Professional Documents

Culture Documents

PEPET Film (35754-E Data Sheet)

PEPET Film (35754-E Data Sheet)

Uploaded by

Anthony BokovOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PEPET Film (35754-E Data Sheet)

PEPET Film (35754-E Data Sheet)

Uploaded by

Anthony BokovCopyright:

Available Formats

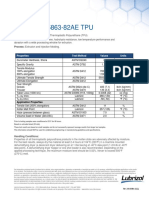

Product Data Sheet

PerfecFlex® 35754 - E

Description: Clear Polyester-based Non-forming Film with EZ Peel® Sealant

Film Composition Component Materials Thickness

(mils)

Thickness

(microns)

Exterior Side

OPET 0.48 12

PE 0.5 13

EZ Peel® Sealant 1.5 38

Sealant Side

Layer Construction

OPET / PE / EZ Peel® Sealant

Typical Applications

- Excellent clear lidding material for PerfecFlex® forming film

- Most widely used material for medical device lidding and pouch applications

- Cost effective option for film-to-film pouches

- Compatible with electron beam and gamma radiation

Material Attributes

- Standard peel force

- EZ Peel® sealant provides consistent peel force and excellent visual transfer

- Excellent heat and dimensional stability

- Good lay-flat with minimal curl

- Can be trap printed for ink protection

Machinery

- Horizontal Form, Fill, and Seal (HFFS)

- Platen and rotary style pouch equipment

Technical Information

PerfecFlex® 35754 - E

Typical

Values Units Test Methods

Physical Properties

Basis Weight: 40.1 lbs./3000 sq.ft. CTM #3001.00 / ASTM D-4321

65.3 g/SM

Gauge: 2.5 mils CTM #3306.00 / ASTM D-2103

63.5 microns

Yield: 10773 sq.in./lb. CTM #3001.00 / ASTM D-4321

15 SM/Kg

Haze: 14 % ASTM D-1003

Mechanical Properties

Tensile Strength MD: 20 lb.f./in. ASTM D-882

89 N/25.4mm

Tensile Strength TD: 20 lb.f./in. ASTM D-882

89 N/25.4mm

Elongation MD: 100 % ASTM D-882

Elongation TD: 75 % ASTM D-882

Elmendorf Tear MD: 24 grams ASTM D-1922

Elmendorf Tear TD: 30 grams ASTM D-1922

Slow Impact: 30 Newtons ASTM F-1306

Permeation Properties

MVTR: <1.0 gms H2O/100 sq in/24 hours ASTM F-1249

(Moisture)

<16 gms H2O/SM/24 hours

Testing Conditions: 100 F, 90% RH (37.8 C, 90% RH)

OTR: <10.0 cc/100 sq in/24 hours ASTM D-3985

(Oxygen)

<155 cc/SM/24 hours

Testing Conditions: 73 F, 0% RH (23C 0%)

This document is in compliance with IoPP Medical Packaging Technical Committee Guidelines for Data Sheets

Recommended Storage Conditions: Perfecseal recommends all material be stored in a clean dry environment and away from any

direct heat. Storage conditions should be between 65F (18C) and 75F (24C) at 40 to 55% relative humidity. Keep in original

packaging until ready for use.

Revision Level: 1 Revision Date: 04/21/2006

IMPORTANT NOTICE TO PURCHASER: The information presented here is intended as background data to assist in product

evaluation and verification. The product features, properties, characteristics, and performance data have been determined through

sampling, testing, and statistical analysis during qualification and product manufacture. Other sampling or test procedures may

produce different values. A material used in a particular application must be tested by the customer for suitability for the intended

use, and user assumes all risk and liability whatsoever in connection therewith. Revisions are not intended to indicate a process

or product change, but a reflection of current technologies. No freedom in your own particular application is inferred. This is not a

product specification, nor will it form part of any ensuing sales contract from patent infringement.

