Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

31 viewsBD1 00 I S 0010 - 0 Fiscal Gas Metering

BD1 00 I S 0010 - 0 Fiscal Gas Metering

Uploaded by

DucCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- BD1-00-I-S-0001 - 1 Spec Integrated Control and Safety System (ICSS)Document109 pagesBD1-00-I-S-0001 - 1 Spec Integrated Control and Safety System (ICSS)Duc80% (5)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- HRSG Project Work Area DistributionDocument6 pagesHRSG Project Work Area DistributionDucNo ratings yet

- Iecex Certificate of ConformityDocument23 pagesIecex Certificate of ConformityDucNo ratings yet

- Material Safety Data Sheets: (MSDS)Document5 pagesMaterial Safety Data Sheets: (MSDS)DucNo ratings yet

- RefractoryDocument38 pagesRefractoryDucNo ratings yet

- BD100IR0002 - 0 HIPPS Valves Technical and Budgeting EstimatesDocument32 pagesBD100IR0002 - 0 HIPPS Valves Technical and Budgeting EstimatesDucNo ratings yet

- BD100IE0010 - 0 Fiscal Gas MeteringDocument23 pagesBD100IE0010 - 0 Fiscal Gas MeteringDucNo ratings yet

- BD1-00-I-S-0010 - 0 Fiscal Gas MeteringDocument80 pagesBD1-00-I-S-0010 - 0 Fiscal Gas MeteringDucNo ratings yet

- Vv3144-003-A-135!0!0010 Method Statement For Roof Fan InstallationDocument24 pagesVv3144-003-A-135!0!0010 Method Statement For Roof Fan InstallationDucNo ratings yet

- Vv3144-003-A-135 - 0 - 0010 Method Statement For Roof Fan InstallationDocument24 pagesVv3144-003-A-135 - 0 - 0010 Method Statement For Roof Fan InstallationDucNo ratings yet

- VJ215B-001-A-821 - 0 Installation Manual Refractory Lining Co BoilerDocument19 pagesVJ215B-001-A-821 - 0 Installation Manual Refractory Lining Co BoilerDucNo ratings yet

BD1 00 I S 0010 - 0 Fiscal Gas Metering

BD1 00 I S 0010 - 0 Fiscal Gas Metering

Uploaded by

Duc0 ratings0% found this document useful (0 votes)

31 views80 pagesOriginal Title

BD1 00 I S 0010_0 Fiscal Gas Metering

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

31 views80 pagesBD1 00 I S 0010 - 0 Fiscal Gas Metering

BD1 00 I S 0010 - 0 Fiscal Gas Metering

Uploaded by

DucCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 80

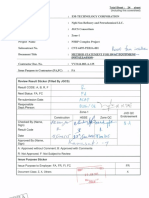

IEN DONG PETROLEUM OPERATING COMPANY

—— BIEN DONG 1 PROJECT

tem in pe eat

DOC. NO, — ~ =

‘OFFSHORE FACILITIES Page tof 74

1-00-45-0010

SPECIFICATION

GAS FISCAL METERING SYSTEM

© | 17Sept70 | Approved tor Use aru | Rev wg hy eel 7

‘rapr10_ | ~ Approved or Design (AFD) | RPK 8

@_| Feb 0 | Rerewved for Approval REA) | APY |W ca

CL Tiana | sawed foranproval Fay | RY | WS ca

Bi | T3Nevoe | sued forReview (FR) | APY | WS 7

[a tanec Teed for mv) ws 1

ev | _ Date Description 1ecka_| WP Appa | BD POCAne'a

4

Specification for Gas Fiscal Metering System Document No: B1-00+-5-0010

7-Sept-2010,

ITRODUCTION

11 Project Description

1.2 Purpoce

1.3 Acronyms ae Asbreviations

44 Definitions

15 Order of Precedence

[APPLICABLE SPECIFICATIONS, CODES AND STANOARDS

2.1 Project Documents and Speciiatons

2.2. International Codes and Standards

2.3. Applicable Vetnam Standareés

2.4 Wieiamese Laws and Repuations

(GENERAL REQUIREMENTS

3.4 VENDOR Scope and Responsibly

3.2 vENOORHAZOP

3.2 VENDOR Technical Asstance

34 VENDOR'S Exceptions

35 Operation and Design Lite

3.6 Location and Environmental Conditions

3.7 Hazardous rea Classification

3.8 Environmental Protection

3.9 Welt Contr

30. Transportation

3.11 COMPANY Supplies

2.12 Unite of Neaurements

‘TECHNICAL REQUIREMENTS

44 General

42 Project Speci Requrement

43 FS Skid Instrumentation

44 Fiscal Metering Panet

Date

Page 20174

Rev 10

‘TABLE OF CONTENTS

“Tile: Specification for Gas Fiscal Metering System

Date 7-Sept-2010,

Page orm

Rev

Document No: 100--5-0010

10.

"

2

45 Buy Back as

48 Mechanical-Pping

47 Strcturat

48° electrical

INSPECTION AND TESTING

51 Inspection

5.2 Quality Asurance:

5.3. Caliveaion, Testing and VT

54 Certificate of Acceptance

PROTECTIVE COATING AND INSULATION

MARKING

TA Sea Nameplate

7.2 Equipment Nameplate

SPECIAL TOOLS

2:1 ntllaton and Cmmisioning

82 VT Teo

Panes

PACKING AND SHIPPING

10.1. Preparation for Shipment

10.2. import Permits

WARRANTY

DOCUMENTATION AND TRAINING

2.1 Docamentation and ravings

12.2 Training and Operation

ATTACHNENT 1 - Gas Export Operating Criteria and Specification

ATTACHMENT 2 - Gas Fiscal Metering System Heat & Material Blance

ATTACHNENT 3 - Associated Gas Fiscal Metering Stern Typical Drawings

“Tile: Specification for Gas Fiscal Metering System ‘Document No: 801-00-45-0010

ate 7-Sept-2010

Paae oma

Rev

INTRODUCTION.

