Professional Documents

Culture Documents

P PVC To Ductile Pipe Couplings

P PVC To Ductile Pipe Couplings

Uploaded by

Brandon HoltenCopyright:

Available Formats

You might also like

- Factura Comercial DHLDocument2 pagesFactura Comercial DHLLorena Velásquez71% (7)

- TDS Calde Flow LM 74 A IpDocument1 pageTDS Calde Flow LM 74 A IpSamuelBartoMuntheNo ratings yet

- Presentation On Camlock CouplingDocument21 pagesPresentation On Camlock CouplingqwertygmailNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Constri'CtionDocument2 pagesConstri'CtionHendra StanleyNo ratings yet

- Balaji Wall TextureDocument13 pagesBalaji Wall TextureMadhav ReddyNo ratings yet

- RASCOflex Americas SpecSheetDocument4 pagesRASCOflex Americas SpecSheetJohn loboNo ratings yet

- Rascoflex - Flexible Hose SprinklerDocument4 pagesRascoflex - Flexible Hose SprinklerPaulina CabreraNo ratings yet

- Single U-Bolt & Strap Service SaddlesDocument3 pagesSingle U-Bolt & Strap Service SaddlesAl JameelNo ratings yet

- Katalog Produk Fire FightingDocument11 pagesKatalog Produk Fire FightingRiyan SiregarNo ratings yet

- Series 20-21 SS Butterfly ValvesDocument2 pagesSeries 20-21 SS Butterfly ValvesQuangNgocNo ratings yet

- 7FOS Series: Universal Multi-Cartridge Filter HousingsDocument2 pages7FOS Series: Universal Multi-Cartridge Filter HousingsHernan GilNo ratings yet

- Series M Knife Gate ValveDocument11 pagesSeries M Knife Gate ValveRicardo MoralesNo ratings yet

- Bermad: FP/FS 400Y Torrent Valve Engineering DataDocument12 pagesBermad: FP/FS 400Y Torrent Valve Engineering Dataeitan-daliaNo ratings yet

- 437 - Control Valve For General ApplicationsDocument16 pages437 - Control Valve For General ApplicationsWahyu TryNo ratings yet

- Catalogo Aurora PneumaticDocument84 pagesCatalogo Aurora PneumaticSam MarmorNo ratings yet

- 111.335.00.5 SpecsheetDocument1 page111.335.00.5 Specsheetsms9869No ratings yet

- Control Valves Two PortDocument16 pagesControl Valves Two Portwendelreis19746883100% (1)

- BF Series: Single Bag Housings: #1, #2, #3 and #4 SizesDocument8 pagesBF Series: Single Bag Housings: #1, #2, #3 and #4 SizesRicardo BurgosNo ratings yet

- Lav 1 Faucet Kohler K 73168 4Document2 pagesLav 1 Faucet Kohler K 73168 4Enak CenirNo ratings yet

- KEDDCO BinderDocument74 pagesKEDDCO BinderWillian FigueroaNo ratings yet

- 4 HP Pneumatic Chain Saw: Powerful Cutting of Wood, Polyethylene and PlasticDocument4 pages4 HP Pneumatic Chain Saw: Powerful Cutting of Wood, Polyethylene and Plasticedgar clemente carbajalNo ratings yet

- SpecificationsDocument1 pageSpecificationsbondsupplyNo ratings yet

- KN Ife Ga Te & Bu Tte Rfly Va Lve S E: Valves & EquipmentDocument14 pagesKN Ife Ga Te & Bu Tte Rfly Va Lve S E: Valves & EquipmentravishankarNo ratings yet

- USF Series: ASME Code Multi-Cartridge Filter Housings-Four Through Fifty-Two RoundDocument2 pagesUSF Series: ASME Code Multi-Cartridge Filter Housings-Four Through Fifty-Two Roundprabal rayNo ratings yet

- 04 Sucker RodDocument7 pages04 Sucker RodYoyi YuniasNo ratings yet

- 07 Solid Stream NozzlesDocument7 pages07 Solid Stream Nozzlesahmad bahlakeNo ratings yet

- CLASS 173.4 - Custom FRP - Bisphenol (Abrasive)Document3 pagesCLASS 173.4 - Custom FRP - Bisphenol (Abrasive)Lizeth IsidroNo ratings yet

- Spec I Fi Ca Tions: Weymouth™Document2 pagesSpec I Fi Ca Tions: Weymouth™Saúl MolinaNo ratings yet

