Professional Documents

Culture Documents

Collapse of The Giotto Avenue Building in Foggia

Collapse of The Giotto Avenue Building in Foggia

Uploaded by

Mauricio Benitez AlvarezCopyright:

Available Formats

You might also like

- Prestressed-Precast Design SpreadsheetDocument6 pagesPrestressed-Precast Design SpreadsheetCivilax.com100% (3)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Single Phase Half Wave Controlled ConverterDocument7 pagesSingle Phase Half Wave Controlled ConverterAlexNo ratings yet

- Building Failure - Causes and Case StudiesDocument14 pagesBuilding Failure - Causes and Case Studiesresha bhatiaNo ratings yet

- Gujarat Technological Univercity: C.K. Pithawala College of Engineering & TechnologyDocument17 pagesGujarat Technological Univercity: C.K. Pithawala College of Engineering & TechnologyParth AnajwalaNo ratings yet

- Lab Report HighwayDocument5 pagesLab Report HighwayNora NorazisahNo ratings yet

- Building Collapse ReportDocument6 pagesBuilding Collapse ReportDamy UnnNo ratings yet

- Dasar Teori MatlabDocument7 pagesDasar Teori MatlabshellaNo ratings yet

- Electrical Sleep InducerDocument80 pagesElectrical Sleep InducerDiana FarhatNo ratings yet

- VenturiDocument7 pagesVenturishagsNo ratings yet

- LS1 - Determination of Jet Velocity and Nozzle EfficiencyDocument9 pagesLS1 - Determination of Jet Velocity and Nozzle EfficiencyfaezahjalalNo ratings yet

- Skid Resistance Pavement Marking MaterialsDocument11 pagesSkid Resistance Pavement Marking Materialsuocmogiandi_aNo ratings yet

- CIVL 2510 - LAB1 - Hydraulic JumpDocument7 pagesCIVL 2510 - LAB1 - Hydraulic JumpmaxNo ratings yet

- Result Shear Force N Bending MomentDocument6 pagesResult Shear Force N Bending MomentAku PunyeNo ratings yet

- Beam DesignDocument10 pagesBeam DesignMAGED MOHMMED AHMED QASEMNo ratings yet

- Rozaimi Mohd Noor MFKA2009Document99 pagesRozaimi Mohd Noor MFKA2009chin_kb100% (1)

- 2241 001Document36 pages2241 001Amro Al-Hinai50% (2)

- Fluid MechanicsDocument19 pagesFluid MechanicsengNo ratings yet

- H2 Full Lab Report For RealDocument20 pagesH2 Full Lab Report For RealMohd Nik Harith FawwazNo ratings yet

- Geotechnical Investigation 1225510757282453 9Document39 pagesGeotechnical Investigation 1225510757282453 9fandhiejavanov2009No ratings yet

- Wonders and TechnologyDocument15 pagesWonders and TechnologyEmilio MordiniNo ratings yet

- Continuous Beam Design With Moment Redistribution (CSA A23.3-14) PDFDocument35 pagesContinuous Beam Design With Moment Redistribution (CSA A23.3-14) PDFtimNo ratings yet

- Geotechnical Foundation Design For Some of The Wor PDFDocument14 pagesGeotechnical Foundation Design For Some of The Wor PDFJEFFERSON LAZON ZAMORANo ratings yet

- Numerical Modelling of The Structural Behaviour of JointsDocument2 pagesNumerical Modelling of The Structural Behaviour of JointsSara BACHIRNo ratings yet

- CON3002 Part 2 - 1Document31 pagesCON3002 Part 2 - 1楊子慶No ratings yet

- Summary of MaterialsDocument2 pagesSummary of Materialsjhoan tegereroNo ratings yet

- Final Exam Hydraulic Jan2012Document9 pagesFinal Exam Hydraulic Jan2012Anni SuhanaNo ratings yet

- Curved BeamsDocument14 pagesCurved BeamsRajesh MaleyNo ratings yet

- Portal FrameDocument6 pagesPortal FrameBatrisyialya RusliNo ratings yet

- Templeman Et Al 2021 Cutting Shoe DesignDocument41 pagesTempleman Et Al 2021 Cutting Shoe DesignBrian Sheil100% (1)

- Beam Analysis Using The Stiffness MATRIX Method PDFDocument23 pagesBeam Analysis Using The Stiffness MATRIX Method PDFjacksonNo ratings yet

- Cceer10 01Document583 pagesCceer10 01Ulissipo1955No ratings yet

- Half-Cell Potential Test From The Upper-Side and The Lower-Side of Reinforced Concrete Slabs: A Comparative StudyDocument6 pagesHalf-Cell Potential Test From The Upper-Side and The Lower-Side of Reinforced Concrete Slabs: A Comparative StudyANNADURAINo ratings yet

- Design Sheet Word - 複本Document17 pagesDesign Sheet Word - 複本Cheuk Kit CheungNo ratings yet

- Universiti Tun Hussein Onn Malaysia: ConfidentialDocument3 pagesUniversiti Tun Hussein Onn Malaysia: ConfidentialZahirah SaffriNo ratings yet

- 4.1. Modelling Confinement in Concrete Columns and Bridge Piers Through 3D Nonlinear Finite Element AnalysisDocument8 pages4.1. Modelling Confinement in Concrete Columns and Bridge Piers Through 3D Nonlinear Finite Element AnalysisFaraaz FaisalNo ratings yet

- Anil2015 Based On ATCDocument15 pagesAnil2015 Based On ATCbx hanNo ratings yet

- Structural Failure Evaluation of A Substandard RC BuildingDocument15 pagesStructural Failure Evaluation of A Substandard RC BuildingHariprasad .v.prabhakarNo ratings yet

- Ambient Vibration Testing of Existing Buildings: Experimental, Numerical and Code ProvisionsDocument9 pagesAmbient Vibration Testing of Existing Buildings: Experimental, Numerical and Code ProvisionsRonnie BalucanNo ratings yet

- Vulnerability Assessment of Reinforced Concrete Component Building Structure Using Crack DetectionDocument5 pagesVulnerability Assessment of Reinforced Concrete Component Building Structure Using Crack DetectionroshankojuNo ratings yet

- Quotation For Amantran CHS Miraroad PDFDocument5 pagesQuotation For Amantran CHS Miraroad PDFShakuntala GuptaNo ratings yet

- Experimental Study On Dynamic Characteristics of DDocument15 pagesExperimental Study On Dynamic Characteristics of DPeteris SkelsNo ratings yet

