proposed to

carry out new initial load test PLT-2A at pier location CP155 for 530 MT.

QAP (DDC-Structures) Page 8

You might also like

- PAPER+ +Collapse+of+Soil+in+Pile+Bore+and+Its+Stabilisation+Using+Bentonite+SuspensionDocument9 pagesPAPER+ +Collapse+of+Soil+in+Pile+Bore+and+Its+Stabilisation+Using+Bentonite+SuspensionPrashanth Seshamani Iyer100% (1)

- Methodology of Static Pile Load TestDocument33 pagesMethodology of Static Pile Load Testraju_420034520100% (2)

- Routine Vertical Load Test Report For P-5 Conducted at KMMLDocument8 pagesRoutine Vertical Load Test Report For P-5 Conducted at KMMLshaaz v s mNo ratings yet

- Job Procedure For Pile Load TestDocument30 pagesJob Procedure For Pile Load Testpratimwhite100% (1)

- Pile Load Test ProcedureDocument24 pagesPile Load Test ProcedureRamkumar K100% (4)

- Kentledge of Pile Load TestDocument6 pagesKentledge of Pile Load Testkartick adhikary100% (7)

- Lateral Pile Load Test For PilesDocument8 pagesLateral Pile Load Test For PilesSubrahmanaya S Murthy TATA100% (3)

- (Paper) Launching Girders Risk ChecklistDocument4 pages(Paper) Launching Girders Risk ChecklistRAJENDRA PRASAD100% (2)

- Job Mix Formula For Cement Treated Sub Base: (IRC SP 89-2010)Document1 pageJob Mix Formula For Cement Treated Sub Base: (IRC SP 89-2010)Dwijendra Chanumolu100% (2)

- Methology For Mastic AshphaltDocument6 pagesMethology For Mastic Ashphaltvenkateswara rao PothinaNo ratings yet

- IRC78-2014 B-3 Appendix-9 Bi-Axial Load Testing of Piles - Draft 27-10-2017 PDFDocument22 pagesIRC78-2014 B-3 Appendix-9 Bi-Axial Load Testing of Piles - Draft 27-10-2017 PDFHemant YesajiNo ratings yet

- Vertical Load Test - Design - 2-1Document7 pagesVertical Load Test - Design - 2-1Abir Sengupta100% (1)

- Project On Sugarcane BaggasseDocument26 pagesProject On Sugarcane BaggasseV Deepak Kumar75% (4)

- Dynamic Load Test 1200mm DiaDocument6 pagesDynamic Load Test 1200mm DiaVB665100% (1)

- Pile Load Test Methodology - Kentledge Method - Cyclic-RoutineDocument10 pagesPile Load Test Methodology - Kentledge Method - Cyclic-RoutineHarshit DubeyNo ratings yet

- Test Pile MethodologyDocument7 pagesTest Pile MethodologyCOME TO KNOWNo ratings yet

- Pile Load Test PDFDocument11 pagesPile Load Test PDFAjit P. SinghNo ratings yet

- Lateral Load Test Methodology and Design For Agra-TundlaDocument13 pagesLateral Load Test Methodology and Design For Agra-Tundlabp chaudharuNo ratings yet

- Pile Load Test MethodologyDocument4 pagesPile Load Test MethodologyAkhilesh Dwivedi100% (1)

- Methodology For Verticial Initial Cyclic Load Test by Reaction MethodDocument4 pagesMethodology For Verticial Initial Cyclic Load Test by Reaction MethodvivekNo ratings yet

- Anchor Pile Load Test MethodologyDocument11 pagesAnchor Pile Load Test MethodologyHegdeVenugopal50% (4)

- SOP of Pull Out, Lateral & Compression - REV01Document8 pagesSOP of Pull Out, Lateral & Compression - REV01Prince MittalNo ratings yet

- Kentledge DetailsDocument3 pagesKentledge DetailsAbir Sengupta100% (2)

- Method Statement of Routine Pile Load Test (Dynamic)Document3 pagesMethod Statement of Routine Pile Load Test (Dynamic)Akhilesh Dwivedi100% (2)

- WMM Mix DesignDocument23 pagesWMM Mix DesignjanardangaurNo ratings yet

- Initial Pile Load Test Report Anchor MethodDocument8 pagesInitial Pile Load Test Report Anchor MethodShakti SharmaNo ratings yet

- Plate Load Test at InaruwaDocument34 pagesPlate Load Test at InaruwaSushant Giri100% (1)

