Professional Documents

Culture Documents

Demystifying Contact Tips

Demystifying Contact Tips

Uploaded by

nateOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Demystifying Contact Tips

Demystifying Contact Tips

Uploaded by

nateCopyright:

Available Formats

(https://ads.thefabricator.com/delivery/ck.php?

oaparams=2__bannerid=833__zoneid=1__cb=5aabd1ed2d__oadest=http%3A%2F%2Fwww.hougen.com%2F)

Home (/) / Article (/?filter=article) / Consumables (/?filter=article&category=consumables)

/ Demystifying contact tips

g+at+its+best+are+just+as+critical+as+anything+else+needed+to+produce+a+quality+weld.+&img=https://cdn.thefabricator.com/a/demystifying-

Demystifying contact tips

The more you know, the better they will perform

PRACTICAL WELDING TODAY SEPTEMBER/OCTOBER 2013 (/PUBLICATION/PWT/SEPTEMBER-OCTOBER-2013)

SEPTEMBER 5, 2013

BY RUDY SIMMONS (/AUTHOR/RUDY-SIMMONS)

(https://cdn.thefabricator.com/a/demystifying-contact-tips-fig1.jpg?size=1000x1000)

Using a contact tip that is too big or too small can create problems such as microarcing, overheating, friction, and wire jamming

—all of which can lead to wire burnback.

Contact tips are one of the most frequently misunderstood and most often replaced components of a welding gun

setup. The contact tip is responsible for guiding the wire and transferring the current from the conductor tube—

sometimes referred to as a swanneck or gooseneck—through the filler wire and ultimately to the workpiece. Its

critical functions include current transfer and wire targeting.

Contact tip size determines what wire size you can use and the amount of filler material that will be distributed

during welding. When a contact tip begins to wear, the through-hole elongates and loses electrical conductivity,

which greatly affects the gun’s ability to transfer current to the welding wire. Additionally, the tool center point (TCP)

begins to fluctuate as the wire dances around inside the now oversized tip. These conditions lead to poor arc starts,

lower penetration, and decreased weld quality.

Choosing the correct contact tip for your welding application and understanding how to keep it performing at its best

are just as critical as choosing all the other components and parameters needed to produce a quality weld.

Common Contact Tip Types

Three types of contact types are most commonly used in welding applications, and each has its pros and cons.

Standard Copper Contact Tip (E-Cu). A standard copper contact tip has a relatively high current transfer rate at

greater than 55 S/m* electrical conductivity, and it is used mostly in hand-held welding applications.

Although standard copper offers the highest conductivity of all of the standard alloys, it is more susceptible to

mechanical wear than other materials. As a raw mineral, copper naturally is relatively soft, which means it makes

current transfer easier, but it also means the material has a lower melting point. As the temperature rises in an E-Cu

tip, it becomes softer than the wire that is being fed through it. As the copper softens, the wire wears and deforms

the internal diameter of the tip. This prevents the wire from contacting the tip correctly, which decreases conductivity

and leads to arc-start issues, burnback, and poor welds.

The E-Cu tip is usually the most affordable, so it’s generally an acceptable trade-off to frequently replace it when

precise wire targeting is not critical.

Copper-Chrome-Zirconium Contact Tip (CuCrZr). A copper-chrome-zirconium tip generally is used in automated

and robotic welding applications where precise TCP is needed and high duty cycles occur. Although there is some

decline in electrical conductivity compared with the standard copper tip (50 S/m), it is sufficient for most steel

applications.

However, since CuCrZr alloy softens at a much higher temperature, it tends to have a longer life span than standard

copper tips. Generally speaking, the tip maintains its shape up to approximately 932 degrees F versus 500 degrees

for E-Cu. Therefore, the higher-density material leads to a lower wear rate and increases the tip’s performance and

productivity.

Silver-Plated CuCrZr Contact Tip. Over the years technological advancements in contact tips have revealed that

silver plating the interior and exterior of a CuCrZr tip further enhances its overall performance.

