Professional Documents

Culture Documents

2638D - Snap Ring Gasket Composite

2638D - Snap Ring Gasket Composite

Uploaded by

Rocio AriasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2638D - Snap Ring Gasket Composite

2638D - Snap Ring Gasket Composite

Uploaded by

Rocio AriasCopyright:

Available Formats

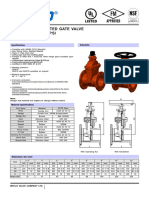

NEW ITEM CROSS O.D. PART CUT LENGTHS NEW ITEM CROSS O.D.

PART CUT LENGTHS

SEC. 10 NO.

REFERENCE

SECTION TO FIT * TO EQUAL

GIW PUMPS

NO.

REFERENCE

SECTION TO FIT * TO EQUAL

GIW PUMPS

8243P 8231P "B" 53.700 168 23/32 LSA-54 ADJUSTABLE LINER

4.432 10

8244P 8241P "E" 41.250 128 3/4 LSA-36 (HD) ADJUSTABLE LINER

A 8245P 8202P "E" 21.500 67 LSA-21 ADJUSTABLE LINER

10

8246P 8125P "E" 31.972 99 3/4 LSA-32 ADJUSTABLE LINER

8247P 8240P "A" 70.065 218 21/32 LSA-64 (HD) ADJUSTABLE LINER

1.345 +.045

+.060

-.000

4.500 8248P 8208P "B" 41.9375 130 7/8 MDX-350 PUMP

.020

.564 +.045

-.000

-.000

8249P 8126P "E" 36.237 113 MDX-300 PUMP

8250P 8127P "A" 48.500 151 1/4 LSA-48 (HD) ADJUSTABLE LINER

8251P 8239P "A" 53.977 168 7/16 MDX-500 PUMP

10

8252P 8242P "B" 55.100 171 59/64 MDX-400 PUMP

10 8253P 8203P "B" 44.939 140 1/4 LSA-44 ADJUSTABLE LINER

2.985

8254P 8149P "A" 39.478 123 1/4 LSA-40 ADJUSTABLE LINER

B

10

8258P 8257P "E" 28.045 87 1/2 MDX-150 PUMP

8259P 8255P "E" 35.398 110 15/32 MDX-200 PUMP

1.113 +.045

+.060

-.000

3.031 8261P 8260P "B" 67.000 209 3/32 MDX-550 PUMP

.020

.587 +.045

-.000

-.000

8262P 8256P "A" 93.250 291 MDX-750 PUMP

8263P 8264P "B" 63.500 198 5/32 MDX-450 PUMP

8266P - 3 1/32 "B" 46.500 145 1/8 LSA-42

10 8268P 8122P "E" 25.222 78 3/4 LSA-25 ADJUSTABLE LINER

10 8269P - 4 1/2 "A" 85.660 267 5/16 28 TBC-84

2.893

C 8271P 8229P 4 1/2 "A" 53.740 167 11/16 WBC-54 ADJUSTABLE LINER

10

8272P - "E" 31.478 98 15/64 MDX-200X225 PUMP

.978 +.030

+.040

-.000

2.938

.468 +.030

-.000

-.000

.020

10

10

3.016 10

D

FOR GIW ENGINEERING USE ONLY

.691 +.030

-.000

+.040

3.063 NOTE: SNAP RING GASKETS CUT TO LENGTH SO AS TO HAVE

.159 +.030

.020

-.000

-.000

1/4" STRETCH IN CIRCUMFERENCE PER FOOT OF DIA.

FORMULA:

STEP 1. (C = πD) = CIRCUMFERENCE (FOR INITIAL DESIGN)

2. O.D. PART (*) ÷ 12 = A

3. .250 X A = B

10

10 10 4. CIRCUMFERENCE - B = CUT LENGTH

2.216 (a + b)h

E AREA OF GASKET = + tL

10

2

h = (COS 10 )L h

.550 +.030

t

COS 10 = .98481

-.000

+.040

a

2.250

.159 +.030

.020

-.000

b

-.000

NOTE: DIMENSIONS a&b

DO NOT INCLUDE t

L

CALCULATION IN EDG 16

.333 +.030

REV CLEANUP/REDRAWN IN NX, ADDED ITEM

-.000

NOTES: 14 FEB 2014 O NAN LRP

NO. 8272P

DATE REVISION REV BY APPR

10 10 1. GASKET NO. AND "OUTSIDE" STENCILED IN BOLD PRINT

1.231 TEFLON-LINED SNAP RING GASKET,

ON OUTSIDE SURFACE OF GASKET.