- Research PaperDocument6 pagesResearch PaperRaman MaharjanNo ratings yet

- Compiled (Modified by Incorporating Electrical Works But My Part Not Finished Yet)Document14 pagesCompiled (Modified by Incorporating Electrical Works But My Part Not Finished Yet)daveadeNo ratings yet

- 49 (1) 0098Document18 pages49 (1) 0098Mohammed Ashrey Shendi RatebNo ratings yet

- Assessment of in Situ Characteristic Concrete StrengthDocument11 pagesAssessment of in Situ Characteristic Concrete StrengthSwëêt Rãsçäl SëlvåNo ratings yet

- Structural Assessment For Deteriorated Old BuildinDocument12 pagesStructural Assessment For Deteriorated Old BuildinPaul Jefferson PamaniNo ratings yet

- Compiledmodified by Incorporating Electrical Works But My Part NotDocument14 pagesCompiledmodified by Incorporating Electrical Works But My Part NotdaveadeNo ratings yet

- Buildings 12 00079Document4 pagesBuildings 12 00079engmakki93No ratings yet

- Seismic Analysis of Double Curved Arch Dams Based PerformanceDocument4 pagesSeismic Analysis of Double Curved Arch Dams Based PerformancelorikNo ratings yet

- Sandolietal IS2021Document2 pagesSandolietal IS2021Nicola ChieffoNo ratings yet

- Inspection and Diagnosis Tests For Structural Safety Evaluation - A Case StudyDocument9 pagesInspection and Diagnosis Tests For Structural Safety Evaluation - A Case StudyNicola ChieffoNo ratings yet

- 152.prefabricated Multistory Structure Exposure To Engineering Seismicity by UsingDocument6 pages152.prefabricated Multistory Structure Exposure To Engineering Seismicity by UsingVishvajit KohakadeNo ratings yet

- Automation in ConstructionDocument15 pagesAutomation in ConstructionOMAR ALONSO MEDINA PACHECONo ratings yet

- 1 s2.0 S1474034616300027 MainDocument11 pages1 s2.0 S1474034616300027 Mainbx hanNo ratings yet

- Fundamental.. Period of Reinforced Concrete Shear Wall PDFDocument15 pagesFundamental.. Period of Reinforced Concrete Shear Wall PDFPrabhakaranNo ratings yet

- Annex eDocument23 pagesAnnex eဒုကၡ သစၥာNo ratings yet

- Investigation of The Condominium Building Collapse in Surfside, Florida: A Video Feature Tracking ApproachDocument27 pagesInvestigation of The Condominium Building Collapse in Surfside, Florida: A Video Feature Tracking ApproachSparkly DraigNo ratings yet

- 1800-Article Text-7627-1-10-20150929Document21 pages1800-Article Text-7627-1-10-20150929Laxmith ShettyNo ratings yet

- Shear TestDocument18 pagesShear TestHatem SebouiNo ratings yet

- En 13084 2 2007 Free Standing Chimneys Concrete ChimneysDocument28 pagesEn 13084 2 2007 Free Standing Chimneys Concrete Chimneysanon_528053663100% (1)

- Congdo-Han: Bill of Quantity For SteelDocument57 pagesCongdo-Han: Bill of Quantity For SteelKien KingNo ratings yet

- Moment CoeffetionDocument31 pagesMoment CoeffetionDilon TkhomaNo ratings yet

- Utkarsh Industrial Training ReportDocument39 pagesUtkarsh Industrial Training Reportprosperity facilitation100% (1)

- Latest Date For Receipt of Comments: 28 October 2023: Form 36Document131 pagesLatest Date For Receipt of Comments: 28 October 2023: Form 36J MrNo ratings yet

- Causes of Concrete SpallingDocument2 pagesCauses of Concrete SpallingPaul WONGNo ratings yet

- GI Bridge Inspection Report-2013Document3 pagesGI Bridge Inspection Report-2013WXYZ-TV Channel 7 DetroitNo ratings yet

- Residential Pile Grade BeamsDocument1 pageResidential Pile Grade BeamsaiplNo ratings yet

- STERA3D Technical Manual PDFDocument310 pagesSTERA3D Technical Manual PDFMacNo ratings yet

- Item No Description Unit Qty: A. Substructure 1. Excavation and Earth WorkDocument6 pagesItem No Description Unit Qty: A. Substructure 1. Excavation and Earth WorkmayaNo ratings yet

- The Concrete Producer Article PDF - Troubleshooting Precast Cracks in Hollow-Core SlabsDocument4 pagesThe Concrete Producer Article PDF - Troubleshooting Precast Cracks in Hollow-Core SlabsmahmoodgulamNo ratings yet

- T.K Group of Industries: "Wooden Floor & Wooden Tiles"Document8 pagesT.K Group of Industries: "Wooden Floor & Wooden Tiles"Aminul Haque PavelNo ratings yet

- Chapter 4 Flexural Design - (Part 1) - 1Document21 pagesChapter 4 Flexural Design - (Part 1) - 1Huzaifa ZafarNo ratings yet

- IBS Seminar Notes Yeap 1.0 - QS Perspective On HKL SCACC 10dec13Document18 pagesIBS Seminar Notes Yeap 1.0 - QS Perspective On HKL SCACC 10dec13mrlobboNo ratings yet

- Module 4 &5 Ultimate Strength DesignDocument37 pagesModule 4 &5 Ultimate Strength Designkookie maeNo ratings yet

- Alternate Roofing Materials: To R.C.CDocument33 pagesAlternate Roofing Materials: To R.C.CVenkatNo ratings yet

- A Comparative Study of BNBC 1993 and 2017 Provisions For The Design of Multistoried Steel Buildings in High Wind and High Seismic ZoneDocument6 pagesA Comparative Study of BNBC 1993 and 2017 Provisions For The Design of Multistoried Steel Buildings in High Wind and High Seismic ZoneSajedur Rahman Mishuk100% (3)

- EC Drive - EC PlusDocument21 pagesEC Drive - EC PlusMohammed FarhanNo ratings yet

- Me Summer 2020Document2 pagesMe Summer 2020SIDDIQUI HasmataliNo ratings yet

- Measuring Concrete Work 1Document19 pagesMeasuring Concrete Work 1Akbar RafeekNo ratings yet

- Cost Reduction Through Cost Effective ConstructionDocument3 pagesCost Reduction Through Cost Effective ConstructionShalom ArayaNo ratings yet

- CT QuestionsDocument26 pagesCT QuestionsBala Gopal100% (1)

