Professional Documents

Culture Documents

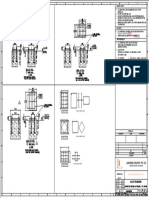

M101 - Cold Storage Mech - Plan

M101 - Cold Storage Mech - Plan

Uploaded by

LiaqatSrakOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M101 - Cold Storage Mech - Plan

M101 - Cold Storage Mech - Plan

Uploaded by

LiaqatSrakCopyright:

Available Formats

OUTDOOR UNITS OUTDOOR UNIT

18KW @ -2⁰C SST & 40⁰C DST 18KW @ -2⁰C SST & 40⁰C DST

GENERAL NOTES:

25 mmø 3m HIGH FENCE

ARROUND 1. REFRIGERANT PIPING AND FITTINGS SHALL BE COPPER SCHEDULE 40.

EQUIPMENT

2. ALL REFRIGERANT PIPING SHALL BE INSULATED WITH FACTORY

FABRICATED R-20 INSULATION.

3. ALL SIZES AND DIMENSIONS ARE SHOWN IN MILLIMETERS (mm)

25 mmø

UNLESS OTHERWISE NOTED.

6675

25 mmø

25 mmø

4. COOLING UNITS ARE CONTROLLED BY THERMOSTATE, INSTALL

25 mmø

THERMOSTATS 1.4m ABOVE FINISH FLOOR.

T

PRE COOLER 5. REFRIGERANT SUCTION PIPE NOT TO EXCEED MANUFACTURER'S

25 mmø

6.4m x 6.6m x 5.7mHT MAXIMUM LENGTH.

6430

CAP. 50 MT BATCH/12HR

INDOOR UNIT TEM. 4.4o C 6. TEMPERATURE RANGE FOR EACH UNIT SHALL BE -2oC TO 20oC.

RH. 90 - 95

7. A TEMPERATURE INDICATOR SHALL BE PROVIDED ON DOOR TO EACH

COLD STORAGE ROOM.

25 mmø

T

AIR CURTAIN

COLD ROOM 133 m2

T CAP. 200 MT NOTES:

TEM. 0o C

15130

SD

veranda

RH. 90 - 95 1. OUTDOOR UNITES SHALL INCLUDE CONDENSING COIL, FAN/FANS

25 mmø

AIR CURTAIN

Size: 2200x7225

ASSEMBLY WITH PROTECTIVE GAURD, COMPRESSOR MOUNTS LIQUID

SD

+450

DISCHARGE AND SUCTION LINES, PROVSION FOR ELECTRIC POWER

TEMPERATURE CONNECTIONS, PROTECTIVE CHARGE, OIL SEPARATOR INCLUDING

INDOOR UNIT AND RH INDICATOR CHECK VALVE INTEGRATED IN UNIT, LARGE RECEIVER FIR SYSTEM

veranda WITH A HIGHER REFRIGERANT CHARGE WITH A CONNECTION OF

Size: 2200x6150

PRESSURE RELIEF VALVE.

+450

UP

2. OUTDOOR UNITS SHALL MOUNT ON CONCRETE PAD, LIQUID

THERMOSTATE

AIR CURTAIN

FOR DETAIL SEE

DWG # A-501

REFRIGERANT SUPPLY TEMPERATURE IS -2oC AND REFRIGERANT

TEMPERATUR IN SUCTION LINE IS 40oC. COPRESSOR SHALL BE SEMI

HERMETIC WITH CRANCASE HEATER, MOUNTED ON A BASE PLATE,

T RECEIVER WITH OUTLET CONNECTIONS,

facility Room

Size: 3000x4500

O.K.B:950

3. EVAPORATOR / INDOOR COILS SHAL BE CAPABLE TO MAINTAIN 0-2 ⁰C

ROOM TEMPERATURE WITH 5 TD AND HAVING 13600 CMH TO MAINTAIN

+450 UP THE PROPER AIR FLOW IN THE ROOM. THE UNIT AIR THROW SHALL BE

6520

AIR CURTAIN

MORE THAN 20 M TO MAINTAIN PROPER AIR CIRCULATION IN THE

ROOM.

