Professional Documents

Culture Documents

Magnetic Particle Inspection Report: TEM INSPECTED: Assembly (X Over 2",pipes 2",elbows)

Magnetic Particle Inspection Report: TEM INSPECTED: Assembly (X Over 2",pipes 2",elbows)

Uploaded by

Khalil ChabbouhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Magnetic Particle Inspection Report: TEM INSPECTED: Assembly (X Over 2",pipes 2",elbows)

Magnetic Particle Inspection Report: TEM INSPECTED: Assembly (X Over 2",pipes 2",elbows)

Uploaded by

Khalil ChabbouhCopyright:

Available Formats

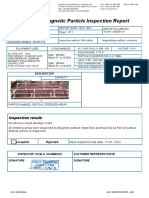

MAGNETIC PARTICLE INSPECTION REPORT

Customer: WEATHERFORD. Report No:1254872A785

Rig: N-A Date: 14/12/2020

Next MPI inspection due date: 13/12/2021

Test Location: weatherford Base II w.o n:

PAGE: 1 OF 1

TEM INSPECTED: Assembly( x over 2",Pipes 2",elbows)

SERIAL / ID NO: 5566

Material: N/A Surface Condition: Cleaned to Bare Metal

o

Welding Process: N/A Test Temperature: Ambient 23 C

Welder ID: N/A Illumination: Minimum 1000Lx

Drawing No: N/A 2

Black Intensity: 1000 μ watts/cm min

Materials Used for Magnetic Particle Test / Inspection

Equipment Ser No. Equipment X Ser No. Magnetizing Process : Continuous Residual

AC YOKE 7973 UV METER: X 1320005430 Magnetizing Current : Alternating Direct

DC COIL 176 LIGHT METER: 1320005430 Equipment Ser No. AC YOKE 4.5kg Test Weight OK

BLACK LIGH 180 YOKE TEST WEIGHT A205 Magnetic Field Strength Indicator M1159 COIL 1200 AMP TURNS

Consumables X

Type Batch

X No. Magnetizing Coil Prods Yoke

Method : Permanent Magnet

WHITE CONTRAST PAINT PFINDER L1 102932 Magnetic Field Indicator: Burmah Castrol Strip

BLACK MAGNETIC INK PFINDER L1 029065 Light Intensity:Illumination before inspection 1000 Lx

Demagnetization: YES No

WET FLUORESECENT X PFINDER L1 165526

DRY POWDER N-A N-A Particle consontration : black ink 2.4/100ml

Particle consontration : fluorescent 0.4/100ml

Specifications: : API RP 8B Magnetic Particles Dry Wet

OTHER: ASTM 709-08

Inspection category - Visible Fluorescent

Scope of Work: 100% Magnetic Particle Inspection ON all welding areas were inspected

Results: No surface breaking defects found in areas inspected at the time of test

Acceptable to the applied code

No obvious visual damage noted

Tool OK, Ready to Ship Needs Repair Tool Rejected, Do Not Use

Inspectors Name khalil chabbouh Customer

Qualification: ASNT INSPECTOR LEVEL II

signature

You might also like

- Cswip 3.0 ReportingDocument32 pagesCswip 3.0 ReportingAvijit DebnathNo ratings yet

- Thread Protector Testing - PTR-7.3.10-7-LCSG-FULL-PLASTIC-API-5-CT-PERFORMANCE-TEST-REPORTDocument38 pagesThread Protector Testing - PTR-7.3.10-7-LCSG-FULL-PLASTIC-API-5-CT-PERFORMANCE-TEST-REPORTInChy Rencarnation PoseidonNo ratings yet

- Design and Fabrication of Spice DryersDocument80 pagesDesign and Fabrication of Spice DryersANAND KRISHNAN100% (2)

- 07 Bubble BreakDocument25 pages07 Bubble BreakWeb LogueandoNo ratings yet

- Mpi Pipe Rack PR 03-1.Document1 pageMpi Pipe Rack PR 03-1.Khalil ChabbouhNo ratings yet

- MI Barite Tank 2 Mpi RepDocument7 pagesMI Barite Tank 2 Mpi RepChristopher Jones100% (1)

- Procedure Qualification Records (PQR) : KAL.f.009 REV:01 01.07.2002Document2 pagesProcedure Qualification Records (PQR) : KAL.f.009 REV:01 01.07.2002Walid BdeirNo ratings yet

- Paharpur Cooling Towers LTD: Magnetic Particle Testing ReportDocument1 pagePaharpur Cooling Towers LTD: Magnetic Particle Testing ReportGoutam Kumar DebNo ratings yet

- Weld Inspection Report / Sentence Sheet Print Full Name: Specimen NumberDocument6 pagesWeld Inspection Report / Sentence Sheet Print Full Name: Specimen NumberWalid BdeirNo ratings yet