- Work Request and Pouring Permit Files 1Document21 pagesWork Request and Pouring Permit Files 1Os ManNo ratings yet

- Literature Review CDocument5 pagesLiterature Review Cpravin nadekarNo ratings yet

- Notes: - : Plan of Deck SlabDocument1 pageNotes: - : Plan of Deck SlabNirajan MarwaitNo ratings yet

- Ii UnitDocument5 pagesIi UnitMligo ClemenceNo ratings yet

- WS TDG 35 Floor Diaphrams in Timber Buildings 09-20Document34 pagesWS TDG 35 Floor Diaphrams in Timber Buildings 09-20Joseph Booker100% (1)

- Design of Splicing of RafterDocument3 pagesDesign of Splicing of Rafterkeerthivasan_mrvNo ratings yet

- Basf Masterbrace Fibre TdsDocument2 pagesBasf Masterbrace Fibre TdsMohamed Abo-ZaidNo ratings yet

Collapse of The Giotto Avenue Building in Foggia

Collapse of The Giotto Avenue Building in Foggia

Uploaded by

Mauricio Benitez AlvarezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Collapse of The Giotto Avenue Building in Foggia

Collapse of The Giotto Avenue Building in Foggia

Uploaded by

Mauricio Benitez AlvarezCopyright:

Available Formats

Structural Engineering International

ISSN: 1016-8664 (Print) 1683-0350 (Online) Journal homepage: https://www.tandfonline.com/loi/tsei20

Collapse of the Giotto Avenue Building in Foggia

Fabrizio Palmisano (Lecturer), Amedeo Vitone (Assoc. Prof.), Claudia Vitone

(Dr) & Vitantonio Vitone (Assoc. Prof.)

To cite this article: Fabrizio Palmisano (Lecturer), Amedeo Vitone (Assoc. Prof.), Claudia Vitone

(Dr) & Vitantonio Vitone (Assoc. Prof.) (2007) Collapse of the Giotto Avenue Building in Foggia,

Structural Engineering International, 17:2, 166-171, DOI: 10.2749/101686607780680709

To link to this article: https://doi.org/10.2749/101686607780680709

Published online: 23 Mar 2018.

Submit your article to this journal

Article views: 37

View related articles

Citing articles: 1 View citing articles

Full Terms & Conditions of access and use can be found at

https://www.tandfonline.com/action/journalInformation?journalCode=tsei20

Collapse of the Giotto Avenue Building in Foggia

Fabrizio Palmisano, Lecturer, Dept. of Civil Eng. and Architecture Sciences, Politecnico di Bari, Italy.

Amedeo Vitone, Assoc. Prof.; Claudia Vitone, Dr; Vitantonio Vitone, Assoc. Prof.; Dept. of Civil and

Environmental Eng., Politecnico di Bari, Italy.

Summary numerically quantify its structural

safety before the collapse.

The case that the researchers had to analyse on behalf of the Public Prosecutor’s

Office, was the initial failure that triggered the unexpected collapse of a rein- Moreover, design and construction er-

forced concrete building during the night of November 11th, 1999. They also had rors were detected and examined in

to reconstruct the event starting from the individuation of the causes of such order to evaluate their contribution

crumbling that is still remembered for its serious sacrifice of human lives. Togeth- in transforming the recognised initial

er with the detailed report of the case, the paper intends to make a useful contri- local rupture into a tragic progressive

bution to the crucial topic concerning the choice of the most appropriate method collapse.

to perform this sort of autopsy, without neglecting any technical guideline.

Keywords: structural collapse; assessment; reliability; re-calculation; probabilistic The Methodology Used in the

analysis.

Investigation

Since the night of the building collapse

(Figs. 2 and 3), investigations, surveys

Introduction University) in addition to highly quali- and tests were carried out to obtain

fied external consultants [1]. every useful information to under-

The extreme sensitivity of the analy- stand the causes and dynamics of the

The investigative path had to start from collapse.

sis was due to the fact that the Giotto

the difficult work of data acquisition

avenue building (Fig. 1)—even if very The main steps of the methodology

requiring patience: document exami-

similar to others built in the same city that was used were the following:

nation, questioning, visual inspections

by the same contractor, designed by

and tests on ruins to establish physical – Historical-kinematic reconstruction

the same structural engineer and still

and mechanical properties of materials, of the collapse based on questioning,

standing—collapsed only 30 years

tests on the nearby building (the so- video-photographic documentation

after its construction without any evi-

called “twin building”, which did not and visual inspections of the ruins.

dent premonitory sign and without the

collapse but was later, demolished). – Acquisition of technical data

occurrence of any accidental action

(e.g. earthquake, explosion). The com- Deterministic re-calculations accord- necessary to create a model using:

plex study that had to be carried out ing to current codes and to the one the few available documents of the

needed the maximum synergy and, to in effect at the time of construc- original design, on-site geometrical

this purpose, the researchers involved tion as well as probabilistic analy- surveys, visual sample inspections,

three Italian universities (Politecnico di ses of the structural reliability of the laboratory tests to establish mat-

Bari, Politecnico di Milano, Basilicata building were carried out in order to erial properties, the analysis of

Fig. 1: CAD Model of the Giotto Avenue Building Fig. 2: Back View of the Collapsed Building

166 Structures Worldwide Structural Engineering International 2/2007

X218.indd 166 4/26/07 4:11:27 PM

quality of concrete used in the con- evidence that the problem was not re-

struction was so poor that this could lated to steel quality but to concrete

be considered the main defect of the weakness and detailing errors. These

building. observations were confirmed by labo-

ratory tests: mechanical testing gave in

The terrible quality of the concrete was

fact good results about the strength and

first recognised from visual inspections

ductility of smooth and ribbed bars.

of the ruins:

– the concrete looked extremely Time and Creep Effects

heterogeneous;

Fig. 3: Front View of the Collapsed – extraneous elements were found According to the codes in paragraphs

Building in structural elements (e.g. wooden 2.1.6.1 and 2.1.6.2 of CEB-FIP Model

pieces, a metal can, a rubber Code 90 [2], “time effects” were evalu-

puppet); ated. The compressive strength of con-

video-photographic documentation, – a large amount of sand was found in crete varies with time and it depends on

geological and geotechnical tests on the concrete; the type of cement, temperature, cur-

foundation soil. – the concrete looked very porous ing conditions and application of sus-

– Numerical analysis of the model. (due to the high water-to-cement tained loads. The estimated reduction

– Identification of design and ratio used); of concrete compressive strength of

construction errors and analysis the first floor columns after 30 years

of their influence on the collapse Laboratory test results to evaluate was about 7,5%.

