Professional Documents

Culture Documents

FINAL Advanced Materials - Graphite Coatings

FINAL Advanced Materials - Graphite Coatings

Uploaded by

Reno MurdaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FINAL Advanced Materials - Graphite Coatings

FINAL Advanced Materials - Graphite Coatings

Uploaded by

Reno MurdaCopyright:

Available Formats

Technical Datasheet

Rev. N° - 11.06.2019

Graphite coatings

PRESENTATION

We propose 5 types of coating and graphite impregnations for fine grain isostatic graphite

(< 10µm):

Pyrolytic Carbon: with the use of high-temperature, high-pressure chemical vapour

deposition, (CVD process), the ultra-pure pyrolytic carbon coating provides a smooth

surface, high density, strength and hardness along with very low porosity making it

virtually impermeable to fluids and gases. The coating thickness is typically 2 to 30

microns. Pyrolytic carbon coating is composed of 99.9995% elemental carbon and is

virtually free of organic or metallic impurities. This process prevents the formation of

SiC (Silicon Carbide) in contact with the silicon. The coating resists attack by

hydrofluoric (HF) and most other acids. Thermal shock will not cause spalling,

crazing or flaking of the coating. It is ideal for both semiconductor and solar

applications. It is thermally stable and ideal for applications with temperatures up to

550°C in the presence of oxygen and up to 2500°C in vacuum or inert atmosphere.

SiC: Also obtained using the CVD process, the SiC layer is 75 to 125 microns thick.

This treatment can seal the graphite completely, the result being a high-quality tool

that is virtually inert to all process gases and chemicals, with great hardness,

resistance to oxidation and good thermal conduction.

PTFE: We also provide PTFE treatments which increase resistance to acids,

eliminating porosity while maintaining the thermal characteristics of the graphite.

Methacrylate resin: Graphite can also be impregnated with this resin which will

ensure that the graphite provides excellent sealant capacities.

Antimony (only available for carbo-graphite): Our graphite can be impregnated with

antimony for applications where resistance to wear is essential.

For any question, please contact: info@final-materials.com

4 avenue de Strasbourg – 68350 Didenheim – France – Tel : +33 (0)3 67 78 78 78 - www.final-materials.com

Wiesenstrasse 23E – 76887 Bad Bergzabern – Deutschland – Tel: + 49 (0)6343 93 93 145 1 /2

Technical Datasheet

Rev. N° - 11.06.2019

Graphite coatings

GRAPHITE ADHESIVE

Adhesive Cotronics 931 bonds Graphite or carbon components for use to 3000°C with 99%

pure graphite. Just apply and cure at 120°C. Resbond 931 has excellent adhesion to graphite,

and other porous surfaces, forming graphite to graphite bonds with strengths measuring more

than 17.5 N/mm². 931 is ideal for repairing broken or cracked graphite trays, components,

fixtures, dies; filling and rebuilding crevices, cracks, worn areas and bonding graphite cloths,

felts, boards, etc.

GRAPHITE SPRAY

The graphite spray allows lubrication of metal, plastic or rubber parts without using fat. The

binder allows to fix a film of graphite powder of very fine particle size with virtually no

thickness on different materials.

Applications

Agent Dry lubrication for all materials

Anti-seize agent for all materials

Release agent

For any question, please contact: info@final-materials.com

4 avenue de Strasbourg – 68350 Didenheim – France – Tel : +33 (0)3 67 78 78 78 - www.final-materials.com

Wiesenstrasse 23E – 76887 Bad Bergzabern – Deutschland – Tel: + 49 (0)6343 93 93 145 2 /2

You might also like

- Citizen M16Document64 pagesCitizen M16Favoreel Patrick100% (1)

- 2001 - G.ciardelli - Membrane Separation For Wastewater Reuse in The Textile IndustryDocument9 pages2001 - G.ciardelli - Membrane Separation For Wastewater Reuse in The Textile IndustrypablocolindresNo ratings yet

- FINAL Advanced Materials - COTRONICS - Ceramic AdhesiveDocument15 pagesFINAL Advanced Materials - COTRONICS - Ceramic AdhesiveBharathidasan SugumaranNo ratings yet

- 17AS.002 FINAL Advanced Materials - Graphite Coatings and SuspensionDocument3 pages17AS.002 FINAL Advanced Materials - Graphite Coatings and SuspensionsimphiweNo ratings yet