- Dembla Gate ValvesDocument20 pagesDembla Gate ValvesMohit AroraNo ratings yet

- Spesifikasi UW Concrete CutterDocument2 pagesSpesifikasi UW Concrete CutterMuhammad YusufNo ratings yet

- ACA0291 GBDocument12 pagesACA0291 GBJosé Mariano ContrerasNo ratings yet

- Rotary Control Valve: K-MaxDocument12 pagesRotary Control Valve: K-MaxBrLuxy1952No ratings yet

- 200 Series Inverted Bucket Steam Traps: Cast Iron For Vertical InstallationDocument2 pages200 Series Inverted Bucket Steam Traps: Cast Iron For Vertical InstallationbhaskarbabaiNo ratings yet

- Rotary Control Valve: K-MaxDocument12 pagesRotary Control Valve: K-MaxBrLuxy1952No ratings yet

- 184 Darley254Document1 page184 Darley254Jose MelloNo ratings yet

- Style 400 Steel Coupling: (For 12" and Larger Pipe)Document4 pagesStyle 400 Steel Coupling: (For 12" and Larger Pipe)picottNo ratings yet

- GE250 Combination Torch Handles EnglishDocument4 pagesGE250 Combination Torch Handles EnglishVijo JoseNo ratings yet

- Omni Sleeve Wall Pipe Penetration Sleeve: SIGMA CorporationDocument4 pagesOmni Sleeve Wall Pipe Penetration Sleeve: SIGMA CorporationJojolasNo ratings yet

- 01 Rubber HoseDocument26 pages01 Rubber Hosewenny_tpdNo ratings yet

- Broco ExplaningDocument3 pagesBroco Explaningsequeiradiver1No ratings yet

- K-72760 Spec US-CA Kohler enDocument2 pagesK-72760 Spec US-CA Kohler en15101980No ratings yet

- Akron Style 4826 NewDocument3 pagesAkron Style 4826 Newluisa fernanda ordoñez casasNo ratings yet

- Clarkson - Knife Gate Valves - KS3 - Install Manual - 2022-11 - r00Document18 pagesClarkson - Knife Gate Valves - KS3 - Install Manual - 2022-11 - r00Vitor BandeiraNo ratings yet

- ACA Clamps&ConnectorsDocument4 pagesACA Clamps&ConnectorsvenkyeeeNo ratings yet

- Product BrochureDocument16 pagesProduct Brochurevishnu300022No ratings yet

- Series HUSDocument24 pagesSeries HUSsamialganNo ratings yet

- Wheatley Series 500 BRDocument8 pagesWheatley Series 500 BRanuarsgNo ratings yet

- Piping Materials - Olets The Piping Engineering WorldDocument3 pagesPiping Materials - Olets The Piping Engineering Worldrenger20150303100% (1)

- Resilient Seated: CommercialDocument25 pagesResilient Seated: Commercialagung wijayaNo ratings yet

- Transparent Level Gauge Series 2000: Product Data Sheet No. 7Document1 pageTransparent Level Gauge Series 2000: Product Data Sheet No. 7Alfonso BlancoNo ratings yet

- PLN-1200-3.07-01, Iss 01 - Product Catalogue PDFDocument12 pagesPLN-1200-3.07-01, Iss 01 - Product Catalogue PDFsakscribNo ratings yet

- PLN-1200-3.07-01, Iss 01 - Product Catalogue PDFDocument12 pagesPLN-1200-3.07-01, Iss 01 - Product Catalogue PDFsakscribNo ratings yet

- Flanged Spherical Pipe Joints: - Elastomeric Expansion Joints / Flexible ConnectorsDocument2 pagesFlanged Spherical Pipe Joints: - Elastomeric Expansion Joints / Flexible ConnectorsKhaled Al AkhdarNo ratings yet

- Vertical Flame ArresterDocument5 pagesVertical Flame ArresterMustafa PardawalaNo ratings yet

- Branch Connection Fittings (MSS SP-97) - Weldolet®, Sockolet®, Thredolet®, Latrolet®, Elbolet®, Nipolet®, Sweepolet®Document3 pagesBranch Connection Fittings (MSS SP-97) - Weldolet®, Sockolet®, Thredolet®, Latrolet®, Elbolet®, Nipolet®, Sweepolet®dchz_62No ratings yet

