Professional Documents

Culture Documents

DTC P0505 Idle Control System Malfunction: Circuit Description

DTC P0505 Idle Control System Malfunction: Circuit Description

Uploaded by

williamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DTC P0505 Idle Control System Malfunction: Circuit Description

DTC P0505 Idle Control System Malfunction: Circuit Description

Uploaded by

williamCopyright:

Available Formats

DI–109

DIAGNOSTICS – ENGINE

DI38I–04

DTC P0505 Idle Control System Malfunction

CIRCUIT DESCRIPTION

The rotary solenoid type IAC valve is located on the throttle

Intake Air body and intake air bypassing the throttle valve is directed to

Throttle Valve Chamber the IAC valve through a passage.

In this way the intake air volume bypassing the throttle valve is

From regulated, controlling the engine speed.

Air The ECM operates only the IAC valve to perform idle–up and

Cleaner provide feedback for the target idling speed.

Signal

ECM

Valve To Cylinder

IAC Valve

P01559

DTC No. DTC Detecting Condition Trouble AreaTrouble Area

S IAC valve is stuck or closed

S Open or short in IAC valve circuit

Idle speed continues to vary greatly from the target speed

P0505 S Open or short in A/C switch circuit

(2 trip detection logic)

S Air induction system

S ECM

2000 CELICA (RM744U)

DI–110

DIAGNOSTICS – ENGINE

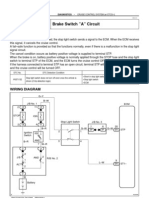

WIRING DIAGRAM

Engine Room J/B ECM

I1

EFI ISC Valve

1 EFI No. 1 3

B–R 5 3 2

2A 2C 18

B–R 1

E5 RSO

1 2 B–W

3

EFI Relay

12 W–B

21

2F E3 MREL

7 2H L–B

FL MAIN W–B

A

21

J2 A

J/C E5 EO1

W–B

A W–B

Battery

EB EC

A09123

2000 CELICA (RM744U)

DI–111

DIAGNOSTICS – ENGINE

INSPECTION PROCEDURE

HINT:

Read freeze frame data using TOYOTA hand–held tester or OBD II scan tool. Because freeze frame records

the engine conditions when the malfunction is detected, when troubleshooting it is useful for determining

whether the vehicle was running or stopped, the engine warmed up or not, the air–fuel ratio lean or rich, etc.

at the time of the malfunction.

1 Check engine idle speed.

PREPARATION:

(a) Warm up engine to normal operating temperature.

(b) Switch off all accessories.

(c) Switch off alrconditioning.

(d) Shift transmission into ”N” or neutral position.

(e) Connect the OBD II scan tool or TOYOTA hand–held tester to DLC3 on the vehicle.

(f) Using SST, connect terminals TE1 and E1 of the DLC1.

CHECK:

Check the difference of engine speed between the ones less than 5 sec. and more than 5 sec. after connect-

ing terminals TE1 and E1 of the DLC1.

OK:

Difference of engine speed: More than 100 rpm.

OK Go to step 6.

NG

2000 CELICA (RM744U)

DI–112

DIAGNOSTICS – ENGINE

2 Check voltage between terminals RSO, RSC of ECM connector and body ground.

ON PREPARATION:

(a) Remove the ECM cover.

(b) Disconnect the E5 connector of ECM.

(c) Turn the ignition switch ON.

CHECK:

Measure voltage between terminals RSO of the ECM connec-

E5 tor and body ground,

Connector

RSO (+) OK:

A09086 A09100 Voltage: 9 – 14 V

OK Go to step 4.

NG

3 Check IAC valve (See page SF–40).

NG Replace IAC valve.

OK

Check for open and short in harness and

connector between engine room J/B No.2

and IAC valve and ECM (See page IN–30).

4 Check operation of the IAC valve (See page SF–40).

NG Repair or replace IAC valve.

OK

2000 CELICA (RM744U)

DI–113

DIAGNOSTICS – ENGINE

5 Check the blockage of IAC valve and the passage to bypass the throttle valve.

NG Repair or replace IAC valve.

OK

Check and replace ECM (See page IN–30).

6 Check for A/C signal circuit (See page AC–68).

NG Repair or replace.

OK

Check air induction system

(See page SF–1).