- 97 145Document2 pages97 145anon_251242493No ratings yet

- p911 de 2021-06 0 Eng ScreenDocument4 pagesp911 de 2021-06 0 Eng ScreenanhnguyenhaiNo ratings yet

- 92-Nba-1-7 GS - Emd Eu TDSDocument5 pages92-Nba-1-7 GS - Emd Eu TDSRoberto Velarde AlvaradoNo ratings yet

- Graphit 33Document2 pagesGraphit 33Manuel Armindo RibeiroNo ratings yet

- Pu Sealant Mccoy Soudal Soudaflex 611 Pu SealantDocument2 pagesPu Sealant Mccoy Soudal Soudaflex 611 Pu SealantsasidharkanthetiNo ratings yet

- Sikacem Gunit 133Document2 pagesSikacem Gunit 133the pilotNo ratings yet

- Senotherm Paint - 1666-: Technical Information Processing InstructionDocument4 pagesSenotherm Paint - 1666-: Technical Information Processing InstructionYavuz KeskinNo ratings yet

- Sumo For Panel Technical Data Sheet Rev 1 010122Document6 pagesSumo For Panel Technical Data Sheet Rev 1 010122Nam Hoàng HảiNo ratings yet

- 12 PAPYEX Flexible Graphite Mersen - 09 PDFDocument14 pages12 PAPYEX Flexible Graphite Mersen - 09 PDFarizagameroNo ratings yet

- Diamant Technical Data Sheet DWH 310 FLDocument4 pagesDiamant Technical Data Sheet DWH 310 FLhoriaNo ratings yet

- Sikaflex Construction DDocument3 pagesSikaflex Construction Dthe pilotNo ratings yet

- Azko Coating Hjf14r r4 Es eDocument4 pagesAzko Coating Hjf14r r4 Es eKrishna KumarNo ratings yet

- Castrol Longtime PD1 & PD2 Product Data SheetDocument3 pagesCastrol Longtime PD1 & PD2 Product Data SheetAmit NaikNo ratings yet

- Fisa TehnicaDocument2 pagesFisa TehnicaAlexandru GamanNo ratings yet

- CBN Blade Tip AbradableDocument8 pagesCBN Blade Tip Abradablebehtam2407No ratings yet

- Firecryl FRDocument2 pagesFirecryl FRSeunNo ratings yet

- Coated Diamonds E6Document2 pagesCoated Diamonds E6Farhaan MukadamNo ratings yet

- M4 Ep PDFDocument2 pagesM4 Ep PDFjunaid112No ratings yet

- Gases - The Invisible Secret of Laser Material Processing: Gases Play An Essential Role For Effective Laser OperationDocument4 pagesGases - The Invisible Secret of Laser Material Processing: Gases Play An Essential Role For Effective Laser OperationHarshSuryavanshiNo ratings yet

- CEILCOTE 163 CorocreteDocument2 pagesCEILCOTE 163 CorocreteGabor VictorNo ratings yet

- Sikafloor - 325: 2-Part PUR Resin Self Smoothing Screed and Seal CoatDocument6 pagesSikafloor - 325: 2-Part PUR Resin Self Smoothing Screed and Seal Coatthe pilotNo ratings yet

- Sikafloor 24NPurcem IDDocument4 pagesSikafloor 24NPurcem IDRobin PrayogoNo ratings yet

- Non Metallic Flat GasketsDocument4 pagesNon Metallic Flat GasketsMarko ZoricicNo ratings yet

- SES Amercoat Dimetcote 9Document4 pagesSES Amercoat Dimetcote 9kamalkashNo ratings yet

- Touchwood Wood Stain (SB)Document2 pagesTouchwood Wood Stain (SB)vitharvanNo ratings yet

- Devcon Plastic Steel Putty (A) - TDSDocument3 pagesDevcon Plastic Steel Putty (A) - TDSsibi_s_raj100% (2)

- Pds Hempadur Pro Zinc 17380 En-GbDocument2 pagesPds Hempadur Pro Zinc 17380 En-GbThines Kumar0% (1)

- Jotatemp 1000 Ceramic Technical Data SheetDocument5 pagesJotatemp 1000 Ceramic Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Aluminium Plastic Composite PanelDocument9 pagesAluminium Plastic Composite PanelFrankie ChanNo ratings yet