TEMPERATURE

AND RH INDICATOR

COLD STORAGE MECHANICAL

1

PLAN

M101

1 : 100

No. Description Date

COLD STORAGE MECH. PLAN

11/4/2020 1:55:27 AM

Project number Project Number

Date Issue Date

M101

Drawn by Author

PRUNE PROCESSING COMPLEX

Checked by Checker Scale 1 : 100

You might also like

- 38RMDocument26 pages38RMMohamed SaadAllah67% (3)

- Ushio ReinetsuDocument1 pageUshio Reinetsuironite100% (2)

- ServiceManuals LG Fridge GRL257NI GR-L257NI Service ManualDocument128 pagesServiceManuals LG Fridge GRL257NI GR-L257NI Service Manualspeedo1512100% (1)

- RFG297AA Fast Track R1 PDFDocument6 pagesRFG297AA Fast Track R1 PDFRoberto Augusto Aristizabal MorenoNo ratings yet

- Mohawk Riserlite Indoor Outdoor Fiber CableDocument2 pagesMohawk Riserlite Indoor Outdoor Fiber CablecolinyNo ratings yet

- Armstrong 4SCU14LB-OMNIGUARD SPECSHEETDocument9 pagesArmstrong 4SCU14LB-OMNIGUARD SPECSHEETMichael MartinNo ratings yet

- Chilled Water AHU - Performance Data PDFDocument12 pagesChilled Water AHU - Performance Data PDFLynel Arianne TaborNo ratings yet

- Carrier 40RMS-2SB Data SheetDocument12 pagesCarrier 40RMS-2SB Data SheetDnicol ArtNo ratings yet

- Mizer No-Bleed Pilot ValveDocument2 pagesMizer No-Bleed Pilot ValveKate FaulhaberNo ratings yet

- Equipment Schedule For Ducted Split Uniu Ercc: Split Air Conditioner Window Air ConditionerDocument4 pagesEquipment Schedule For Ducted Split Uniu Ercc: Split Air Conditioner Window Air ConditionerSathyajethNo ratings yet

- 40LX Ceiling Concealed CCAC InstallationDocument17 pages40LX Ceiling Concealed CCAC Installationjeferson binayNo ratings yet

- HitecsaDocument28 pagesHitecsaleonelNo ratings yet

- URS R404aDocument1 pageURS R404aironiteNo ratings yet

- General Structural NotesDocument5 pagesGeneral Structural NotesreinerNo ratings yet

- 40rs - 72dpi UMA CarreierDocument12 pages40rs - 72dpi UMA CarreierReinaldo JoseNo ratings yet

- ISOLATORDocument1 pageISOLATORkmas1612No ratings yet

- Riser Diagram: General Notes Schedule of Loads and ComputationsDocument1 pageRiser Diagram: General Notes Schedule of Loads and Computationsallan dela vegaNo ratings yet

- WD 23.05.01 (Louver + FL Garage)Document9 pagesWD 23.05.01 (Louver + FL Garage)keita.issaNo ratings yet

- R0 - All Structural Details - Foundation 15.11.22-A2-ANCHOR BOLT DETAILS (02 OF 02)Document1 pageR0 - All Structural Details - Foundation 15.11.22-A2-ANCHOR BOLT DETAILS (02 OF 02)Farhan DanishNo ratings yet

- LM Tower - FDN - DWG - Pgcil - 271023Document1 pageLM Tower - FDN - DWG - Pgcil - 271023SECURE STRUCTURENo ratings yet

- Standard Details - Water: 475 MM (APPROX.)Document1 pageStandard Details - Water: 475 MM (APPROX.)Shane MoynihanNo ratings yet

- Drrdock Repair Jobs (Excluding DD Routines) No 1Document15 pagesDrrdock Repair Jobs (Excluding DD Routines) No 1Amit Raj AnandNo ratings yet

- General Notes and Specifications: Generator Set Specification DataDocument1 pageGeneral Notes and Specifications: Generator Set Specification DataErwin Bernard NionesNo ratings yet

- Box Culvert 1Document1 pageBox Culvert 1aloopakoda5No ratings yet

- System Syzer TEH-175ADocument8 pagesSystem Syzer TEH-175AMario JoséNo ratings yet

- El 05 PDFDocument1 pageEl 05 PDFRhobbie NolloraNo ratings yet

- Piping GuideDocument28 pagesPiping Guidealfonsodelar100% (1)

- CSL Pipes Fittings Price List 2019 2020Document25 pagesCSL Pipes Fittings Price List 2019 2020Maureen CheronoNo ratings yet

- CMP 783 793Document2 pagesCMP 783 793Jose Carlos ReinaNo ratings yet

- International Equipment: CatalogueDocument24 pagesInternational Equipment: CatalogueFahmi FahreziNo ratings yet

- 40rm 4sbDocument12 pages40rm 4sbsarcitoNo ratings yet

- 004-Tunnel-1 Main Tunne Lining Detail Class - LDocument1 page004-Tunnel-1 Main Tunne Lining Detail Class - LVikas ChauhanNo ratings yet