1.4 Project Description

Bion Dong Petroleum Operating Company is the operator of Blocks 05.2 and 05.3 approximately

“Mok southeast of Vang Ta, off the coast of Vietnam.

“This spectcation applies to all facies and projects in these Blocks

1.2 Purpose

“This Speciation covers the minimum requirements forthe design, engineering, procurement,

manufacturing, assembly, fabrication, Integration, configuration, Inspection, testing,

commissioning, traning and delivery of a gas fiscal metering system (FMS) consisting of 3

‘complete FUS skid (HT-SK-2800) and a FHS panel (HT-FNC-2800) tobe installed on Production &

(@aarter Platform in Hat Thach(PQP HT)

Vendor shall provide the Gas FS that have a history of at least vee fled installed systems

hich have been used in similar services for fv years or longer.

Vendor shall ensure that all equpment and services sipped meet the requirements of this

specification, the codes and stander and all other associated documents nominated herein,

sinether the equipment or services are supplied by the Vendor diecty or by his Sub Vendor.

AL deviations frm this specification or the documents referred to herein shall be stated In

‘writing. In the absence of sch statement, i willbe assimed thatthe requirements ofthe

specication are followed without exception. Any deficlencies in ths respect that ae identified

‘uring or subsequent to fabrication shal be ecified at the Vendors cast.

1.3. Acronyms and Abbreviations

ron seerican Gas Association

Asc ‘Automatic Gain Contr

at American Petroleum insite

ase ‘American Society of Mechanical Engincers

ast American Sctety of Testing and Materials

arex ‘Aamospheres Explosives

ans -merican Welding Society

a. Barret

con Candition Based Monitoring

cer Central Conert Roam

ea Electro Magnetic interference

rar Factory Acceptance Testing

Title: Specification for Gas Fiscal Metering System Document No: B01-00-15-0010

Date r7Sept-2010

Page Sof 74

Rev

Fas Fire & Gas Systm

rus scl Metering System consisting of Ska and Panels),

cc Ges chromatograph

rsa as Purchase and Sales Agreement

He Hydrocarbon

Henc He Chi in Cty

a Human Hache Interface

ar Hel Tach

uv Independent Atr Vertcation Tests

Ics Integrated Control & Safety System

tec International Electrotechnical Commission

eee Insitute of Electrical & Electronic Engineers

50 International Organization fr Standards

® Ingress Protection

5 ineascally Safe

8 neton Box

ta ving Quarters

ov otor Operated valve

ews anual of Petroleum Measurement Standards

ut Moc Tinh

nes Nam Gon Son Ppetine

om International Organization of Legal Metrology

es Process Cntrl System

Pop Production & Quarters Platform

POPHT Hal Thach Production & Quarters Patfoem

Rr Radio frequency interference

sar Site Acceptance Test

si Site integration Test

0s Shutdown system

src Stream Flow Computer

sw Signal to Noise Rolo

sos Speed Of Sound

s Stailes Steet

“Tile: Specification for Gas Fiscal Metering System Document No: B01-00:45-0010

ate 17-Sep-2010

Pose, of74

Rev

supe Supervisory Computer consisting of controller and workstation/HM

unm trasonc Flow Meter

us Uninterruptible Power Supply

vos Velocity of Sound

wae Wattnead Platform

WP-HTY Hal Thach 1 Wellhead Platform

WHP-ATI Moc Tinh 1 Welthend Platform

we WorleyParsons LTD

4.4. Definitions

‘conpany Bien Dong Joint Operating Company

CONSULTANT | WorleyParsons, Kuala Lumpur

contractor | TR person group, or organization responsible for the construction of

platform

‘The person, group, or argnlzation who places purchase order on the

purcuaser | The be

‘Independent 3. Party Certifying Authority appointed by VENDOR

‘rapa parry | approved bythe COMPANY for ceretying specie equlpment/equpment

pactages fabricated at VENDOR stop.

‘Compan /PURCHASER appointed person, group organization acting in

INSPECTOR behalf ofthe Company/Purchaser responsible for inspection and witness

testing of equipment equipment packages at Vendors shop

‘an independant agency contacted by the COMPANY to provide

Clasfication/Certieation services to Bien Dong! Field Development

CERTIFYING | Project's facts from design review to construction & commnisioning

ALTHORTY | tarp in accordance with CA Res & Rito, apple Coes

Standards & Vietnamese Reiser (VR) Regulations.

“Tile: Specification for Gas Fiscal Metering System ‘Document No: 8D1-00:45-0010,

ate 1 17Sept-2010

Pose. 27074

Rev 20

The person, group, or organization responsible for the desan,

o manufacture, testing, and load-out shiping at the Equpment.

“The person, group, or organization who may be employed by VENDOR to

provide. services for the design, manufacture, testing, and load

Sub-vendor | out/shipping of the equipment, or, to. provide materials, sub

omponents, and subassemblies fr incorporation within. VENOOR's

Scope ot sappy.

A schedule of lspection and test activites Identifying the stages at

Inspection and | which VENDOR, COMPANT, third parties, oF Independent inspectors are

Test Plan (TP) | involved and acatonaliy ientying the Involved. specifications,

acceptance eritara, and instructions that are relevant.

ray Division of an installation into hazardous areas and no-hazardou areas

Classification | andthe subdivision of hazardous ones

Three-dimensional space in which a flammable atmosphere may be

Hezardous area | expected to be present at such frequneses as to requte specs,

recautlons forthe contra of potential fgnition sources

‘rea in wich an explosive gas atmosphere f not expected tobe present

Nonazardous | in quantities such as to requ spela precautions fr the construction,

aren instalation and use of electrical apparatus and equipment in “normal

operation”

May Indieates posible couse of action,

‘Sha Indicates mandatory requirement.