- Definition and Details of Socket Weld Fittings ASMEDocument7 pagesDefinition and Details of Socket Weld Fittings ASMEMehman NasibovNo ratings yet

- AVK Gate Valve Maintenance-Free Design ConceptDocument8 pagesAVK Gate Valve Maintenance-Free Design ConceptRakesh Sasidharan PillaiNo ratings yet

- Actuator SpecificationDocument12 pagesActuator SpecificationFactory FactoryNo ratings yet

- Gaseous Hydrogen Piping SpecificationDocument5 pagesGaseous Hydrogen Piping SpecificationAndri DoemeriNo ratings yet

- Cladding Design GuideDocument21 pagesCladding Design GuideJISHA MATHEWNo ratings yet

- CatalogoVCW EN Mai20Document11 pagesCatalogoVCW EN Mai20snri0da9No ratings yet

- CC Marine 2013-14 Catalogue - PumpsDocument94 pagesCC Marine 2013-14 Catalogue - PumpsGregGGH100% (1)

- Portable Tank BrochureDocument4 pagesPortable Tank BrochureDavid RodriguesNo ratings yet

- Zahra Kalantar - Properties of Bituminous Binders ModifiedDocument11 pagesZahra Kalantar - Properties of Bituminous Binders Modifiedzeidan111No ratings yet

- Astm A 615 Steel 2015Document8 pagesAstm A 615 Steel 2015wenming chenNo ratings yet

- 15-5240 enDocument14 pages15-5240 enRafa Lopez PuigdollersNo ratings yet

- Welding of Duplex Stainless SteelDocument7 pagesWelding of Duplex Stainless Steelel_sharkawy2011No ratings yet

- Physics Investigatory ProjectDocument14 pagesPhysics Investigatory Project09shasNo ratings yet

- English for Oil and Gas Solomchak Ozarko Moiseyenko ІDocument186 pagesEnglish for Oil and Gas Solomchak Ozarko Moiseyenko ІNeonila KryvtsunNo ratings yet

- Page 4 PDF StoneDocument2 pagesPage 4 PDF Stoneraja qammarNo ratings yet

- Solution Manual Reinforced Concrete McCormac 9th EditionDocument12 pagesSolution Manual Reinforced Concrete McCormac 9th EditionLarry66% (29)

- Tcbe 1202-5 LimeDocument48 pagesTcbe 1202-5 LimeshafikNo ratings yet

- Project: Project No: AuthorDocument37 pagesProject: Project No: Authorabdullah_23320666No ratings yet

- Epoxy Adhesion To Metals: Advances in Polymer Science January 1986Document40 pagesEpoxy Adhesion To Metals: Advances in Polymer Science January 1986Ekrem DoğanNo ratings yet

- Introduction To GlassDocument25 pagesIntroduction To GlassankithaNo ratings yet

- Method Statement WallDocument11 pagesMethod Statement WalldeviesrigatiNo ratings yet

- Ben Ammar 2014Document12 pagesBen Ammar 2014Anand NagarajanNo ratings yet

- Arijit Nandi - Design of RC StructuresDocument3 pagesArijit Nandi - Design of RC Structuresarijit nandiNo ratings yet

- Astm A709 GR 36Document2 pagesAstm A709 GR 36Henry Burgos N.No ratings yet

- Experiment No. 6 Pit Furnace Melting Practice: Aim TheoryDocument3 pagesExperiment No. 6 Pit Furnace Melting Practice: Aim TheoryDhananjay ShimpiNo ratings yet

- List ProfessorsDocument6 pagesList ProfessorsDonny pasaribuNo ratings yet

- S355J2 N, S355J2+N, En10025-2 s355j2n Steel PlateDocument2 pagesS355J2 N, S355J2+N, En10025-2 s355j2n Steel PlateEswaranNo ratings yet

- Cadangan Membina Surau As-Shaarif, Kampung Changkat Chermin, Beruas, Perak Darul RidzuanDocument8 pagesCadangan Membina Surau As-Shaarif, Kampung Changkat Chermin, Beruas, Perak Darul RidzuanMuhaimin RohizanNo ratings yet

- Normal GT II 18325458507 Pltgu Tanjung BatuDocument2 pagesNormal GT II 18325458507 Pltgu Tanjung Batudhavit wijayantoNo ratings yet

- Polyvinylacetate & Derivatives: Jitendra SinghDocument25 pagesPolyvinylacetate & Derivatives: Jitendra SinghHILL RANGAMATINo ratings yet