dynamics. concrete mechanical characteristics

– Inspections on samples taken are presented later in this paper. According to the codes in paragraph

from the demolition of the “twin 2.1.6.4 of CEB-FIP Model Code 90 [2],

Physical and chemical tests unveiled the creep coefficient was evaluated for

building”. very serious errors in mix design and the first floor columns. Its value, equal

in construction techniques: to 3,77, was higher than the values of

Depositions on the Collapse – From the chloride penetration depth normal concrete in typical conditions;

and on Previous Facts profile determinations, it could be this indicated that the transfer of in-

assessed that the concrete was not ternal actions from concrete to steel

A survivor gave evidence that about threatened by chloride attacks. reinforcements was bigger than in

20 minutes before the collapse loud – Carbonation depth determinations typical cases. For instance, in the case

creaks were heard and failure signs indicated that carbon dioxide of a first floor column the calculated

(cracks on the partition walls, cracks penetration was from 15 mm to 137 compressive stress after 30 years was

and deformation of the floor slabs) mm; the carbonation penetration almost four times the initial compres-

were seen. According to those who level deeper than the expected one sive stress; this means that there was

witnessed the collapse, the building un- (almost 45 mm) for a medium-low a very high risk of buckling of vertical

derwent a so-called “pancake effect” quality concrete indicated that the steel bars with consequent concrete

without any rotation of the external examined concrete quality was spalling and reduction of the effective

façades. Only the façade next to the terrible. section. An evidence of this phenome-

“twin building” rotated towards the – X-ray diffractometric tests excluded non was given by a photograph, shown

internal part of the collapsed building. that concrete could be threatened in Fig. 4, and found under the ruins,

by chemical attacks. which showed a first floor column with

Even though a few months before the

– Compressive strength tests indicated a buckled reinforcement bar.

collapse some creaks were heard and

some cracks on the partition walls that only two cores had resistance

were discovered, from the depositions greater than 15 MPa; these values Re-Calculations

of the survivors and of the occupiers’ were confirmed by rebound hammer

relatives and friends, there is no evi- and ultrasonic pulse velocity tests. After having understood the possible

dence of important premonitory signs, – The absence of deteriorating reac- causes and dynamics of collapse, a re-

which could be connected to an im- tions indicated that the very low calculation of the structure became

minent structural failure. These signs concrete strength values were due to necessary to verify the hypothesis

were in fact similar to the ones that it the use of extremely poor concrete made and to numerically quantify the

is possible to find in every reinforced during building construction. structural safety of the building before

building of the 1970s, mainly due to an – On the basis of indirect consi- the collapse.

excess of floor slab deformation with derations it was estimated that the

water-to-cement ratio (w/c) was Reinforced concrete buildings con-

service loads. structed in Italy during the years from

≥1,2; more than twice the value

usually employed nowadays for 1955 to 1975 seem to be very sensi-

normal concrete. tive to a progressive collapse risk. In

Quality of Structural Materials fact, the general absence of effective

On the other side, from visual in- horizontal and vertical ties, very poor

Visual Inspections and Laboratory

spections, steel reinforcement quality “quality” of the reinforcement design

Tests

seemed to be good even if major errors and assembly and very low concrete

From the numerous laboratory tests in detailing were found. Reinforcement resistance increase the risk that the

carried out on samples taken from the bars underwent large deformations failure of a single load bearing element

structural elements of the collapsed without breaks, in fact in the ruins they can cause a collapse disproportionate

building, it appeared clearly that the were found intact with hooks: this gave to the original cause [3].

Structural Engineering International 2/2007 Structures Worldwide 167

X218.indd 167 4/26/07 4:11:32 PM

10

Stress over the allowable value

9

Residual resistance

8 Design stress

Stress [MPa]

5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15 5

s

16

17

18

19

20

21

22

23

24

25

26

27

28

0

bi

1

/3

29

Column

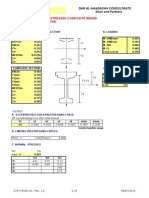

Fig. 5: Design stresses of the first floor columns re-calculated using the national code in

effect at the time of construction

Re-Calculation Using the Allowable of concrete strength α = 1,00, as shown

Stress Method of the 1999 Italian in the next paragraph.

Code

In Fig. 7, design axial loads of the first

Fig. 4: A first floor column with a buckled

Columns were verified using a cube floor columns are shown. It is possible

reinforcement bar

compressive strength (Rck). This was to observe that the columns from n. 21

calculated, according to ENV 1991-1 to n. 29/30, which are the central col-

In the following, the results of de- [4], from the 5% fractile of the normal umns of the building, are overstressed.

terministic and probabilistic calcula- distribution of the cube compressive It is worth noting that this situation is

tions performed on the columns, the strength (Rckcar) obtained by labora- less critical than the one shown in the

most sensitive structural elements, are tory tests carried out on concrete cores previous paragraph because the Italian

shown. of the collapsed building, using a con- allowable stress method gives informa-

version factor which takes account of tion not only about the ultimate limit

Re-Calculation Using the Italian the decrease of in-place strength ver- states but also about the serviceability

Code in Effect at the Time of sus the characteristic strength. limit states.

Construction It is worth highlighting that this value

Columns were verified using the allow- of Rck, obtained by laboratory tests Probabilistic Analysis

able value of the compressive stress carried out on concrete cores taken

In the probabilistic method, the prob-

(6,0 MPa) used in the original design, from the columns of the building 30

ability of failure in a structural element

which is the same as the maximum al- years after its construction, takes into

Pf is the probability that the random

lowable value of the code at the time account the reduction of strength for

variable strength R* is smaller than

of construction. the “time effects”, even if the calcu-

the random variable load effect S*.

lated reduction was not so significant

This verification corresponds to the (about 7,5%). Using this method columns were veri-

one that the structural designer should fied, and according to Eurocode 2 [5],

have performed in 1968 assuming From Fig. 6, in which design stresses

subjected to axial load N and to bend-

that the concrete had the maximum of the first floor columns are shown, it

ing moment M = (h/20)N where h is

strength indicated by the Italian code is possible to observe that the check is

the depth of the cross section.

at the time of construction. This means not satisfied for all the columns, except

that, in this re-calculation, the real me- for columns n. 1 and n. 11. The “failure curve” depends on sev-

chanical characteristics of the concrete, eral random variables: the concrete

measured by laboratory tests carried Re-Calculation Using the Eurocode strength fc, the steel strength fs, the

out on structural elements of the col- 2 Ultimate Limit State Method cross section geometry A, the longitu-

lapsed building, were not considered. dinal reinforcement As.

