Professional Documents

Culture Documents

CH E 160 Stiehl or BR Heinen James85 Material Balances 2 - Structured

CH E 160 Stiehl or BR Heinen James85 Material Balances 2 - Structured

Uploaded by

SiskeAlfatiyaCopyright:

Available Formats

You might also like

- The Perfect Answer Chemistry Revision Guide - Edexcel IGCSE 9-1 - 1st Edition PDFDocument34 pagesThe Perfect Answer Chemistry Revision Guide - Edexcel IGCSE 9-1 - 1st Edition PDFKevir Man100% (13)

- Ejercicios.1-Varios Equipos, Multicomponentes, Sin RX PDFDocument4 pagesEjercicios.1-Varios Equipos, Multicomponentes, Sin RX PDFMafee VelezNo ratings yet

- 12D8Document2 pages12D8Sorrawit Tantipalakul0% (2)

- Assignment ReactiveDocument2 pagesAssignment ReactiveNUREEN DAYANA BINTI MOHD IZMANIZAN A21ET01940% (1)

- Exp 11: Analysis of (Co (NH3) 5Cl) Cl2Document6 pagesExp 11: Analysis of (Co (NH3) 5Cl) Cl2Marla Basa50% (2)

- Large Scale Power Generation Using Fuel CellDocument23 pagesLarge Scale Power Generation Using Fuel Cellnaveen vattimalla100% (3)

- CBE 202 Homework #1: Introduction To Chemical and Biomolecular EngineeringDocument2 pagesCBE 202 Homework #1: Introduction To Chemical and Biomolecular Engineering김민성No ratings yet

- Chemical Calculations For Chemical Engineering Problems in Material Balance Recycle Bypass PurgeDocument34 pagesChemical Calculations For Chemical Engineering Problems in Material Balance Recycle Bypass PurgeLuizRenanFariasBarbosaNo ratings yet

- Dec 2, 2018Document41 pagesDec 2, 2018Muhammad Irfan MalikNo ratings yet

- Taller BalanceDeMateria UnidadesMultiples 2024-1Document3 pagesTaller BalanceDeMateria UnidadesMultiples 2024-1Jeison Estiven Lopez OrtegaNo ratings yet

- LN Meb 4Document18 pagesLN Meb 4Siti Noranisa hidayahNo ratings yet

- Material Balance SheetDocument4 pagesMaterial Balance Sheetsyed waheed ul hasanNo ratings yet

- DistillationDocument12 pagesDistillationAbhishek SardaNo ratings yet

- Probset3. MaterialbalancesDocument8 pagesProbset3. MaterialbalancesAbi MukundNo ratings yet

- Homework 2Document2 pagesHomework 2Sabrina RosazzaNo ratings yet

- Practice Makes Perfect in Chemistry: Organic ChemistryFrom EverandPractice Makes Perfect in Chemistry: Organic ChemistryRating: 3 out of 5 stars3/5 (1)

- IntroductionDocument44 pagesIntroductionJudebarb94No ratings yet

- Assignment On Cpe 351 (Chemical Engineering Process Calculations)Document2 pagesAssignment On Cpe 351 (Chemical Engineering Process Calculations)Akpan Anthonia AthanasiusNo ratings yet

- SKKK1113 Tutorial Assignment-04-ReactiveDocument2 pagesSKKK1113 Tutorial Assignment-04-ReactiveNUREEN DAYANA BINTI MOHD IZMANIZAN A21ET0194No ratings yet

- CHE260M Assignment 3Document1 pageCHE260M Assignment 3wfwekfhwNo ratings yet

- LN Meb 3Document22 pagesLN Meb 3Siti Noranisa hidayahNo ratings yet

- Organic Chemistry Revision: Grade 10Document24 pagesOrganic Chemistry Revision: Grade 10blacksheep9810No ratings yet

- Distillation Lab 9.10.2014Document10 pagesDistillation Lab 9.10.2014Ahmed AliNo ratings yet

- Unit 1 Review AnswersDocument3 pagesUnit 1 Review AnswershelloblargNo ratings yet

- ChecalDocument10 pagesChecalAnonymous Su5mGPPMNo ratings yet

- 12D8Document2 pages12D8Sorrawit Tantipalakul0% (1)