- Broschure Gland Packing Teadit 2Document2 pagesBroschure Gland Packing Teadit 2Desmon GultomNo ratings yet

- InLiquidation BombayDocument26 pagesInLiquidation BombayUrvin ShahNo ratings yet

- Advantages and Limitations of FRPDocument4 pagesAdvantages and Limitations of FRPWolfMensch1216No ratings yet

P PVC To Ductile Pipe Couplings

P PVC To Ductile Pipe Couplings

Uploaded by

Brandon HoltenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P PVC To Ductile Pipe Couplings

P PVC To Ductile Pipe Couplings

Uploaded by

Brandon HoltenCopyright:

Available Formats

SPECIFICATION

®

QUANTUM WIDE RANGE CAST COUPLING

MODEL 461

Follower Sleeve

Bolt

Nut

Washer

Gasket

8.00” Coupling Shown

APPLICATIONS

Joining plain-end pipe of different outside diameters with same nominal size

Typical Uses

Replace split or excessively damaged pipe

Standard Pipe Sizes

1-1/2” to 12” nominal

Carbon Steel, Stainless Steel, Ductile Iron, Asbestos Cement, PVC, HDPE

Type of Pipe

(see notes for thin wall PVC & HDPE applications)

250 psi

Working Pressure

MATERIALS

Cast using Ductile Iron 65-45-12 per ASTM A536

Follower

Flexi-Coat® fusion bonded epoxy finish which meets application methods AWWA C213

Permanently marked with part number and pipe size range for proper selection

Integral bolt head pocket for one wrench installation

Designed to provide up to 1.65” of range with a single follower

Tabs cast in follower to center and concentrate sealing force uniformly over gasket

Cast using Ductile Iron 65-45-12 per ASTM A536

Sleeve

Flexi-Coat® fusion bonded epoxy finish which meets application methods AWWA C213

Single sleeve design for each nominal pipe size reducing inventory

Nitrile (Buna-N) per ASTM D2000

Gasket

NSF/ANSI 61 and 372 certified

Compounded to resist water, oil, natural gas, acids, alkalies, most (aliphatic) hydrocarbon fluids, and many

Temperature range: -20ºF to +180ºF

other chemicals

Leading edge of gasket has molded in ribs for maximum sealing against sleeve

Permanently marked with part number and pipe size range for proper selection

Rev 3/8/16 www.smith-blair.com Page 1 of 4

SPECIFICATION

®

QUANTUM WIDE RANGE CAST COUPLING

MODEL 461

Bolts

HSLA Carbon Steel per AWWA C111/A21.11

Epoxy coated threads to prevent galling

Size: 1-1/2” - 8” nominal pipe size = 5/8”-11UNC x 10.50” long, Oval Neck Track Head

10” - 12” nominal pipe size = 5/8”-10UNC x 13.50” long, Oval Neck Track Head

Rolled threads for improved physical characteristics, greater thread accuracy, and smooth surface finish

Nut

HSLA Carbon Steel per AWWA C111/A21.11

Fluoropolymer coated to prevent galling

5/8”-11UNC, Heavy Hex Semi-Finished

Carbon Steel per ASTM F844

Washer

Fe/Zn coated per ASTM F1941-10

5/8” Type A Plain

Utilized to preserve corrosion resistance of epoxy coated surfaces and increase bearing surface

LISTINGS

UL certified to NSF/ANSI 61 and 372

Meets applicable AWWA C219 standards

OPTIONS

Type 304 Stainless Steel hardware with fluoropolymer coated nuts to prevent galling

Type 316 Stainless Steel hardware with fluoropolymer coated nuts to prevent galling

Alternative gasket material (e.g. Viton, EPDM, etc.)

Protected gasket (brass spring molded into leading edge)

Anode connector

Insulating boot(s)

NOTES

This product does not restrain the pipe from pulling out of the fitting

Pipe stiffeners are required when this product is used on HDPE and thin wall PVC pipe

Flexi-Coat® and Quantum® are registered trademarks of Smith-Blair, Inc.