2000 CELICA (RM744U)

You might also like

- Nelson Physics 11 SolutionsDocument14 pagesNelson Physics 11 SolutionsRhea100% (1)

- 3UR-FE Engine ProperDocument8 pages3UR-FE Engine Properwilliam86% (7)

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- Charles Baudelaire '' The Painter of Modern Life''Document8 pagesCharles Baudelaire '' The Painter of Modern Life''Rana ZulqarnainNo ratings yet

- Skid Control Ecu Communication Stop Mode: Circuit DescriptionDocument12 pagesSkid Control Ecu Communication Stop Mode: Circuit DescriptionAfghan SportNo ratings yet

- DTC 14 Timing Control System Malfunction: Circuit DescriptionDocument3 pagesDTC 14 Timing Control System Malfunction: Circuit DescriptionFerry DarmawanNo ratings yet

- CiacisDocument8 pagesCiacisVladimir CedeñoNo ratings yet

- Circuit Inspection DTC P0100 Mass Air Flow Circuit MalfunctionDocument4 pagesCircuit Inspection DTC P0100 Mass Air Flow Circuit MalfunctionJuanloNo ratings yet

- 056 - Anti-Lock Brake System - IG Power Source CircuitDocument3 pages056 - Anti-Lock Brake System - IG Power Source CircuitfranciscoNo ratings yet

- ECM Power Source CircuitDocument4 pagesECM Power Source CircuitJerry AlexanderNo ratings yet

- M Di 0145 PDFDocument4 pagesM Di 0145 PDFJuanCarlosCastilloNo ratings yet

- Fuel Pressure ControlDocument4 pagesFuel Pressure ControlSirleh SalehNo ratings yet

- DTC C1231/31 Malfunction in Steering Angle Sensor CircuitDocument4 pagesDTC C1231/31 Malfunction in Steering Angle Sensor CircuitCarlos MonarNo ratings yet

- Codigo de FallaDocument5 pagesCodigo de FallaMarco Yarasca RomeroNo ratings yet

- DTC 33 Intake Shutter Control Circuit MalfunctionDocument2 pagesDTC 33 Intake Shutter Control Circuit Malfunctiondima65No ratings yet

- DTC C1378/44 Capacitor Communication Circuit MalfunctionDocument4 pagesDTC C1378/44 Capacitor Communication Circuit Malfunctionshalyn matines dabulamanziNo ratings yet

- Source Voltage Drop: Circuit DescriptionDocument3 pagesSource Voltage Drop: Circuit DescriptionPhang KumwingNo ratings yet

- Fuel Pump ControlDocument9 pagesFuel Pump ControlDaniel Mamani ParedezNo ratings yet

- Circuit Inspection DTC P0100/31 Mass Air Flow Circuit MalfunctionDocument6 pagesCircuit Inspection DTC P0100/31 Mass Air Flow Circuit MalfunctionMiguel ruizNo ratings yet

- DTC P0571/52 Brake Switch "A" CircuitDocument4 pagesDTC P0571/52 Brake Switch "A" CircuitErln LimaNo ratings yet

- ECM Power Source CircuitDocument4 pagesECM Power Source CircuitErln LimaNo ratings yet

- DTC P1200 Fuel Pump Relay/ECU Circuit MalfunctionDocument4 pagesDTC P1200 Fuel Pump Relay/ECU Circuit MalfunctiononealNo ratings yet

- Srs Warning Light Circuit Malfunction (Always Light Up, When DTC Is Not Output)Document3 pagesSrs Warning Light Circuit Malfunction (Always Light Up, When DTC Is Not Output)Phang KumwingNo ratings yet

- Charging PDFDocument16 pagesCharging PDFred eagle winsNo ratings yet

- DTC 12 Actuator Magnetic Clutch CircuitDocument3 pagesDTC 12 Actuator Magnetic Clutch CircuitIcaro FerreiraNo ratings yet

- Starter Cut Relay PDFDocument2 pagesStarter Cut Relay PDFPhang Kumwing0% (1)

- DTC 32 Injection Pump Correction System Malfunc-Tion: Circuit DescriptionDocument2 pagesDTC 32 Injection Pump Correction System Malfunc-Tion: Circuit DescriptionsundarNo ratings yet

- Cic 13404Document3 pagesCic 13404GEME MSDFNo ratings yet

- MAFDocument4 pagesMAFJonn Sim-One100% (1)

- 19 +ECU+Power+Source+CircuitDocument5 pages19 +ECU+Power+Source+Circuitmoh12109100% (1)