- Method Statement For Conducting High Strain Dynamic Pile Testing of 1200Mm Dia R.C. Bored PilesDocument6 pagesMethod Statement For Conducting High Strain Dynamic Pile Testing of 1200Mm Dia R.C. Bored PilesFaisal RizwanNo ratings yet

- Pile Load Test Procedure-2Document9 pagesPile Load Test Procedure-2S GoudaNo ratings yet

- Methodology For PQC (00) Toll Plaza L&TDocument4 pagesMethodology For PQC (00) Toll Plaza L&TDeven PatleNo ratings yet

- Checklist For Bored Cast In-Situ Piles ReniforcmentDocument4 pagesChecklist For Bored Cast In-Situ Piles ReniforcmentSureshKumarNo ratings yet

- Methodology Well Foundation (R3)Document14 pagesMethodology Well Foundation (R3)jitendra100% (3)

- BBS For Test Pile-03 at OMG - 1000mm DiaDocument5 pagesBBS For Test Pile-03 at OMG - 1000mm DiaAjay MalikNo ratings yet

- What Are The Requirements of Bentonite (Powder and Suspension) Used in Piling Work As Per IS-2911Document2 pagesWhat Are The Requirements of Bentonite (Powder and Suspension) Used in Piling Work As Per IS-2911Pritha DasNo ratings yet

- Cast-In-Situ Bored Piling Works by ConventionalMethod1Document11 pagesCast-In-Situ Bored Piling Works by ConventionalMethod1jitendraNo ratings yet

- Load Test Load Calculations & ChartDocument12 pagesLoad Test Load Calculations & ChartHegdeVenugopalNo ratings yet

- Precast Pier Cap 01Document1 pagePrecast Pier Cap 01Gajendra Bisht100% (1)

- Pile Load Test Procedure-1Document5 pagesPile Load Test Procedure-1S GoudaNo ratings yet

- Indian HighwaysDocument95 pagesIndian HighwaysTLOFFICE PATNANo ratings yet

- Vertical Pile Load Test (Sabarmati Station Building)Document9 pagesVertical Pile Load Test (Sabarmati Station Building)Vipin Kumar ParasharNo ratings yet

- Method Statement For Construction of PilesDocument27 pagesMethod Statement For Construction of PilesShakti Sharma100% (1)

- Report On Vertical Pile Load TestDocument39 pagesReport On Vertical Pile Load TestTest EngineerNo ratings yet

- Directorate General Border Roads Directorate General Border Roads Directorate General Border RoadsDocument14 pagesDirectorate General Border Roads Directorate General Border Roads Directorate General Border RoadsAaron WilsonNo ratings yet

- 26.05.2021-METHOD STATEMENT - VERTICAL LOAD TEST by Anchor MethodDocument16 pages26.05.2021-METHOD STATEMENT - VERTICAL LOAD TEST by Anchor MethodpdksubudhiNo ratings yet

- Danta - Lateral Load Test Report Final-05.01.24Document18 pagesDanta - Lateral Load Test Report Final-05.01.24Deepak avinashNo ratings yet

- Launching Girder Assembly ChecklistDocument3 pagesLaunching Girder Assembly ChecklistWan Noor AzirahNo ratings yet

- SOP Pile Load Test PDFDocument5 pagesSOP Pile Load Test PDFSoigne Consultants100% (2)

- MBIU Report Gorakhpur BypassDocument167 pagesMBIU Report Gorakhpur BypassRaghav SharmaNo ratings yet

- 51) CASE STUDY - Design and Installation of Driven Piles For High Rise Building PDFDocument134 pages51) CASE STUDY - Design and Installation of Driven Piles For High Rise Building PDFGV RamasubbaraoNo ratings yet

- Methodology of UPVDocument3 pagesMethodology of UPVAnonymous eKt1FCDNo ratings yet

- Method Statement For Construction of Bored Cast In-Situ Piles Using Mechanical Rotary RigDocument5 pagesMethod Statement For Construction of Bored Cast In-Situ Piles Using Mechanical Rotary RigVijay Jamadar100% (2)

- Larsen & Toubro Limited - Ecc Division: Page 1 of 4Document4 pagesLarsen & Toubro Limited - Ecc Division: Page 1 of 4Akhilesh DwivediNo ratings yet

- Pile Dynamic Test MethodologyDocument3 pagesPile Dynamic Test Methodologykom1984No ratings yet

- Irc 78 2014 PDFDocument100 pagesIrc 78 2014 PDFRajen KoleyNo ratings yet

- Bridge Load TestDocument4 pagesBridge Load Testvivek100% (1)

