Professional Documents

Culture Documents

Taper Att

Taper Att

Uploaded by

AADM 72Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Taper Att

Taper Att

Uploaded by

AADM 72Copyright:

Available Formats

1.

SHOP-MADE TAPER ATTACHMENT mounted on small lathe can be adjusted to turn outside or inside tapers on

work mounted between centers or in a chuck for taper boring. Attachment is made entirely from stock materials

By Waller E. Burton

T URNING A TAPER by offsetting the

tailstock of the lathe is a common prac-

tice but the method has several disadvan-

tages. In turning a taper by offsetting, the

lathe centers are out of alignment which

can result in inaccuracies due to burring of

the center holes in the work, also possible

scoring of the lathe tail center. Only work

mounted between centers can be tapered

by the offset method; taper boring cannot

be done. In small shops where the amount 2. SLOTTED ENDS of swiveling bar, or carrier, are

of taper work does not warrant the outlay finished in lathe with milling cutter or rotary file

for a conventional taper attachment it is

possible, using stock materials, to make one

to fit nearly all small lathes. 3. SLIDE BLOCKS are first bored offcenter, then

The taper attachment pictured in Fig. 1 reamed. If desired, blocks can be made from brass

and on the opposite page was made to fit a

9-in. lathe. As a rule the parts dimensioned

in Fig. 6 through 8 will be suitable for vari-

ous makes of 9-in. lathes and possibly those

of slightly larger or smaller swing. Note

that two of the parts are not fully dimen-

sioned, the cross-slide connector and the

bracket. Figs. 7 and 8. You can use .125 or

¼-in. stock for the connector, depending on

the clearance. The 5-in. dimension on the

bracket was found adequate for the lathe

pictured, but may not be for all lathes in

this size range. The bracket can be made

JANUARY 1962 197

from a short length of heavy steel angle or

can be made by welding two pieces of ½-in.

flat steel at a 90-degree angle. The bracket

is screwed to the flat on the back face of the

lathe carriage, Fig. 5. The dimensions on

the angle bracket carrying the V-way

clamp, Fig. 6, also should be checked with

your lathe before cutting stock. The lower

track, Figs. 5 and 8, should be parallel with

the lathe ways.

The slides, Fig. 5, are bored offcenter and

reamed as in Fig. 3. After reaming, saw

cuts (or milling cuts) are run through into

the bore and into one side as indicated.

Then when the capping piece is screwed in

place, the setscrews, with locknuts, provide

for clamping the slides at any point along

4. SLIDE BLOCKS should be lapped after reaming to

the tracks. Then each slide is lapped to its

assure smooth operation. Drill-rod track is coated track, using a lapping compound and a full-

with lapping compound. Block is stroked by hand length stroke as in Fig. 4. After roughing

TABLE

CARRIER

PIVOT

SCALE AT END OF TABLE

CROSS SLIDE CROSS-SLIDE

CONNECTOR SCREW STEEL

UPPER DIA., REAM

TRACK

SAW KERF

TABLE

CARRIER

TABLE-SUPPORT STEEL

SOCKET SETSCREW

BLOCK

SLIDE,

BRACKET 2 REQD.

LOWER

LATHE TRACK

CARRIAGE

V-WAY CLAMP

MUST BE MADE

TO FIT LATHE

STEEL

TH'D.

STEEL ANGLE

, TO FIT

V-WAY

SCREWS

HOLLOW-HEAD

SETSCREW

V-WAY CLAMP

198 POPULAR MECHANICS

6-A DEPTH MICROMETER is used to make

close measurements when calibrating

out undersize with drill and hack-

saw, the curved slots near the ends

of the carrier and table can be fin-

ished with a rotary file (or milling

cutter) as in Fig. 2. Each member

is pivoted on a piece of hardwood

which is locked in the milling vise.

Then the work is hand-fed to the

file or cutter.

Finished parts and partial as-

semblies are pictured in Figs. 9

through 12. In Fig. 11 the parts are

set for a l-in.-per-ft. taper. The

first step in calibrating is to check

alignment of the upper track with

the edge of the carrier nearest the

lathe and also alignment of the

R. R

TAP

CROSS-SLIDE

CONNECTOR

UPPER TRACK,

DRILL ROD SWIVELING

CARRIER

ALTERED

SCREW

(SEE A)

WITNESS

MARK STEEL

TABLE

STEEL

TO FIT LATHE

CARRIAGE

LOWER TRACK,

LOCK-

NUTS

DRILL ROD

10-32

SOCKET

SCREW

SETSCREW

BRACKETS-MUST BE

STEEL, 2 REQD.

MADE FROM HEAVY

STEEL ANGLE OR FLAT

STOCK TO FIT LATHE

JANUARY 1962 199

9. TABLE AND ANGLE BASE showing lower track and 1O. CROSS-SLIDE CONNECTOR is bolted to underside

support blocks setscrewed to underside of table. Slide of lathe compound as in foreground. In background

blocks are shown in relative positions on table and lower block is shown in position on built-up base. Slide

base. These parts are all made from stock materials block should be lapped to track with fine compound

lower track with the edge of the table near-

est the lathe bed. The two check points

should be 12 in. apart as in the upper de-

tail. Fig. 5. Make a note of any variation.