COMPOSITE

F 2. CONSULT SHOP ORDER FOR MATERIAL REQUIREMENTS.

3. SEE 2629D FOR REGULAR SNAP RING GASKETS.

.550 +.030

-.000

CONFIDENTIAL Grovetown, Georgia USA

10

THIS IS AN UNPUBLISHED MANUSCRIPT WHICH CONTAINS VALUABLE TRADE A KSB Company

KSB

.020

SECRET INFORMATION AND IS ONLY CONDITIONALLY ISSUED, NEITHER

+.040 RECEIPT NOR POSSESSION THEREOF CONFERS OR TRANSFERS ANY RIGHT

SHEET 1 OF 1

1.250 OR TECHNICAL INFORMATION SHOWN THEREIN, NOR ANY RIGHT TO DISCLOSE DRAWN MSA REF: 2629D

-.000 OR TRANSFER THE SAME TO ANY THIRD PARTY OR TO REPRODUCE THIS

DRAWING (DOCUMENT) OR ANY PART THEREOF UNLESS BY WRITTEN AGREEMENT APPROVED

IN OR LICENSE TO USE THE SUBJECT MATTER THEREOF, OR ANY DESIGN

WITH OR WRITTEN PERMISSION FROM THE OWNER, GIW INDUSTRIES, INC DATE 25 JAN 2008

NO: 2638D

BASIC MATERIAL STANDARD March 2013

D2000 GR 2AA414A13B13EA14F17-PTFE

WSZ

W053

Previous GIW Material Code: 01RUT

1 Material Specification

Material to have Teflon lined material along inner diameter of the gasket material. Vendor and material to be

Engineering approved.

Vendor to indicate part number and “OUTSIDE” on proper gasket surface.

Temperature and chemical limits of neoprene shall be considered in application.

ASTM D-2000, 2AA414A13B13EA14F17

Neoprene

Type A

Class A

40 Shore A

2031 psi minimum tear strength

400% minimum elongation

Heat Resistance (Test Method D395, 70 hours at 70°C):

Max. Change in hardness: ±15 Shore A points

Copyright to ISO 16016

Max. Change in tensile strength: ±30%

Max. Change in ultimate elongation: -50%

Compression Set

Test Method D395, Method B, 22 hours at 70°C: Max. Change: 12.8%

Water Resistance

Test Method D471, 70 hours at 100°C: Max. Volume Change: 10%

Low-temperature resistance

Test Method D2137, method C, 9.3.3: Non-brittle after 3 minutes at -40°C (pass/fail): Pass

2 References

SYNA-FLEX Compound #1434 Blended Neoprene or Engineering approved equal.

Wedge shaped circular gasket used to seal suction or hub plates to shell in LSA style pump assemblies.

See MSDS for any safety information

KSB GIW Industries, Inc. Engineering (Leland Curtiss)

You might also like

- Mesin Brondol Sawit-1Document1 pageMesin Brondol Sawit-1dd yonoNo ratings yet

- Certificacion UL 1741 IEEE 15 47 Sunny Boy-UsDocument2 pagesCertificacion UL 1741 IEEE 15 47 Sunny Boy-UsYoslin RuizNo ratings yet

- T9 Series Electrical Schematic - 84416543Document6 pagesT9 Series Electrical Schematic - 84416543alexNo ratings yet

- LA-A961Pgoliad MLK 14 Uma Dock A00 1007Document53 pagesLA-A961Pgoliad MLK 14 Uma Dock A00 1007Yusuf CokNo ratings yet

- Parts Catalog Correction 1Document2 pagesParts Catalog Correction 1theBAUNo ratings yet

- Clarion Eqs746 SM PDFDocument9 pagesClarion Eqs746 SM PDFJavierNieblaNo ratings yet

- Heiden RotatorsGR104DBDocument3 pagesHeiden RotatorsGR104DBsssydorenko100% (1)

- VT 11075Document4 pagesVT 11075horcsabNo ratings yet

- Assesment of Risks From High Pressure Natural Gas PipeleinesDocument62 pagesAssesment of Risks From High Pressure Natural Gas Pipeleinesthawdar100% (1)