Columns were also verified accord-

ing to Eurocode 2 [5], subjected to For the random variable fs, the 5% frac-

From Fig. 5, in which design stresses of

axial load N and to bending moment tile deterministic value was assumed.

the first floor columns are shown, it is

M = (h/20)N, where h is the depth of For the cross section geometry A and

possible to observe that the axial com-

the cross section. the longitudinal reinforcement As, the

pression check is not satisfied for the

measured values were assumed.

columns from n. 21 to n. 29/30 which The characteristic value of the cubic

are the central columns of the build- strength (Rck) mentioned earlier was To evaluate the random variable fc,

ing, where the stresses are higher than used as well as a parabola-rectangle the compressive strength fcar of the

permissible limits. diagram with a reduction coefficient cores taken from the columns of the

168 Structures Worldwide Structural Engineering International 2/2007

X218.indd 168 4/26/07 4:11:36 PM

collapsed building was the starting 9

point. The cores (80 in total) were Stress over the allowable value

8

taken from the columns of the build-

Residual resistance

ing 30 years after its construction, so 7 Design stress

these fcar values already included the

strength reduction due to “time ef- 6

fects”. From fcar, the estimated cubic

Stress [MPa]

strength of the cores (fcar-cub) was cal- 5

culated according to the BS 6089: 1981

4

[6]. The cylindrical effective strength

(Fig. 8) is then: 3

fcar-cil = 0,83 fcar-cub 2

Using probability charts, both the nor- 1

mal and the log-normal density func-

tions (Fig. 9) seemed to be suitable 0

for fcar-cil. The normal density function

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15 5

s

16

17

18

19

20

21

22

23

24

25

26

27

28

0

bi

1

/3

29

was chosen because it was the only Column

one that passed both the chi-square

Fig. 6: Design stresses of the first floor columns re-calculated using the allowable stress

and K-S tests with a significance level

method of the 1999 Italian code

of 5%.

The next step was to obtain the ran-

dom variable R*. pressive strength and unfavourable ef- The normal density function was cho-

fects resulting from the way the load is sen for R* and the efficiency was veri-

In the Ultimate Limit State (ULS)

applied. fied using chi-square and K-S tests.

method, the capacity check is made

using the relation: In the case of the Giotto avenue build- For the random variable R*, the coef-

ing, the first part of the coefficient ficient of variation was:

γRR ≥ γSS

could be considered equal to one be-

σ ( R *)

COV ( R *) =

The evaluated concrete strength distri- cause the random variable was ob-

≅ 0, 22

bution took into account the variation tained from laboratory tests carried µ ( R *)

of material properties and uncertain- out on concrete specimens taken from

ties due to mixing, transportation, cast- the columns 30 years after the con- This value is significantly bigger than

ing, compacting and curing. So, to have struction. The second part of the coef- the ones relative to columns designed

the final random variable of concrete ficient was also assumed equal to one and built according to current codes [7].

strength, only the part of the partial in the assumption of overestimating The origin of such a significant scatter-

safety factor γc corresponding to model the concrete strength at the moment ing of data is due to the large scatter-

and geometrical uncertainties (=1,05) of the collapse. ing of the concrete strength measured

was applied. by laboratory tests and it is a confirma-

From the histogram of fcar-cil, using the

Moreover, in the ULS method a fac- assumed values for fs, A, As, γc, the his- tion of the inhomogeneous quality of

tor α = 0,8 ÷ 1 is used to take into togram of the resistance Ri for the first the concrete observed at first sight.

account long term effects on the com- floor columns was obtained. The random variable S* depends on

single random variables si represent-

ing loads applied on the structure. All

300 permanent loads, with the exception of

Axial load over the maximum

resistant value

concrete weight, were considered as

250 Residual resistance normal random variables with mean

Design axial load value and standard deviation accord-

ing to ENV 1991-1 [4].

200

Concrete self-weight was measured

Axial load [10KN]

on the cores taken from the columns

150 of the collapsed building. The normal

density function was chosen for the

concrete self-weight random variable

100

and the efficiency was verified using

chi-square and K-S tests.

50 According to European and Italian

codes, concrete self-weight was in-

0

creased by 100 daN/m3 in order to take

account of the reinforcement presence.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15 5

s

16

17

18

19

20

21

22

23

24

25

26

27

28

0

bi

1

/3

29

Column Concerning variable loads, only part of

Fig. 7: Design axial loads of the first floor columns re-calculated using the Eurocode 2 sustained loads [7, 8] was assumed in

ULS method probabilistic analysis, in order to have

Structural Engineering International 2/2007 Structures Worldwide 169

X218.indd 169 4/26/07 4:11:41 PM

18%

16% normal distribution

14% Log-normal distribution

12% 0,020

10% 0,018

0,016

8% 0,014

6% 0,012

0,010

p

4%

0,008

2%

0,006

0% 0,004

4,0-5,0

5,0-6,0

6,0-7,0

7,0-8,0

8,0-9,0

9,0-10,0

10,0-11,0

11,0-12,0

12,0-13,0

13,0-14,0

14,0-15,5

0,002

0,000

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

fcar-cil [MPa] fcar-cil [MPa]

Fig. 8: Histogram of fcar-cil Fig. 9: Normal and log-normal density functions of fcar-cil

a more realistic scenario with refer- failure of two first floor columns (n° About the causes that produced such a

ence to the collapse diagnosis. 24 and 25), located just next to the ruinous collapse, analysis of finds and

staircase. of reinforcement layout confirmed

After the evaluation of the single ran-

the grave vulnerability of the building

dom variables si distributions, vertical The very high values of the probability

with respect to the risk of progressive

action on each column was calculated of failure calculated for the central col-

collapse [9].

as a combination of these. umns of the building were not only due

to the poor mechanical concrete char- Among the several detected errors and

Finally from the random variable

acteristics but also to arbitrary reduc- serious deficiencies, in particular the

“safety margin” M = R*–S*, the col-

tion of the safety factors carried out by following have to be reported: absence

umns failure probability Pf was calcu-

the designer, as it is possible to notice of connecting beams between foot-

lated.