The index mark, or witness mark, at each

end of the carrier bar moves along a scale

which at one end indicates taper in inches

per foot and at the other end in degrees of

side angle (half the included angle). To

lay out the taper-per-foot scale make two

marks on the table 12 in. apart on the edge

toward the lathe. With a depth micrometer,

Fig. 6-A, measure, at the marks, the dis-

tance from the table edge to the edge of the

carrier. At the zero(0) setting these meas-

urements should be equal. For a taper of

1 in. per ft. the difference in the micrometer

measurements will be ½ in. Make a scale

mark to indicate this setting. Then lay off

the graduations with dividers from .125 or ¼

in. to 4 in. on each side of zero(0), Fig. 5,

the upper right-hand detail. At the other

11. TABLE WITH CARRIER BAR is set for 1 -in.-per-ft. end of the swiveling carrier calibrate a

taper. Also shown is upper slide block in position scale indicating to 10 degrees on each side

of zero (0), using a protractor.

12. UPPER SLIDE BLOCK showing cover plate and How Attachment Is Used

screw holding connector. Note the hollow setscrews

When the attachment is set up for use,

the cross-feed screw on the lathe carriage

must be either disconnected or removed

entirely, depending on the lathe. Use the

compound to control the tool feed. After

setting the carrier to turn the taper de-

sired, move the cross slide so the tool is in

position to start the first cut. Then tighten

the nut that locks the cross-slide connector

to the upper slide block on the taper attach-

ment. The slide block should be adjusted

so that there is no play in its movement

along the track. Back off the cutting tool

so that it clears the work for each return

of the lathe carriage. Use a slow feed for

the final cut. Before starting to turn a taper

either inside or outside, make sure that the

attachment is held rigidly in place on the

lathe, that all nuts have been drawn tight

and the slides properly adjusted. Apply

light lubricant to all sliding parts. * * *

200 POPULAR MECHANICS

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

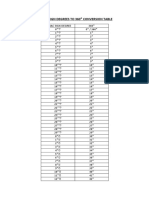

- Zodiac Sign Degrees To 360 Degrees Conversion TableDocument8 pagesZodiac Sign Degrees To 360 Degrees Conversion TableSandra Barnett Crossan100% (1)

- Debt Payment TrackerDocument1 pageDebt Payment TrackerSandra Barnett CrossanNo ratings yet

- Eliminate HumansDocument1 pageEliminate HumansSandra Barnett CrossanNo ratings yet

- Chrysler 2005 SebringDocument291 pagesChrysler 2005 SebringSandra Barnett CrossanNo ratings yet

- Pantry InventoryDocument1 pagePantry InventorySandra Barnett CrossanNo ratings yet

- 04 EmotionalDocument2 pages04 EmotionalSandra Barnett CrossanNo ratings yet

- Azed No. 2,372 Plain: Up (6) Alcatraz? (5, 2 Words)Document1 pageAzed No. 2,372 Plain: Up (6) Alcatraz? (5, 2 Words)Sandra Barnett CrossanNo ratings yet

- Freezer Inventory: Item Quantity DateDocument1 pageFreezer Inventory: Item Quantity DateSandra Barnett CrossanNo ratings yet

- Motivation and Factors Affecting MotivationDocument13 pagesMotivation and Factors Affecting MotivationSandra Barnett CrossanNo ratings yet

- Chapter 4: "A Drug Not To Be Neglected": Medicalizing Hashish in 1840s FranceDocument69 pagesChapter 4: "A Drug Not To Be Neglected": Medicalizing Hashish in 1840s FranceSandra Barnett CrossanNo ratings yet

- Email Beyond Basics ALL PDFDocument75 pagesEmail Beyond Basics ALL PDFSandra Barnett CrossanNo ratings yet

- Email Beyond Basics 1Document17 pagesEmail Beyond Basics 1Sandra Barnett CrossanNo ratings yet

- # Try Saying This... Instead of This..Document1 page# Try Saying This... Instead of This..Sandra Barnett CrossanNo ratings yet

- 2832-Saws & How To Use ThemDocument1 page2832-Saws & How To Use ThemSandra Barnett CrossanNo ratings yet

- Basic Electricity Lesson 02Document17 pagesBasic Electricity Lesson 02Sandra Barnett CrossanNo ratings yet

- Astro Anecdotes PDFDocument4 pagesAstro Anecdotes PDFSandra Barnett CrossanNo ratings yet

- ProgrammingGroundUp 0 9 PDFDocument236 pagesProgrammingGroundUp 0 9 PDFSandra Barnett CrossanNo ratings yet

- Carpentry For BoysDocument139 pagesCarpentry For BoysSandra Barnett CrossanNo ratings yet

- 2861-Wheel & Shaft PullersDocument1 page2861-Wheel & Shaft PullersSandra Barnett CrossanNo ratings yet

- 2950-Patterns With Fins & FlangesDocument1 page2950-Patterns With Fins & FlangesSandra Barnett CrossanNo ratings yet

- 2948-Patterns For Hollow CastingsDocument1 page2948-Patterns For Hollow CastingsSandra Barnett CrossanNo ratings yet

- 2837-Screws & How To Fit ThemDocument1 page2837-Screws & How To Fit ThemSandra Barnett CrossanNo ratings yet

- 2947 Simple PatternmakingDocument1 page2947 Simple PatternmakingSandra Barnett CrossanNo ratings yet

- 2833-How To Use DrillsDocument1 page2833-How To Use DrillsSandra Barnett CrossanNo ratings yet