These product specifications were correct at the time of publication and are subject to change without notice

See the Smith-Blair® web site for part numbers and ordering information

See the Smith-Blair® web site for warranty information

See the Smith-Blair® web site for corrosion warnings

Rev 3/8/16 www.smith-blair.com Page 2 of 4

SPECIFICATION

®

QUANTUM WIDE RANGE CAST COUPLING

MODEL 461

Recommended Pipe to Pipe Centerline Gaps

Optimum Gaps

Sleeve Length Maximum Gap

Straight Run Deflected Joints

5” 1/2” 1” 2”

7” 1/2” 1-1/2” 3”

10” 1” 2-1/4” 4-1/2”

Longer Than 10” 1” 2-3/4” "Sleeve Length" – 6”

Pipe gap to be centered in coupling sleeve.

Total Maximum Allowable Axial Pipe Movement per Coupling

Coupling Size Allowable Movement

3/4" to 2" 1/8"

2-1/2" to 10" 1/4"

10-3/4" and Larger 3/8"

Pipe End Tolerances

Pipe OD Minus Tolerance Plus Tolerance

1/2" up to 16" -0.06 +0.06

>16" up to 24" -0.08 +0.08

>24" up to 42" -0.10 +0.10

>42" -0.06 +0.12

Maximum Angular Deflection per Coupling

Center Sleeve Length

Nominal Pipe Size

5" 7" 10" and Larger

1/2" up to 2" 7° 7° 7°

>2" up to 12" 4° 4-1/2° 4-1/2°

>12" up to 24" 2-1/2° 4° 4-1/2°

>24" up to 36" - 3-1/2° 4°

>36" up to 42" - 3° 3-1/2°

>42" up to 60" - 2-1/2° 3°

>60" up to 80" - - 2-1/2°

>80" up to 100" - - 2°

>100" - - -

30 Globe Ave, Texarkana, AR 71854

Ph: 870-773-5127 • Fax: 870-773-5212

Toll-Free Numbers: Ph: 800-643-9705 • Fax: 800-648-6792

Rev 3/8/16 www.smith-blair.com Page 3 of 4

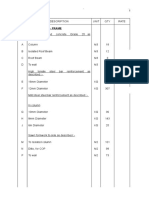

"C"

SLEEVE LENGTH

"A"

PIPE SIZE RANGE

PART NUMBER

"B"

O.A.L.

NOTES:

1. SEE SMITH-BLAIR CATALOG FOR PIPE RANGE AVAILABILITY CERTIFIED TO NSF/ANSI 61-G & 372

2. 8" COUPLING SHOWN OTHER SIZES SIMILAR TOLERANCES U.N.O. NOTES:

REMOVE BURRS APP'D DATE

.XX= .03

.XXX= .015 AND SHARP EDGES

FRACTIONS= DO NOT SCALE DWG. CK'D

NOM. PIPE PIPE O.D. HARDWARE APPROX ANGLES= 1 DATE

A B C MACH. FIN= SCALE:

SIZE RANGE QTY. SIZE WEIGHT (LBS) ALL DIMENSIONS DRN DATE

ARE IN INCHES. N/A CHD 1/13/15

1.50 1.81 TO 2.28 6.50 11.00 4 2 5/8" X 10.50" 8.2

TITLE

2 2.34 TO 2.85 7.00 11.00 4 2 5/8" X 10.50" 10.0 SPECIFICATION

2.50 2.84 TO 3.35 7.50 11.00 4 2 5/8" X 10.50" 10.0 QUANTUM® WIDE RANGE CAST COUPLING

3 3.46 TO 4.21 8.50 11.00 5 4 5/8" X 10.50" 15.0 MODEL 461

4 4.46 TO 5.60 10.50 11.00 5.50 4 5/8" X 10.50" 26.0

P/N

6 6.54 TO 7.65 12.50 11.00 6 4 5/8" X 10.50" 33.0 N/A

8 8.54 TO 9.85 15.25 11.00 6 4 5/8" X 10.50" 44.0 WRENCH SIZE CHART SMITH-BLAIR, Inc. 1 1/13/15

10 10.65 TO 12.20 18.00 14.00 7.50 8 5/8" X 13.00" 72.0 NUT SIZE SPEC_461.DRW OF

TEXARKANA, ARKANSAS 1

12 12.75 TO 14.40 20.25 14.00 7.50 8 5/8" X 13.00" 89.0 5/8"-11UNC HH 1-1/16" DWG. NO. SHEET REV.