Should Indicates preferred couse of action.

wa Indicates an intention of action

Independent Auditor Verification Tests (IAVT) carved out at intervals

‘agreed inthe GPSA, ver the operating period ofthe patform to

wr ‘oni thatthe FHS configuration, performance, callration, total

Uncertainty ete are in accordance with the GPSA. (The AVT shal be

‘ried out by an independent argalzationaporoved by the Vietnamese

Standards and aaurement Dot.

AS Supervisory computer consisting of PLC based or microprocessor based

redundant controler, PC-based worstation and HM

The dedicated ty UPM connected to dedicated duty SFC, reports

Duty Meter vihich ae used for nvacig purposes.

“Tile: Specification for Gas Fiscal Metering System ‘Document No: 801-00:45-0010

ate + 17-Sep-2010

Page of74

Rev 10

“The dedicated Reference UFM connected toa dedicated Reference FC,

Reference reports which are used for as reference curing series check of the uty

Meter meter. This meter sal be used as standby meter nthe event that the

‘uty frat avaiable,

15

‘Order of Precedence

‘he project data sheets complete with the project drawings and thls specification are

considered asthe overall governing documents determining VENDOR's scope of werk and supp).

Inthe event that thee are conflicts with items ef information contained within these

‘documents, the following order of precedence shall be used when interpreting the information

of PURCHASER provided decurentation and references

rst: Purchase Order

SECOND: This specification

“To: Acsociated Datasets and Drawings

FOURTH: Project Decuments and Specifications

Fen Referenced ces and standards

‘ay lscrepancies or conifticts arpng the documents Usted above shal be called tothe attention

(of PURCHASER fr resolution with COMPANY prior to purchase, design or Fabrication.

Statutory requirements of Vietnamese regulations and the Gas Purchase and Sales Agreement

{GPSA) sal take precedence over the above.

“Tile: Specification for Gas Fiscal Metering System Document No: 801-00--8-0010

ate

Page

Rev

APPLICABLE SPECIFICATIONS, CODES AND STANDARDS.

2.4. Project Documents and Specifications

How ‘Psa

0%-00--F-0002 Fiscal Gas Metering Sytem Prilosophy

eo.00-£5.017 Specification fr Power, lnstrument, Contra &

“Telecommunicaton Cables

po.00-65.0020 Specification fr Electrical Requirement for Package Equipment.

01-00-1502 Specification Instrumentation & Contos fr Package

Equipment

0.00--5-008 Spectcation for Actuated Valves

01-00--0-1000 (CSS Architecture Block Diagram

.01-00--0-1001 Instrument Systm interface Block Diagrams

01-00-¢-0-1000 Telecommunication Systems Architecture Block Diagram

POP ATR OTT40 RID - Export Gas Fiscal Metering (2x 1008)

Woe MTT-R0-3107 RID - Export Gas Launcher (HTI-L-2910)

PQPsT--0-5015| Central Contre Room Equipment Layout

Pop-T-P-0-2004 Equipment Layout - Mezzanine Deck

| B-00-R-r-0003 Process Walving and Isolation Philosophy

‘000-87. 0004 Process Vent and Orin Philosophy

‘000. s.0001 Piping Class Speciation

‘8000-7 s-0002 Specification Piping Fabrication, Installation, Inspection and

Testing

‘80-00-0002 Manual Valves Specification with Data Sheet

| sor00-P.x 0002 Pring stress Analysis Design Basis

0-00-W-R-0002 “Topeldes Material Selection Report

0-00.45-0551 Specification for Protective Coatings

| mooomsone Specification for Welding for Piping & Equment

Bo-00-8-5-0333, Specification for Irsulaton for Equipment and Pping

Bo.00.4s.0%4 Specification fr Vendor Inspection

Bo.00-8-5-0335| Specification fr Vendor Orang and Documentation

Specification fr Spare Parts Requirements

so-00.4s-0357 Specification fr Sk Mounted Package Equipment

| ao0o.nsor2e Specification for Pressure Vessels

Tile: Specification fr Gas Fiscal Metering System Document No: BD1-00+-S-0010

2.2. international Codes and Standards

‘The Fiscal gas metering systems design shall comply with all relevant national and international

standards and codes of practice. The standards used shal be current and shall not have Been

superseded

‘As 2 mininum, all eculpment supplied as part ofthis package shal be desined, manufactured

and delivered in accordance withthe relevant section of the natlonal international Codes,

Standards and Regulations, sisted Below, The latest editions of codes and standards, incuding

fal addenda, supplements or revisions current at time of purchase order, a8 ised by the

feliowing authorities shall apply:

4+ American Gas Association (AGA)

+ American Petcteum Institte (491)

+ tnterationa Electrotechnical Commision (IEC)

+ lnterational Standard Organization (50)

Seth Standards intttion (85)

les the System VENDORS responsibity to ensure he and his sub-VENOORS fly comply with all

the applicable Codes, Standards and Repuations.

Paticular attention is drawn tothe following standards and codes of practice:

+ odes OF rate

Applicable Intematfonsl Codes & Standards

acne Compressibity and Super-compressility for Natura Gas and other

Hyarocarbon Goes

AGn9 Measurement of Gas by Muitkpath Ultrasonic Meter (2007 Eaton)