- CC Road PDFDocument222 pagesCC Road PDFPhani PitchikaNo ratings yet

- Pile Load TestDocument4 pagesPile Load TestRitesh Dahiya100% (1)

- A Revolution To Stop Punching of Anchor Cone in PSC Girder 1659263632Document13 pagesA Revolution To Stop Punching of Anchor Cone in PSC Girder 1659263632Sanjay MishraNo ratings yet

- Bridge Evaluation Report - 87m - R1Document15 pagesBridge Evaluation Report - 87m - R1hari om sharmaNo ratings yet

- JV of Shirish Patel & Associates Consultants PVT Limited & Indus Consultrans PVT LTDDocument540 pagesJV of Shirish Patel & Associates Consultants PVT Limited & Indus Consultrans PVT LTDarif_rubin100% (1)

- WMS-002 Pile Driving by Pile-Driving Barge REV.ADocument136 pagesWMS-002 Pile Driving by Pile-Driving Barge REV.AVan Cuong PhamNo ratings yet

- DBR VupDocument15 pagesDBR Vuparif_rubinNo ratings yet

- Costing - 2021-2022 - 28.072023Document804 pagesCosting - 2021-2022 - 28.072023arif_rubinNo ratings yet

- Design of 4L 31.25m SpanDocument1 pageDesign of 4L 31.25m Spanarif_rubinNo ratings yet

- AASHTO Hook DetailDocument1 pageAASHTO Hook Detailarif_rubinNo ratings yet

- Yfc Project PVT Ltd. DMRC: JV of Shirish Patel & Associates Consultants PVT Limited & Indus Consultrans PVT LTDDocument2 pagesYfc Project PVT Ltd. DMRC: JV of Shirish Patel & Associates Consultants PVT Limited & Indus Consultrans PVT LTDarif_rubinNo ratings yet

- Schedule of Bearing Load (31M Span & R 420M)Document1 pageSchedule of Bearing Load (31M Span & R 420M)arif_rubinNo ratings yet

- JV of Shirish Patel & Associates Consultants PVT Limited & Indus Consultrans PVT LTDDocument540 pagesJV of Shirish Patel & Associates Consultants PVT Limited & Indus Consultrans PVT LTDarif_rubin100% (1)

- 31.25m 4L Concrete Dime DRG - 1Document1 page31.25m 4L Concrete Dime DRG - 1arif_rubinNo ratings yet

- 31.25m 4L Concrete Dime DRG - 1Document1 page31.25m 4L Concrete Dime DRG - 1arif_rubinNo ratings yet

- Nagpur Metro Rail Project: Systra-Aecom-Egis-RitesDocument1 pageNagpur Metro Rail Project: Systra-Aecom-Egis-Ritesarif_rubinNo ratings yet

- Nagpur Metro Rail Project: Systra-Aecom-Egis-RitesDocument1 pageNagpur Metro Rail Project: Systra-Aecom-Egis-Ritesarif_rubinNo ratings yet

- 4L BOx Girder Concrete Dimension DRGDocument1 page4L BOx Girder Concrete Dimension DRGarif_rubinNo ratings yet

- Appendix A: Dead Load & Sidl Load Calculation: SPAN-1 SPAN-2Document2 pagesAppendix A: Dead Load & Sidl Load Calculation: SPAN-1 SPAN-2arif_rubin50% (2)

- Double Deck Substructure Design ReportDocument280 pagesDouble Deck Substructure Design Reportarif_rubin100% (4)

- Ground Water Table Value As Per CGWB Data: (Refer Appendix A)Document1 pageGround Water Table Value As Per CGWB Data: (Refer Appendix A)arif_rubinNo ratings yet

- Appendix A: Dead Load & Sidl Load Calculation: SPAN-1 SPAN-2Document2 pagesAppendix A: Dead Load & Sidl Load Calculation: SPAN-1 SPAN-2arif_rubin50% (2)

- Pile Capacity in Granular SoilDocument7 pagesPile Capacity in Granular Soilarif_rubinNo ratings yet

- Appendix EDocument51 pagesAppendix Earif_rubinNo ratings yet

- Pres Tress I-Girder Design SheetDocument70 pagesPres Tress I-Girder Design Sheetarif_rubinNo ratings yet

- Appendix G PDFDocument1 pageAppendix G PDFarif_rubinNo ratings yet

- Appendix DDocument63 pagesAppendix Darif_rubinNo ratings yet

- Appendix H PDFDocument59 pagesAppendix H PDFarif_rubinNo ratings yet

- Spine Girder - Prestress DesignDocument109 pagesSpine Girder - Prestress Designarif_rubinNo ratings yet

