Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

90 viewsRemaining Useful Life Prediction of Automotive Engine Oils Using MEMS Technologies

Remaining Useful Life Prediction of Automotive Engine Oils Using MEMS Technologies

Uploaded by

Shubham KumarThis document proposes using MEMS sensors and neural networks to predict the remaining useful life of automotive engine oils. It involves developing an "intelligent on-board DIP system" using a "microsensor web" to measure oil parameters like oxidation, acidity, additives, and soot. These parameters are inputs to a neural network to create an "oil condition parameter" that is trended over time. Advanced prognostic techniques are then applied to the trend to predict remaining useful life. The methodology aims to extend oil change intervals through online monitoring of engine conditions, oil measurements, and correlating this data using the proposed intelligent system.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- The Mighty Mars Rover Discussion GuideDocument4 pagesThe Mighty Mars Rover Discussion GuideHoughton Mifflin HarcourtNo ratings yet

- Mass Air Flow Sensor Diagnostics For Adaptive Fueling Control ofDocument6 pagesMass Air Flow Sensor Diagnostics For Adaptive Fueling Control ofSinAnime ConAnimeNo ratings yet

- How To Write An Argumentative Essay in 9 Easy StepsDocument3 pagesHow To Write An Argumentative Essay in 9 Easy StepsSuryadi SarminsonNo ratings yet

- Estructura de ProyectoDocument12 pagesEstructura de ProyectoCidit DescartesNo ratings yet

- Vehicular Engine Oil Service Life Characterization Using On-Board Diagnostic Sensor DataDocument5 pagesVehicular Engine Oil Service Life Characterization Using On-Board Diagnostic Sensor DataJane wangNo ratings yet

- Remaining Useful Life Prediction of Lubricating Oil With Dynamic Principal Component Analysis and Proportional Hazards ModelDocument8 pagesRemaining Useful Life Prediction of Lubricating Oil With Dynamic Principal Component Analysis and Proportional Hazards ModelShubham KumarNo ratings yet

- Cigre A2 - 105 - 2014Document8 pagesCigre A2 - 105 - 2014Chris ParkinsonNo ratings yet

- T4I Documento de Trabajo de Tarea 02Document8 pagesT4I Documento de Trabajo de Tarea 02David VelascoNo ratings yet

- The Common Fault Diagnosis Method of Diesel Engine: Zhibin Wang, Yu Zhao, Jian Yan and Jiafeng XuDocument3 pagesThe Common Fault Diagnosis Method of Diesel Engine: Zhibin Wang, Yu Zhao, Jian Yan and Jiafeng XuNemer RaslenNo ratings yet

- Example of An Integrated Conception Use of Methods For Monitoring Wear Particles in The Lubrication System of AircraftDocument10 pagesExample of An Integrated Conception Use of Methods For Monitoring Wear Particles in The Lubrication System of AircraftSambuddha KhanNo ratings yet

- Sae Technical Paper Series: James F. Sinnamon and Mark C. SellnauDocument17 pagesSae Technical Paper Series: James F. Sinnamon and Mark C. SellnauFabio GuedesNo ratings yet

- Benefits of Lubricant Oil Analysis For Maintenance Decision Support: A Case StudyDocument8 pagesBenefits of Lubricant Oil Analysis For Maintenance Decision Support: A Case Studymunal23No ratings yet

- Oil Analysis Best PracticesDocument15 pagesOil Analysis Best Practicesmike100% (1)

- Natural Gas Engine ODocument8 pagesNatural Gas Engine Ogoldy456No ratings yet

- 347 4.survey On Vehicle Health Monitoring SystemDocument2 pages347 4.survey On Vehicle Health Monitoring SystemSachin KumarNo ratings yet

- Misfire Detection of A Turbocharged Diesel Engine by Using Artificial Neural NetworksDocument7 pagesMisfire Detection of A Turbocharged Diesel Engine by Using Artificial Neural NetworksJean Carlos PinedaNo ratings yet

- A Predictive Algorithm For Estimating The Quality of Vehicle Engine OilDocument11 pagesA Predictive Algorithm For Estimating The Quality of Vehicle Engine OilJoseNo ratings yet

- Research Papar Khushal WordDocument5 pagesResearch Papar Khushal WordKHUSHAL KAKAR (kakaran.)No ratings yet

- ASTM D7720-11 (Reapproved 2017)Document14 pagesASTM D7720-11 (Reapproved 2017)carlos trilloNo ratings yet

- Limit Values For LubricantsDocument28 pagesLimit Values For LubricantsSindley LimaferNo ratings yet

- Oil Debris Analysis For Condition Monitoring of An IC EngineDocument3 pagesOil Debris Analysis For Condition Monitoring of An IC EngineJaime BerryNo ratings yet

- Reliability Analysis For Refinery Plants: February 2017Document11 pagesReliability Analysis For Refinery Plants: February 2017DilipSinghNo ratings yet

- Machines: Monitoring The Oil of Wind-Turbine Gearboxes: Main Degradation Indicators and Detection MethodsDocument24 pagesMachines: Monitoring The Oil of Wind-Turbine Gearboxes: Main Degradation Indicators and Detection MethodsGuilherme Souza GomesNo ratings yet

- Global Evaluation of The Drivability of Calibrated Diesel Engine MapsDocument6 pagesGlobal Evaluation of The Drivability of Calibrated Diesel Engine MapsKhac-Hoang NguyenNo ratings yet

- Model Based Diagnosis For The Air Intake System of The SI-EngineDocument12 pagesModel Based Diagnosis For The Air Intake System of The SI-EngineecasayangNo ratings yet

- Microchemical Journal: Roman M. Balabin, Ravilya Z. Sa Fieva, Ekaterina I. LomakinaDocument8 pagesMicrochemical Journal: Roman M. Balabin, Ravilya Z. Sa Fieva, Ekaterina I. LomakinaLuqmanNo ratings yet

- Maintaining Lube Oil System Cleanliness in Motor Bearing ApplicationsDocument34 pagesMaintaining Lube Oil System Cleanliness in Motor Bearing ApplicationsDawn Moon100% (1)

- Comparison of Engine Calibration Methods Based On Design of Experiments (Doe)Document21 pagesComparison of Engine Calibration Methods Based On Design of Experiments (Doe)Kaushal PanchalNo ratings yet

- 2 Article Failure Rate Analysis of IC Engine ComponentsDocument10 pages2 Article Failure Rate Analysis of IC Engine ComponentsMIKINo ratings yet

- Intelligent Detection and Real-Time Monitoring of Engine Oil Aeration Using A Machine Learning ModelDocument19 pagesIntelligent Detection and Real-Time Monitoring of Engine Oil Aeration Using A Machine Learning ModelHưng HoàngNo ratings yet

- Foroughi 2021Document8 pagesForoughi 2021abntrenanNo ratings yet

- D 6837 - 04 - Rdy4mzcDocument60 pagesD 6837 - 04 - Rdy4mzcNguyễn Bằng NộiNo ratings yet