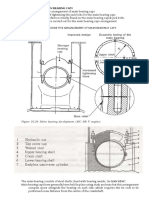

(https://cdn.thefabricator.com/a/demystifying-contact-tips-fig2.jpg?size=1000x1000)

When a contact tip begins to wear, the through-hole elongates and loses electrical conductivity, which greatly affects the gun’s

ability to transfer current to the welding wire.

Silver is more conductive than copper (62.1 S/m), which reduces microarcing, extends contact tip life, improves arc

starts, and provides consistent weld quality. Silver is approximately 17 percent denser than copper and it has a

higher melting point. Silver’s shiny surface helps to reflect heat. As a result, spatter doesn’t adhere to the tip as

easily and it doesn’t wear down quite as quickly. In fact, the life span of a silver-plated CuCrZr contact tip can be

nine times longer than that of a standard precision-drawn copper tip.

With significant improvements in material, a silver-plated contact tip can cost up to 50 percent more than the

standard nonplated CuCrZr tip. Welders who choose to use a silver-plated contact tip usually do so for one reason

—less welding downtime. The more a robot welds, the greater the throughput. Based on the overall longevity,

current transfer, and quality of material, the silver-plated tips are an excellent choice for automatic and robotic

welding applications.

Advice to Avoid Common Contact Tip Problems

Once you’ve matched your contact tip to your welding application, there are a few things you can do to make sure

you are getting the most out of it and not inadvertently creating problems that could decrease its life span or

effectiveness.

Let the torch cool before you change a contact tip. A hot torch can make changing a contact tip very

difficult and hazardous. The presence of heat makes it easier to cross-thread the new contact tip, ruining not

only the tip, but also the torch neck.

Use the correct tip size. Using an oversized tip results in poor current transfer; increased microarcing; and

hotter tip temperatures, which lead to wire burnback. Using an undersized tip increases friction and causes

the wire to jam in the tip or feed erratically, which also results in wire burnback.

Properly tighten the tip. A contact tip that has not been tightened down correctly causes poor current

transfer, microarcing, and overheating. When this takes place you will most likely experience erratic wire

feeding, poor arc starts, and burnback of the weld wire into the tip.

Read your tip’s appearance for problems that you can’t necessarily see. A contact tip that has turned

blue or purple is generally a sign that you have a poor connection (including the ground), your consumables

are too big, or you have exceeded the torch’s amperage rating or duty cycle. In severe instances the contact

tip’s exterior surface will become covered in scale.

* S/m, siemens per meter, also written as m/Ω mm2, meter per ohm millimeter squared, is a unit of measurement for

electric conductivity.

You May Also Like

(/article/arcwelding/gmaw- (/article/arcwelding/8- (/article/consumables/what- (/article/arcwelding/understanding-

guns-consumables-and- criteria-for-choosing-the- to-know-about-robotic- ultrasonic-welding)

more-7-common- right-gmaw-gun) welding-gun-liners)

Understanding ultrasonic

questions-answered) 8 criteria for choosing the What to know about welding

GMAW guns, right GMAW gun robotic welding gun

(/article/arcwelding/understanding-

consumables, and more: liners

(/article/arcwelding/8- ultrasonic-welding)

7 common questions

criteria-for-choosing-the- (/article/consumables/what-

answered

right-gmaw-gun) to-know-about-robotic-

welding-gun-liners)

(/article/arcwelding/gmaw-

guns-consumables-and-

more-7-common-

questions-answered)

Rudy Simmons

Product Engineer

Abicor Binzel Corp.

650 Medimmune Court, Suite 110

Frederick, MD 21703

Phone: 800-542-4867

http://www.binzel-abicor.com (http://www.binzel-abicor.com)

More Content by Rudy Simmons (/author/rudy-simmons)

Published In...

Practical Welding Today

The WELDER, formerly known as Practical Welding Today, is a

showcase of the real people who make the products we use and work

with every day. This magazine has served the welding community in

North America well for more than 20 years.