AcA10 ‘Speed of Sound In Natural Gas ater related Hycrocabon Gases

APINPHS Chapter Fidelity and Securty of Flow Measurement Pulsed Data - Data

55 ‘Transmision Systems

{ABINPWS Chapter Section 2. Automatic Sampling of Petroleum and Petroleum

52 Products (1995 Eaton)

seinen cect Secon Fon Merona ng etn Meter Stems

APIRP 550. Part Sections 1 & 2 - Analyzers ant Process Chromatographs

1ST 1945 Standard Test Method for Analysis by Gas Chomatographs

asta oai77 Standard Practice for Automatic Sampling of Petroleum & Petroleum

Progucts

rex 1008 Equipment and Protective systems in potentially explosive areas

cra 261 ‘Obtaining Natural Ga Samples for Analyse by Gas Chromatography

vec 60079 Electrical apparatus for explosive gas atmospheres

vec 60529 Degrees of Protection Provided by Enclosures

“ile: Specification for Gas Fiscal Metering System Document No: BD1-00+-5-0010

ate

age

Rev

ec 60801 3 Electromagnetic Commpatibity for Industral Process Measurement

and Control Equipment

1503171 Petroleum Liquids - Automatic Pipeline Sampling

505168 Measurement of fu low - Procedure forthe evaluation of

Uncertainties

\s05178 Measurement of Fluid Flow: Estimation of Uncertainty of Ultrasonic

Flow meters (2005 ation)

sos ‘Gas analysis Preparation of calibration gas mixure gravimetric

method

|s06974- Parts 1,3 Natural gas - Detemnination of composition wth defined uncetanty

es by gas cvomatowaphy

06976 Natural gas - Calaton of Calorie Value, Density & Re. Density

‘so r0715 Natural gas - Sampling guidtines

‘so 10723 Natural gas - Performance Evaluation for On-Line AnalyticlSytens

95 21180 6327 as analy. Determination ofthe water dew pol of natural gs.

2008 Cote surface condensation hygrometers

150 7006 Assessment of uncertainty inthe calibration and use of flow

‘measurement devices - Part 2: Noninear calbratan relatensips

's0 12013 Natural Gas -Caleulaton of Compeesion Factor

IsorTe 12765 Measurement of Fluid Flow in Closed Conduts - Methods Using

‘Transit Time Ultrasonic Flowmeter

150 170884 Mexsurement of Fluid Flow n Closed Conduits ~ Utrasonic meters

tor gas,

‘owe n137-4 Gas Meters Part 1 Apples to gas meters based on any principle,

ted fo meter the quantity of gas in volume, mass or energy units

‘hat has passed Uvaugh the meter at operating cdo

aan ‘Allocation Agreement Measurement Manu

2.3. plicable Vietnam Standards

TCIM 6171-1996. Vietnamese Standard for Fixed Ofshoe Patorms - Regations for the

Technical Supervision and Casification

‘TCYN 6767-2000 Vietnamese Standard for Fixed Ofshre Platforms Part 3 Machinery and

Proces Systems

2.4. Vietnamese Laws and Regulations

“The Vietnam Petroleum Law 1983,

‘The Vietnam Environmental Regations fr Ol & Gas Operations 1990

“Toe Vietnam Environmental Law 1994

‘he Labour Law issued by National Asserbly

aoe

Title: Specification for Gas Fiscal Metering System Document No: BD1-00+-5-0010

3.

at

Date #17 Sept2010

Page H20f74

Rev

(GENERAL REQUIREMENTS

‘VENDOR Scope and Responsibility

AA Generat

“This specication together with the atached appendices as well a all applicable codes,

standards and regulations defines the functional requirement for the design, UFH

‘aloration, material procurement, manufacture, fabrication, supply, performance,

Inspection, testing, painting, devery, shipping, handling, storage, and. stat

upieommissioning/AVT assistance of a complete Gas Fical Metering System to be

fretales at POP-T platform, require for BD project.

‘The VENDOR sal be stely responsible for furnishing the complete Gas Metering Skis (SK:

2800) ncudig all strumentation and canto, calibration ane sampling facies and alt

accesories to ensure satisfactory operation under the service conditions described inthis

speciation. Also, the VENDOR shall be solely responsible for the design and fabrication

of sis.

‘Te VENOOR should draw upon his exiting, pre-engineered or proven standard designs to

sstiey the funcional requirements ghven inthis specification together wlth the attached

associated documents and crawing.

‘Te VENDOR shal submit fll echnical details of his metering sytem, which shall mest

the requirement detailed herein. Aspects ofthe requirements, which cannot be met, shall

be dentiie. Variation trom the requirement detailed herein hall be clearly explained

‘Tee VENDOR's submission shal provide suiclent data to allow the metering system to be

‘evaluated against the estimated ite-ycte cost forthe proposed metering system. In this

respect, equipment captal cost, cost of spares, weight, ste, instalation, maintenance,

reliability and production downtime costs shall be considered.

Al required software fr the metering function, systam dlagnastis, asset management

and data transmission, inlusing asociated software licenses shall be provided and all.

relevant data loaded

‘VENDOR shal assume single point responsibly forall aspects ofthe work. Ths includes

buts nt limited to timely completion, son withthe COMPANY or CONTRACTOR, aon

with any. SUPPLIER. /sib-VENDOR of specialized items, co-ordination of the work,

performance guarantee and provision of warrenty fr the system,

‘VENDOR shall supply such equipment, which has been proven to operate reliably in an

‘offshore environment. — VENDOR shall provide references along with the bid where

‘cuipment identical to that proposed here is in continuous operation in an offshore

‘environment for at east two years. No prototypes of any kind are permitted. All

equipment shall be new. Reference Ust shall Mighlght the lstallations where the same

model of the meters (as quoted), are use.

Tile: Specification for Gas Fiscal Metering Sytem Document No: 801-00--5-0010

‘The VENDOR shall specifically note that the final handover of the system shall be

considered complete only when the SAT of the complete metering systems / skids /

Instrmentation / accesories etc ae svecessuily completed and commissioned and the

offehore AVT accepted

‘AL eaulpmentnstrument shall be validated and calibrated and the IAVT results as

Getalied inthe IAVT procedures stall be agreed and signed by COMPANY. The sytem shall

be consiered handed over after COMPANY or INSPECTOR sgn the handover cetfcate.