- International Limited: Magnetic Particle Inspection ReportDocument43 pagesInternational Limited: Magnetic Particle Inspection ReportMichael OkwuwaNo ratings yet

- Welding Procedure Specification (WPS) : Page: 1/1Document5 pagesWelding Procedure Specification (WPS) : Page: 1/1Walid BdeirNo ratings yet

- Ultrasonic Test Report: Before AfterDocument7 pagesUltrasonic Test Report: Before AfterMenad SalahNo ratings yet

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document5 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair Vanmazhy100% (1)

- Engineering Specifications - Inspection: Rev. FDocument17 pagesEngineering Specifications - Inspection: Rev. Fstephen lewellen100% (1)

- Calibration Certificate: Page 1 / 1Document1 pageCalibration Certificate: Page 1 / 1Eduard GadzhievNo ratings yet

- Magnetic Particle Inspection Report: Test Performed by Witnessed/ Reviewed by Aries Client Class/TpiDocument1 pageMagnetic Particle Inspection Report: Test Performed by Witnessed/ Reviewed by Aries Client Class/TpiMurugan Raja100% (1)

- Hardness Test Report: Test Details Machine DetailsDocument1 pageHardness Test Report: Test Details Machine DetailsESHWAR CHARYNo ratings yet

- Surface Preparation & Painting ProcedureDocument9 pagesSurface Preparation & Painting ProcedureRam ThevarNo ratings yet

- Sembcorp Marine Integrated Yard PteDocument3 pagesSembcorp Marine Integrated Yard PteMd. Mizanur Rahaman100% (1)

- WI-08 - Work Instruction For Use of UTM 18.03.2021Document1 pageWI-08 - Work Instruction For Use of UTM 18.03.2021Saurav KumarNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument2 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationWaranya Musika100% (1)

- Cert - Mobile Crane 30T - LOLER - Model Rok300Document2 pagesCert - Mobile Crane 30T - LOLER - Model Rok300Rafael Lecu100% (1)

- SPIJ - Flow 04 ProductionDocument20 pagesSPIJ - Flow 04 ProductionPandu Priyo Pambudi MbeNo ratings yet

- 7.1 Inspection TeamDocument70 pages7.1 Inspection TeamWalid BdeirNo ratings yet

- Rigging Platform 25-05-2022-1Document1 pageRigging Platform 25-05-2022-1dele jimohNo ratings yet

- Magnetic Praticle Inspection ProcedureDocument9 pagesMagnetic Praticle Inspection ProcedureTouil HoussemNo ratings yet

- Job Safety Analysis (Jsa) : Normal Ppe, Hand and Firnger Pinch PointsDocument1 pageJob Safety Analysis (Jsa) : Normal Ppe, Hand and Firnger Pinch PointskhurramNo ratings yet

- NCR Close-Out Sheet FormatDocument2 pagesNCR Close-Out Sheet FormatAdarsh AshNo ratings yet

- PRES TIG Hot Wire Narrow Gap Welding enDocument25 pagesPRES TIG Hot Wire Narrow Gap Welding enRavishankarNo ratings yet

- MT Form Asme PDFDocument1 pageMT Form Asme PDFTrung Tinh HoNo ratings yet

- Daily Welding Report: Quality Control FormDocument1 pageDaily Welding Report: Quality Control FormashwinNo ratings yet

- Result of Inspection: ConclusionDocument5 pagesResult of Inspection: ConclusionBayu Aringga putraNo ratings yet

- Dokumen - Tips Wqt-FormatDocument2 pagesDokumen - Tips Wqt-FormatMr Pie100% (1)

- Ut PWPS 001Document1 pageUt PWPS 001Goutam Kumar Deb100% (1)

- Structural Steel and Pipe Work ProcedureDocument5 pagesStructural Steel and Pipe Work ProcedureMohamed100% (2)

- 4260Document10 pages4260Lipika GayenNo ratings yet

- 3g Tar WPQTR Form Aws d1.1Document2 pages3g Tar WPQTR Form Aws d1.1Scott AdkinsNo ratings yet

- Procedure For Liquid Penetrant ExaminationDocument12 pagesProcedure For Liquid Penetrant ExaminationShashank ParmarNo ratings yet

- Welding & NDE Summary Sheet (BE)Document12 pagesWelding & NDE Summary Sheet (BE)MulPXNo ratings yet

- 04 Dye Penetration TestDocument10 pages04 Dye Penetration TestTulasidas SugguNo ratings yet