You might also like

- Factura Comercial DHLDocument2 pagesFactura Comercial DHLLorena Velásquez71% (7)

- TDS Calde Flow LM 74 A IpDocument1 pageTDS Calde Flow LM 74 A IpSamuelBartoMuntheNo ratings yet

- Presentation On Camlock CouplingDocument21 pagesPresentation On Camlock CouplingqwertygmailNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Constri'CtionDocument2 pagesConstri'CtionHendra StanleyNo ratings yet

- Balaji Wall TextureDocument13 pagesBalaji Wall TextureMadhav ReddyNo ratings yet

- RASCOflex Americas SpecSheetDocument4 pagesRASCOflex Americas SpecSheetJohn loboNo ratings yet

- Rascoflex - Flexible Hose SprinklerDocument4 pagesRascoflex - Flexible Hose SprinklerPaulina CabreraNo ratings yet

- Single U-Bolt & Strap Service SaddlesDocument3 pagesSingle U-Bolt & Strap Service SaddlesAl JameelNo ratings yet

- Katalog Produk Fire FightingDocument11 pagesKatalog Produk Fire FightingRiyan SiregarNo ratings yet

- Series 20-21 SS Butterfly ValvesDocument2 pagesSeries 20-21 SS Butterfly ValvesQuangNgocNo ratings yet

- 7FOS Series: Universal Multi-Cartridge Filter HousingsDocument2 pages7FOS Series: Universal Multi-Cartridge Filter HousingsHernan GilNo ratings yet

- Series M Knife Gate ValveDocument11 pagesSeries M Knife Gate ValveRicardo MoralesNo ratings yet

- Bermad: FP/FS 400Y Torrent Valve Engineering DataDocument12 pagesBermad: FP/FS 400Y Torrent Valve Engineering Dataeitan-daliaNo ratings yet

- 437 - Control Valve For General ApplicationsDocument16 pages437 - Control Valve For General ApplicationsWahyu TryNo ratings yet

- Catalogo Aurora PneumaticDocument84 pagesCatalogo Aurora PneumaticSam MarmorNo ratings yet

- 111.335.00.5 SpecsheetDocument1 page111.335.00.5 Specsheetsms9869No ratings yet

- Control Valves Two PortDocument16 pagesControl Valves Two Portwendelreis19746883100% (1)

- BF Series: Single Bag Housings: #1, #2, #3 and #4 SizesDocument8 pagesBF Series: Single Bag Housings: #1, #2, #3 and #4 SizesRicardo BurgosNo ratings yet

- Lav 1 Faucet Kohler K 73168 4Document2 pagesLav 1 Faucet Kohler K 73168 4Enak CenirNo ratings yet

- KEDDCO BinderDocument74 pagesKEDDCO BinderWillian FigueroaNo ratings yet

- 4 HP Pneumatic Chain Saw: Powerful Cutting of Wood, Polyethylene and PlasticDocument4 pages4 HP Pneumatic Chain Saw: Powerful Cutting of Wood, Polyethylene and Plasticedgar clemente carbajalNo ratings yet

- SpecificationsDocument1 pageSpecificationsbondsupplyNo ratings yet

- KN Ife Ga Te & Bu Tte Rfly Va Lve S E: Valves & EquipmentDocument14 pagesKN Ife Ga Te & Bu Tte Rfly Va Lve S E: Valves & EquipmentravishankarNo ratings yet

- USF Series: ASME Code Multi-Cartridge Filter Housings-Four Through Fifty-Two RoundDocument2 pagesUSF Series: ASME Code Multi-Cartridge Filter Housings-Four Through Fifty-Two Roundprabal rayNo ratings yet

- 04 Sucker RodDocument7 pages04 Sucker RodYoyi YuniasNo ratings yet

- 07 Solid Stream NozzlesDocument7 pages07 Solid Stream Nozzlesahmad bahlakeNo ratings yet

- CLASS 173.4 - Custom FRP - Bisphenol (Abrasive)Document3 pagesCLASS 173.4 - Custom FRP - Bisphenol (Abrasive)Lizeth IsidroNo ratings yet

- Spec I Fi Ca Tions: Weymouth™Document2 pagesSpec I Fi Ca Tions: Weymouth™Saúl MolinaNo ratings yet

- Dembla Gate ValvesDocument20 pagesDembla Gate ValvesMohit AroraNo ratings yet

- Spesifikasi UW Concrete CutterDocument2 pagesSpesifikasi UW Concrete CutterMuhammad YusufNo ratings yet