3.1.2 VENDOR data with big

{VENDOR shall submit with his bid VENDOR data in accordance with the VORL icuding the

faliowing. (Failure to comply with the requirement may result in squaifiation of the

bi)

(1) Propose sytem architecture and narrative (including procedure fr switching for

series check, selecting standby meter and buy-back metering),

(2) Caeulation procedure (block sagram and bret raratve),

(3) Calealation procedure for Buy-back ss,

(4) st of UP diagnostic checks and bit narrative,

(8) CADrawings / dimensional deta,

(6) Flow Metering Panel layout and deta,

(Weigh calculations deta,

(8) Meter sizing calculations using approved software,

(9) Uncertainty caleuaton versus flow percentages,

(10) Ust of approved soferare,

(11) Reference Uist forall the items

(2) Technical catalogues for instruments and all accesories incl. sample handling

systems,

(13) Bil of material of major components and Manufacturer,

(04) Propose Sub-VENDOR tit or approval by the CONPANY,

(05) Power / Instrument Air quirements,

(16) Performance and Approval Certificate for UFM (type tet),

(07) Functional Design Specification immediatly after contract award),

(18) Detae of Catraton /Crser gs Supper (Visnam),

(19) Detalis of factity (Vietnam) where Validation Toos ae calibrated,

Title: Specification for Gas Fiscal Metering System

eo)

ay

Details of UF Cabration Laboratory,

Proposed IAVT Specialist based in Vietnam,

{VENDOR shal umish wth bi, completed datasheets with deals ncuding manufacturer,

model

Ba3.

1

a4

‘safety certification, material of construction, performance capabilites, et.

\vew0oR’s Experience

\VEWOOR shal have proven capabiity wth worldwide experience in supply and

design of Export Gas Custody Metering System, especially In afshore application,

"VENDOR shall supply such equipment, which has been proven to operate reliably

in minim of 2 offshore facilites of similar design In terms of flowrate, fusd

composition, temperature and pressure conditions

[Al equipment and materials offered and supplied shall be reliable and fed

‘roven in the specied environmental and praces operating conditions

Equipment and materials shall be VENDOR'S staidard product property selected

and applied in compliance withthe specified conditions.

"VENDOR shall have proven tack records in weléwide and Asia Paciic and after

sales service support.

‘VENDOR shal provide organizations chart with key personne C¥s for sch similar

scope of supply

Sub- VENDORS

In general sub-VENDOR materials and components shall comply with relevant standards

referenced in the technical requisition of relevant international recognised standards. In

some cases, a standard equipment package may utlise VENDOR'S standard sub-VENDORS

so that substitution is impracticable, Details of these items shall be provided as a

claifieation.

Detals of proposed sub-VENDORS shal be provided in the proposal. Any changes ater

Placement ofa purchase order shal be subject to writen appcoval by COMPANY.

ans

Scope of Supely

VENDOR shal provide metering package a olows

Export Gas ial Metering hi (Tg Number: HT-SK-2600)

‘Mon Export Gos FMS

2x 100% (Oaty Meter and StandbyReterence Meter) runs using Aosone

V2. 16% ANSI Class 16008 RT, Duplex SS body / Titanium transducers

using mutpathvranst tne type vlkasone ow meaeurment technique with

overall uncertainty of /-0.6%4 o bet.

Tile: Specification for Gas Fiscal Metering System Document No: D1-00+-5-0010

Date 11750962010

Page H150f74

Rev 10

(One (1) spare Altosonie V12, 1% ANSI Class 1600 RT, Duplex SS boay/

Tran ransducrs UFM ev ow candione, os spare.

+ 2x 100% ABB TotaFiow NGC 8209) Gas Ctvamatographs completo with

sampling system analyser and contol stalled in series on the common

Inlet header to measure the gas companent as per the attached process

dataset, An Analyzer Shelter (naturally ventilated shelter provided to

house the Gas Chromatograph components shal be installed inthe ski

(One (1) Amok (241 CE) HC Dewpoint analyze complet with ts

associated components, diated sampler tko-f point and sampling

‘systom ow ioral altvation wee stalled atthe commen ft of the

fiscal gas metering si,

(One (1) Amtek (3060-0L¥) Moisture Dewpoint analyzer complet with is

associsied components, ddiated sampler take-off point and samelirg

_systom cw ogra calration it, et. installed at the common it of the

‘sea gs metering si

(One (1) Welker Gas auto-samplng system atthe common head for

‘continous automatic ow & tne proportions sampling a constant pressure

{95 sample fer natura as capabe of proving gas sample at process ine

ressure ov dutystandby samping Botte, spare samping bots, ee

Insalted ot the common inlet ofthe fscol gos metering shi

(Ono (1) Yotogowa (EX) HART complnt Smar pressure varsmitor|

Instled downateem of UFM fr each meter un mounted wil flanged

integral double leck and bled valve a the process line tapping Bange ar

rose to sid JB.

‘One (1) Yokogawa (EN) HART compliant Smart temperature element with

hal P1100 RTD remot and Duplex SS tevmowels neta

‘founsirea of UFM fr each mele run and comely re-wted fo Skid JB,

~ Two 2) ABBWB! Prosswe Geuges wih gicerve filed, 150mm aa and

stainless sto! case completly mounted witha flanged itegaldoubl block

‘and bleed vae atthe process ne tapping Range installed a the et and

‘ile! or ach maar un.

+ One (9) Duplex SS Thermowels wth DNSO x 15008 RTH flanged connection

_rovded wih cover Nanged and plugged for Iseton of mercury thermometer

forloealindeaton insted a toilet and out french moter rn,

+ One (1) Solarten-Mekray 7812) Denstometer rine type with sampling

‘kop prouded and completely mounted for each meter run ae presated fo

‘i 8,

Two (2) 16", ANS! Class 15008 RT Rotork (20) Motor psrated valves

completely mounted a ilt and out of each moar run aed pro-ared to slid

‘DB. Open/Close postion switches wired fo skid JB.

Two (2) 16"

ANSI Class 15009 RT! Manvel operated eatin vats

“Title: Specification for Gas Fiscal Metering Systom Document No: B1-004-5-0010

compete instaed att ond ute! of each meer run, provided wi oct

postion indeatons wn 2x it sntehesforremets pan & cles indeatons

and pro-wire to shi J.