- Specification: 70.78412 Revision: I Date: August 13, 2010 Specification - General Procedure - Brinell and Rockwell Hardness TestingDocument4 pagesSpecification: 70.78412 Revision: I Date: August 13, 2010 Specification - General Procedure - Brinell and Rockwell Hardness Testingstephen lewellenNo ratings yet

- TubestarDocument29 pagesTubestarPernando Saga100% (1)

- Safety Alert Space HeatersDocument2 pagesSafety Alert Space HeatersRamadan KareemNo ratings yet

- Summary TER of 13 Unit 20FT ISO Dry ContainerDocument219 pagesSummary TER of 13 Unit 20FT ISO Dry ContainerGhilman0529No ratings yet

- KYORITSU Earth Testers (4105A)Document1 pageKYORITSU Earth Testers (4105A)tivaro bakabtNo ratings yet

- F.e.& Scba InspectionDocument5 pagesF.e.& Scba InspectionAviects Avie JaroNo ratings yet

- QC ReportDocument12 pagesQC ReportManikandan MNo ratings yet

- International Limited: Certificate of Visual Examination and MpiDocument2 pagesInternational Limited: Certificate of Visual Examination and MpiMichael OkwuwaNo ratings yet

- Handling ToolsDocument21 pagesHandling ToolsMehmet SoysalNo ratings yet

- Quality Docs DEP 17 0803Document7 pagesQuality Docs DEP 17 0803Edwin MPNo ratings yet

- Eye Bolt Inspection Report: Last of ExaminationDocument7 pagesEye Bolt Inspection Report: Last of ExaminationRonniNo ratings yet

- BÖHLER (MSDS) SMAW-AVESTA 2205 E2209-15 Expires 15-12-05Document2 pagesBÖHLER (MSDS) SMAW-AVESTA 2205 E2209-15 Expires 15-12-05PubcrawlNo ratings yet

- Team Mentor/ Leader Mr. Manish Gautam, Team Members:-Rakesh Kumar, Uday Gururani, Ankur Agarwal, Arvind, Antony, Sathish, RohitDocument1 pageTeam Mentor/ Leader Mr. Manish Gautam, Team Members:-Rakesh Kumar, Uday Gururani, Ankur Agarwal, Arvind, Antony, Sathish, RohitRakesh KumarNo ratings yet

- SWP-12 Pressure TestDocument3 pagesSWP-12 Pressure TestLumin HanNo ratings yet

- Risk Assessment Maintenance: L - Likelihood S - Severity RL - Risk LevelDocument3 pagesRisk Assessment Maintenance: L - Likelihood S - Severity RL - Risk LevelMohamed Elnagdy100% (1)

- Elevator Link Ears MPIDocument1 pageElevator Link Ears MPIRanjithNo ratings yet

- Back Gouging ProcedureDocument2 pagesBack Gouging ProcedureVishal SharmaNo ratings yet

- Inspection Equipment InstructionDocument21 pagesInspection Equipment InstructionSaravana kumar NagarajanNo ratings yet

- 1 WPS & PQRDocument2 pages1 WPS & PQRManoranjan sharmaNo ratings yet

- WPS - 0601 00112 01 PDFDocument1 pageWPS - 0601 00112 01 PDFAnonymous zzMwR2aNNo ratings yet

- Mpi 44444286 ..Document1 pageMpi 44444286 ..Khalil ChabbouhNo ratings yet

- 0026 Lifting PlugDocument1 page0026 Lifting PlugKhalil ChabbouhNo ratings yet

- 2370 Cross OverDocument1 page2370 Cross OverKhalil ChabbouhNo ratings yet

- Mpi Report With Uv Trdi1 Spacer Can New1Document2 pagesMpi Report With Uv Trdi1 Spacer Can New1Khalil ChabbouhNo ratings yet

- 0011 Lifting PlugDocument1 page0011 Lifting PlugKhalil ChabbouhNo ratings yet

- TB 5003,, (New4Document1 pageTB 5003,, (New4Khalil ChabbouhNo ratings yet

- X Over 8Document1 pageX Over 8Khalil ChabbouhNo ratings yet

- Mpi 44444286 ..Document1 pageMpi 44444286 ..Khalil ChabbouhNo ratings yet

- Bushing Drive Sub 31766Document1 pageBushing Drive Sub 31766Khalil ChabbouhNo ratings yet

- Fishing Jar 285204 .Document1 pageFishing Jar 285204 .Khalil ChabbouhNo ratings yet

- TB0084Document1 pageTB0084Khalil ChabbouhNo ratings yet

- 02 Spiral Drill Collar Slip Groove 6 1-2 4 1-2 IfDocument2 pages02 Spiral Drill Collar Slip Groove 6 1-2 4 1-2 IfKhalil ChabbouhNo ratings yet