- Data Sheet - DPX3 - 630 - MT - ENGv1.3 PDFDocument13 pagesData Sheet - DPX3 - 630 - MT - ENGv1.3 PDFEdwin Armando Abella P.No ratings yet

- Manual RM KLV400 ENG ITADocument4 pagesManual RM KLV400 ENG ITAPhilippe ANGELOTNo ratings yet

- Samsung Bn41-02079a Bn41-02295a Ua32f4088ar Ua32f4088aj Power Pus SCHDocument1 pageSamsung Bn41-02079a Bn41-02295a Ua32f4088ar Ua32f4088aj Power Pus SCHgrigor-yuraNo ratings yet

- Fisher Controls: Tight Shutoff-Throttling-sleeve Design With TFEDocument14 pagesFisher Controls: Tight Shutoff-Throttling-sleeve Design With TFEfiguev2208No ratings yet

- BN44 00353a PDFDocument3 pagesBN44 00353a PDFFabio Pedroso de MoraisNo ratings yet

- g3.. Gear Pump..Re10039Document10 pagesg3.. Gear Pump..Re10039vijayramchandra88No ratings yet

- Cable Connectors To RMUDocument10 pagesCable Connectors To RMUSaqib RasoolNo ratings yet

- Service Manual (Supplement) Colour Television: Model No. CP21EF1Document16 pagesService Manual (Supplement) Colour Television: Model No. CP21EF1ReneNo ratings yet

- Carvin Schematic - TS100CDocument1 pageCarvin Schematic - TS100CdodNo ratings yet

- Casio Standard/Desktop/Scientific CalculatorsDocument2 pagesCasio Standard/Desktop/Scientific CalculatorsNathaniel Lumpas EvangelistaNo ratings yet

- PDF Created With Fineprint Pdffactory Trial Version: L1 R1 R2 R3 L2Document3 pagesPDF Created With Fineprint Pdffactory Trial Version: L1 R1 R2 R3 L2redovidiuNo ratings yet

- SPC Avenger 220 Cruise Street Abs Rev 26 Dec 19Document91 pagesSPC Avenger 220 Cruise Street Abs Rev 26 Dec 19Bharat MalviyaNo ratings yet

- 5kab PCDocument49 pages5kab PCsitaramsahandsonsNo ratings yet

- 40-Ipl32l-Pwg1xg China Psu PDFDocument3 pages40-Ipl32l-Pwg1xg China Psu PDFAlessandro Bonifacio Bonifacio100% (1)

- Protistor FusiblesDocument16 pagesProtistor FusiblesEdgar Sierra RodriguezNo ratings yet

- Mesin Brondol Sawit-4Document1 pageMesin Brondol Sawit-4dd yonoNo ratings yet

- Lift Arms & BOB-TACH - S220Document3 pagesLift Arms & BOB-TACH - S220joanvasquez61No ratings yet

- Alfa 50 RegulatorDocument2 pagesAlfa 50 Regulatorykoze100% (1)

- RX-V1700 Service ManualDocument162 pagesRX-V1700 Service ManualBCSchoolNo ratings yet

- Jockey V1 125 Fi V1 (Sj25he)Document127 pagesJockey V1 125 Fi V1 (Sj25he)milcaNo ratings yet

- Legrand Main Price List April 2023Document268 pagesLegrand Main Price List April 2023anuvindanuvindNo ratings yet

- RVR M2HC5-1010NS RVRDocument45 pagesRVR M2HC5-1010NS RVRJan-Willem SloetjesNo ratings yet

- Sin Amp: Capacitors Parts List Resistors PotsDocument1 pageSin Amp: Capacitors Parts List Resistors PotsMilan ZlatanovicNo ratings yet

- f0211 300 NP FLG X FLG Data SheetDocument1 pagef0211 300 NP FLG X FLG Data SheetRay LujanNo ratings yet

- Sanken IC Regulators (2000)Document354 pagesSanken IC Regulators (2000)PelotaDeTrapoNo ratings yet

- FONTE24V2ADocument1 pageFONTE24V2AFábio Menezes100% (1)

- Triode Electronics Aa764 Champ Layout: 5Y3GT 6V6GT 12AX7Document1 pageTriode Electronics Aa764 Champ Layout: 5Y3GT 6V6GT 12AX7Sergio RiveroNo ratings yet