+ Crossover tines complete with 216%, ANS! Class 15008RT2 Rotrk (120)

MOVs, 1x check valve and pipework orientated horizontally and in same

lane as the stream meters.

| Restriction orifice patos preinstalled on vet lnes of ki litt are

lowdown header

‘kid mount Junction Boxes (sparat for 1 and Now signals) reared

or exch of signals, with ts osecate sutabe glen, earthing, and et

pre-mounted and pre-wired inside the sid

eorng skit eabies itorconnecte or presred rom inserts lo

‘coresponding Junction Boxes, compete wit abl trays and supports

etrng eka tubing and Swagook fing pre-connectod fm process

conection fo insruments, ubing tray and supers.

+ Metering skid complete wth al pipework, ts associated spools ings

mating Manges, ans, vent, sample points and insulation ee including

profi fr each moter un

= Vents and rains complete wth manually operated isolation valves.

Motring skid complete wit al stucturs works, ts assole requ

fnsrumont, stanchions, syparts and at

Rack mounted duty and standby carer gus bottles for GCHI cw switching

rmanifota

ack mounted duty and stand calibration gas bots for GC#Y c/w

switching manifold.

Rack mounted duty and standby carrier sa bottles for GCA c/w stcing

moniels.

+ Rock mounted duty and standby calbrtion gos Bottles for GIR. ctw

switching manifold.

UM Transducer “Offline” Retractor Too

IAYT / Voidotion tots, os required ineluding Test equipments fr PT TT

16C. HC Dewpoint Analyzer! H20 Dewpoint Anelyzer !Densitometer and

Sofivare package

a-bock Gos Meter

110096 fly asombied buy-back mater rn using rane Now

meesuremort tecnique wih veal uncertainty of! 0.8% ar bets

“Tile: Specification for Gas Fiscal Metering System Document No: BO1-00:-8-0010

ate + W7Sept2010

Page 7 of 74

Rev

~ Ono (1) Optisnic V6, 4” ANSY Cass 16004 RT, Duplex SS boy Tau

\vansaveers Utvasone Gas flow mer using multpath wana time ype flow

rmassurement techni

(One (1) Optisanie V6, 4, ANS! Claes 100% RT Duplex SS body / Tan

transducers Uasone Gas flow moter, as spare (Option)

‘One (1) Yokogawa (EH) HART compat Smart pressure tansmiter|

instated dewnstoam of UFM wih a forged nepal double block ad be

Valve at te process ine tapping Mange and pre-wire o skid JB

+ no (1) Yokogawa (EX) HART compliant Smart tomperatireoloment wth

lal Pr 100 RTD 4-te inet and Duplex SS thermowellsinstated

Adounstrear of EM and completely pre-wired to std JB.

Two (2) ABEHIGR Pressure Gauges with glycerine filed. 160m dial and

stainless steal case completely mounted witha aged integral double lock

and bed valve at tho process ie taping Range installed a te tant

utet of buy-back meter can

‘Duplex SS Thermowel with DNSO x 15008 RT Hanged connection proves

‘ah cover flanged ar plugged fr nsorton of mercury thermometer fr foe

Inca,

‘DN100 x 15008 RTL Completely mounted, povided wth ocal postion

Indications with 2x nt sites for mote open & ose ielications or pre-

vied to hid JB

‘Sample take-off robe and sampling ln fo the buy-back sample gas.

+ Buyback meter un fv al pipework, ts associated spools, fings, mating

Manges, dans, vents. sample points and insulation ee

Vent and dein complete with manualy operated soation valves

= Buynsck meter ew al souctural works, te assecaed requted instrument,

stanchions, supports and ot.

2, FNS Panel (Tag Number: HT-FHS-2800)

Flow Metering Panel (800mm W x BOC Dx 2100 H) completely assembled

‘nd pre-wired panel Inclusng;

2. On0(1) Alon Brady PLC wih 2 CPU madles, 2 Powor Supply meds,

2 Communication madues.

One (t) HP OL 360 Supervisory HM

One (1) spare HP DL 360 Supervisory HM

4. 2x Sunmie 8800 stream Flow Computers (FC) for min meter runs.

1 Summit 2800 Stream Flow Computers ($C) for buybck meter run.

One (1) spare Summit 8800 Stream Flow Computer.

“Tile: Specification for Gas Fiscal Metering System Document No: BD1-00+-5-0010

Date 7-Sept-2010,

Page $18 0f74

Rev 10

|% Online validation software, integrated withthe Hl software,

2x ABD TotalFlow GC Conrliers

Mechanical non-ezettable Sta Vol totalser counters

2 Mechanical non-resetabl St Mas totaliser counters

2 Mechanical non-rsetable St Enery totale counters

2 Mechanical non-revetable BTU counters fr totalsr Std Vol

mm. 3.xMochanial non esetable buyback Std Vol + mass + BTU totalser

‘counters

1 Volition Repo printer

0. 1x Sereen/ Alarm printer

LT FMS Report Printer

4 Allsofeware packages and software licenses ofthe fiscal meterog

systems

3.6 Scope of Work

‘The sal gas metering system VENDOR Selected for this projec shal provide project

engineering and project management services, especie, fnclucng provision of

require test facies, test equipment, experienced engineers and technicians

‘The VENDOR scope of work shal include but ot inited to the folowing

‘+ Mecering package design and documentation,

“+ Project management and coordination with ub-Contractors, COMPANY and

Fabrication yard Contractor

‘+ Configuration and engineering of all system and 1/0 hardware inetating HMI/YDU

‘operating systems necessary to meet the functional and desig requirements

detailed inthis speciation and referenced documents,

“+ Assembly ad testing ofthe FNS pane complete with power suples and

Stand imperil Units

= Temperature

= Une density

= standard density

= Gross Heating Value

ev pont temperature (water and HC for es)

as compton (ot)

“The supervsory computer shal ncude at lest two independent registers for

storing the quantities fr each meter ran. I hal not be possible to delete or

“change the registers by operator encroachment, power fire ee

“Te supervisory computer shall automatically record and store for at least 90 days

the metering data including the following

{At intervals of si hous: cumulative quantities, ferential pressure and average

‘values of pressure, temperature and density. At intervals of 6 hours: cumulative

‘quantities.