- Appendix H PDFDocument59 pagesAppendix H PDFarif_rubinNo ratings yet

- BuildTech - Development of Construction TechnologiesDocument10 pagesBuildTech - Development of Construction TechnologiesSheena BasmayorNo ratings yet

- Concrete Morter Cube QC 452 - 2, 7, 28 D - Strength 15-10-2020 PDFDocument1 pageConcrete Morter Cube QC 452 - 2, 7, 28 D - Strength 15-10-2020 PDFjajajajNo ratings yet

- Lifting EquipmentDocument82 pagesLifting Equipmentchandrahas reddyNo ratings yet

- Selecting Non-Metallic Com-Ponents For API Separators: Water SolutionsDocument1 pageSelecting Non-Metallic Com-Ponents For API Separators: Water SolutionsGladys Gabriela Quispe RamosNo ratings yet

- Solar Chimney: AbstractDocument1 pageSolar Chimney: AbstractRikki RevsNo ratings yet

- The Nickel Advantage in Duplex Stainless SteelsDocument15 pagesThe Nickel Advantage in Duplex Stainless SteelsgullenariNo ratings yet

- An Experimental and Characteristic Study of Abaca Fiber ConcreteDocument10 pagesAn Experimental and Characteristic Study of Abaca Fiber ConcreteAika LorenNo ratings yet

- RX Screw CataloguesDocument2 pagesRX Screw CataloguesPuppala Laxmana PrasadNo ratings yet

- Comment - EEP Procurement Manual - Mgmt-Aa - RevisedDocument150 pagesComment - EEP Procurement Manual - Mgmt-Aa - RevisedBelay TadesseNo ratings yet

- Upah Borongan Civil Gudang KCP GCMDocument6 pagesUpah Borongan Civil Gudang KCP GCMRahardi HardNo ratings yet

- Anatomy of Boiler FailureDocument19 pagesAnatomy of Boiler Failureکاشف ساقیNo ratings yet

- Environmental and Social Action Plan (ESAP) (Draft)Document24 pagesEnvironmental and Social Action Plan (ESAP) (Draft)GeoVakNo ratings yet

- PLATE 01 Design 04Document3 pagesPLATE 01 Design 04Jerame BruceNo ratings yet

- Fire Pump Shut Off Operation 1682811247Document11 pagesFire Pump Shut Off Operation 1682811247Faisal AlotaibiNo ratings yet

- Tipolo WH Gantt ChartDocument15 pagesTipolo WH Gantt ChartMayeterisk RNo ratings yet

- Cob, A Vernacular Earth Construction Process in The Context of Modern Sustainable BuildingDocument17 pagesCob, A Vernacular Earth Construction Process in The Context of Modern Sustainable BuildingMilena Vallone PottNo ratings yet

- Agap2 Group OverviewDocument15 pagesAgap2 Group OverviewharidileepNo ratings yet

- Road Map For Digital Design and ConstructionDocument20 pagesRoad Map For Digital Design and ConstructionSyl Vain RissNo ratings yet

- Structural Design and Detailed Drawing of A Steel Industrial Building - 510418108 - Debayan GhoshDocument67 pagesStructural Design and Detailed Drawing of A Steel Industrial Building - 510418108 - Debayan GhoshhelloNo ratings yet

- Notes Api650Document6 pagesNotes Api650MasoodMiyanNo ratings yet

- Final Draft Report of Building Bye-Laws FrameworkDocument58 pagesFinal Draft Report of Building Bye-Laws FrameworkRabindra Dawadi100% (6)

- 13 Tooling, Screws and ConsumablesDocument39 pages13 Tooling, Screws and ConsumablesngotiensiNo ratings yet

- Math PTDocument17 pagesMath PT• C O L E •No ratings yet

- Data Schedule - 12CX2.5MM2 - XVC7VDocument5 pagesData Schedule - 12CX2.5MM2 - XVC7VBurhan SharafNo ratings yet

- Section Iii Design Criteria FOR Potable Water Distribution SystemsDocument10 pagesSection Iii Design Criteria FOR Potable Water Distribution SystemsRamces SolimanNo ratings yet

- Diploma in Construction and Real Estate Project ManagementDocument1 pageDiploma in Construction and Real Estate Project ManagementberrezegNo ratings yet

- HARDWAREDocument32 pagesHARDWARE20021155567% (3)

- P O R T F O L I O: Manthan ManoharDocument29 pagesP O R T F O L I O: Manthan ManoharManthan ManoharNo ratings yet