- Kenwood Ka-7100 SCH PDFDocument3 pagesKenwood Ka-7100 SCH PDFDuy Tuan NguyenNo ratings yet

- Yamaha RX-V2400 SchematicDocument19 pagesYamaha RX-V2400 Schematicp_oneNo ratings yet

- Consumable Parts - I-C - AmadaDocument6 pagesConsumable Parts - I-C - AmadaShyam JanardhananNo ratings yet

- Hydraulic Hand PumpDocument7 pagesHydraulic Hand Pumpcrni rokoNo ratings yet

- A Simple Horizontal Mill Steam Engine With Slide Valve by H.Muncaster. Notes, Parts and AssembliesDocument1 pageA Simple Horizontal Mill Steam Engine With Slide Valve by H.Muncaster. Notes, Parts and AssembliesStojan Pece CmarNo ratings yet

- Yamaha RX v350 HTR 5730Document74 pagesYamaha RX v350 HTR 5730domisoft100% (1)

- SK Product HandbookDocument110 pagesSK Product Handbooksupriyo110No ratings yet

- Zakon o Javnim PutevimaDocument4 pagesZakon o Javnim PutevimaVladimir ĐorđevićNo ratings yet

- SM-A015A SVC (Phonelumi - Com)Document42 pagesSM-A015A SVC (Phonelumi - Com)Abdallah AL-ObideNo ratings yet

- Brosur Pompa DS Dan DVSDocument4 pagesBrosur Pompa DS Dan DVSBilly Christovel100% (1)

- Yamaha rxv671 PDFDocument171 pagesYamaha rxv671 PDFAnuraEdirisingheNo ratings yet

- Price List Wasser Pump (2016.07.01)Document1 pagePrice List Wasser Pump (2016.07.01)kosasih aji somantri100% (1)

- RVR M2GPSRXNV-0110NS RVRDocument12 pagesRVR M2GPSRXNV-0110NS RVRJan-Willem SloetjesNo ratings yet

- 653Document127 pages653dailynote2004No ratings yet

- Infineon-Design Guide Boost Type CCM PFC ICE3PCSxx-AN-v02 00-EN PDFDocument26 pagesInfineon-Design Guide Boost Type CCM PFC ICE3PCSxx-AN-v02 00-EN PDFThai Anh NguyenNo ratings yet

- A51 A52 CylinderDocument6 pagesA51 A52 CylinderBiswanath LenkaNo ratings yet

- Legrand Inter Detector Dual 048806Document4 pagesLegrand Inter Detector Dual 048806FranciscoOlivaNo ratings yet

- Alarm ListDocument74 pagesAlarm ListLee TyNo ratings yet

- Cooling Fan Motor Kit - S650Document2 pagesCooling Fan Motor Kit - S650Edmundas ŽemaitisNo ratings yet

- Lithonia Downlighting Contractors Buyers Guide 1985Document62 pagesLithonia Downlighting Contractors Buyers Guide 1985Alan MastersNo ratings yet

- Parts Catalogue: ScootersDocument118 pagesParts Catalogue: Scooters黃錦秀No ratings yet

- RCU说明书美加Document9 pagesRCU说明书美加Andrea Chavez MurilloNo ratings yet

- Both Sides: Revisions ECN Rev. Description Date Revised by A Release 5/2/19 B Relocating Missign Components 3/10/2022 BXSDocument5 pagesBoth Sides: Revisions ECN Rev. Description Date Revised by A Release 5/2/19 B Relocating Missign Components 3/10/2022 BXSSteve SitkoNo ratings yet

- RB 624590 007Document1 pageRB 624590 007Er Md AamirNo ratings yet

- Contoh Uji Validitas & Reliabilitas PDFDocument5 pagesContoh Uji Validitas & Reliabilitas PDFnisa auliaNo ratings yet

- Module 1 - Nomenclature of Organic Compounds Lab 1Document6 pagesModule 1 - Nomenclature of Organic Compounds Lab 1Nelzen GarayNo ratings yet

- Activation Energy: - The Arrhenius EquationDocument19 pagesActivation Energy: - The Arrhenius EquationemilyNo ratings yet

- 4.negative and Zero SequenceDocument6 pages4.negative and Zero Sequencebalaer0550% (2)