Preview the Digital Edition (http://www.practicalwelding-digital.com)

(https://www.twitter.com/TheWELDERmag)

Subscribe to The WELDER (/subscription/pub/pwt)

Read more from this issue (/publication/pwt/september-october-2013)

Related Companies

ABICOR BINZEL USA, Inc. (https://www.thefabricator.com/directory/showroom/abicor-binzel-corp)

0 Comments The Fabricator

1 Login

Recommend t Tweet f Share Sort by Best

Start the discussion…

LOG IN WITH

OR SIGN UP WITH DISQUS ?

Name

Be the first to comment.

✉ Subscribe d Add Disqus to your siteAdd DisqusAdd 🔒 Disqus' Privacy PolicyPrivacy PolicyPrivacy

Upcoming Industry Events

Laser Welding and Material Processing

Training (/event/laser-welding-and-material-

processing-training)

JULY 30-31,2019 | ANAHEIM, CA

8th Global Automotive Lightweight Materials

Summit North America 2019 (/event/8th-

global-automotive-lightweight-materials-

summit-north-america-2019)

AUGUST 20-22, 2019 | DETROIT, MI

wire and Tube Southeast Asia (/event/wire-

and-tube-southeast-asia)

SEPTEMBER 18-20, 2019 THA

Titanium USA 2019 (/event/titanium-usa-

2019)

SEPTEMBER 22-25, 2019 | MOBILE, AL

Made In America 2019 (/event/made-in-

america-2019)

OCTOBER 3-6, 2019 | INDIANAPOLIS, IN

Deburring Expo (/event/deburring-expo)

OCTOBER 8-10, 2019 | KARLSRUHE, DEU

parts2clean, the International Trade Fair for

Industrial Parts and Surface Cleaning

(/event/parts2clean-the-international-trade-

fair-for-industrial-parts-and-surface-cleaning)

OCTOBER 22-24, 2019 | STUTTGART, DEU

See All Industry Events » (/?filter=event)

Most Popular Content This Week

The benefits of automated deburring

(/article/finishing/the-benefits-of-automated-

deburring)

Belco Industries cuts component cutting time

with high-powered fiber laser

(/article/lasercutting/belco-industries-cuts-

component-cutting-time-with-high-powered-

fiber-laser)

Remember your best boss?

(/article/shopmanagement/remember-your-

best-boss)

Hard work, persistence pay off for young

welder headed to WorldSkills

(/article/arcwelding/hard-work-persistence-

pay-off-for-young-welder-headed-to-

worldskills)

Schuler to deliver two press lines to Sitem

S.p.A. (/news/stamping/schuler-to-deliver-

two-press-lines-to-sitem-spa)

SafanDarley E-Brake Premium: 100% servo

electronic press brake (/video/safandarley-e-

brake-premium-100-servo-electronic-press-

brake)

Jorgensen Conveyors purchases nearly $1

million worth of new equipment

(/news/bending/jorgensen-conveyors-

purchases-nearly-1-million-worth-of-new-

equipment)

8th Global Automotive Lightweight Materials

Summit North America 2019 (/event/8th-

global-automotive-lightweight-materials-

summit-north-america-2019)

Robinson Metal to expand in Wisconsin

(/news/shopmanagement/robinson-metal-to-

expand-in-wisconsin)

Marvin Wortell, owner of Triton Metal

Products, dies at 100

(/news/stamping/marvin-wortell-owner-of-

triton-metal-products-dies-at-100)

Visit our Affiliated Websites

(https://www.fmanet.org)

(https://www.canadianmetalworking.com) Membership (https://www.fmanet.org/membership)

Features Training (https://www.fmanet.org/training)

(https://www.canadianmetalworking.com/features/) News (https://www.fmanet.org/blog)

Blogs (https://www.canadianmetalworking.com/blogs/) Events (https://www.fmanet.org/events)

News (https://www.canadianmetalworking.com/news/)

New Products

(https://www.canadianmetalworking.com/products/)

(https://www.fabtechexpo.com)

FABTECH News (https://www.fabtechexpo.com/blog)

Attend (https://www.fabtechexpo.com/attend)

Exhibit (https://www.fabtechexpo.com/exhibit)

Education Program

(https://www.fabtechexpo.com/learn)