‘The fue of the supervttory computer shal nt affect the inteyry and funetons

ofthe flow computers.

‘uputs to Report Printer

Report Pinter shal print the following:

Metering reports from SUPC,

Metering reports rom SFC,

(Other reports as conigured in SUPC and SFC e.g. alarm reports, series,

check ests, AVT results, download of screen dat, trend data, buy-back

Tile: Specification for Gas Fiscal Metering System Document No: BD1-00+-5-0010

Date 2 7-Sept2010

Page (of 74

Rev 10

metering report.

hy Beater Fnerons

Print metering reports

Provide alarm loging and alam report printing.

Prin he IAVT reports

Print parameter fle (constants, default values, etc.) from flow

‘computers, both fied and changesble data,

screen cues.

4) Data islays Requirements

Display permanently sal be provided forthe following, as minimums

Stations as total

Station Volume total

Display, when selected, shall not be limited to the fllowing information, in

cogineering units to five sgiicant figures

= station mas lowrate ae total for al steams

station volumetric flowrate and total for al streams

= keyboard entered lar Kimi

keyboard entered constants

Individual meter run station play

enstometer periodic time

5) Metering Reports

Separate reports are required forte following

+ Export concsP Y

+ Export conese2

+ Buyback Gos

+ Blowdown (Colculted)

+ Plzform Repressurization

Vendor shall proposed types of metering reports eg. Neterng Invoice Reports,

Metering System Status Reports and UVT Reports in the Functional Design

Spectiaton fr review and approval. information Included Inthe reports shall

‘clade following

The: Specification for Gas Fiscal Metering Sytem Document No: BD1-00-15-0010

Date = 7Sept 2010

Page 70f 74

Rev 10

“Time and date

+ Total mas pase in 24h in metic tons (ln terms of components C1 to

(+ and total)

“otal standard volume passed in 24 hrs in m3 & Sf.

+ Average flow over 24 sin thousands of Sms & Sf3.

+ aximum flow over 24 hrs in thousands ofS & Sf.

+ Winimum flow over 24 sn thousands af Sn & Sf.

-verage density in g/m.

+ Alarm summary reports.

+ Parameter of file contents

+ "Shap shot” operating values report.

In adetion an alarm message stall be printed each ime any of the computers 80

oftine a5 4 result of ether a failure or manwallyintited actions such as

Callraton/IAVE activities et

-meterg reports shall be generate at preset ines oon demand vi the UPC as

follows:

Curent Report (instantaneous)

Hoary Reports

‘Allocation Report

= Daily Reports

Honthy Report

(OnDemand Report

Invoice Reports and Satu Reports sal include following as & minim;

Ccmuative & istantaneos Volume

Camuttive & instantaneous Mass

+ Gamuative& instantaneous Energy Temperature

+ Pree

Live denity

Standard density

{Gros Heating Value (Gas),

ew paint temperature (mater and/or hydrocarbon for Gas)

Tile: Specification fr Gas Fiscal Metering System Document No: BD1-004-5-0010

Date = 17-Sept2010

Page of 74

Rev 10

+ Gas composition (not 8)

Interface with Pcs

‘Th PCS sal trface withthe SUPC via al redundant Modis TCP/IP serial tink

as shown in ISS Architecture Diagram (Orang no BDI-004-D-1000) and Instrument

‘Sytem Interface Block Digrams (Drawing no BD1-004-0-100%),

Vendor shall be responsible to provide all necessary hardware / software support to

meet this requrement.

CS shall interface withthe UPC to synctvonize time with te GPS based Network

Time Server.

‘The PES shall interface withthe SUPC to retrieve data and depay instantaneous

Alowrates and comusative tat onthe PCS Hl. Retrieved data sal include also

alas and events.

‘The PCS sha erface withthe SUPC, to retrieve Metering Status Reports with

contents a listed in above section for ranszson to Onshore Dinh Co Terminal via

the platform VSAT link and leased land tne as depicted in Telecormmuniations

Block Diagram (rawing no 8D1-00-C-0-100),

45 Stream Flow Computers (SFC)

Execution Funetions

‘The stream flow computers shall execute te following tasks, as minum

+ nput signal processing

= Neasure and tnearze process signals

+ Determine status of signals and create alarms.

Compute instantaneous and totlised volume le, mass flow and energy

Automatic fallback “last good valve” oof manual Keyed default value or

‘aeulated value (AGA 8 for density) upon loss of presse, density of

temperature inputs

Use tachup operating gas density calculated from computer determines

AGA 8 (PTZ method).

‘Communicate with dedicated SUPC.

+ Check valicty of input signals rom eld transmitters.

+ Diagrostics checks including VOS measurement and check against

calculated data, sit analyss.

“Tile: sSpecifcation for Gas Fiscal Metering Sytem Document No: BD1-00-45-0010

»

4

ate 1 17Sept2010

Poge 249 0°74

Rev 10

Alans events and status.

Defauit data, lst good values when used shall be marked or denied to

dtfereniate I rom normal data

‘The flow computers shal hve no other fanetions other than tote fvaived nthe

metering.

‘The SEC shall contain self checking/dlgnostc features and any fare fn the

‘computer shall be indicated both on the on S&C dplay, the SUPC HM and

leansmitted as an alarm to the PCS via the SUPC, The SFC shall monitor

‘calculation procedures and programme loops which are executed at preset

Intervals by means af a watchdog function,

In addition, the SFC shall splay the UFM meter dlagnostc check esse, VOS

td Gain levels rom each set of UF transducers and swt canton at each

meter run for monitoring and performance anayss purposes.