- ACA0291 GBDocument12 pagesACA0291 GBJosé Mariano ContrerasNo ratings yet

- Rotary Control Valve: K-MaxDocument12 pagesRotary Control Valve: K-MaxBrLuxy1952No ratings yet

- 200 Series Inverted Bucket Steam Traps: Cast Iron For Vertical InstallationDocument2 pages200 Series Inverted Bucket Steam Traps: Cast Iron For Vertical InstallationbhaskarbabaiNo ratings yet

- Rotary Control Valve: K-MaxDocument12 pagesRotary Control Valve: K-MaxBrLuxy1952No ratings yet

- 184 Darley254Document1 page184 Darley254Jose MelloNo ratings yet

- Style 400 Steel Coupling: (For 12" and Larger Pipe)Document4 pagesStyle 400 Steel Coupling: (For 12" and Larger Pipe)picottNo ratings yet

- GE250 Combination Torch Handles EnglishDocument4 pagesGE250 Combination Torch Handles EnglishVijo JoseNo ratings yet

- Omni Sleeve Wall Pipe Penetration Sleeve: SIGMA CorporationDocument4 pagesOmni Sleeve Wall Pipe Penetration Sleeve: SIGMA CorporationJojolasNo ratings yet

- 01 Rubber HoseDocument26 pages01 Rubber Hosewenny_tpdNo ratings yet

- Broco ExplaningDocument3 pagesBroco Explaningsequeiradiver1No ratings yet

- K-72760 Spec US-CA Kohler enDocument2 pagesK-72760 Spec US-CA Kohler en15101980No ratings yet

- Akron Style 4826 NewDocument3 pagesAkron Style 4826 Newluisa fernanda ordoñez casasNo ratings yet

- Clarkson - Knife Gate Valves - KS3 - Install Manual - 2022-11 - r00Document18 pagesClarkson - Knife Gate Valves - KS3 - Install Manual - 2022-11 - r00Vitor BandeiraNo ratings yet

- ACA Clamps&ConnectorsDocument4 pagesACA Clamps&ConnectorsvenkyeeeNo ratings yet

- Product BrochureDocument16 pagesProduct Brochurevishnu300022No ratings yet

- Series HUSDocument24 pagesSeries HUSsamialganNo ratings yet

- Wheatley Series 500 BRDocument8 pagesWheatley Series 500 BRanuarsgNo ratings yet

- Piping Materials - Olets The Piping Engineering WorldDocument3 pagesPiping Materials - Olets The Piping Engineering Worldrenger20150303100% (1)

- Resilient Seated: CommercialDocument25 pagesResilient Seated: Commercialagung wijayaNo ratings yet

- Transparent Level Gauge Series 2000: Product Data Sheet No. 7Document1 pageTransparent Level Gauge Series 2000: Product Data Sheet No. 7Alfonso BlancoNo ratings yet

- PLN-1200-3.07-01, Iss 01 - Product Catalogue PDFDocument12 pagesPLN-1200-3.07-01, Iss 01 - Product Catalogue PDFsakscribNo ratings yet

- PLN-1200-3.07-01, Iss 01 - Product Catalogue PDFDocument12 pagesPLN-1200-3.07-01, Iss 01 - Product Catalogue PDFsakscribNo ratings yet

- Flanged Spherical Pipe Joints: - Elastomeric Expansion Joints / Flexible ConnectorsDocument2 pagesFlanged Spherical Pipe Joints: - Elastomeric Expansion Joints / Flexible ConnectorsKhaled Al AkhdarNo ratings yet

- Vertical Flame ArresterDocument5 pagesVertical Flame ArresterMustafa PardawalaNo ratings yet

- Branch Connection Fittings (MSS SP-97) - Weldolet®, Sockolet®, Thredolet®, Latrolet®, Elbolet®, Nipolet®, Sweepolet®Document3 pagesBranch Connection Fittings (MSS SP-97) - Weldolet®, Sockolet®, Thredolet®, Latrolet®, Elbolet®, Nipolet®, Sweepolet®dchz_62No ratings yet

- Definition and Details of Socket Weld Fittings ASMEDocument7 pagesDefinition and Details of Socket Weld Fittings ASMEMehman NasibovNo ratings yet

- AVK Gate Valve Maintenance-Free Design ConceptDocument8 pagesAVK Gate Valve Maintenance-Free Design ConceptRakesh Sasidharan PillaiNo ratings yet

- Actuator SpecificationDocument12 pagesActuator SpecificationFactory FactoryNo ratings yet

