Professional Documents

Culture Documents

XT 55 Box

XT 55 Box

Uploaded by

nwoha0 ratings0% found this document useful (0 votes)

17 views1 pageghtrx

Original Title

xt 55 box

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentghtrx

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

17 views1 pageXT 55 Box

XT 55 Box

Uploaded by

nwohaghtrx

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 1

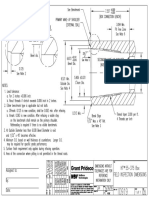

BENCHMARK

GPmark™ DETAIL

Xmark™ DETAIL

0.063

See Note 2

7

Bevel dia.

0.125

See Note 2

NOTES:

1. Lead tolerance:

«. For 2 inches +0.006 inch

b. Recut threads if stretch exceeds 0.006 inch in 2 inches

2. Either benchmark type is applicable but not both,

a. GPrnark: 0.125 is new condition, shall be 062 min, after reta

b. Xmark: 0.063 is new condition. After refacing a visible step

on the benchmark shall remain on the primary shoulder.

Rethreading is required if there is no visible benchmark

5. At Outside Diameter less than 6.958, Bevel Diameter is void

See BENCHMARK —

PRIMARY MAKE-UP SHOULDER

(SEAL)

| 7.260 *$83 —=

‘

(BOX CONNECTION LENGTH)

3,000 Win,

Pit Free Zone

See Note 6

t

6.873 ath

15

a9

‘SECONDARY MAKE-UP SHOULDER vA |

873 hie Bae NS

evel Di.

" (MECHANICAL STOP) \

6.438 Min. 5.814 10.031 5.203 Ref.

Gute Chore Dia Cyindicc Oi

See Note 4

cing,

Thread taper 0.750" per ft.

3.5 Threads per inch

and 1/32" x 45° becomes effective 1 0" won oe bet

4, Ninimum 0.D. based on wall thickness at counterbore. Larger 0. cote ss

may be required for specific gfade performance ee Note

5. Surface finish requirement only applies during refacing operation

6. Area of the connection where pitng i not permitted in the thread roots

EEEEEREE a

S SSRSESR . ‘ DIMENSIONS. WMHOUT mi EF

Assigned To: Saas" Grant Pridecoy sy rnices se FoR XT™ 95. Box

Py ea REFERENCE FIELD INSPECTION DIMENSIONS

a ge 388 INFORMATION ONLY

7 =|= ma EP 5/7/99 lee rae ie

Date ke Bsklsels ame” 1D865 Fre [07

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- XT 57 BoxDocument1 pageXT 57 BoxnwohaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Fid XT™ 38 Box 1e328Document1 pageFid XT™ 38 Box 1e328nwohaNo ratings yet

- Field Inspection HT™ 2-3.8 SLH90 Box1E997Document1 pageField Inspection HT™ 2-3.8 SLH90 Box1E997nwohaNo ratings yet

- 1J126Document1 page1J126nwohaNo ratings yet

- Field Inspection HT™ 55-375 Box 1D919Document1 pageField Inspection HT™ 55-375 Box 1D919nwohaNo ratings yet

- Field Inspection Mw20 Pin 1h674Document1 pageField Inspection Mw20 Pin 1h674nwohaNo ratings yet

- Field Inspection HT™ 2-3.8 SLH90 Box1E997Document1 pageField Inspection HT™ 2-3.8 SLH90 Box1E997nwohaNo ratings yet

- Field Inspection HT™ 65 Box 1E919Document1 pageField Inspection HT™ 65 Box 1E919nwohaNo ratings yet

- Field Inspection HT™ 55-375 Pin 1D918Document1 pageField Inspection HT™ 55-375 Pin 1D918nwohaNo ratings yet

- XT 31 PinDocument1 pageXT 31 PinnwohaNo ratings yet

- Covid - 19 Contingency PlanDocument6 pagesCovid - 19 Contingency PlannwohaNo ratings yet

- Field Inspection XT™ 26 Pin 1E920Document1 pageField Inspection XT™ 26 Pin 1E920nwohaNo ratings yet

- How To View The Material Certificate: By: Eng. Mohamed Farouk BayomiDocument9 pagesHow To View The Material Certificate: By: Eng. Mohamed Farouk BayominwohaNo ratings yet

- WPS Understanding: By: Eng. Mohamed Farouk BayomiDocument11 pagesWPS Understanding: By: Eng. Mohamed Farouk BayominwohaNo ratings yet

- Bouygues Construction Nigeria Limited: Weld History SheetDocument5 pagesBouygues Construction Nigeria Limited: Weld History SheetnwohaNo ratings yet

- WPS Understanding: By: Eng. Mohamed Farouk BayomiDocument11 pagesWPS Understanding: By: Eng. Mohamed Farouk BayominwohaNo ratings yet