- CitcandcDocument4 pagesCitcandcrenimoNo ratings yet

- C1742 PDFDocument8 pagesC1742 PDFbob loblawNo ratings yet

- Ci P0500Document2 pagesCi P0500David BenazeraNo ratings yet

- DTC P0300 Random/Multiple Cylinder Misfire Detected: Circuit DescriptionDocument6 pagesDTC P0300 Random/Multiple Cylinder Misfire Detected: Circuit DescriptionsalusfrankNo ratings yet

- DTC P0705 Transmission Range Sensor Circuit Malfunction (PRNDL Input)Document4 pagesDTC P0705 Transmission Range Sensor Circuit Malfunction (PRNDL Input)luisNo ratings yet

- DTC P0505 Idle Control System Malfunction: Circuit DescriptionDocument3 pagesDTC P0505 Idle Control System Malfunction: Circuit DescriptionRC VilledaNo ratings yet

- DI102Document6 pagesDI102Erln LimaNo ratings yet

- Matrix 2003 2zz 7Document5 pagesMatrix 2003 2zz 7alan lantiguaNo ratings yet

- Schematic Winding MachineDocument1 pageSchematic Winding MachineĐịa LinhNo ratings yet

- DTC 14 Actuator Mechanical Malfunction: Circuit DescriptionDocument3 pagesDTC 14 Actuator Mechanical Malfunction: Circuit DescriptionIcaro FerreiraNo ratings yet

- This Document Has Been Printed From SPI . Not For Resale: Engine Management SystemDocument10 pagesThis Document Has Been Printed From SPI . Not For Resale: Engine Management SystemHaidar Al Mosawi100% (1)

- DI12Document2 pagesDI12Erln LimaNo ratings yet

- TestDocument9 pagesTestFauzi NanangNo ratings yet

- Pulse-Width-Modulation Control Circuits Az7500EDocument13 pagesPulse-Width-Modulation Control Circuits Az7500EMy shop Cool100% (1)

- DTC P1600 ECM BATT Malfunction: Circuit DescriptionDocument2 pagesDTC P1600 ECM BATT Malfunction: Circuit DescriptionDesron SamuelNo ratings yet

- DI60Document2 pagesDI60Erln LimaNo ratings yet

- Light Control Switch Circuit: Wiring DiagramDocument3 pagesLight Control Switch Circuit: Wiring DiagramPhang KumwingNo ratings yet

- SPN FMI ListDocument5 pagesSPN FMI ListWilder Dianderas Mandujano100% (1)

- Diagnostics EngineDocument5 pagesDiagnostics EnginePablo B. SoaresNo ratings yet

- 2AZ FE ChargingDocument21 pages2AZ FE ChargingTaufik RahmanNo ratings yet

- (TOYOTA) Manual de Cableado Toyota Corolla 2004 InglesDocument288 pages(TOYOTA) Manual de Cableado Toyota Corolla 2004 Inglesingenieria ipchileNo ratings yet

- DTC P0A0F/238 Engine Failed To Start: Circuit DescriptionDocument5 pagesDTC P0A0F/238 Engine Failed To Start: Circuit DescriptionGregori LoayzaNo ratings yet

- Ka 3511Document28 pagesKa 3511analias100% (1)

- M Di 0091 DTC1222 PDFDocument5 pagesM Di 0091 DTC1222 PDFSelvin GalindoNo ratings yet

- Power WindowDocument38 pagesPower WindowHuy PhạmNo ratings yet

- Lokasi Komponen - 70Document20 pagesLokasi Komponen - 70Gonot DanardonoNo ratings yet

- DTC 14 Timing Control System Malfunction: Circuit DescriptionDocument3 pagesDTC 14 Timing Control System Malfunction: Circuit DescriptionFerry Darmawan100% (1)

- DTC Always ON Malfunction in ECU: Circuit DescriptionDocument3 pagesDTC Always ON Malfunction in ECU: Circuit DescriptionErln LimaNo ratings yet

- Az7500bp - Pulse-Width-Modulation Control CircuitsDocument13 pagesAz7500bp - Pulse-Width-Modulation Control CircuitsArv Juur100% (3)

- ECM PowerDocument6 pagesECM PowerDaniel Mamani ParedezNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- 1GR-FE ENGINE CONTROL: SFI SYSTEM: P0340, P0342, P0343, P0345, P0347, P0348: Camshaft Position Sensor Circuit MalfunctionDocument12 pages1GR-FE ENGINE CONTROL: SFI SYSTEM: P0340, P0342, P0343, P0345, P0347, P0348: Camshaft Position Sensor Circuit MalfunctionwilliamNo ratings yet