- ARAI-Update Q12223 11836Document10 pagesARAI-Update Q12223 11836nishu solankiNo ratings yet

- Fuel Gas Efficiency BMP - Efficient Use of Fuel Gas in Engines (Module 7) PDFDocument76 pagesFuel Gas Efficiency BMP - Efficient Use of Fuel Gas in Engines (Module 7) PDFKopi BrisbaneNo ratings yet

- Exp FinalDocument4 pagesExp Finalhugo mendozaNo ratings yet

- Real Time Monitoring of Vital Health Parameters of The VehicleDocument8 pagesReal Time Monitoring of Vital Health Parameters of The VehicleInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Engine Condition MonitoringDocument8 pagesEngine Condition MonitoringShiddiq QiNo ratings yet

- Mancini Giorgio TesiDocument135 pagesMancini Giorgio Tesiesthermulenga021No ratings yet

- Diesel Engine Fault Detection Using Vibr1Document9 pagesDiesel Engine Fault Detection Using Vibr1achraf zegnaniNo ratings yet

- Cired 2019 - 995Document5 pagesCired 2019 - 995Technology developmentsNo ratings yet

- DCA For Production Forecasting Base On Machine LearningDocument14 pagesDCA For Production Forecasting Base On Machine LearningQuy Tran XuanNo ratings yet

- Effectiveness of A Novel Sensor Selection Algorithm in PEM Fuel Cell On-Line DiagnosisDocument10 pagesEffectiveness of A Novel Sensor Selection Algorithm in PEM Fuel Cell On-Line DiagnosisMohmmed MahmoudNo ratings yet

- 10 1 1 98 9640 PDFDocument7 pages10 1 1 98 9640 PDFDev RaiNo ratings yet

- The Classification and Regression Tree Approach To Pump Failure Rate AnalysisDocument9 pagesThe Classification and Regression Tree Approach To Pump Failure Rate AnalysisNabila MahardianaNo ratings yet

- Condition Monitoring of Wind Turbine Gearbox Bearing Based On Deep Learning ModelDocument10 pagesCondition Monitoring of Wind Turbine Gearbox Bearing Based On Deep Learning ModelDarshan PatilNo ratings yet

- Measurement of Effects of Automotive Engine Oils On Fuel Economy of Passenger Cars and Light-Duty Trucks in Sequence VIB Spark Ignition EngineDocument60 pagesMeasurement of Effects of Automotive Engine Oils On Fuel Economy of Passenger Cars and Light-Duty Trucks in Sequence VIB Spark Ignition EngineMohanadNo ratings yet

- Application - Reservoir Fluid PropertiesDocument20 pagesApplication - Reservoir Fluid PropertiesDarshak SakhreliyaNo ratings yet

- Frank Pedersen - Diesel Engine Combus - jun.2005.SECPDocument53 pagesFrank Pedersen - Diesel Engine Combus - jun.2005.SECPAhmed Samir We ShreenNo ratings yet

- Determination of Injection Parameters UsDocument12 pagesDetermination of Injection Parameters UsHoi TranNo ratings yet

- A Virtual Sensor For Predicting Diesel Engine Emissions From Cylinder Pressure DataDocument9 pagesA Virtual Sensor For Predicting Diesel Engine Emissions From Cylinder Pressure DataKhac-Hoang NguyenNo ratings yet

- Definitionofa Motor Oil Change Intervalfor High Volume Diesel Engines Basedonits Current Characteristics AssessmentDocument11 pagesDefinitionofa Motor Oil Change Intervalfor High Volume Diesel Engines Basedonits Current Characteristics Assessmentkenny apataNo ratings yet

- Virtual Calibration Method For Diesel Engine by Software in The Loop Techniques M. C. Cameretti, E. Landolfi, T. Tesone and A. CaraceniDocument18 pagesVirtual Calibration Method For Diesel Engine by Software in The Loop Techniques M. C. Cameretti, E. Landolfi, T. Tesone and A. CaraceniDiep Hau ThanNo ratings yet

- Application of Roms To Aeroengines Health Monitoring: April 2019Document20 pagesApplication of Roms To Aeroengines Health Monitoring: April 2019tadele10No ratings yet

- 10.2478 - Pomr 2022 0047Document8 pages10.2478 - Pomr 2022 0047fgadshfdjfhgNo ratings yet

- ASTM D613 - Cetane NumberDocument31 pagesASTM D613 - Cetane NumberZiauddeen NoorNo ratings yet

- A Machine Learning Approach To Information Extraction From Cylinder Pressure SensorsDocument12 pagesA Machine Learning Approach To Information Extraction From Cylinder Pressure SensorsKhac-Hoang NguyenNo ratings yet

- Evaluation of Engine Oils in A High Speed, Single-Cylinder Diesel Engine-Caterpillar 1R Test ProcedureDocument63 pagesEvaluation of Engine Oils in A High Speed, Single-Cylinder Diesel Engine-Caterpillar 1R Test ProcedureDavid CazorlaNo ratings yet

- Multivariate Petroleum Price Prediction Model With CNN-LSTM Using Attention MechanismDocument12 pagesMultivariate Petroleum Price Prediction Model With CNN-LSTM Using Attention MechanismInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- For KS Diagnosis Specs Limits Shell LubeAnalyst Condemnation Limits Mar 081Document56 pagesFor KS Diagnosis Specs Limits Shell LubeAnalyst Condemnation Limits Mar 081l447280100% (4)

- Multi-Objective Optimization in Chemical Engineering: Developments and ApplicationsFrom EverandMulti-Objective Optimization in Chemical Engineering: Developments and ApplicationsGade Pandu RangaiahNo ratings yet

- Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid DriveFrom EverandBosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid DriveRobert Bosch GmbHNo ratings yet

- Automotive Electronic Diagnostics (Course 2)From EverandAutomotive Electronic Diagnostics (Course 2)Rating: 4 out of 5 stars4/5 (2)

- 7 Best Tax Saving SchemeDocument13 pages7 Best Tax Saving SchemeShubham KumarNo ratings yet

- Features: Brand LG Samsung LG Fly Model GM 360i l5800 (Galaxy 3) GT540 (Optimus) IvoryDocument4 pagesFeatures: Brand LG Samsung LG Fly Model GM 360i l5800 (Galaxy 3) GT540 (Optimus) IvoryShubham KumarNo ratings yet

- Parameter Estimation and Remaining Useful Life Prediction of Lubricating Oil With HMMDocument7 pagesParameter Estimation and Remaining Useful Life Prediction of Lubricating Oil With HMMShubham KumarNo ratings yet

- Impact IIT Alumni 1Document22 pagesImpact IIT Alumni 1Shubham KumarNo ratings yet

- 3G Tariffs - Aircel Assam 3g Plan and 3G ServicesDocument3 pages3G Tariffs - Aircel Assam 3g Plan and 3G ServicesShubham KumarNo ratings yet