You might also like

- MF6400 WSM 10 en PDFDocument186 pagesMF6400 WSM 10 en PDFosteanu100% (4)

- LLBF 122FDocument1 pageLLBF 122FYefrain J. ArzolayNo ratings yet

- Product Data SheetDocument2 pagesProduct Data SheetshahneillNo ratings yet

- 3 Property R3450 EngDocument1 page3 Property R3450 EngMohit MohataNo ratings yet

- Sé Etec: ApplicationsDocument1 pageSé Etec: ApplicationsMohit MohataNo ratings yet

- Delrin100 NC10Document2 pagesDelrin100 NC10avinashchauhan2695No ratings yet

- Driscoplex 5300 Series Pe3608 / (Pe3408) : Geothermal Systems Data SheetDocument2 pagesDriscoplex 5300 Series Pe3608 / (Pe3408) : Geothermal Systems Data SheetmariannyNo ratings yet

- TDS ASIA MACLINE TMH Rev7 Mar 2015Document1 pageTDS ASIA MACLINE TMH Rev7 Mar 2015Andrew Zapanta Jr.No ratings yet

- 3 Property H7900 EngDocument1 page3 Property H7900 EngMohit MohataNo ratings yet

- Driscopipe 8100 PE4710-PE100 / (PE3408) : Pipe Data SheetDocument2 pagesDriscopipe 8100 PE4710-PE100 / (PE3408) : Pipe Data SheetmariannyNo ratings yet

- Driscoplex 3100 Series Pipe Data Sheet: Property Unit Test Procedure Typical ValueDocument2 pagesDriscoplex 3100 Series Pipe Data Sheet: Property Unit Test Procedure Typical ValuemariannyNo ratings yet

- Séetec: ApplicationsDocument1 pageSéetec: ApplicationsAdonis BasilioNo ratings yet

- UmaPET - TFDocument3 pagesUmaPET - TFLuz Angela GuerreroNo ratings yet

- Ficha Tecnica Material BcoDocument1 pageFicha Tecnica Material BcoDaniel NavaNo ratings yet

- UK NatureFlex NPFDocument2 pagesUK NatureFlex NPFHavir GhteuNo ratings yet

- 3 Property H1501 EngDocument1 page3 Property H1501 EngMohit MohataNo ratings yet

- Ensinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Document2 pagesEnsinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Arthur EmidioNo ratings yet

- Driscoplex 6500 Pe2708 / (Pe2406) Pipe: Pipe & Fittings Data SheetDocument2 pagesDriscoplex 6500 Pe2708 / (Pe2406) Pipe: Pipe & Fittings Data SheetmariannyNo ratings yet

- Pellethane 5863-82AE TPU: Technical Data SheetDocument2 pagesPellethane 5863-82AE TPU: Technical Data SheetaNo ratings yet

- PP TD20 Lotte JHC-372Document1 pagePP TD20 Lotte JHC-372Herman SujarwantoNo ratings yet

- POM Delrin 500CLDocument2 pagesPOM Delrin 500CLcountzeroaslNo ratings yet

- Lotrène FE8000 2014 04 16Document2 pagesLotrène FE8000 2014 04 16aman.chaudhary3663No ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsvassaNo ratings yet

- LLBF 218aDocument1 pageLLBF 218aYefrain J. ArzolayNo ratings yet

- Estane 58887Document2 pagesEstane 58887M J VoraNo ratings yet

- ASTM FL7100U Eng 240223Document1 pageASTM FL7100U Eng 240223MERVENo ratings yet

- POM Delrin 900 HFDocument2 pagesPOM Delrin 900 HFcountzeroaslNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- TDS (CPP Lamination-30Document1 pageTDS (CPP Lamination-30Zaheer AbbasNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data Sheetnadaelbeltagy4No ratings yet

- W11la080 (30%)Document1 pageW11la080 (30%)Pame Zúñiga MartínezNo ratings yet

- Lldpe FN810 (Octeno Sin Slip)Document2 pagesLldpe FN810 (Octeno Sin Slip)Hữu LộcNo ratings yet