- Mpi Pipe Rack PR 03-1.Document1 pageMpi Pipe Rack PR 03-1.Khalil ChabbouhNo ratings yet

- 04 Spiral Drill Collar Slip Groove 4 3-4Document2 pages04 Spiral Drill Collar Slip Groove 4 3-4Khalil ChabbouhNo ratings yet

- Hp013 Lifting SubDocument1 pageHp013 Lifting SubKhalil ChabbouhNo ratings yet

- 03 HWDP Spiral 3 1-2 New ReportDocument2 pages03 HWDP Spiral 3 1-2 New ReportKhalil ChabbouhNo ratings yet

- 4 Legs Sling INA 182-1.Document1 page4 Legs Sling INA 182-1.Khalil ChabbouhNo ratings yet

- DME 2 Design of Spur GearDocument3 pagesDME 2 Design of Spur Gearthe secret legendNo ratings yet

- Beam AnalysisDocument14 pagesBeam AnalysisJakayaro Surianfo SyitasialoNo ratings yet

- Solar Thermal Hydrogen Production Via Reforming and Thermo Chemical CyclesDocument15 pagesSolar Thermal Hydrogen Production Via Reforming and Thermo Chemical CyclesСтефанија ЦековскаNo ratings yet

- Pile ClassificationDocument7 pagesPile ClassificationFarhan KhanNo ratings yet

- Njase Girls Secondary School: Department of Natural SciencesDocument4 pagesNjase Girls Secondary School: Department of Natural SciencesDaryll KabasoNo ratings yet

- Problem Set 1 SolutionsDocument15 pagesProblem Set 1 SolutionsNathan HaleNo ratings yet

- AsentamientosDocument205 pagesAsentamientosRodrigo AlfaroNo ratings yet

- Section : Operation of Instruments and ControlsDocument18 pagesSection : Operation of Instruments and ControlsHussainRazviNo ratings yet

- 7-6 ProbabilityDocument1 page7-6 Probabilityapi-507888392No ratings yet

- Advanced Course On Thermodynamic Models 2017Document4 pagesAdvanced Course On Thermodynamic Models 2017Luis FollegattiNo ratings yet

- Soil NailDocument305 pagesSoil Nailosamosa33% (3)

- Fluid Mechanics QtnsDocument3 pagesFluid Mechanics QtnsAnonymous NV1AeWXEo100% (1)

- UJTDocument43 pagesUJTRahul KiniNo ratings yet

- A2 XFa YDocument16 pagesA2 XFa Ylalith kumar100% (1)

- Paper: Coke Formation in The Oxidative Dehydrogenation of Ethylbenzene To Styrene by TEOMDocument12 pagesPaper: Coke Formation in The Oxidative Dehydrogenation of Ethylbenzene To Styrene by TEOMHanif Angga PutraNo ratings yet

- Plant Detection and Mapping For Agricultural Robots Using A 3D LIDAR SensorDocument9 pagesPlant Detection and Mapping For Agricultural Robots Using A 3D LIDAR SensorManar HosnyNo ratings yet

- Fastener Tightening PDFDocument3 pagesFastener Tightening PDFAbdullah AnsariNo ratings yet

- STEP File Analyzer PMI Representation STPDocument365 pagesSTEP File Analyzer PMI Representation STPwenNo ratings yet

- Concept Strengthening Sheet (CSS-01) Based On FTS-01&02 (A& B) - PhysicsDocument9 pagesConcept Strengthening Sheet (CSS-01) Based On FTS-01&02 (A& B) - PhysicsGarvit ModiNo ratings yet

- (Math) McGraw-Hill - Teach Yourself Trigonometry (1992)Document199 pages(Math) McGraw-Hill - Teach Yourself Trigonometry (1992)Bhert DjbsevenNo ratings yet

- BAS Flyer PDFDocument2 pagesBAS Flyer PDFFilip TeofilskiNo ratings yet

- Spheerol Epl GreaseDocument2 pagesSpheerol Epl GreaseRaja YadavNo ratings yet

- Electrostatics & CapacitanceDocument1 pageElectrostatics & CapacitancerockyNo ratings yet

- Introduction To Ultrasonic Thickness MeasurementDocument18 pagesIntroduction To Ultrasonic Thickness MeasurementNail Widya Satya100% (1)

- The Age of Metamaterials: EditorialDocument1 pageThe Age of Metamaterials: EditorialkhyatichavdaNo ratings yet

- Offshore Facilities: Technology FocusDocument8 pagesOffshore Facilities: Technology FocusAdhi Putra PamungkasNo ratings yet

- CanadaDocument108 pagesCanadafahmi fadillaNo ratings yet

- Depth PerceptionDocument39 pagesDepth Perceptionsandy_jaat100% (1)