- Resolving Stop (Blue Screen) Errors in Windows 7: Windows 10 Devices Apps+games Downloads How-To Great ThingsDocument6 pagesResolving Stop (Blue Screen) Errors in Windows 7: Windows 10 Devices Apps+games Downloads How-To Great ThingsShubham KumarNo ratings yet

- Understanding Microsoft iSCSI Initiator Features and ComponentsDocument4 pagesUnderstanding Microsoft iSCSI Initiator Features and ComponentsShubham KumarNo ratings yet

- 15 Brutally Honest Phases of A Man Falling in LoveDocument6 pages15 Brutally Honest Phases of A Man Falling in LoveShubham KumarNo ratings yet

- List of EDA ToolsDocument4 pagesList of EDA ToolsShubham KumarNo ratings yet

- IES 2006 EE Conventional Paper01Document5 pagesIES 2006 EE Conventional Paper01Shubham KumarNo ratings yet

- How Much Can You Afford To Buy A House For?: by Sanket DhanorkarDocument10 pagesHow Much Can You Afford To Buy A House For?: by Sanket DhanorkarShubham KumarNo ratings yet

- Sectoral List of IndustriesDocument15 pagesSectoral List of IndustriesShubham KumarNo ratings yet

- Ten Questions To Ask Before You Buy A HouseDocument16 pagesTen Questions To Ask Before You Buy A HouseShubham KumarNo ratings yet

- IES 2006 EE Conventional Paper02Document7 pagesIES 2006 EE Conventional Paper02Shubham KumarNo ratings yet

- IES 2007 EE Conventional Paper01Document5 pagesIES 2007 EE Conventional Paper01Shubham KumarNo ratings yet

- IES 2003 EE Conventional Paper02Document6 pagesIES 2003 EE Conventional Paper02Shubham KumarNo ratings yet

- The World's Largest Public Companies ListDocument79 pagesThe World's Largest Public Companies ListShubham KumarNo ratings yet

- IES 2001 EE Conventional Paper01Document4 pagesIES 2001 EE Conventional Paper01Shubham KumarNo ratings yet

- IES 2003 EE Conventional Paper01Document5 pagesIES 2003 EE Conventional Paper01Shubham KumarNo ratings yet

- IES 2004 EE Conventional Paper01Document4 pagesIES 2004 EE Conventional Paper01Shubham KumarNo ratings yet

- IES 2001 EE Conventional Paper02Document8 pagesIES 2001 EE Conventional Paper02Shubham KumarNo ratings yet

- IES 2005 EE Conventional Paper02Document6 pagesIES 2005 EE Conventional Paper02Shubham KumarNo ratings yet

- IES 2005 EE Conventional Paper01Document5 pagesIES 2005 EE Conventional Paper01Shubham KumarNo ratings yet

- PCB Design TipsDocument14 pagesPCB Design TipsShubham Kumar100% (1)

- Five Ultimate Sector For Long Term InvestmentDocument8 pagesFive Ultimate Sector For Long Term InvestmentShubham KumarNo ratings yet

- IES 2004 EE Conventional Paper02Document6 pagesIES 2004 EE Conventional Paper02Shubham KumarNo ratings yet

- IIT - PCM-2003 With Solutions PDFDocument32 pagesIIT - PCM-2003 With Solutions PDFShubham KumarNo ratings yet

- Shenzhen Pkcell Battery Co., LTD: Model Li-Polymer 503562 1200mah 3.7V With PCMDocument5 pagesShenzhen Pkcell Battery Co., LTD: Model Li-Polymer 503562 1200mah 3.7V With PCMShubham KumarNo ratings yet

- Gendered Spaces Understanding The Socio-Symbolic Impact On The SpatialDocument22 pagesGendered Spaces Understanding The Socio-Symbolic Impact On The SpatialSanskrutiNo ratings yet

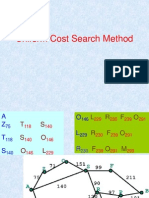

- Lecture 5 Uniform Cost SearchDocument14 pagesLecture 5 Uniform Cost Searchandrey90No ratings yet

- The Effectiveness of Using Random Text in Improving Reading Comprehension (Arsyisya Paradiba)Document31 pagesThe Effectiveness of Using Random Text in Improving Reading Comprehension (Arsyisya Paradiba)Sri MeriyantiNo ratings yet

- RegistrationDocument9 pagesRegistrationhkalertNo ratings yet

- Media and Information SourcesDocument15 pagesMedia and Information Sourcesdanilolacsayao1No ratings yet

- Co Existing Concepts of Management Control The Containment of TensionsDocument18 pagesCo Existing Concepts of Management Control The Containment of TensionsNurfadilah HanifahNo ratings yet

- The Genre of DescribingDocument15 pagesThe Genre of DescribingTazqia Aulia ZakhraNo ratings yet

- Are Tattoos FashionDocument84 pagesAre Tattoos FashionAna MariaNo ratings yet

- Tesema LendeboDocument277 pagesTesema LendeboBoru WakoNo ratings yet

- Memorizing Vocabulary Through Mind Mapping TechniqueDocument8 pagesMemorizing Vocabulary Through Mind Mapping TechniqueeireneglaiosNo ratings yet

- Top 32 Teacher Survey Questions For Questionnaires - QuestionProDocument13 pagesTop 32 Teacher Survey Questions For Questionnaires - QuestionProSue RajkumarNo ratings yet

- Pawan Rana Final Project BbaDocument76 pagesPawan Rana Final Project BbaMohit SoniNo ratings yet

- Importance of Reliable Geotechnical Investigation For Safe and Economical Foundation Design of Civil StructuresDocument5 pagesImportance of Reliable Geotechnical Investigation For Safe and Economical Foundation Design of Civil StructuresAshwini ShettyNo ratings yet

- Perception and Behavioural Outcome Towards COVID-19 Vaccine Among Students and Faculties of Nursing Colleges at GujaratDocument9 pagesPerception and Behavioural Outcome Towards COVID-19 Vaccine Among Students and Faculties of Nursing Colleges at GujaratKailash NagarNo ratings yet

- BookofProceedings ICOPEV2014Document314 pagesBookofProceedings ICOPEV2014Jeronimo SantosNo ratings yet

- Unit-4 Applied StatisticsDocument23 pagesUnit-4 Applied StatisticsRidham chitreNo ratings yet

- Theory of Mind and Pragmatics - Assessments and ResourcesDocument18 pagesTheory of Mind and Pragmatics - Assessments and ResourcesVera LúciaNo ratings yet

- Session1 - Introduction To Business ResearchDocument17 pagesSession1 - Introduction To Business ResearchjavoleNo ratings yet

- Rackham Dissertation TimelineDocument4 pagesRackham Dissertation TimelinePayForAPaperCanada100% (1)