- Zytel HTN52 G35 HSLDocument5 pagesZytel HTN52 G35 HSLVisan GheorgheNo ratings yet

- TDS F4600Document2 pagesTDS F4600tech.omNo ratings yet

- Ranpelen j-590kDocument1 pageRanpelen j-590kRicardo CorreaNo ratings yet

- Polimaxx 1102K Product Data Sheet 1 1Document1 pagePolimaxx 1102K Product Data Sheet 1 1Kaleb Rido ManurungNo ratings yet

- Polimaxx 1102K Product Data Sheet 1 1Document1 pagePolimaxx 1102K Product Data Sheet 1 1Kaleb Rido ManurungNo ratings yet

- Pink Anti Static Bag BondlineDocument2 pagesPink Anti Static Bag Bondlineeky susilowatiNo ratings yet

- PP RANDOM Lotte - Ranpelen - J590K MI 44Document1 pagePP RANDOM Lotte - Ranpelen - J590K MI 44Luis LOZANONo ratings yet

- Exceed™ XP 8318MJ: Performance PolymerDocument2 pagesExceed™ XP 8318MJ: Performance PolymerMaram YasserNo ratings yet

- HOSTAPHAN® Polyester films..PETDocument10 pagesHOSTAPHAN® Polyester films..PETsreeeragNo ratings yet

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

- Pghsim33 01NCDocument2 pagesPghsim33 01NCRanjan GnanaoliNo ratings yet

- 3812 ExceedDocument2 pages3812 ExceedJimmys GothiqueNo ratings yet

- Cx5 14 Single Use Film Validation Guide REFER For ABOUT FILMDocument15 pagesCx5 14 Single Use Film Validation Guide REFER For ABOUT FILMCampaign MediaNo ratings yet

- PC Abs Spec SheetDocument2 pagesPC Abs Spec SheetAli YudiNo ratings yet

- FB3003Document2 pagesFB3003davidsonnet0% (1)

- H1 AftDocument4 pagesH1 Aftmp3475No ratings yet

- Product Data Sheet PP 200Document1 pageProduct Data Sheet PP 200AlonsoNo ratings yet

- Tencate Mirafi HP 370Document1 pageTencate Mirafi HP 370Tony_candyNo ratings yet

- Dow Elite 5400G TDSDocument2 pagesDow Elite 5400G TDSAli RazuNo ratings yet

- Y25GRDocument1 pageY25GRPiyush A JoshiNo ratings yet

- Spec Geo Bag PDFDocument1 pageSpec Geo Bag PDFBAMBANG IRAWANNo ratings yet

- Datasheet - r680s - Randompp - e 3Document2 pagesDatasheet - r680s - Randompp - e 3Gulzar HossainNo ratings yet

- Geotex 801 PdsDocument1 pageGeotex 801 PdsClaudiaNo ratings yet

- GP100ORXP enUS ASTMDocument1 pageGP100ORXP enUS ASTMRaul ArmendarizNo ratings yet

- ELITE 5401G: Blown Film ResinDocument2 pagesELITE 5401G: Blown Film ResinEndayenew MollaNo ratings yet

- H T NH A Lldpe 1002en TdsDocument1 pageH T NH A Lldpe 1002en TdsChu ChuNo ratings yet

- H T NH A Lldpe 1002en TdsDocument1 pageH T NH A Lldpe 1002en TdsChu ChuNo ratings yet

- Hdpe Me8000 (En)Document1 pageHdpe Me8000 (En)Judith Casstañeda AgurtoNo ratings yet

- Lecture Slides Week 14Document21 pagesLecture Slides Week 14ghd hfgsd hgfsNo ratings yet

- BE Electronics Engineering - Syllabus PDFDocument37 pagesBE Electronics Engineering - Syllabus PDFsneha singhNo ratings yet