- Flex 68wDocument2 pagesFlex 68wYasher Meera SaibNo ratings yet

- IndustrialDocument462 pagesIndustrialTamagnsewNegnNo ratings yet

- Sicomet 9020Document2 pagesSicomet 9020Gilad KorenNo ratings yet

- The Background of Thermoforming The Advantages of ThermoformingDocument7 pagesThe Background of Thermoforming The Advantages of ThermoformingA MahmoodNo ratings yet

- Hanson Thermalite Technical Manual 2012Document56 pagesHanson Thermalite Technical Manual 2012mauNo ratings yet

- TI Furadur Kitt 322 - enDocument3 pagesTI Furadur Kitt 322 - engonzalogvargas01No ratings yet

- Mee4001-Tool Design Latest Developments On Cutting Tools and Coatings Name:Shrey S Jain REGNO:18BME1225 Faculty:Dr. Umasankar Slot:F1Document13 pagesMee4001-Tool Design Latest Developments On Cutting Tools and Coatings Name:Shrey S Jain REGNO:18BME1225 Faculty:Dr. Umasankar Slot:F1Shrey JainNo ratings yet

- SheraplexDocument2 pagesSheraplexDv Maria Pradhika0% (1)

- Gehotex w8 enDocument2 pagesGehotex w8 enVincent BachellerieNo ratings yet

- Nitoseal 290Document4 pagesNitoseal 290Venkata RaoNo ratings yet

- TDS Levelling - PlasterDocument3 pagesTDS Levelling - PlasterNandhagopal DhandapaniNo ratings yet

- PDS - Sikaflex®-11 FC+ PDFDocument5 pagesPDS - Sikaflex®-11 FC+ PDFblancogonzalosNo ratings yet

- Rolling Mills WRs Coating Alternative - Thermal Spraying by HVAF - AIST 2022Document4 pagesRolling Mills WRs Coating Alternative - Thermal Spraying by HVAF - AIST 2022Alexandar MarinkovicNo ratings yet

- Properties Applications and Types of MEGTRON PCB LaminatesDocument7 pagesProperties Applications and Types of MEGTRON PCB LaminatesjackNo ratings yet

- PETg Data SheetDocument4 pagesPETg Data SheetVikram BorkhediyaNo ratings yet

- Autonet by Mirka: The Ultra-Efficient World of Net SandingDocument8 pagesAutonet by Mirka: The Ultra-Efficient World of Net Sandingdamirboljat4545No ratings yet

- Tds Cosmo CA 500 200 enDocument3 pagesTds Cosmo CA 500 200 enLana ŠpoljarićNo ratings yet

- E - 9039 - Sika - Per - 3326 EG-HDocument4 pagesE - 9039 - Sika - Per - 3326 EG-HBogdan DavidescuNo ratings yet

- M7 ZR PDFDocument2 pagesM7 ZR PDFjunaid112No ratings yet

- Sikadur 30Document3 pagesSikadur 30Hakiki SaputraNo ratings yet

- Epocoat 111 PDFDocument3 pagesEpocoat 111 PDFjunaid112No ratings yet

- PUR Uebersicht Engl 0211Document10 pagesPUR Uebersicht Engl 0211Boris KuseljNo ratings yet

- 19-PM-2015-16 Gripcoat Coating On Rewinder NR VapiDocument2 pages19-PM-2015-16 Gripcoat Coating On Rewinder NR VapiPankaj PandeyNo ratings yet

- 3.road MarkingDocument9 pages3.road MarkingMalith De SilvaNo ratings yet

- Film Thickness Per Coat: Technical Data Sheet Jotafloor Topcoat EDocument1 pageFilm Thickness Per Coat: Technical Data Sheet Jotafloor Topcoat ETamerTamerNo ratings yet

- Sikadur 30 PDFDocument5 pagesSikadur 30 PDFDarwin SyahputraNo ratings yet

- Laser Sintering with Plastics: Technology, Processes, and MaterialsFrom EverandLaser Sintering with Plastics: Technology, Processes, and MaterialsNo ratings yet

- DWD Accessories 09Document4 pagesDWD Accessories 09Mario Allesina JuniorNo ratings yet

- Trellex Hose Flanges GasketsDocument6 pagesTrellex Hose Flanges GasketsHassan ShirivandNo ratings yet