- THE RELATIONSHIP AMONG PROFICIENCY LEVEL, LANGUAGE LEARNING STRATEGY USAGE and LEARNER AUTONOMY OPINIONDocument13 pagesTHE RELATIONSHIP AMONG PROFICIENCY LEVEL, LANGUAGE LEARNING STRATEGY USAGE and LEARNER AUTONOMY OPINIONSelimNo ratings yet

- BA 187 Case Analysis-Toys IncDocument2 pagesBA 187 Case Analysis-Toys Incshia_pena100% (2)

- Barringer Ppt03stDocument27 pagesBarringer Ppt03stapi-3727525100% (1)

- English For Academic Purposes: January 2017Document33 pagesEnglish For Academic Purposes: January 2017Cey BarrackNo ratings yet

- 2015 IV Fluid in ChildrenDocument22 pages2015 IV Fluid in ChildrenltgcanlasNo ratings yet

- POM Unit1 PDFDocument22 pagesPOM Unit1 PDFShwetha MudireddyNo ratings yet

- AncovaDocument18 pagesAncovaJoanne LewNo ratings yet

- The Scope of SociologyDocument3 pagesThe Scope of SociologyALI HASSANNo ratings yet

- Title: A Comparative and Exploratory Study of Motor Oil Branding in Nigeria and The UK Name: Shehu Mohammed JalloDocument361 pagesTitle: A Comparative and Exploratory Study of Motor Oil Branding in Nigeria and The UK Name: Shehu Mohammed JalloIrfan RamdhaniNo ratings yet

Remaining Useful Life Prediction of Automotive Engine Oils Using MEMS Technologies

Remaining Useful Life Prediction of Automotive Engine Oils Using MEMS Technologies

Uploaded by

Shubham Kumar0 ratings0% found this document useful (0 votes)

90 views2 pagesThis document proposes using MEMS sensors and neural networks to predict the remaining useful life of automotive engine oils. It involves developing an "intelligent on-board DIP system" using a "microsensor web" to measure oil parameters like oxidation, acidity, additives, and soot. These parameters are inputs to a neural network to create an "oil condition parameter" that is trended over time. Advanced prognostic techniques are then applied to the trend to predict remaining useful life. The methodology aims to extend oil change intervals through online monitoring of engine conditions, oil measurements, and correlating this data using the proposed intelligent system.

Original Description:

Remaining Useful Life Prediction of Automotive Engine Oils Using MEMS Technologies

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document proposes using MEMS sensors and neural networks to predict the remaining useful life of automotive engine oils. It involves developing an "intelligent on-board DIP system" using a "microsensor web" to measure oil parameters like oxidation, acidity, additives, and soot. These parameters are inputs to a neural network to create an "oil condition parameter" that is trended over time. Advanced prognostic techniques are then applied to the trend to predict remaining useful life. The methodology aims to extend oil change intervals through online monitoring of engine conditions, oil measurements, and correlating this data using the proposed intelligent system.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

90 views2 pagesRemaining Useful Life Prediction of Automotive Engine Oils Using MEMS Technologies

Remaining Useful Life Prediction of Automotive Engine Oils Using MEMS Technologies

Uploaded by

Shubham KumarThis document proposes using MEMS sensors and neural networks to predict the remaining useful life of automotive engine oils. It involves developing an "intelligent on-board DIP system" using a "microsensor web" to measure oil parameters like oxidation, acidity, additives, and soot. These parameters are inputs to a neural network to create an "oil condition parameter" that is trended over time. Advanced prognostic techniques are then applied to the trend to predict remaining useful life. The methodology aims to extend oil change intervals through online monitoring of engine conditions, oil measurements, and correlating this data using the proposed intelligent system.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

Proceedings of the American Control Conference

Chicago, Illinois June 2000

Remaining Useful Life Prediction of Automotive Engine Oils Using MEMS Technologies'

S. Jagannathan and G.V.S. Raju

Intelligent Systems Laboratory

The University of Texas at San Antonio

6900 North Loop 1604 West

San Antonio, Texas 78249.

Abstract effects and driving styles. Therefore, a sensor-based approach is

This paper proposes a novel adaptive methodology where both chosen as an alternative.

micro-sensors and models are used in conjunction with neural On the other hand, there are currently no sensors available that

network/fuzzy classification algorithm to predict the quality of accurately and reliably measure the condition of engine oils.

engine oils. The condition of the engine oil is defined as a single Further, several oil parameters need to be measured and even if

variable and trended. Advanced prognostic algorithms are then sensors are deployed, models are still required to process sensor

applied on the oil condition trends to predict the remaining useful data and to predict the condition of engine oils. Studies

life of engine oils. Experimental results are given. conducted by the authors [6-71 and others at Daimler-Chrysler [ 11

1. Introduction conclude that a hybrid, also referred to as dual approach

Considerable effort is being aimed by many automotive, (combination of sensors and models), has to be used to extend oil

drain intervals.

earthmoving and construction, aerospace, DOD, navy and others

[l-21 to extend the engine oil drain intervals beyond the periods Oxidation, antioxidant breakdown, additive depletion, soot

currently recommended without affecting engine's life. This is accumulation, total acid numbedtotal base number, oil

being driven by oil costs, oil disposal costs, reduced maintenance consumption, wear metals are considered prognostic indicators

and regulatory environmental concerns. A reliable means of [1,6]. What makes these indicators predictable is their strong

monitoring the oil condition is through the use of an intelligent dependence upon the engine operating conditions, oil type and

on-board DIP system, which will permit new kind of predictive or brand, and application and environmental factors. In this paper, a

just-in-time maintenance (JIT), and that, could save oil usage and novel hybrid approach is proposed to create an on-board

costs and it will improve the environment. Since this area intelligent DIP system (IODPS) through monitoring engine

involves proprietary information, historical data collection, operating conditions, measuring oil parameters, and correlating

this information with oil condition. This IODPS will comprise of

application, environmental factors and driving habits, not many

papers report the research results. several microsensors, referred here as microsensor web, with

In [l-21, overviews of oil drain interval problem are given intelligent on-line learning algorithms. Microsensor web, which is

where they present the difficulties to be addressed for developed based upon micro-mechanical systems (MEMS)

technology, will be deployed to measure proenostic indicators.

diagnostic/prognostic (DIP) applications. Problems include

determination of engine oil degradation and operational factors, Intelligent algorithms based on neural networks that are

presented in this paper use the prognostic indicators to obtain the

development of sensors to measure oil quality, generation of on-

board models using data, and obviating the need for a dual engine oil condition parameter. This oil condition parameter is

then trended and advanced prognostic techniques are applied to

approach with sensors and model-based methodology. Literature

is also reported for diagnostic application of engines using model- determine the remaining useful life. Experimental results are

presented to illustrate the proposed methodology.

based, sensor-based methods and a combination thereof [SI.