- TD 62305Document9 pagesTD 62305hassanNo ratings yet

- Module 4 Communication For Work Purposes Unit 1: Formal and Informal Reports in A Work PlaceDocument4 pagesModule 4 Communication For Work Purposes Unit 1: Formal and Informal Reports in A Work PlaceGab IgnacioNo ratings yet

- Lesson 8 Wlan TroubleshootingDocument107 pagesLesson 8 Wlan Troubleshootingmadhav surineniNo ratings yet

- BEM 126 Mikroskop Digital - V2 English - Win10Document40 pagesBEM 126 Mikroskop Digital - V2 English - Win10Jeven Hanbert JeremyNo ratings yet

- 20480B Programming in HTML5 With JavaScript and CSS3Document11 pages20480B Programming in HTML5 With JavaScript and CSS3zolodjoNo ratings yet

- GSM Network ArchitectureDocument55 pagesGSM Network Architecturealeesha1987No ratings yet

- Instructions enDocument14 pagesInstructions enflash_90697638No ratings yet

- Konstantinos Lisgaras: Professional ProfileDocument2 pagesKonstantinos Lisgaras: Professional ProfileKonstantinos LisgarasNo ratings yet

- 21a Lab4 IntroDocument5 pages21a Lab4 Introkarthikp207No ratings yet

- Citibank, N.A. Fraud Prevention PO BOX 769027-9027 SAN ANTONIO TX 78245-9963Document2 pagesCitibank, N.A. Fraud Prevention PO BOX 769027-9027 SAN ANTONIO TX 78245-9963Munir El FakihNo ratings yet

- Vocational Training ReportDocument15 pagesVocational Training ReportSaroj KumarNo ratings yet

- DH Hac Hdw1200em Poc Datasheet 201904041Document3 pagesDH Hac Hdw1200em Poc Datasheet 201904041Sylvain DeryckereNo ratings yet

- Informatics Engineering An International Journal IEIJDocument2 pagesInformatics Engineering An International Journal IEIJAnonymous w6iqRPANo ratings yet

- D95-110-125 - Brochure - EnterpriseDocument12 pagesD95-110-125 - Brochure - Enterprisekhoi vuNo ratings yet

- Centrifugal and Axial Compressor Control by Gregory K. McMillanDocument133 pagesCentrifugal and Axial Compressor Control by Gregory K. McMillanDaniel Villanueva100% (2)

- Ekm - December - 2023-1Document2 pagesEkm - December - 2023-1kamaleshwerNo ratings yet

- Student Java Online Documentation AdvancDocument35 pagesStudent Java Online Documentation AdvancVijayNo ratings yet

- Mercruiser Shift CablesDocument9 pagesMercruiser Shift CablesJSMarine Parts ChinaNo ratings yet

- S.Achudhan: Automotive-Sales EngineerDocument2 pagesS.Achudhan: Automotive-Sales EngineerSobbyNo ratings yet

- Tugas 4 (Inverse Response Chapter 17)Document5 pagesTugas 4 (Inverse Response Chapter 17)PKM KLAMPIS NGASEMNo ratings yet

- CILINDROSDocument36 pagesCILINDROSRenzo Paredes ObandoNo ratings yet

- Lenovo RecoveryDocument6 pagesLenovo RecoverycNo ratings yet

- Nissan Livina L11 - Engine Control SystemDocument629 pagesNissan Livina L11 - Engine Control SystemH. Yusmira (Kang Otto)No ratings yet

- HIMA TrainingDocument26 pagesHIMA TrainingmshahabahmadNo ratings yet

- Micrometer 1Document1 pageMicrometer 1Ikhuosho AbodeNo ratings yet

- VLSIDocument12 pagesVLSIPeer MohamedNo ratings yet

- Arduino UNO Con NRF24L01PDocument6 pagesArduino UNO Con NRF24L01PspidyheroNo ratings yet