(https://www.nutsandboltsfoundation.org)

Scholarships

(https://www.nutsandboltsfoundation.org/scholarships)

Manufacturing Camps

(https://www.nutsandboltsfoundation.org/camps)

News (https://www.nutsandboltsfoundation.org/news)

Donate

(https://www.nutsandboltsfoundation.org/donate)

Subscriptions (/subscription)

Advertise with Us (/mediakit)

Contact Us (/contact-us)

En Español (/espanol)

Industry Tradeshows (/?filter=event)

FMA Store (https://www.fmanet.org/store)

Job Board (https://jobs.fmanet.org)

TheFabricator.com provides metal fabrication professionals with market news, the industry's best articles, product news, and

conference information from the Fabricators & Manufacturers Association, Intl. (https://www.fmanet.org)

(/publication/fab) (/publication/sj) (/publication/pwt)

(/publication/tpj) (/pwtv) (/tpjtv)

© 2019 FMA Communications, Inc. All rights reserved.

2135 Point Blvd., Elgin, IL 60123 | 815-399-8700 | info@thefabricator.com

(mailto:info@thefabricator.com)

Terms of Use (https://www.fmanet.org/terms-of-use) | Privacy Policy (https://www.fmanet.org/privacy-

policy)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- A-13-03144 - WIDIA - Advances 2014 - EN - Metric PDFDocument421 pagesA-13-03144 - WIDIA - Advances 2014 - EN - Metric PDFOvidiu ChertesNo ratings yet

- Understanding Contact Tips For MIG WeldingDocument9 pagesUnderstanding Contact Tips For MIG WeldingnateNo ratings yet

- ADM4 LiteratureDocument2 pagesADM4 LiteraturenateNo ratings yet

- Stick To The Basics - Welding ProductivityDocument8 pagesStick To The Basics - Welding ProductivitynateNo ratings yet

- Select 90c d2Document1 pageSelect 90c d2nateNo ratings yet

- Quantum Arc 3Document2 pagesQuantum Arc 3nateNo ratings yet

- SM 70enDocument6 pagesSM 70ennateNo ratings yet

- Understanding Contact Tips For MIG WeldingDocument9 pagesUnderstanding Contact Tips For MIG WeldingnateNo ratings yet

- Since We Opened Our Doors in 1907, National Standard Has Been Setting The Standard For Consistent Product QualityDocument48 pagesSince We Opened Our Doors in 1907, National Standard Has Been Setting The Standard For Consistent Product QualitynateNo ratings yet

- MIG Gun MythbustingDocument4 pagesMIG Gun MythbustingnateNo ratings yet

- Choosing Shielding Gases For Arc Welding - The FabricatorDocument5 pagesChoosing Shielding Gases For Arc Welding - The FabricatornateNo ratings yet

- 7 Effects of Shielding Gas - The FabricatorDocument4 pages7 Effects of Shielding Gas - The FabricatornateNo ratings yet

- How Customized MIG Guns Improve Welding - Industrial Equipment News (IEN)Document3 pagesHow Customized MIG Guns Improve Welding - Industrial Equipment News (IEN)nateNo ratings yet

- Down To The Wire - Welding ProductivityDocument4 pagesDown To The Wire - Welding ProductivitynateNo ratings yet

- Main BearingDocument28 pagesMain BearingCadet Aviral Jha [9335]100% (1)

- 6061 Aluminum Plate - AMS 4027 - 6061-T651 PlateDocument3 pages6061 Aluminum Plate - AMS 4027 - 6061-T651 Platemini p shendeNo ratings yet

- B-21-B-21 Vcopper and Copper AlloysDocument7 pagesB-21-B-21 Vcopper and Copper Alloysluis_may22No ratings yet

- Unlock-Durcomet 100 (CD-4MCu)Document8 pagesUnlock-Durcomet 100 (CD-4MCu)Dimas Pratama PutraNo ratings yet

- BS en 12952-2-2011Document42 pagesBS en 12952-2-2011Mokhammad Fahmi Izdiharrudin100% (1)