Many factors affect engine oil performance including 2. Methodology

viscosity, total acid number (TAN), total base number (TBN), soot Figure 1 illustrates the proposed methodology for extending

accumulation, contaminants, engine operational factors such as oil drain intervals using engine operational factors, oil parameters

engine speed, load and so on. Present oil analysis is usually done and driving habits. This methodology will consists of a

off-line with a complex chemical laboratory benchmark procedure microsensor web to measure pressure, temperature, sump oil level

and specialized interpretation skills. Oil may significantly and temperature, relative humidity, coolant temperature, engine

degrade before the next oil sample is analyzed. Also, since a rack and so on and on-board models. Capacitive sensors with

change in oil viscosity implies that the oil has significantly temperature compensation will be used to measure contaminants

degraded, the need for an on-line method for oil degradation is in engine oil. A survey of microsensors is given in [3] and for

even more apparent. automotive applications in [4]. Based on the existing literature, it

Though model-based approach for oil life prediction results in is safe to say that temperature, pressure and level sensors are

low cost, the method is only as good as the underlying data that is available in MEMS technologies whereas more work is required

used in deriving the model. Also, since the oil deterioration is a to measure acidity or else the amount of remaining alkali base

complex process, it is not only very expensive to create a model present in these engine oils.

through standard laboratory tests, driving tests and oil analysis Microsensors measure oxidation, TAN, TBN, dispersants and

results but also impossible to create an accurate model for all additives. In fact, Bio-MEMS group at Ohio State University [ 11

engine operating conditions, oil types and brands, environmental has developed a sensor that measures pH value, which correlates

with TAN. Under certain conditions, antioxidants in the oil could

This work is supported by an NSF Grant

0-7803-5519-9/00 $10.00 0 2000 AACC 351 1

be measured as well using this sensor. Similar to measuring TAN, value, provided the prognostic indicators are applied at its input.

the investigators envision that additive depletion and TBN can be Here 6 input nodes, 5 hidden-layer neurons, and one output node

measured using suitable microsensors, which is attempted in this was selected for the neural network. This oil condition trend is

work. In fact, a MEMS-based sensor was developed by coating used as an input to the advanced data analysis module [5]. The

the electrodes of the sensor appropriately with a zinc and output of the module is a linear approximation of the trend as

aluminum compound, which will correlate with additives. A shown in Figure 2. Using the linear approximation and the limit

MEMS-based sensor was used to measure TBN. values, the remaining useful life is calculated. If the linear

Oil consumption and amount of oil added to the sump can be approximated value crosses the limits, then an event is generated

measured with MEMS level sensors [4-51. Therefore, it is clear as shown in Figure 2.

that an array of microsensors can be deployed to measure 4. Conclusions

prognostic indicators though MEMS sensors are currently This paper presents a hybrid approach of predicting the

unavailable to measure wear metals. Future work involves quality and remaining useful life of engine oils for industrial and

developing microsensors for wear metals. In this work, data was automotive applications. Oxidation, antioxidant breakdown,

collected and analyzed off-line to create the oil condition additive depletion, soot accumulation, total acid numbedtotal base

parameter using both sensors and models. To fuse information number, oil consumption, wear metals were considered prognostic

from sensors and models, a NN is used through back propagation. indicators based on a detailed study. It was shown that oil quality

The prognostic indicators for engine oils and engine could be predicted from these indicators since the engine

operational factors are used as inputs under a set of detectability operating conditions, oil types and brand, and application and

conditions (similar to observability concept in control theory) are environmental factors influences these indicators.

presented to the NN to create the oil degradation parameter. Using these indicators, a novel hybrid approach is proposed to

Apriori data, based on several engine tests, is used to train the create an on-board intelligent D/P system (IODPS) that can

hybrid neurdfuzzy structure and to arrive at a valid oil monitor engine operating conditions, measure oil parameters and

degradation value. This value will be used as an input to the correlate this information with oil condition. An oil condition

proposed data analysis methods. Intelligent data analysis methods trend was generated using a hybrid neuro fuzzy system.

were applied on these prognostic indicators by comparing the Advanced data analysis methods were deployed to predict the

trend values against predefined limits. If any or a combination of remaining useful life. Results were presented after conducting

these indicators, crossed the limits, a prognostic warning message experiments from an engine. The proposed methodology was

was created to alert the appropriate personnel. The outcome is the successfully,used to determine the condition of engine oils.

remaining life, time left to change the engine oil and the

associated confidence. _- -

3. Results I

An automotive diesel engine was selected. Data was collected

by running the engine under different loading conditions. This

essentially involved running the automobile engine around the

city for a number of hours, An oil sample was collected at every

hour and analyzed. All the required prognostic indicators were

measured and used by the neuro-fuzzy scheme to generate the oil

condition trend. In fact, off-line analysis was performed to

evaluate the condition of the engine oil and a normalized value

t .. ,

WC..

-

. -

-PI

,”’

L

*,.I..

Figure 2: Automobile Engine Oil Life Prediction,

5. References

1) J. DeGaspari, “Recording Oil’s Vital Signs”, Mech.

Engineering Magazine, pp. 54-56, May 1999.

2) T. Stevens, “Keep ‘EM Running”, Industrial World, pp. 38-41,

October 6, 1997.

3) H. Fujita, “A Decade of MEMS and its Future”,

Conference on Industrial Svstems, pp.112-118.

4) D.S. Eddy and D.R. Sparks, “Application of MEMS

Technology in Automotive Sensors and Actuators”, hoc. of the

m, vol. 86, no.8, pp.1747-1755. Aug. 1998.

5) S . Jagannathan, “Method and Apparatus for Predicting a Fault

Condition”, Patent Allowed, June 1999.

6) S. Jagannathan, D. R. Schricker, T. Simpson, “System and

Figure 1: On-board intelligent diagnostic/prognostic system. Apparatus for determining the condition of engine oil based on

was obtained to denote the oil condition at that sampling instant. soot modeling”, US Patent No. 5.914.890June 1999.