- Worksheet 1Document4 pagesWorksheet 1Yasmin ArebNo ratings yet

- Source and Use of AlkaneDocument14 pagesSource and Use of AlkanearnigyuNo ratings yet

- 2020 CHEE2001 Week 6 Tutorial SheetDocument2 pages2020 CHEE2001 Week 6 Tutorial SheetMuntaha ManzoorNo ratings yet

- Material Balances Without Chemical Reactions (Single Units)Document26 pagesMaterial Balances Without Chemical Reactions (Single Units)sipasheNo ratings yet

- Recycle, Bypass, Purge, and Makeup: DR - Firas Salim Mohammed Al-GhulamiDocument25 pagesRecycle, Bypass, Purge, and Makeup: DR - Firas Salim Mohammed Al-GhulamiAbdulla DoskiNo ratings yet

- Chapter 1: Lecture 1:: Material Balances For Chemical EngineersDocument18 pagesChapter 1: Lecture 1:: Material Balances For Chemical EngineersFrank MtetwaNo ratings yet

- W20 EOC HW 51Document2 pagesW20 EOC HW 51LESLI RODRIGUEZ BENDEZUNo ratings yet

- CBE 202 HW 2 (Revised)Document2 pagesCBE 202 HW 2 (Revised)김민성No ratings yet

- Lectut CHN-102 PDF ReactiveDocument4 pagesLectut CHN-102 PDF ReactiveTanmaysainiNo ratings yet

- Mass and Energy Balances: Dr. Rakesh KumarDocument16 pagesMass and Energy Balances: Dr. Rakesh KumarVishal SinghNo ratings yet

- Chemistry of FuelDocument6 pagesChemistry of FuelIsaiah Danniel PerezNo ratings yet

- Problem Set 3-1Document1 pageProblem Set 3-1Carlo Luis LeeNo ratings yet

- TK-315 CPI2 - 1 - NonReacting SystemsDocument33 pagesTK-315 CPI2 - 1 - NonReacting SystemsBayu Purnama Ridjadi75% (4)

- Anaerobic Processes (Chapter 10) : AdvantagesDocument13 pagesAnaerobic Processes (Chapter 10) : AdvantagesΔημητρηςΣαρακυρουNo ratings yet

- Material and Energy BalancesDocument9 pagesMaterial and Energy BalancesAbdulkudus AbdulshukurNo ratings yet

- Problems 2Document32 pagesProblems 2Pritesh Bhakta50% (6)

- Combustion Reactions: OxygenDocument12 pagesCombustion Reactions: OxygenHemish A VaidyaNo ratings yet

- 2023-2 화공입문설계 - 문제풀이 Chapter4 배포용Document11 pages2023-2 화공입문설계 - 문제풀이 Chapter4 배포용권상엽No ratings yet

- 2020 Mid-Term 1 QuestionsDocument2 pages2020 Mid-Term 1 QuestionsDiana BeirutiNo ratings yet

- CHE 251 Assignment 3Document2 pagesCHE 251 Assignment 3Appah Ernest OpokuNo ratings yet

- Set 1aDocument11 pagesSet 1aKIER GASGANo ratings yet

- Tutorial 3Document2 pagesTutorial 3Nadhirah AzudinNo ratings yet

- Combustion ProblemsDocument2 pagesCombustion ProblemsMary Grace Garcia100% (2)

- Midterm CaeDocument17 pagesMidterm CaeDianne AlarconNo ratings yet

- Lab 2: The CO /H O System: Applied Water Chemistry Department of Chemical Engineering Technical University of LundDocument4 pagesLab 2: The CO /H O System: Applied Water Chemistry Department of Chemical Engineering Technical University of Lundprakash patelNo ratings yet

- CHM 125 Exp 2Document6 pagesCHM 125 Exp 2lyananafishaNo ratings yet

- 8-Essence of Esterification Sp16Document7 pages8-Essence of Esterification Sp16kerredaiNo ratings yet

- Mass BalanceDocument5 pagesMass BalanceSidharth RazdanNo ratings yet

- ChE 12 CHE 111 2015-16Document4 pagesChE 12 CHE 111 2015-16aanika roshniNo ratings yet

- KD (JY3 (D: L-1/T-2/CHEDocument15 pagesKD (JY3 (D: L-1/T-2/CHEAbdul BariNo ratings yet