- Yield Point Phenomenon in Metals and AlloysDocument311 pagesYield Point Phenomenon in Metals and AlloysAbhigyan BhuyanNo ratings yet

- Result and Calculation Evt 637 Exp 4Document4 pagesResult and Calculation Evt 637 Exp 4NUR IYLIANIS ISMAILNo ratings yet

- Metals: © 2013 Marshall Cavendish International (Singapore) Private Limited © 2014 Marshall Cavendish Education Pte LTDDocument64 pagesMetals: © 2013 Marshall Cavendish International (Singapore) Private Limited © 2014 Marshall Cavendish Education Pte LTDAbdul HadiNo ratings yet

- TDS Hardcarb 60 (#ETT - EN - 20.1)Document2 pagesTDS Hardcarb 60 (#ETT - EN - 20.1)Jimit ShahNo ratings yet

- Explosive Welding: - Mechanical Department - R.D. Eng. College, GZB - 3 YrDocument18 pagesExplosive Welding: - Mechanical Department - R.D. Eng. College, GZB - 3 YrShivam SharmaNo ratings yet

- Speeds & Feeds DrillsDocument9 pagesSpeeds & Feeds DrillsHolleyMooreNo ratings yet

- SMST-Tubes Product Range en 2010 WebDocument16 pagesSMST-Tubes Product Range en 2010 Webalbejo_r9No ratings yet

- Evaluation of Mechanical Properties of Aluminium-7029 Hybrid Composite MaterialDocument39 pagesEvaluation of Mechanical Properties of Aluminium-7029 Hybrid Composite MaterialPrajwal Vemala JagadeeshwaraNo ratings yet

- Cimtech 609e - InsolDocument2 pagesCimtech 609e - InsolsobheysaidNo ratings yet

- Rusting Fill in The BlanksDocument2 pagesRusting Fill in The BlanksPayalNo ratings yet

- 2021 Hyundai Aluminium Products (Brochure) - EngDocument16 pages2021 Hyundai Aluminium Products (Brochure) - EngmuratcanNo ratings yet

- Cotm 2103 HandoutDocument116 pagesCotm 2103 Handoutfitsum tesfayeNo ratings yet

- (Brian Cantor, Keyna O'Reilly) Solidification and (B-Ok - CC) PDFDocument437 pages(Brian Cantor, Keyna O'Reilly) Solidification and (B-Ok - CC) PDFscribedoctorNo ratings yet

- Awe CourseDocument9 pagesAwe CoursevsnaiduqcNo ratings yet

- Material and Process For NDT Technologys PDFDocument164 pagesMaterial and Process For NDT Technologys PDFwajidNo ratings yet

- Stainless Steel Properties PDFDocument8 pagesStainless Steel Properties PDFprajash007No ratings yet

- Assistant Engineer in KamcoDocument16 pagesAssistant Engineer in KamcoLearn Mechanical EngineeringNo ratings yet

- Solufore Fitting System Material SelectionDocument13 pagesSolufore Fitting System Material SelectionMauro TognocchiNo ratings yet

- OE-AN41220-ARL 4460 Fe-1010Document4 pagesOE-AN41220-ARL 4460 Fe-1010Adela BaltinNo ratings yet

- Copper-Nickel-Tin Spinodal Alloy Strip: Standard Specification ForDocument6 pagesCopper-Nickel-Tin Spinodal Alloy Strip: Standard Specification ForDanZel DanNo ratings yet

- Chief Engineer Officer, Small Vessel, III/2 Written Examination SyllabusDocument11 pagesChief Engineer Officer, Small Vessel, III/2 Written Examination SyllabusAdrianDanNo ratings yet

- Tubing: Tubing Selection Tubing Handling Gas Service Tubing Installation Types of TubingDocument16 pagesTubing: Tubing Selection Tubing Handling Gas Service Tubing Installation Types of TubingsandeshmusaleNo ratings yet

- GME Sample Questions - Fleet ManagementDocument4 pagesGME Sample Questions - Fleet ManagementRichardson Panavelil57% (7)

- Astm B139Document5 pagesAstm B139Jamil SalmanNo ratings yet