- Emerson Oil SeparatorDocument2 pagesEmerson Oil SeparatorHardiman ArbiNo ratings yet

- Comparative Quotation Analysis Report: Diff - Amount/Pc Total Increase - AmountDocument4 pagesComparative Quotation Analysis Report: Diff - Amount/Pc Total Increase - AmountSunil PatelNo ratings yet

- Merkel - Guides-Guide Strip FBDocument3 pagesMerkel - Guides-Guide Strip FBÖzgür GürkanNo ratings yet

- Accessories: Elbow / Grs - Guide Rail Systems: Product FeaturesDocument2 pagesAccessories: Elbow / Grs - Guide Rail Systems: Product FeaturessagbvnNo ratings yet

- Speedocontrol Flp-WormDocument1 pageSpeedocontrol Flp-WormVipesh SinghNo ratings yet

- MilSpec CatalogDocument26 pagesMilSpec Catalogdavid yau100% (3)

- RCC Design & DetailsDocument1 pageRCC Design & DetailsKanhaiya PanwarNo ratings yet

- Pentair Goyen Manifold Mount Pulse Jet ValvesDocument11 pagesPentair Goyen Manifold Mount Pulse Jet ValvesAbhishek PatelNo ratings yet

- Ras18 22skveDocument114 pagesRas18 22skveRodrigo VictorNo ratings yet

- Carrier Rm-psd1 25 To 45.5 TRDocument26 pagesCarrier Rm-psd1 25 To 45.5 TRhany100% (1)

- Alfagomma - Oil & GasDocument115 pagesAlfagomma - Oil & GasIgor Bastos100% (1)

- Resource - Instructions - 0898-2725 - 2725 Jet-Fill TensiometersDocument12 pagesResource - Instructions - 0898-2725 - 2725 Jet-Fill TensiometersZarin Tasnim ChowdhuryNo ratings yet

- Ventilnorte Filo Range PDFDocument2 pagesVentilnorte Filo Range PDFcoutinholopesNo ratings yet

- TransamDocument8 pagesTransammaribel delos reyesNo ratings yet

- Pluscut 105 PDFDocument2 pagesPluscut 105 PDFAleksandar RakicNo ratings yet

- General Notes & Specifications PDFDocument2 pagesGeneral Notes & Specifications PDFPriodeep ChowdhuryNo ratings yet

- Hydrant Valve, Single Outlet: Technical Data SheetDocument2 pagesHydrant Valve, Single Outlet: Technical Data Sheetonepiece123mineNo ratings yet

- 38AUM 60Hz PDC V9Document40 pages38AUM 60Hz PDC V9hgogoriyaNo ratings yet

- 7x7 Culvert-Personal ClientDocument1 page7x7 Culvert-Personal ClientNishimonKonwarNo ratings yet

- 38aum 50hz PDC v4Document36 pages38aum 50hz PDC v4khaled salahNo ratings yet

- WF2000 Gas Wall Furnace Installation Manual 614281hDocument15 pagesWF2000 Gas Wall Furnace Installation Manual 614281hAdam CleggNo ratings yet

- GP-MR200 Stator Wire Details PDFDocument2 pagesGP-MR200 Stator Wire Details PDFButnaru JanNo ratings yet

- ClariflocculatorDocument1 pageClariflocculatorPabitra Kumar PuhanNo ratings yet

- kc7783r PDFDocument1 pagekc7783r PDFHaris WidiyantoNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Advanced Thermoforming: Methods, Machines and Materials, Applications and AutomationFrom EverandAdvanced Thermoforming: Methods, Machines and Materials, Applications and AutomationRating: 5 out of 5 stars5/5 (1)

- Annex-2 (Inverter - SP-Manual)Document16 pagesAnnex-2 (Inverter - SP-Manual)LiaqatSrak50% (2)

- P101 - Restroom Plumbing PlanDocument1 pageP101 - Restroom Plumbing PlanLiaqatSrakNo ratings yet

- Design of Solar Pumping System For RuralDocument4 pagesDesign of Solar Pumping System For RuralLiaqatSrakNo ratings yet

- Driange Plan-Sewer-Drainage PlanDocument1 pageDriange Plan-Sewer-Drainage PlanLiaqatSrakNo ratings yet

- Sardar Jamal New Proofed Thsss PDFDocument214 pagesSardar Jamal New Proofed Thsss PDFLiaqatSrakNo ratings yet

- Personal History Form: United Nations Nations UniesDocument8 pagesPersonal History Form: United Nations Nations UniesLiaqatSrakNo ratings yet