- Homework 1 EVF401G Material and Energy Balance: Due Date: 23:59 PM, Monday 17.01.2022Document17 pagesHomework 1 EVF401G Material and Energy Balance: Due Date: 23:59 PM, Monday 17.01.2022Sabrina RosazzaNo ratings yet

- Process Enginnering FundamentalsDocument65 pagesProcess Enginnering FundamentalsMeng KiatNo ratings yet

- Practice Makes Perfect in Chemistry: Organic Chemistry with AnswersFrom EverandPractice Makes Perfect in Chemistry: Organic Chemistry with AnswersNo ratings yet

- Practice Makes Perfect in Chemistry: Acids, Bases, and Salts with AnswersFrom EverandPractice Makes Perfect in Chemistry: Acids, Bases, and Salts with AnswersNo ratings yet

- Plastic Mold Steels High Quality: HI-PM SeriesDocument6 pagesPlastic Mold Steels High Quality: HI-PM SeriestaknevNo ratings yet

- Chapter 18 BQDocument10 pagesChapter 18 BQTarek GhaddarNo ratings yet

- DPG 482Document6 pagesDPG 482Krittika ChandranNo ratings yet

- Chestnut Oak Shells Activated CarbonDocument41 pagesChestnut Oak Shells Activated CarbonVũ Văn NguyênNo ratings yet

- CHEM 403L Module 5 - Post-Laboratory QuestionsDocument3 pagesCHEM 403L Module 5 - Post-Laboratory QuestionsjustinNo ratings yet

- Swarrnim Startup and Innovation University Department of Civil Engineering Semester: 3 Sub: Concrete TechnologyDocument6 pagesSwarrnim Startup and Innovation University Department of Civil Engineering Semester: 3 Sub: Concrete TechnologyAkshay Kumar SutariyaNo ratings yet

- One Step Synthesis of Mn3O4 NanoparticlesDocument6 pagesOne Step Synthesis of Mn3O4 Nanoparticlessiti fatimahNo ratings yet

- P-ISSN 2722-1334 E-ISSN 2721-1894: 1. PendahuluanDocument14 pagesP-ISSN 2722-1334 E-ISSN 2721-1894: 1. PendahuluanNorma SafitriNo ratings yet

- To Study The Performance and Emission Characteristics of 5% Hydrogen Blend in Diesel EngineDocument6 pagesTo Study The Performance and Emission Characteristics of 5% Hydrogen Blend in Diesel EnginePravin nitnawareNo ratings yet

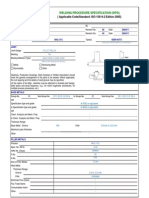

- Welding Procedure Specification (WPS) : (Applicable Code/Standard: ISO 15614-2 Edition 2005)Document2 pagesWelding Procedure Specification (WPS) : (Applicable Code/Standard: ISO 15614-2 Edition 2005)saioman100% (7)

- Hardness, Conductivity, TDS MeasurementDocument2 pagesHardness, Conductivity, TDS Measurementdiego calleNo ratings yet

- HCL PDFDocument13 pagesHCL PDFjoycepeterNo ratings yet

- 1052 Emulsion Bulk (5.1)Document3 pages1052 Emulsion Bulk (5.1)tarek aneesNo ratings yet

- Piercan Tradeshow PresentationDocument23 pagesPiercan Tradeshow PresentationDangthieuhoi VuNo ratings yet

- AM ECOHANCE Remo XPDocument11 pagesAM ECOHANCE Remo XPHồ NghĩaNo ratings yet

- Theme: Technology in Chemistry Chapter: Polymer Title of Project: Stationery HolderDocument30 pagesTheme: Technology in Chemistry Chapter: Polymer Title of Project: Stationery HolderTecky JerryNo ratings yet

- Lanolin 6ppDocument6 pagesLanolin 6ppicrao100% (1)

- A Review On Current Research Trends in Electrical Discharge Machining (EDM)Document15 pagesA Review On Current Research Trends in Electrical Discharge Machining (EDM)dinesh veerNo ratings yet

- Mineral PDFDocument57 pagesMineral PDFMasuda SultanaNo ratings yet

- Chem Project - Pari GuptaDocument8 pagesChem Project - Pari GuptaPari GuptaNo ratings yet