- D1038-11 Standard Terminology Relating To Veneer and PlywoodDocument4 pagesD1038-11 Standard Terminology Relating To Veneer and PlywoodRony YudaNo ratings yet

- Belzona 1341-3 - UnlockedDocument2 pagesBelzona 1341-3 - UnlockedimtiazNo ratings yet

- Woodkeeper: Fill-O-Dent & Wood StainerDocument2 pagesWoodkeeper: Fill-O-Dent & Wood StainerPuneeth RajNo ratings yet

- Sheet 5Q Manufacturing Processes 1Document1 pageSheet 5Q Manufacturing Processes 1Ahmed Rabie Abd ElazeemNo ratings yet

- Weathering Steel Information, A588, A242, Corten Unique PropertiesDocument2 pagesWeathering Steel Information, A588, A242, Corten Unique Propertiesvijayarangam1984No ratings yet

- Asian Finish Paint Pc0246Document2 pagesAsian Finish Paint Pc0246m_geniusNo ratings yet

- Chemical Kinetics AssinmentDocument9 pagesChemical Kinetics AssinmentKhushi TiwariNo ratings yet

- Rust Veto 211 D 1214 GB 0Document1 pageRust Veto 211 D 1214 GB 0sobheysaidNo ratings yet

- 660.501 A01 Standard Clean (Class SC) Inspection and Acceptance RequirementsDocument3 pages660.501 A01 Standard Clean (Class SC) Inspection and Acceptance Requirementspuwarin najaNo ratings yet

- TDS Dulux Silk EmulsionDocument2 pagesTDS Dulux Silk EmulsionpastorgeeNo ratings yet

- Flammable Liquids and Compressed Gas Information SheetDocument3 pagesFlammable Liquids and Compressed Gas Information Sheetaverois ibn roisNo ratings yet

- Bulk Deformation Processes in Metalworking: Review QuestionsDocument22 pagesBulk Deformation Processes in Metalworking: Review QuestionsAnant Kumar0% (1)

- Code-Compliant Guardrail Post Connections: Technical BulletinDocument4 pagesCode-Compliant Guardrail Post Connections: Technical BulletinbassigwNo ratings yet

- TibDocument75 pagesTibCNo ratings yet

- Tube LeakageDocument38 pagesTube LeakageSantanu DuttaNo ratings yet

- Module Iv - Paints Varnishes and DistemperDocument15 pagesModule Iv - Paints Varnishes and DistemperAishwaryaNo ratings yet

- ABRO 3450 Foil/Skrim/Kraft (FSK) Sealing Tape: Product InformationDocument1 pageABRO 3450 Foil/Skrim/Kraft (FSK) Sealing Tape: Product InformationKhabbab Hussain K-hNo ratings yet

- Can I Use Galvanized Sheet Metal For Kitchen TabletopDocument2 pagesCan I Use Galvanized Sheet Metal For Kitchen TabletopmarketingNo ratings yet

- Tender8650 1Document744 pagesTender8650 1Siddharth BhattacharyaNo ratings yet

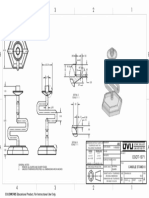

- EGDT-1071: SOLIDWORKS Educational Product. For Instructional Use OnlyDocument1 pageEGDT-1071: SOLIDWORKS Educational Product. For Instructional Use OnlyJCNo ratings yet

- Tds-Uk-627rr (Seajet 027 Saiko) - 15-04-2021Document2 pagesTds-Uk-627rr (Seajet 027 Saiko) - 15-04-2021Ben Abdelkader MehdiNo ratings yet

- Everything About Diaper Production Machinezjady PDFDocument2 pagesEverything About Diaper Production Machinezjady PDFbeercrush71No ratings yet

- Vibra TiteDocument1 pageVibra TitesasidharkanthetiNo ratings yet

- Jushi - TDS-EMC For P02Document1 pageJushi - TDS-EMC For P02Sofya AndarinaNo ratings yet

- Corrosion Types of Corrosion Uniform CorrosionDocument2 pagesCorrosion Types of Corrosion Uniform CorrosionKiran SNNo ratings yet

- Fastener Solutions CenterDocument28 pagesFastener Solutions CentertribleprinceNo ratings yet