Input Functions

Input sgnals fom each meter run (ota 2 ras)

‘One ultrasonic Nawmeter- R485 Modbus RTU serial ink

(ne pressure transmiter- analog 420 mA analogue sera

(One temperature element - Avice RT input

(One density transmitter - frequency signal Hold)

Signals (eg. GC data and operation modes) from SUPC via system data bus

Input Creu Precision Requirements

Precislon of ADC conversion of analog 420 mA sanals sal be 16 its or better,

Precision of periodc time measurement shall be better than +/-5 nanoseconds for

eros times of approx 200-300 microseconds

‘The A/D conversion shall not contribute systematic eros tothe measurement

“otal inaccuracy inthe analog to digital conversion including resolution, det

Uinearty, repeatabity end other random erors shal be less than 40.0258 of fl

scale rending

Were a single A/D conversion sued, a backup converter required

For general system calculation, the algorithm which is to be wsed for the

computation of al quantities required for contractual or regulator purposes shall

be sch that errors these quantities de to rounding or truncation are ess than

30.0018 ofthe true valve,

‘Output Functions

‘The: Specification for Gas Fiscal Metering System ‘Document No: BD1-00:45-0010,

°

Signals tothe dedicated supervsory computer shal nude:

= Volume tow rate and totals

= Mass aw rate and totals

Energy flow ate and totals

‘Operating ad standard density

‘Operating temperature

Operating pressure

Alarm, events and status

SFC Keumnd Entered sanals

‘An operator interface, vin key-pad shal be provided to permit operator entry of

‘data required forthe low measurements icing te flowing:

Constants

Default values.

Values, in kp, ofthe upstream pressure equivalent to 4 and 20 mA.

Values, in degC, ofthe downstream temperature equivalent to resitance

change (RTO element)

+ Equation constants for densitometer.

Mean diameter of meter run at upstream tapping plane at caltation

temperature Note: VENDOR to provide temperature at which D (am) was

mmossured

Low and High flow / pressure / temperate alarm ints.

+ Low and High measured density alarm Units 4 inits~ LL, LH &

Facilities shall be provided to prevent access to computer by unauthorized

personne. This facility shall enabled by authorized persons e.. for AVT purposes.

Lav Software

LUVT software shall be provided for verfication tests of the entire FMS. The software

shall be based onthe CONPANY appcoved LAV procedure, It shall enable the ess to be

carried ut ina semi-automatic manner by means of menu driven guidelines. t shall

‘nee the flowing tas

Inspection

2. Series check ofthe UFNs and analyse of ess

Function test of MOVs.

Specification for Gas Fiscal Metering System Document No: BD1-0045-0010

Date 17Sept-2010

Page stot 74

Rev 10

4. Calibration check of flld instruments inciuding GC, PT, TT, OT and analysis of

results,

5. input sgnals check

16 Constants check

7. Flow caledation checks.

‘The IAVT / calibration software with the fllowig features shalt be considered,

1. User editing of computer and eld equipment deta

2. Selecting, vewing and piting of fda calibration tet sheets

3. Select, slay and accep deicated fed injected test values either as one single

point check or cress the span ofthe instrument under IAVT.

Where required, computation based on the operate-entered (keypad) values and

comparison withthe expected flowrate / integration /summation.

‘On completion ofthe procedure an output report shall be printed giving all details of "as

found values and as let” and deviation percent for each instrument. In cases where

adjustment and changes to instrument reports done, remark column shal be provide.

‘ere there is oo acjtment, the as fone shal be the same asthe 35 lef” (option).

‘Tha 2 lef column then shall havea remark saying Refer to as found

‘The report shal Include the current date and five () signature boxes for witness

Names of witnesses shall be entered vis keyboard

“The IAVT software shall allow part of the IAVT steps to be aborted inthe event that

readings ae reaistered prior tothe condition being stabilize.

Reporting of operations values ofthe meter run to be validated shall automatically be

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- BD1-00-I-S-0001 - 1 Spec Integrated Control and Safety System (ICSS)Document109 pagesBD1-00-I-S-0001 - 1 Spec Integrated Control and Safety System (ICSS)Duc80% (5)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- HRSG Project Work Area DistributionDocument6 pagesHRSG Project Work Area DistributionDucNo ratings yet

- Iecex Certificate of ConformityDocument23 pagesIecex Certificate of ConformityDucNo ratings yet

- Material Safety Data Sheets: (MSDS)Document5 pagesMaterial Safety Data Sheets: (MSDS)DucNo ratings yet

- RefractoryDocument38 pagesRefractoryDucNo ratings yet

- BD100IR0002 - 0 HIPPS Valves Technical and Budgeting EstimatesDocument32 pagesBD100IR0002 - 0 HIPPS Valves Technical and Budgeting EstimatesDucNo ratings yet

- BD100IE0010 - 0 Fiscal Gas MeteringDocument23 pagesBD100IE0010 - 0 Fiscal Gas MeteringDucNo ratings yet

- BD1-00-I-S-0010 - 0 Fiscal Gas MeteringDocument80 pagesBD1-00-I-S-0010 - 0 Fiscal Gas MeteringDucNo ratings yet

- Vv3144-003-A-135!0!0010 Method Statement For Roof Fan InstallationDocument24 pagesVv3144-003-A-135!0!0010 Method Statement For Roof Fan InstallationDucNo ratings yet

- Vv3144-003-A-135 - 0 - 0010 Method Statement For Roof Fan InstallationDocument24 pagesVv3144-003-A-135 - 0 - 0010 Method Statement For Roof Fan InstallationDucNo ratings yet

- VJ215B-001-A-821 - 0 Installation Manual Refractory Lining Co BoilerDocument19 pagesVJ215B-001-A-821 - 0 Installation Manual Refractory Lining Co BoilerDucNo ratings yet