This value was used as the desired value for tuning the networks 7) S . Jagannathan, “System and Apparatus to monitor the

off-line using backpropagation. Further, fuzzy rules were also condition of engine oils by TBN modeling”, US Patent N o

employed

- - to train the neural networks. After several leaming 5.987.976, November 1999.

cycles, the neural network was able to reproduce the oil condition

351 2

You might also like

- The Mighty Mars Rover Discussion GuideDocument4 pagesThe Mighty Mars Rover Discussion GuideHoughton Mifflin HarcourtNo ratings yet

- Mass Air Flow Sensor Diagnostics For Adaptive Fueling Control ofDocument6 pagesMass Air Flow Sensor Diagnostics For Adaptive Fueling Control ofSinAnime ConAnimeNo ratings yet

- How To Write An Argumentative Essay in 9 Easy StepsDocument3 pagesHow To Write An Argumentative Essay in 9 Easy StepsSuryadi SarminsonNo ratings yet

- Estructura de ProyectoDocument12 pagesEstructura de ProyectoCidit DescartesNo ratings yet

- Vehicular Engine Oil Service Life Characterization Using On-Board Diagnostic Sensor DataDocument5 pagesVehicular Engine Oil Service Life Characterization Using On-Board Diagnostic Sensor DataJane wangNo ratings yet

- Remaining Useful Life Prediction of Lubricating Oil With Dynamic Principal Component Analysis and Proportional Hazards ModelDocument8 pagesRemaining Useful Life Prediction of Lubricating Oil With Dynamic Principal Component Analysis and Proportional Hazards ModelShubham KumarNo ratings yet

- Cigre A2 - 105 - 2014Document8 pagesCigre A2 - 105 - 2014Chris ParkinsonNo ratings yet

- T4I Documento de Trabajo de Tarea 02Document8 pagesT4I Documento de Trabajo de Tarea 02David VelascoNo ratings yet

- The Common Fault Diagnosis Method of Diesel Engine: Zhibin Wang, Yu Zhao, Jian Yan and Jiafeng XuDocument3 pagesThe Common Fault Diagnosis Method of Diesel Engine: Zhibin Wang, Yu Zhao, Jian Yan and Jiafeng XuNemer RaslenNo ratings yet

- Example of An Integrated Conception Use of Methods For Monitoring Wear Particles in The Lubrication System of AircraftDocument10 pagesExample of An Integrated Conception Use of Methods For Monitoring Wear Particles in The Lubrication System of AircraftSambuddha KhanNo ratings yet

- Sae Technical Paper Series: James F. Sinnamon and Mark C. SellnauDocument17 pagesSae Technical Paper Series: James F. Sinnamon and Mark C. SellnauFabio GuedesNo ratings yet

- Benefits of Lubricant Oil Analysis For Maintenance Decision Support: A Case StudyDocument8 pagesBenefits of Lubricant Oil Analysis For Maintenance Decision Support: A Case Studymunal23No ratings yet

- Oil Analysis Best PracticesDocument15 pagesOil Analysis Best Practicesmike100% (1)

- Natural Gas Engine ODocument8 pagesNatural Gas Engine Ogoldy456No ratings yet

- 347 4.survey On Vehicle Health Monitoring SystemDocument2 pages347 4.survey On Vehicle Health Monitoring SystemSachin KumarNo ratings yet

- Misfire Detection of A Turbocharged Diesel Engine by Using Artificial Neural NetworksDocument7 pagesMisfire Detection of A Turbocharged Diesel Engine by Using Artificial Neural NetworksJean Carlos PinedaNo ratings yet

- A Predictive Algorithm For Estimating The Quality of Vehicle Engine OilDocument11 pagesA Predictive Algorithm For Estimating The Quality of Vehicle Engine OilJoseNo ratings yet

- Research Papar Khushal WordDocument5 pagesResearch Papar Khushal WordKHUSHAL KAKAR (kakaran.)No ratings yet

- ASTM D7720-11 (Reapproved 2017)Document14 pagesASTM D7720-11 (Reapproved 2017)carlos trilloNo ratings yet

- Limit Values For LubricantsDocument28 pagesLimit Values For LubricantsSindley LimaferNo ratings yet

- Oil Debris Analysis For Condition Monitoring of An IC EngineDocument3 pagesOil Debris Analysis For Condition Monitoring of An IC EngineJaime BerryNo ratings yet

- Reliability Analysis For Refinery Plants: February 2017Document11 pagesReliability Analysis For Refinery Plants: February 2017DilipSinghNo ratings yet

- Machines: Monitoring The Oil of Wind-Turbine Gearboxes: Main Degradation Indicators and Detection MethodsDocument24 pagesMachines: Monitoring The Oil of Wind-Turbine Gearboxes: Main Degradation Indicators and Detection MethodsGuilherme Souza GomesNo ratings yet

- Global Evaluation of The Drivability of Calibrated Diesel Engine MapsDocument6 pagesGlobal Evaluation of The Drivability of Calibrated Diesel Engine MapsKhac-Hoang NguyenNo ratings yet

- Model Based Diagnosis For The Air Intake System of The SI-EngineDocument12 pagesModel Based Diagnosis For The Air Intake System of The SI-EngineecasayangNo ratings yet

- Microchemical Journal: Roman M. Balabin, Ravilya Z. Sa Fieva, Ekaterina I. LomakinaDocument8 pagesMicrochemical Journal: Roman M. Balabin, Ravilya Z. Sa Fieva, Ekaterina I. LomakinaLuqmanNo ratings yet

- Maintaining Lube Oil System Cleanliness in Motor Bearing ApplicationsDocument34 pagesMaintaining Lube Oil System Cleanliness in Motor Bearing ApplicationsDawn Moon100% (1)

- Comparison of Engine Calibration Methods Based On Design of Experiments (Doe)Document21 pagesComparison of Engine Calibration Methods Based On Design of Experiments (Doe)Kaushal PanchalNo ratings yet

- 2 Article Failure Rate Analysis of IC Engine ComponentsDocument10 pages2 Article Failure Rate Analysis of IC Engine ComponentsMIKINo ratings yet

- Intelligent Detection and Real-Time Monitoring of Engine Oil Aeration Using A Machine Learning ModelDocument19 pagesIntelligent Detection and Real-Time Monitoring of Engine Oil Aeration Using A Machine Learning ModelHưng HoàngNo ratings yet

- Foroughi 2021Document8 pagesForoughi 2021abntrenanNo ratings yet

- D 6837 - 04 - Rdy4mzcDocument60 pagesD 6837 - 04 - Rdy4mzcNguyễn Bằng NộiNo ratings yet

- ARAI-Update Q12223 11836Document10 pagesARAI-Update Q12223 11836nishu solankiNo ratings yet

- Fuel Gas Efficiency BMP - Efficient Use of Fuel Gas in Engines (Module 7) PDFDocument76 pagesFuel Gas Efficiency BMP - Efficient Use of Fuel Gas in Engines (Module 7) PDFKopi BrisbaneNo ratings yet

- Exp FinalDocument4 pagesExp Finalhugo mendozaNo ratings yet

- Real Time Monitoring of Vital Health Parameters of The VehicleDocument8 pagesReal Time Monitoring of Vital Health Parameters of The VehicleInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Engine Condition MonitoringDocument8 pagesEngine Condition MonitoringShiddiq QiNo ratings yet

- Mancini Giorgio TesiDocument135 pagesMancini Giorgio Tesiesthermulenga021No ratings yet

- Diesel Engine Fault Detection Using Vibr1Document9 pagesDiesel Engine Fault Detection Using Vibr1achraf zegnaniNo ratings yet

- Cired 2019 - 995Document5 pagesCired 2019 - 995Technology developmentsNo ratings yet

- DCA For Production Forecasting Base On Machine LearningDocument14 pagesDCA For Production Forecasting Base On Machine LearningQuy Tran XuanNo ratings yet