from the re-calculation performed ings; absence of r. c. bearing walls and

As clearly shown in Fig. 10, the worse using the Italian code at the time of of floor slab ties; staircase weakness;

situation is represented by first floor construction. insufficient column stirrups; serious

columns. From the figure, it is possible weakness and discontinuity in beam-

However, in the case of the Giotto av-

to observe that Pf assumes the highest column joint reinforcement; poor con-

enue building, it has to be highlighted

values (from 18,5 to 46,5%) for the struction and design quality of floor

that other even more critical circum-

columns from n. 21 to n. 29/30 which slabs; irregularities in design and con-

stances added to these serious condi-

are the central columns of the build- struction of covers and anchorages and

tions: incorrect reinforcement design

ing. These values are much higher than of reinforcement layout in slabs, beams

and very bad quality of construction.

the ones (about 0,01%) acceptable by and columns; geometrical irregularities

national and international codes. Concerning the causes of the collapse, of bearing elements (particularly seri-

it has to be concluded that the physi- ous for foundation structures).

cal and mechanical characteristics of

Conclusive Remarks Thus, if the probability of the col-

concrete were so poor and the design

lapse of one or two central columns

and construction errors were so seri-

Investigations, numerical analysis and was high, that of such a ruinous and

ous that conventionally, the failure

laboratory tests seem to suggest that rapid mode of failure would have to

of columns n° 24 and 25 had to be

the causes of the unexpected collapse be estimated to be 100% (i.e. it was

considered technically as “occurred”

of the Giotto avenue building can be not a ‘probability’ but, unfortunately,

since the start of the building’s work-

recognised in the exceptional vulner- a certainty).

ing life!

ability of the supporting reinforced

About the influence on the failure The review of the critical remarks that

concrete structures of the building,

process of other events that occurred have arisen from the study of the find-

due to the extremely poor physical and

during the service life of the build- ings and of the “twin building” struc-

mechanical characteristics of concrete

ing, the following conclusions can be tures in [1] has been carried out in order

and to the serious design and construc-

drawn. to highlight those design and construc-

tion errors.

tion deficiencies that, even if not appar-

The analytical approach used to evalu- Even if some local tampering with ently serious, can increase reinforced

ate the reliability of the Giotto avenue structures (e.g. plant adjustment) were concrete building vulnerability.

building, according to [10], started from detected, important demolitions that

could have been responsible for the It has to be therefore stressed that un-

the level 1 method (the deterministic

collapse have to be excluded. fortunately the detected deficiencies

analysis) to arrive at one (the proba-

are not to be considered peculiar to the

bilistic analysis) that is more approxi-

It is also worth noting that the detailed Giotto avenue building, even if a com-

mate than level 3 but less approximate

geotechnical in situ and laboratory bination of extremely unfavourable

than level 2.

investigations carried out excluded events and situations also contributed

From the results of probabilistic analy- the possibility of significant settle- to the occurrence of that tragic event.

sis, it is possible to conclude that the ments influencing the stability of the Nevertheless, it is important to under-

collapse started from the compression building. line that, many deficiencies detected

170 Structures Worldwide Structural Engineering International 2/2007

X218.indd 170 4/26/07 4:11:43 PM

50% Structures. Part 1: Basis of Design, CEN, Brux-

45% elles, 1994.

40% [5] EUROPEAN COMMITTEE FOR STAN-

35% DARDIZATION (CEN). ENV 1992-1-1: Euro-

code 2. Design of Concrete Structures. Part 1-1:

30%

General Rules and Rules for Buildings, CEN,

Pf %

25% Bruxelles, 1991.

20%

[6] BRITISH STANDARD INSTITUTION. BS

15% 6089:1981 Assessment of Concrete Strength in

10% Existing Structures, BSI, London, 1981.

5%

[7] ELLINGWOOD, B.; GALAMBOS, T. H.;

0% MACGREGOR, J. G.; CORNELL C. A. Devel-

1 3 5 7 9 11 13 15 16 18 20 22 24 26 28

opment of a Probability Based Load Criterion

Column for American National Standard A58. Building

Fig. 10: First floor columns probability of failure (Pf) Code Requirements for Minimum Design Loads

in Buildings and Other Structures. NBS Special

Publication, 577, 1980.

in the Giotto avenue building can be [2] CEB. CEB-FIP Model Code 1990. CEB Bul- [8] COROTIS, R. B.; DOSHI, V. A. Probability

easily found in many Italian reinforced letin d’Information n. 213/214, 1993. models for live load survey result. Journal of the

concrete buildings constructed be- Structural Division-ASCE, 103(ST6), 1977, pp.

[3] MARANO, G. C.; PALMISANO, F.;VITONE,

1257–1274.

tween the 1970s and the 1980s. A.; VITONE, C. Dall’analisi dei crolli insegna-

menti per adeguare i criteri di progettazione [9] PALMISANO, F.; RAUSA, P.; VITONE, A.

delle nuove strutture in c.a. Proceedings of the Use of catenary action of reinforcement to pre-

References Conference “Structural Failures and Reliabil- vent progressive collapse in r. c. buildings. Pro-

ity of Civil Structures’’, Venezia, Italy, Decem- ceedings of the “2nd International fib Congress’’,

[1] VITONE, A.; VITONE, V. Relazione tecnica ber, 2001. Napoli, Italy, June, 2006.

definitiva della Consulenza Tecnica di Ufficio

per il crollo dell’edificio di Viale Giotto a Foggia [4] EUROPEAN COMMITTEE FOR STAN- [10] FIB. Management, Maintenance and

dell’11.11.1999. Studio Vitone & Associati, Bari, DARDIZATION (CEN). ENV 1991-1: Eu- Strengthening of Concrete Structures. Fib bulletin

Italy, May 2001. rocode 1. Basis of Design and Actions on 17, Sprint-druck, Stuttgart, 2002.

Buro Happold is presently recruiting experienced

structural engineers for our US offices to work on

projects both in the United States and overseas

For more information on our current vacancies visit our website

or email your resume to recruitment@burohappold.com

www.burohappold.com

Structural Engineering International 2/2007 Structures Worldwide 171

X218.indd 171 4/26/07 4:11:45 PM

You might also like

- Prestressed-Precast Design SpreadsheetDocument6 pagesPrestressed-Precast Design SpreadsheetCivilax.com100% (3)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Single Phase Half Wave Controlled ConverterDocument7 pagesSingle Phase Half Wave Controlled ConverterAlexNo ratings yet

- Building Failure - Causes and Case StudiesDocument14 pagesBuilding Failure - Causes and Case Studiesresha bhatiaNo ratings yet

- Gujarat Technological Univercity: C.K. Pithawala College of Engineering & TechnologyDocument17 pagesGujarat Technological Univercity: C.K. Pithawala College of Engineering & TechnologyParth AnajwalaNo ratings yet