- Gaseous Hydrogen Piping SpecificationDocument5 pagesGaseous Hydrogen Piping SpecificationAndri DoemeriNo ratings yet

- Cladding Design GuideDocument21 pagesCladding Design GuideJISHA MATHEWNo ratings yet

- CatalogoVCW EN Mai20Document11 pagesCatalogoVCW EN Mai20snri0da9No ratings yet

- CC Marine 2013-14 Catalogue - PumpsDocument94 pagesCC Marine 2013-14 Catalogue - PumpsGregGGH100% (1)

- Portable Tank BrochureDocument4 pagesPortable Tank BrochureDavid RodriguesNo ratings yet

- Zahra Kalantar - Properties of Bituminous Binders ModifiedDocument11 pagesZahra Kalantar - Properties of Bituminous Binders Modifiedzeidan111No ratings yet

- Astm A 615 Steel 2015Document8 pagesAstm A 615 Steel 2015wenming chenNo ratings yet

- 15-5240 enDocument14 pages15-5240 enRafa Lopez PuigdollersNo ratings yet

- Welding of Duplex Stainless SteelDocument7 pagesWelding of Duplex Stainless Steelel_sharkawy2011No ratings yet

- Physics Investigatory ProjectDocument14 pagesPhysics Investigatory Project09shasNo ratings yet

- English for Oil and Gas Solomchak Ozarko Moiseyenko ІDocument186 pagesEnglish for Oil and Gas Solomchak Ozarko Moiseyenko ІNeonila KryvtsunNo ratings yet

- Page 4 PDF StoneDocument2 pagesPage 4 PDF Stoneraja qammarNo ratings yet

- Solution Manual Reinforced Concrete McCormac 9th EditionDocument12 pagesSolution Manual Reinforced Concrete McCormac 9th EditionLarry66% (29)

- Tcbe 1202-5 LimeDocument48 pagesTcbe 1202-5 LimeshafikNo ratings yet

- Project: Project No: AuthorDocument37 pagesProject: Project No: Authorabdullah_23320666No ratings yet

- Epoxy Adhesion To Metals: Advances in Polymer Science January 1986Document40 pagesEpoxy Adhesion To Metals: Advances in Polymer Science January 1986Ekrem DoğanNo ratings yet

- Introduction To GlassDocument25 pagesIntroduction To GlassankithaNo ratings yet

- Method Statement WallDocument11 pagesMethod Statement WalldeviesrigatiNo ratings yet

- Ben Ammar 2014Document12 pagesBen Ammar 2014Anand NagarajanNo ratings yet

- Arijit Nandi - Design of RC StructuresDocument3 pagesArijit Nandi - Design of RC Structuresarijit nandiNo ratings yet

- Astm A709 GR 36Document2 pagesAstm A709 GR 36Henry Burgos N.No ratings yet

- Experiment No. 6 Pit Furnace Melting Practice: Aim TheoryDocument3 pagesExperiment No. 6 Pit Furnace Melting Practice: Aim TheoryDhananjay ShimpiNo ratings yet

- List ProfessorsDocument6 pagesList ProfessorsDonny pasaribuNo ratings yet

- S355J2 N, S355J2+N, En10025-2 s355j2n Steel PlateDocument2 pagesS355J2 N, S355J2+N, En10025-2 s355j2n Steel PlateEswaranNo ratings yet

- Cadangan Membina Surau As-Shaarif, Kampung Changkat Chermin, Beruas, Perak Darul RidzuanDocument8 pagesCadangan Membina Surau As-Shaarif, Kampung Changkat Chermin, Beruas, Perak Darul RidzuanMuhaimin RohizanNo ratings yet

- Normal GT II 18325458507 Pltgu Tanjung BatuDocument2 pagesNormal GT II 18325458507 Pltgu Tanjung Batudhavit wijayantoNo ratings yet

- Polyvinylacetate & Derivatives: Jitendra SinghDocument25 pagesPolyvinylacetate & Derivatives: Jitendra SinghHILL RANGAMATINo ratings yet

- Broschure Gland Packing Teadit 2Document2 pagesBroschure Gland Packing Teadit 2Desmon GultomNo ratings yet

- InLiquidation BombayDocument26 pagesInLiquidation BombayUrvin ShahNo ratings yet

- Advantages and Limitations of FRPDocument4 pagesAdvantages and Limitations of FRPWolfMensch1216No ratings yet