- Effectiveness of A Novel Sensor Selection Algorithm in PEM Fuel Cell On-Line DiagnosisDocument10 pagesEffectiveness of A Novel Sensor Selection Algorithm in PEM Fuel Cell On-Line DiagnosisMohmmed MahmoudNo ratings yet

- 10 1 1 98 9640 PDFDocument7 pages10 1 1 98 9640 PDFDev RaiNo ratings yet

- The Classification and Regression Tree Approach To Pump Failure Rate AnalysisDocument9 pagesThe Classification and Regression Tree Approach To Pump Failure Rate AnalysisNabila MahardianaNo ratings yet

- Condition Monitoring of Wind Turbine Gearbox Bearing Based On Deep Learning ModelDocument10 pagesCondition Monitoring of Wind Turbine Gearbox Bearing Based On Deep Learning ModelDarshan PatilNo ratings yet

- Measurement of Effects of Automotive Engine Oils On Fuel Economy of Passenger Cars and Light-Duty Trucks in Sequence VIB Spark Ignition EngineDocument60 pagesMeasurement of Effects of Automotive Engine Oils On Fuel Economy of Passenger Cars and Light-Duty Trucks in Sequence VIB Spark Ignition EngineMohanadNo ratings yet

- Application - Reservoir Fluid PropertiesDocument20 pagesApplication - Reservoir Fluid PropertiesDarshak SakhreliyaNo ratings yet

- Frank Pedersen - Diesel Engine Combus - jun.2005.SECPDocument53 pagesFrank Pedersen - Diesel Engine Combus - jun.2005.SECPAhmed Samir We ShreenNo ratings yet

- Determination of Injection Parameters UsDocument12 pagesDetermination of Injection Parameters UsHoi TranNo ratings yet

- A Virtual Sensor For Predicting Diesel Engine Emissions From Cylinder Pressure DataDocument9 pagesA Virtual Sensor For Predicting Diesel Engine Emissions From Cylinder Pressure DataKhac-Hoang NguyenNo ratings yet

- Definitionofa Motor Oil Change Intervalfor High Volume Diesel Engines Basedonits Current Characteristics AssessmentDocument11 pagesDefinitionofa Motor Oil Change Intervalfor High Volume Diesel Engines Basedonits Current Characteristics Assessmentkenny apataNo ratings yet

- Virtual Calibration Method For Diesel Engine by Software in The Loop Techniques M. C. Cameretti, E. Landolfi, T. Tesone and A. CaraceniDocument18 pagesVirtual Calibration Method For Diesel Engine by Software in The Loop Techniques M. C. Cameretti, E. Landolfi, T. Tesone and A. CaraceniDiep Hau ThanNo ratings yet

- Application of Roms To Aeroengines Health Monitoring: April 2019Document20 pagesApplication of Roms To Aeroengines Health Monitoring: April 2019tadele10No ratings yet

- 10.2478 - Pomr 2022 0047Document8 pages10.2478 - Pomr 2022 0047fgadshfdjfhgNo ratings yet

- ASTM D613 - Cetane NumberDocument31 pagesASTM D613 - Cetane NumberZiauddeen NoorNo ratings yet

- A Machine Learning Approach To Information Extraction From Cylinder Pressure SensorsDocument12 pagesA Machine Learning Approach To Information Extraction From Cylinder Pressure SensorsKhac-Hoang NguyenNo ratings yet

- Evaluation of Engine Oils in A High Speed, Single-Cylinder Diesel Engine-Caterpillar 1R Test ProcedureDocument63 pagesEvaluation of Engine Oils in A High Speed, Single-Cylinder Diesel Engine-Caterpillar 1R Test ProcedureDavid CazorlaNo ratings yet

- Multivariate Petroleum Price Prediction Model With CNN-LSTM Using Attention MechanismDocument12 pagesMultivariate Petroleum Price Prediction Model With CNN-LSTM Using Attention MechanismInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- For KS Diagnosis Specs Limits Shell LubeAnalyst Condemnation Limits Mar 081Document56 pagesFor KS Diagnosis Specs Limits Shell LubeAnalyst Condemnation Limits Mar 081l447280100% (4)

- Multi-Objective Optimization in Chemical Engineering: Developments and ApplicationsFrom EverandMulti-Objective Optimization in Chemical Engineering: Developments and ApplicationsGade Pandu RangaiahNo ratings yet

- Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid DriveFrom EverandBosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid DriveRobert Bosch GmbHNo ratings yet

- Automotive Electronic Diagnostics (Course 2)From EverandAutomotive Electronic Diagnostics (Course 2)Rating: 4 out of 5 stars4/5 (2)

- 7 Best Tax Saving SchemeDocument13 pages7 Best Tax Saving SchemeShubham KumarNo ratings yet

- Features: Brand LG Samsung LG Fly Model GM 360i l5800 (Galaxy 3) GT540 (Optimus) IvoryDocument4 pagesFeatures: Brand LG Samsung LG Fly Model GM 360i l5800 (Galaxy 3) GT540 (Optimus) IvoryShubham KumarNo ratings yet

- Parameter Estimation and Remaining Useful Life Prediction of Lubricating Oil With HMMDocument7 pagesParameter Estimation and Remaining Useful Life Prediction of Lubricating Oil With HMMShubham KumarNo ratings yet

- Impact IIT Alumni 1Document22 pagesImpact IIT Alumni 1Shubham KumarNo ratings yet

- 3G Tariffs - Aircel Assam 3g Plan and 3G ServicesDocument3 pages3G Tariffs - Aircel Assam 3g Plan and 3G ServicesShubham KumarNo ratings yet

- Resolving Stop (Blue Screen) Errors in Windows 7: Windows 10 Devices Apps+games Downloads How-To Great ThingsDocument6 pagesResolving Stop (Blue Screen) Errors in Windows 7: Windows 10 Devices Apps+games Downloads How-To Great ThingsShubham KumarNo ratings yet

- Understanding Microsoft iSCSI Initiator Features and ComponentsDocument4 pagesUnderstanding Microsoft iSCSI Initiator Features and ComponentsShubham KumarNo ratings yet

- 15 Brutally Honest Phases of A Man Falling in LoveDocument6 pages15 Brutally Honest Phases of A Man Falling in LoveShubham KumarNo ratings yet

- List of EDA ToolsDocument4 pagesList of EDA ToolsShubham KumarNo ratings yet

- IES 2006 EE Conventional Paper01Document5 pagesIES 2006 EE Conventional Paper01Shubham KumarNo ratings yet

- How Much Can You Afford To Buy A House For?: by Sanket DhanorkarDocument10 pagesHow Much Can You Afford To Buy A House For?: by Sanket DhanorkarShubham KumarNo ratings yet

- Sectoral List of IndustriesDocument15 pagesSectoral List of IndustriesShubham KumarNo ratings yet