- DTC P0130 Oxygen Sensor Circuit Malfunction (Bank 1 Sensor 1)Document4 pagesDTC P0130 Oxygen Sensor Circuit Malfunction (Bank 1 Sensor 1)williamNo ratings yet

- 1FZ-FE 1FZ-F 1992 Engine RM321E PDFDocument492 pages1FZ-FE 1FZ-F 1992 Engine RM321E PDFwilliamNo ratings yet

- Pershing Ia Operational ScenarioDocument42 pagesPershing Ia Operational ScenarioEd Palmer100% (2)

- Effects of Junk Food and Beverages On AdDocument7 pagesEffects of Junk Food and Beverages On AdAnonymous OP6R1ZSNo ratings yet

- 1.content - Mathematical Physics PDFDocument2 pages1.content - Mathematical Physics PDFbhavikNo ratings yet

- 2.13" SS100-G2-F: Motor Loads General Dimensional DataDocument1 page2.13" SS100-G2-F: Motor Loads General Dimensional DataTonyNo ratings yet

- Maths GPTDocument11 pagesMaths GPTmailNo ratings yet

- Oil Based Mud ThinnerDocument2 pagesOil Based Mud ThinnerjangriNo ratings yet

- ADMModule - S11 12PS-IIIa-2Document28 pagesADMModule - S11 12PS-IIIa-2Lebz Ricaram33% (3)

- Audi A6 (4B) Headlight Aim Control (Dynamic Light)Document2 pagesAudi A6 (4B) Headlight Aim Control (Dynamic Light)Krasimir PetkovNo ratings yet

- 1-Write A Program To Implement The Following Operations On One Dimensional Array A) InsertionDocument19 pages1-Write A Program To Implement The Following Operations On One Dimensional Array A) InsertionAnsh sharmaNo ratings yet

- Permanently Installed SensorsDocument2 pagesPermanently Installed SensorsrodrurenNo ratings yet

- Exercise 2: Rewrite The Sentences Without Changing The Meaning, Beginning As ShownDocument6 pagesExercise 2: Rewrite The Sentences Without Changing The Meaning, Beginning As ShownKhanh Linh TranNo ratings yet

- The Characteristic Golden Brown Colour Associated With Baked Food Is Due To Maillard ReactionsDocument2 pagesThe Characteristic Golden Brown Colour Associated With Baked Food Is Due To Maillard ReactionsDenzHackNo ratings yet

- Technical Data Sheet: Product Name: Product Form: Chemical NameDocument3 pagesTechnical Data Sheet: Product Name: Product Form: Chemical Namesahajahan shaikhNo ratings yet

- Actinomyces OdontolyticusDocument4 pagesActinomyces OdontolyticusLiviu Athos TamasNo ratings yet

- Sudden DeathDocument26 pagesSudden DeathAbang AzharNo ratings yet

- BeachDocument18 pagesBeachkarem754100% (3)

- Basic ChemistryDocument58 pagesBasic ChemistryFrancesco MauriNo ratings yet

- How To Calculate Wind Loads On Roof Mounted Solar Panels - Draft2Document4 pagesHow To Calculate Wind Loads On Roof Mounted Solar Panels - Draft2wellslhNo ratings yet

- SMD 357Document6 pagesSMD 357Marcoantonio AntonioNo ratings yet

- Bd8166efv e PDFDocument20 pagesBd8166efv e PDFmiteshNo ratings yet

- Comparison Between Features Extracted Schema For Mri Breast CancerDocument5 pagesComparison Between Features Extracted Schema For Mri Breast CancerBaru Chandrasekhar RaoNo ratings yet

- SMK Techno ProjectDocument36 pagesSMK Techno Projectpraburaj619No ratings yet

- Experiments in Virtual LabsDocument3 pagesExperiments in Virtual Labs39 Mohit KumarNo ratings yet

- Stative: Special Verbs - They Can Be Used As Stative and As DynamicDocument3 pagesStative: Special Verbs - They Can Be Used As Stative and As DynamicAnonymous Q21YDaSfNo ratings yet

- Rotork Actuator IQ Spec D900Document20 pagesRotork Actuator IQ Spec D900kikita2911*No ratings yet

- Mother JOnes Pinto MadnessDocument6 pagesMother JOnes Pinto MadnessLeidy Patricia CLAUDIO CUYUBAMBANo ratings yet

- Wijs-Cyclohexane MethodDocument4 pagesWijs-Cyclohexane Methodnuur iffahNo ratings yet