- Ramadan 2014 / 1435 Prayer Times ScheduleDocument1 pageRamadan 2014 / 1435 Prayer Times ScheduleLiaqatSrakNo ratings yet

- Support Details For ASHRAE Heat Load Calculation SheetDocument8 pagesSupport Details For ASHRAE Heat Load Calculation SheetShravanNo ratings yet

- ASHRAE Psychrometric ChartsDocument2 pagesASHRAE Psychrometric ChartsJeane Carvalho100% (1)

- Hvac Boq - R0 - 2914Document46 pagesHvac Boq - R0 - 2914Vikash TiwariNo ratings yet

- Daikin Presentation - VRV TechnologyDocument27 pagesDaikin Presentation - VRV TechnologySantosh Baladhye100% (1)

- DCV Modelling: Demand Controlled Ventilation and SustainabilityDocument2 pagesDCV Modelling: Demand Controlled Ventilation and Sustainabilitymasud_me05No ratings yet

- ACMV Design Manual 5 Jan 05 R11Document42 pagesACMV Design Manual 5 Jan 05 R11TienNguyenNo ratings yet

- Kruger Ventilation Industries Pte LTD: A B C D N°xØDocument1 pageKruger Ventilation Industries Pte LTD: A B C D N°xØAzher ANo ratings yet

- CUWD C CatalogueDocument25 pagesCUWD C CataloguetvantvanNo ratings yet

- Carrier Air Cooled ChillerDocument48 pagesCarrier Air Cooled Chillernagmeldeen180% (5)

- Tutorial - Underfloor Air-ConditioningDocument8 pagesTutorial - Underfloor Air-ConditioningJasper_HVACNo ratings yet

- ACC SVN61A en (Installer's Guide)Document24 pagesACC SVN61A en (Installer's Guide)jfisher54No ratings yet

- Ycae Modular Air Cooled Scroll Chiller / Heat Pump: YCAE 065R/S To 0100R/SDocument2 pagesYcae Modular Air Cooled Scroll Chiller / Heat Pump: YCAE 065R/S To 0100R/SAbdulSattarNo ratings yet

- Review of Domestic Heat Pump CopDocument12 pagesReview of Domestic Heat Pump CoppescciaNo ratings yet

- 69NT40-541-001 To 199 OSDocument112 pages69NT40-541-001 To 199 OSDavid Pereira AquinoNo ratings yet

- Leaflet RobustDocument2 pagesLeaflet RobustimriasbajasNo ratings yet

- Aircon Load CalculationDocument4 pagesAircon Load CalculationPari RajendranNo ratings yet

- Presentation On Ventilation in Residential BuildingDocument14 pagesPresentation On Ventilation in Residential BuildingMohammed ImranNo ratings yet

- 10.4 SAU-SAO 045 Technical Selection R01Document3 pages10.4 SAU-SAO 045 Technical Selection R01Harry CulNo ratings yet

- Thermosyphon Reboiler HydraulicsDocument2 pagesThermosyphon Reboiler HydraulicskaramullahrasheedNo ratings yet

- Q2 ETCC Public Meeting Presentations - 05.16.2013Document175 pagesQ2 ETCC Public Meeting Presentations - 05.16.2013David DonosoNo ratings yet

- Ficha Tecnica Equipo Compacto (Rooftop) 20 TR Descarga HorizontalDocument10 pagesFicha Tecnica Equipo Compacto (Rooftop) 20 TR Descarga HorizontalRonald MonzónNo ratings yet

- Cooling SystemDocument8 pagesCooling SystemRâdển Mẳs SựryọỡNo ratings yet

- Edr Designguidelines Hvac Simulation 2edDocument64 pagesEdr Designguidelines Hvac Simulation 2edDavid O. AlmeidaNo ratings yet

- Pemerintah Kabupaten Klungkung Dinas Kesehatan: Jalan Gajah Mada No. 55 Semarapura Telp. (0366) 21150Document4 pagesPemerintah Kabupaten Klungkung Dinas Kesehatan: Jalan Gajah Mada No. 55 Semarapura Telp. (0366) 21150anggaNo ratings yet

- Split ACDocument1 pageSplit ACSameera KudavithanageNo ratings yet

- TemplifierDocument8 pagesTemplifiermdalt9180100% (1)

- Emd5m6a1 Lab Report Thermo 2Document21 pagesEmd5m6a1 Lab Report Thermo 2Zulfaris NasirNo ratings yet

- Actual VCR CycleDocument4 pagesActual VCR Cyclepramod kumar yadavNo ratings yet