- 2 Simulating A Diesel Engine Using A Sector Mesh: Data ProvidedDocument16 pages2 Simulating A Diesel Engine Using A Sector Mesh: Data ProvidedmohanNo ratings yet

- OP Flash DistillationDocument11 pagesOP Flash DistillationDylan Navarro LNo ratings yet

- Grading Rubric TitrationDocument2 pagesGrading Rubric Titrationapi-205419744No ratings yet

- 14.udemy S4hana Course MaterialDocument53 pages14.udemy S4hana Course MaterialArben LaçiNo ratings yet

- Large-Break Loss-Of-Coolant Accident PDFDocument11 pagesLarge-Break Loss-Of-Coolant Accident PDFThiago RobertoNo ratings yet

- Frequently Asked Questions: Orientation Related QuestionDocument31 pagesFrequently Asked Questions: Orientation Related QuestionMiguel Moreno EstévezNo ratings yet

- (Proceedings of Symposia in Pure Mathematics 98) Amir-Kian Kashani-Poor, Ruben Minasian, Nikita Nekrasov, Boris Pioline, Editors-String-Math 2016-American Mathematical Society (2018) PDFDocument314 pages(Proceedings of Symposia in Pure Mathematics 98) Amir-Kian Kashani-Poor, Ruben Minasian, Nikita Nekrasov, Boris Pioline, Editors-String-Math 2016-American Mathematical Society (2018) PDFLav100% (1)

- (Komonov EtAL) Geochem Methods of ProspectingDocument412 pages(Komonov EtAL) Geochem Methods of Prospectingjavicol70No ratings yet

- Statistics and Probability (Quarter Iii, Week 1) Random Variables & Probability DistributionsDocument6 pagesStatistics and Probability (Quarter Iii, Week 1) Random Variables & Probability DistributionsJacqueline Trinidad DeeNo ratings yet

- Determinacion Del Indice de Peróxido ISO 3960Document15 pagesDeterminacion Del Indice de Peróxido ISO 3960ELIZABETHNo ratings yet

- Doors EntryDocument4 pagesDoors EntryAndrea Nicola TurcatoNo ratings yet

- OOVHDL: Object Oriented VHDLDocument6 pagesOOVHDL: Object Oriented VHDLNadir HammadiNo ratings yet

- Intranet ChattingDocument37 pagesIntranet ChattingSubrat Patnaik67% (3)

- Gross Tonnage CalculatorDocument3 pagesGross Tonnage CalculatorSanderNo ratings yet

- AISI 1050 Steel, As RolledDocument2 pagesAISI 1050 Steel, As RolledCristobal Gutierrez CarrascoNo ratings yet

- Emergency Braking SystemDocument4 pagesEmergency Braking Systemieee4mybusinessonlyNo ratings yet

- 2017 Catalog 99812723Document508 pages2017 Catalog 99812723Valco0% (1)

- PracticeProbs (5 - 27 - 07) - CMOS Analog ICs PDFDocument70 pagesPracticeProbs (5 - 27 - 07) - CMOS Analog ICs PDFmyluvahanNo ratings yet

- Liebherr Hs 855 With Hydraulic Slurry Wall Grab EnglishDocument12 pagesLiebherr Hs 855 With Hydraulic Slurry Wall Grab EnglishMary JeanNo ratings yet

- Linear Encoder For CNC Machine and High Accuracy ApplicationsDocument40 pagesLinear Encoder For CNC Machine and High Accuracy ApplicationsMikael BogrenNo ratings yet

- Problemas CompletosDocument16 pagesProblemas CompletosakksNo ratings yet

- T SB 0051 09Document3 pagesT SB 0051 09goombaNo ratings yet

- Limit States Design of Crane Runway GirdersDocument7 pagesLimit States Design of Crane Runway GirdersRatna YanuarNo ratings yet

- Dwnload Full Precalculus Mathematics For Calculus 6th Edition Stewart Test Bank PDFDocument35 pagesDwnload Full Precalculus Mathematics For Calculus 6th Edition Stewart Test Bank PDFkyackvicary.n62kje100% (14)

- Poster-SGT-800-ENG-230127-pdf - Original FileDocument2 pagesPoster-SGT-800-ENG-230127-pdf - Original FileSBNo ratings yet