- Ten Questions To Ask Before You Buy A HouseDocument16 pagesTen Questions To Ask Before You Buy A HouseShubham KumarNo ratings yet

- IES 2006 EE Conventional Paper02Document7 pagesIES 2006 EE Conventional Paper02Shubham KumarNo ratings yet

- IES 2007 EE Conventional Paper01Document5 pagesIES 2007 EE Conventional Paper01Shubham KumarNo ratings yet

- IES 2003 EE Conventional Paper02Document6 pagesIES 2003 EE Conventional Paper02Shubham KumarNo ratings yet

- The World's Largest Public Companies ListDocument79 pagesThe World's Largest Public Companies ListShubham KumarNo ratings yet

- IES 2001 EE Conventional Paper01Document4 pagesIES 2001 EE Conventional Paper01Shubham KumarNo ratings yet

- IES 2003 EE Conventional Paper01Document5 pagesIES 2003 EE Conventional Paper01Shubham KumarNo ratings yet

- IES 2004 EE Conventional Paper01Document4 pagesIES 2004 EE Conventional Paper01Shubham KumarNo ratings yet

- IES 2001 EE Conventional Paper02Document8 pagesIES 2001 EE Conventional Paper02Shubham KumarNo ratings yet

- IES 2005 EE Conventional Paper02Document6 pagesIES 2005 EE Conventional Paper02Shubham KumarNo ratings yet

- IES 2005 EE Conventional Paper01Document5 pagesIES 2005 EE Conventional Paper01Shubham KumarNo ratings yet

- PCB Design TipsDocument14 pagesPCB Design TipsShubham Kumar100% (1)

- Five Ultimate Sector For Long Term InvestmentDocument8 pagesFive Ultimate Sector For Long Term InvestmentShubham KumarNo ratings yet

- IES 2004 EE Conventional Paper02Document6 pagesIES 2004 EE Conventional Paper02Shubham KumarNo ratings yet

- IIT - PCM-2003 With Solutions PDFDocument32 pagesIIT - PCM-2003 With Solutions PDFShubham KumarNo ratings yet

- Shenzhen Pkcell Battery Co., LTD: Model Li-Polymer 503562 1200mah 3.7V With PCMDocument5 pagesShenzhen Pkcell Battery Co., LTD: Model Li-Polymer 503562 1200mah 3.7V With PCMShubham KumarNo ratings yet

- Gendered Spaces Understanding The Socio-Symbolic Impact On The SpatialDocument22 pagesGendered Spaces Understanding The Socio-Symbolic Impact On The SpatialSanskrutiNo ratings yet

- Lecture 5 Uniform Cost SearchDocument14 pagesLecture 5 Uniform Cost Searchandrey90No ratings yet

- The Effectiveness of Using Random Text in Improving Reading Comprehension (Arsyisya Paradiba)Document31 pagesThe Effectiveness of Using Random Text in Improving Reading Comprehension (Arsyisya Paradiba)Sri MeriyantiNo ratings yet

- RegistrationDocument9 pagesRegistrationhkalertNo ratings yet

- Media and Information SourcesDocument15 pagesMedia and Information Sourcesdanilolacsayao1No ratings yet

- Co Existing Concepts of Management Control The Containment of TensionsDocument18 pagesCo Existing Concepts of Management Control The Containment of TensionsNurfadilah HanifahNo ratings yet

- The Genre of DescribingDocument15 pagesThe Genre of DescribingTazqia Aulia ZakhraNo ratings yet

- Are Tattoos FashionDocument84 pagesAre Tattoos FashionAna MariaNo ratings yet

- Tesema LendeboDocument277 pagesTesema LendeboBoru WakoNo ratings yet

- Memorizing Vocabulary Through Mind Mapping TechniqueDocument8 pagesMemorizing Vocabulary Through Mind Mapping TechniqueeireneglaiosNo ratings yet

- Top 32 Teacher Survey Questions For Questionnaires - QuestionProDocument13 pagesTop 32 Teacher Survey Questions For Questionnaires - QuestionProSue RajkumarNo ratings yet

- Pawan Rana Final Project BbaDocument76 pagesPawan Rana Final Project BbaMohit SoniNo ratings yet

- Importance of Reliable Geotechnical Investigation For Safe and Economical Foundation Design of Civil StructuresDocument5 pagesImportance of Reliable Geotechnical Investigation For Safe and Economical Foundation Design of Civil StructuresAshwini ShettyNo ratings yet

- Perception and Behavioural Outcome Towards COVID-19 Vaccine Among Students and Faculties of Nursing Colleges at GujaratDocument9 pagesPerception and Behavioural Outcome Towards COVID-19 Vaccine Among Students and Faculties of Nursing Colleges at GujaratKailash NagarNo ratings yet

- BookofProceedings ICOPEV2014Document314 pagesBookofProceedings ICOPEV2014Jeronimo SantosNo ratings yet

- Unit-4 Applied StatisticsDocument23 pagesUnit-4 Applied StatisticsRidham chitreNo ratings yet

- Theory of Mind and Pragmatics - Assessments and ResourcesDocument18 pagesTheory of Mind and Pragmatics - Assessments and ResourcesVera LúciaNo ratings yet

- Session1 - Introduction To Business ResearchDocument17 pagesSession1 - Introduction To Business ResearchjavoleNo ratings yet

- Rackham Dissertation TimelineDocument4 pagesRackham Dissertation TimelinePayForAPaperCanada100% (1)

- THE RELATIONSHIP AMONG PROFICIENCY LEVEL, LANGUAGE LEARNING STRATEGY USAGE and LEARNER AUTONOMY OPINIONDocument13 pagesTHE RELATIONSHIP AMONG PROFICIENCY LEVEL, LANGUAGE LEARNING STRATEGY USAGE and LEARNER AUTONOMY OPINIONSelimNo ratings yet

- BA 187 Case Analysis-Toys IncDocument2 pagesBA 187 Case Analysis-Toys Incshia_pena100% (2)

- Barringer Ppt03stDocument27 pagesBarringer Ppt03stapi-3727525100% (1)

- English For Academic Purposes: January 2017Document33 pagesEnglish For Academic Purposes: January 2017Cey BarrackNo ratings yet

- 2015 IV Fluid in ChildrenDocument22 pages2015 IV Fluid in ChildrenltgcanlasNo ratings yet

- POM Unit1 PDFDocument22 pagesPOM Unit1 PDFShwetha MudireddyNo ratings yet

- AncovaDocument18 pagesAncovaJoanne LewNo ratings yet

- The Scope of SociologyDocument3 pagesThe Scope of SociologyALI HASSANNo ratings yet

- Title: A Comparative and Exploratory Study of Motor Oil Branding in Nigeria and The UK Name: Shehu Mohammed JalloDocument361 pagesTitle: A Comparative and Exploratory Study of Motor Oil Branding in Nigeria and The UK Name: Shehu Mohammed JalloIrfan RamdhaniNo ratings yet