- Tabel VCDocument1 pageTabel VCgame downloadNo ratings yet

- Mil PRF 5606JDocument13 pagesMil PRF 5606JDNo ratings yet

- Multi-Purpose Cleaner/Degreaser: FeaturesDocument2 pagesMulti-Purpose Cleaner/Degreaser: FeaturesJivendra KumarNo ratings yet

- Chemtreat Challenges of Industrial Boiler Water TreatmentDocument17 pagesChemtreat Challenges of Industrial Boiler Water TreatmentKhondoker Nayeem ul haqueNo ratings yet

- June 2012 MS - Paper 1C Edexcel Chemistry IGCSEDocument32 pagesJune 2012 MS - Paper 1C Edexcel Chemistry IGCSEVideesha AmunugamaNo ratings yet

- Karbol WangiDocument2 pagesKarbol WangicendraNo ratings yet

- Corrosion Problems Associated With Stainless SteelDocument11 pagesCorrosion Problems Associated With Stainless SteelVivek RathodNo ratings yet

CH E 160 Stiehl or BR Heinen James85 Material Balances 2 - Structured

CH E 160 Stiehl or BR Heinen James85 Material Balances 2 - Structured

Uploaded by

SiskeAlfatiyaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CH E 160 Stiehl or BR Heinen James85 Material Balances 2 - Structured

CH E 160 Stiehl or BR Heinen James85 Material Balances 2 - Structured

Uploaded by

SiskeAlfatiyaCopyright:

Available Formats

Leader: James

Material Balances -2 Course: ChE 160

Supplemental Instruction Instructor: Heinen/ Stiehl/ Brenza

Iowa State University

Where: The best location is in your Eide textbook. They should have most of what you need.

Otherwise you could look for the ChE 210 book, Elementary Principles of Chemical Processes.

This book is AMAZING.

Discussion

Material balance concepts are THE MOST IMPORTANT concepts to understand in your

engineering life. If you don’t know how to balance a system, you will have trouble in every

subsequent ChE class. Just a fact.

Concept Questions

What is the basic material balance equation?

What is the basic design of a distillation column?

What are the three basic steps in solving a material balance?

What does it mean for a system to be in steady-state?

Review

A stream containing 5.15 wt% chromium is contained in in the wastewater from a metal finishing plant.

The wastewater stream is fed to a treatment unit that removes 95% of the Cr in the feed and recycles it to

the plant. The residual liquid stream leaving the treatment unit is sent to a waste lagoon. The treatment

unit has a capacity of 4500 kg wastewater/hr. If the wastewater leaves the finishing plant at a rate higher

than the capacity of the treatment unit, the excess bypasses the unit and combines with the residual liquid

leaving the unit, and the combined stream goes to the waste lagoon.

If wastewater leaves the plant at 6000 kg/h, calculate the flow rate of liquid to the waste lagoon and the

mass fraction of Cr in this liquid.

An experiment on the growth rate of certain organisms requires an environment of humid air enriched

with oxygen. Three input streams are fed to an evaporation chamber to produce an output stream with the

desired composition:

1. Liquid water, fed at a rate of 20.0 dm3/min

2. Air (21 mole % O2, the rest N2)

3. Pure oxygen, with a flow rate one-fifth of the molar rate of stream 2.

The output gas is analyzed and found to contain 1.5 mole% water. Calculate all unknown stream

variables.

Methanol is produced by reacting carbon monoxide and hydrogen. A fresh feed stream containing CO

and H2 joins a recycle stream and this combined stream is fed to a reactor. The reactor outlet stream

flows at a rate of 350 mol/min and contains 10.6 mol% H2, 64.0 mol% CO, and 25.4 mol% CH3OH.

This stream then enters a cooler in which most of the methanol is condensed. The liquid methanol

condensate is withdrawn as product, and the gas stream leaving the condenser-which contains the CO2

and H2, as well as 0.4 mole % uncondensed CH3OH vapor-is the recycle stream that combines with the

fresh feed. Determine the production rate of liquid methanol.

Exam Prep

REMEMBER the Law of Conservation of Mass. PLEASE. Oh please oh please.