- Lab Report HighwayDocument5 pagesLab Report HighwayNora NorazisahNo ratings yet

- Building Collapse ReportDocument6 pagesBuilding Collapse ReportDamy UnnNo ratings yet

- Dasar Teori MatlabDocument7 pagesDasar Teori MatlabshellaNo ratings yet

- Electrical Sleep InducerDocument80 pagesElectrical Sleep InducerDiana FarhatNo ratings yet

- VenturiDocument7 pagesVenturishagsNo ratings yet

- LS1 - Determination of Jet Velocity and Nozzle EfficiencyDocument9 pagesLS1 - Determination of Jet Velocity and Nozzle EfficiencyfaezahjalalNo ratings yet

- Skid Resistance Pavement Marking MaterialsDocument11 pagesSkid Resistance Pavement Marking Materialsuocmogiandi_aNo ratings yet

- CIVL 2510 - LAB1 - Hydraulic JumpDocument7 pagesCIVL 2510 - LAB1 - Hydraulic JumpmaxNo ratings yet

- Result Shear Force N Bending MomentDocument6 pagesResult Shear Force N Bending MomentAku PunyeNo ratings yet

- Beam DesignDocument10 pagesBeam DesignMAGED MOHMMED AHMED QASEMNo ratings yet

- Rozaimi Mohd Noor MFKA2009Document99 pagesRozaimi Mohd Noor MFKA2009chin_kb100% (1)

- 2241 001Document36 pages2241 001Amro Al-Hinai50% (2)

- Fluid MechanicsDocument19 pagesFluid MechanicsengNo ratings yet

- H2 Full Lab Report For RealDocument20 pagesH2 Full Lab Report For RealMohd Nik Harith FawwazNo ratings yet

- Geotechnical Investigation 1225510757282453 9Document39 pagesGeotechnical Investigation 1225510757282453 9fandhiejavanov2009No ratings yet

- Wonders and TechnologyDocument15 pagesWonders and TechnologyEmilio MordiniNo ratings yet

- Continuous Beam Design With Moment Redistribution (CSA A23.3-14) PDFDocument35 pagesContinuous Beam Design With Moment Redistribution (CSA A23.3-14) PDFtimNo ratings yet

- Geotechnical Foundation Design For Some of The Wor PDFDocument14 pagesGeotechnical Foundation Design For Some of The Wor PDFJEFFERSON LAZON ZAMORANo ratings yet

- Numerical Modelling of The Structural Behaviour of JointsDocument2 pagesNumerical Modelling of The Structural Behaviour of JointsSara BACHIRNo ratings yet

- CON3002 Part 2 - 1Document31 pagesCON3002 Part 2 - 1楊子慶No ratings yet

- Summary of MaterialsDocument2 pagesSummary of Materialsjhoan tegereroNo ratings yet

- Final Exam Hydraulic Jan2012Document9 pagesFinal Exam Hydraulic Jan2012Anni SuhanaNo ratings yet

- Curved BeamsDocument14 pagesCurved BeamsRajesh MaleyNo ratings yet

- Portal FrameDocument6 pagesPortal FrameBatrisyialya RusliNo ratings yet

- Templeman Et Al 2021 Cutting Shoe DesignDocument41 pagesTempleman Et Al 2021 Cutting Shoe DesignBrian Sheil100% (1)

- Beam Analysis Using The Stiffness MATRIX Method PDFDocument23 pagesBeam Analysis Using The Stiffness MATRIX Method PDFjacksonNo ratings yet

- Cceer10 01Document583 pagesCceer10 01Ulissipo1955No ratings yet

- Half-Cell Potential Test From The Upper-Side and The Lower-Side of Reinforced Concrete Slabs: A Comparative StudyDocument6 pagesHalf-Cell Potential Test From The Upper-Side and The Lower-Side of Reinforced Concrete Slabs: A Comparative StudyANNADURAINo ratings yet

- Design Sheet Word - 複本Document17 pagesDesign Sheet Word - 複本Cheuk Kit CheungNo ratings yet

- Universiti Tun Hussein Onn Malaysia: ConfidentialDocument3 pagesUniversiti Tun Hussein Onn Malaysia: ConfidentialZahirah SaffriNo ratings yet

- 4.1. Modelling Confinement in Concrete Columns and Bridge Piers Through 3D Nonlinear Finite Element AnalysisDocument8 pages4.1. Modelling Confinement in Concrete Columns and Bridge Piers Through 3D Nonlinear Finite Element AnalysisFaraaz FaisalNo ratings yet

- Anil2015 Based On ATCDocument15 pagesAnil2015 Based On ATCbx hanNo ratings yet

- Structural Failure Evaluation of A Substandard RC BuildingDocument15 pagesStructural Failure Evaluation of A Substandard RC BuildingHariprasad .v.prabhakarNo ratings yet

- Ambient Vibration Testing of Existing Buildings: Experimental, Numerical and Code ProvisionsDocument9 pagesAmbient Vibration Testing of Existing Buildings: Experimental, Numerical and Code ProvisionsRonnie BalucanNo ratings yet

- Vulnerability Assessment of Reinforced Concrete Component Building Structure Using Crack DetectionDocument5 pagesVulnerability Assessment of Reinforced Concrete Component Building Structure Using Crack DetectionroshankojuNo ratings yet

- Quotation For Amantran CHS Miraroad PDFDocument5 pagesQuotation For Amantran CHS Miraroad PDFShakuntala GuptaNo ratings yet

- Experimental Study On Dynamic Characteristics of DDocument15 pagesExperimental Study On Dynamic Characteristics of DPeteris SkelsNo ratings yet

- Research PaperDocument6 pagesResearch PaperRaman MaharjanNo ratings yet

- Compiled (Modified by Incorporating Electrical Works But My Part Not Finished Yet)Document14 pagesCompiled (Modified by Incorporating Electrical Works But My Part Not Finished Yet)daveadeNo ratings yet

- 49 (1) 0098Document18 pages49 (1) 0098Mohammed Ashrey Shendi RatebNo ratings yet

- Assessment of in Situ Characteristic Concrete StrengthDocument11 pagesAssessment of in Situ Characteristic Concrete StrengthSwëêt Rãsçäl SëlvåNo ratings yet

- Structural Assessment For Deteriorated Old BuildinDocument12 pagesStructural Assessment For Deteriorated Old BuildinPaul Jefferson PamaniNo ratings yet

- Compiledmodified by Incorporating Electrical Works But My Part NotDocument14 pagesCompiledmodified by Incorporating Electrical Works But My Part NotdaveadeNo ratings yet