1060 Hixson-Lied Student Success Center v 515-294-6624 v sistaff@iastate.edu v http://www.si.iastate.edu

You might also like

- The Perfect Answer Chemistry Revision Guide - Edexcel IGCSE 9-1 - 1st Edition PDFDocument34 pagesThe Perfect Answer Chemistry Revision Guide - Edexcel IGCSE 9-1 - 1st Edition PDFKevir Man100% (13)

- Ejercicios.1-Varios Equipos, Multicomponentes, Sin RX PDFDocument4 pagesEjercicios.1-Varios Equipos, Multicomponentes, Sin RX PDFMafee VelezNo ratings yet

- 12D8Document2 pages12D8Sorrawit Tantipalakul0% (2)

- Assignment ReactiveDocument2 pagesAssignment ReactiveNUREEN DAYANA BINTI MOHD IZMANIZAN A21ET01940% (1)

- Exp 11: Analysis of (Co (NH3) 5Cl) Cl2Document6 pagesExp 11: Analysis of (Co (NH3) 5Cl) Cl2Marla Basa50% (2)

- Large Scale Power Generation Using Fuel CellDocument23 pagesLarge Scale Power Generation Using Fuel Cellnaveen vattimalla100% (3)

- CBE 202 Homework #1: Introduction To Chemical and Biomolecular EngineeringDocument2 pagesCBE 202 Homework #1: Introduction To Chemical and Biomolecular Engineering김민성No ratings yet

- Chemical Calculations For Chemical Engineering Problems in Material Balance Recycle Bypass PurgeDocument34 pagesChemical Calculations For Chemical Engineering Problems in Material Balance Recycle Bypass PurgeLuizRenanFariasBarbosaNo ratings yet

- Dec 2, 2018Document41 pagesDec 2, 2018Muhammad Irfan MalikNo ratings yet

- Taller BalanceDeMateria UnidadesMultiples 2024-1Document3 pagesTaller BalanceDeMateria UnidadesMultiples 2024-1Jeison Estiven Lopez OrtegaNo ratings yet

- LN Meb 4Document18 pagesLN Meb 4Siti Noranisa hidayahNo ratings yet

- Material Balance SheetDocument4 pagesMaterial Balance Sheetsyed waheed ul hasanNo ratings yet

- DistillationDocument12 pagesDistillationAbhishek SardaNo ratings yet

- Probset3. MaterialbalancesDocument8 pagesProbset3. MaterialbalancesAbi MukundNo ratings yet

- Homework 2Document2 pagesHomework 2Sabrina RosazzaNo ratings yet

- Practice Makes Perfect in Chemistry: Organic ChemistryFrom EverandPractice Makes Perfect in Chemistry: Organic ChemistryRating: 3 out of 5 stars3/5 (1)

- IntroductionDocument44 pagesIntroductionJudebarb94No ratings yet

- Assignment On Cpe 351 (Chemical Engineering Process Calculations)Document2 pagesAssignment On Cpe 351 (Chemical Engineering Process Calculations)Akpan Anthonia AthanasiusNo ratings yet

- SKKK1113 Tutorial Assignment-04-ReactiveDocument2 pagesSKKK1113 Tutorial Assignment-04-ReactiveNUREEN DAYANA BINTI MOHD IZMANIZAN A21ET0194No ratings yet

- CHE260M Assignment 3Document1 pageCHE260M Assignment 3wfwekfhwNo ratings yet

- LN Meb 3Document22 pagesLN Meb 3Siti Noranisa hidayahNo ratings yet

- Organic Chemistry Revision: Grade 10Document24 pagesOrganic Chemistry Revision: Grade 10blacksheep9810No ratings yet

- Distillation Lab 9.10.2014Document10 pagesDistillation Lab 9.10.2014Ahmed AliNo ratings yet

- Unit 1 Review AnswersDocument3 pagesUnit 1 Review AnswershelloblargNo ratings yet

- ChecalDocument10 pagesChecalAnonymous Su5mGPPMNo ratings yet

- 12D8Document2 pages12D8Sorrawit Tantipalakul0% (1)

- Worksheet 1Document4 pagesWorksheet 1Yasmin ArebNo ratings yet

- Source and Use of AlkaneDocument14 pagesSource and Use of AlkanearnigyuNo ratings yet

- 2020 CHEE2001 Week 6 Tutorial SheetDocument2 pages2020 CHEE2001 Week 6 Tutorial SheetMuntaha ManzoorNo ratings yet