- Buildings 12 00079Document4 pagesBuildings 12 00079engmakki93No ratings yet

- Seismic Analysis of Double Curved Arch Dams Based PerformanceDocument4 pagesSeismic Analysis of Double Curved Arch Dams Based PerformancelorikNo ratings yet

- Sandolietal IS2021Document2 pagesSandolietal IS2021Nicola ChieffoNo ratings yet

- Inspection and Diagnosis Tests For Structural Safety Evaluation - A Case StudyDocument9 pagesInspection and Diagnosis Tests For Structural Safety Evaluation - A Case StudyNicola ChieffoNo ratings yet

- 152.prefabricated Multistory Structure Exposure To Engineering Seismicity by UsingDocument6 pages152.prefabricated Multistory Structure Exposure To Engineering Seismicity by UsingVishvajit KohakadeNo ratings yet

- Automation in ConstructionDocument15 pagesAutomation in ConstructionOMAR ALONSO MEDINA PACHECONo ratings yet

- 1 s2.0 S1474034616300027 MainDocument11 pages1 s2.0 S1474034616300027 Mainbx hanNo ratings yet

- Fundamental.. Period of Reinforced Concrete Shear Wall PDFDocument15 pagesFundamental.. Period of Reinforced Concrete Shear Wall PDFPrabhakaranNo ratings yet

- Annex eDocument23 pagesAnnex eဒုကၡ သစၥာNo ratings yet

- Investigation of The Condominium Building Collapse in Surfside, Florida: A Video Feature Tracking ApproachDocument27 pagesInvestigation of The Condominium Building Collapse in Surfside, Florida: A Video Feature Tracking ApproachSparkly DraigNo ratings yet

- 1800-Article Text-7627-1-10-20150929Document21 pages1800-Article Text-7627-1-10-20150929Laxmith ShettyNo ratings yet

- Shear TestDocument18 pagesShear TestHatem SebouiNo ratings yet

- En 13084 2 2007 Free Standing Chimneys Concrete ChimneysDocument28 pagesEn 13084 2 2007 Free Standing Chimneys Concrete Chimneysanon_528053663100% (1)

- Congdo-Han: Bill of Quantity For SteelDocument57 pagesCongdo-Han: Bill of Quantity For SteelKien KingNo ratings yet

- Moment CoeffetionDocument31 pagesMoment CoeffetionDilon TkhomaNo ratings yet

- Utkarsh Industrial Training ReportDocument39 pagesUtkarsh Industrial Training Reportprosperity facilitation100% (1)

- Latest Date For Receipt of Comments: 28 October 2023: Form 36Document131 pagesLatest Date For Receipt of Comments: 28 October 2023: Form 36J MrNo ratings yet

- Causes of Concrete SpallingDocument2 pagesCauses of Concrete SpallingPaul WONGNo ratings yet

- GI Bridge Inspection Report-2013Document3 pagesGI Bridge Inspection Report-2013WXYZ-TV Channel 7 DetroitNo ratings yet

- Residential Pile Grade BeamsDocument1 pageResidential Pile Grade BeamsaiplNo ratings yet

- STERA3D Technical Manual PDFDocument310 pagesSTERA3D Technical Manual PDFMacNo ratings yet

- Item No Description Unit Qty: A. Substructure 1. Excavation and Earth WorkDocument6 pagesItem No Description Unit Qty: A. Substructure 1. Excavation and Earth WorkmayaNo ratings yet

- The Concrete Producer Article PDF - Troubleshooting Precast Cracks in Hollow-Core SlabsDocument4 pagesThe Concrete Producer Article PDF - Troubleshooting Precast Cracks in Hollow-Core SlabsmahmoodgulamNo ratings yet

- T.K Group of Industries: "Wooden Floor & Wooden Tiles"Document8 pagesT.K Group of Industries: "Wooden Floor & Wooden Tiles"Aminul Haque PavelNo ratings yet

- Chapter 4 Flexural Design - (Part 1) - 1Document21 pagesChapter 4 Flexural Design - (Part 1) - 1Huzaifa ZafarNo ratings yet

- IBS Seminar Notes Yeap 1.0 - QS Perspective On HKL SCACC 10dec13Document18 pagesIBS Seminar Notes Yeap 1.0 - QS Perspective On HKL SCACC 10dec13mrlobboNo ratings yet

- Module 4 &5 Ultimate Strength DesignDocument37 pagesModule 4 &5 Ultimate Strength Designkookie maeNo ratings yet

- Alternate Roofing Materials: To R.C.CDocument33 pagesAlternate Roofing Materials: To R.C.CVenkatNo ratings yet

- A Comparative Study of BNBC 1993 and 2017 Provisions For The Design of Multistoried Steel Buildings in High Wind and High Seismic ZoneDocument6 pagesA Comparative Study of BNBC 1993 and 2017 Provisions For The Design of Multistoried Steel Buildings in High Wind and High Seismic ZoneSajedur Rahman Mishuk100% (3)

- EC Drive - EC PlusDocument21 pagesEC Drive - EC PlusMohammed FarhanNo ratings yet

- Me Summer 2020Document2 pagesMe Summer 2020SIDDIQUI HasmataliNo ratings yet

- Measuring Concrete Work 1Document19 pagesMeasuring Concrete Work 1Akbar RafeekNo ratings yet

- Cost Reduction Through Cost Effective ConstructionDocument3 pagesCost Reduction Through Cost Effective ConstructionShalom ArayaNo ratings yet

- CT QuestionsDocument26 pagesCT QuestionsBala Gopal100% (1)

- Work Request and Pouring Permit Files 1Document21 pagesWork Request and Pouring Permit Files 1Os ManNo ratings yet

- Literature Review CDocument5 pagesLiterature Review Cpravin nadekarNo ratings yet

- Notes: - : Plan of Deck SlabDocument1 pageNotes: - : Plan of Deck SlabNirajan MarwaitNo ratings yet

- Ii UnitDocument5 pagesIi UnitMligo ClemenceNo ratings yet

- WS TDG 35 Floor Diaphrams in Timber Buildings 09-20Document34 pagesWS TDG 35 Floor Diaphrams in Timber Buildings 09-20Joseph Booker100% (1)

- Design of Splicing of RafterDocument3 pagesDesign of Splicing of Rafterkeerthivasan_mrvNo ratings yet

- Basf Masterbrace Fibre TdsDocument2 pagesBasf Masterbrace Fibre TdsMohamed Abo-ZaidNo ratings yet