- Material Balances Without Chemical Reactions (Single Units)Document26 pagesMaterial Balances Without Chemical Reactions (Single Units)sipasheNo ratings yet

- Recycle, Bypass, Purge, and Makeup: DR - Firas Salim Mohammed Al-GhulamiDocument25 pagesRecycle, Bypass, Purge, and Makeup: DR - Firas Salim Mohammed Al-GhulamiAbdulla DoskiNo ratings yet

- Chapter 1: Lecture 1:: Material Balances For Chemical EngineersDocument18 pagesChapter 1: Lecture 1:: Material Balances For Chemical EngineersFrank MtetwaNo ratings yet

- W20 EOC HW 51Document2 pagesW20 EOC HW 51LESLI RODRIGUEZ BENDEZUNo ratings yet

- CBE 202 HW 2 (Revised)Document2 pagesCBE 202 HW 2 (Revised)김민성No ratings yet

- Lectut CHN-102 PDF ReactiveDocument4 pagesLectut CHN-102 PDF ReactiveTanmaysainiNo ratings yet

- Mass and Energy Balances: Dr. Rakesh KumarDocument16 pagesMass and Energy Balances: Dr. Rakesh KumarVishal SinghNo ratings yet

- Chemistry of FuelDocument6 pagesChemistry of FuelIsaiah Danniel PerezNo ratings yet

- Problem Set 3-1Document1 pageProblem Set 3-1Carlo Luis LeeNo ratings yet

- TK-315 CPI2 - 1 - NonReacting SystemsDocument33 pagesTK-315 CPI2 - 1 - NonReacting SystemsBayu Purnama Ridjadi75% (4)

- Anaerobic Processes (Chapter 10) : AdvantagesDocument13 pagesAnaerobic Processes (Chapter 10) : AdvantagesΔημητρηςΣαρακυρουNo ratings yet

- Material and Energy BalancesDocument9 pagesMaterial and Energy BalancesAbdulkudus AbdulshukurNo ratings yet

- Problems 2Document32 pagesProblems 2Pritesh Bhakta50% (6)

- Combustion Reactions: OxygenDocument12 pagesCombustion Reactions: OxygenHemish A VaidyaNo ratings yet

- 2023-2 화공입문설계 - 문제풀이 Chapter4 배포용Document11 pages2023-2 화공입문설계 - 문제풀이 Chapter4 배포용권상엽No ratings yet

- 2020 Mid-Term 1 QuestionsDocument2 pages2020 Mid-Term 1 QuestionsDiana BeirutiNo ratings yet

- CHE 251 Assignment 3Document2 pagesCHE 251 Assignment 3Appah Ernest OpokuNo ratings yet

- Set 1aDocument11 pagesSet 1aKIER GASGANo ratings yet

- Tutorial 3Document2 pagesTutorial 3Nadhirah AzudinNo ratings yet

- Combustion ProblemsDocument2 pagesCombustion ProblemsMary Grace Garcia100% (2)

- Midterm CaeDocument17 pagesMidterm CaeDianne AlarconNo ratings yet

- Lab 2: The CO /H O System: Applied Water Chemistry Department of Chemical Engineering Technical University of LundDocument4 pagesLab 2: The CO /H O System: Applied Water Chemistry Department of Chemical Engineering Technical University of Lundprakash patelNo ratings yet

- CHM 125 Exp 2Document6 pagesCHM 125 Exp 2lyananafishaNo ratings yet

- 8-Essence of Esterification Sp16Document7 pages8-Essence of Esterification Sp16kerredaiNo ratings yet

- Mass BalanceDocument5 pagesMass BalanceSidharth RazdanNo ratings yet

- ChE 12 CHE 111 2015-16Document4 pagesChE 12 CHE 111 2015-16aanika roshniNo ratings yet

- KD (JY3 (D: L-1/T-2/CHEDocument15 pagesKD (JY3 (D: L-1/T-2/CHEAbdul BariNo ratings yet

- Homework 1 EVF401G Material and Energy Balance: Due Date: 23:59 PM, Monday 17.01.2022Document17 pagesHomework 1 EVF401G Material and Energy Balance: Due Date: 23:59 PM, Monday 17.01.2022Sabrina RosazzaNo ratings yet

- Process Enginnering FundamentalsDocument65 pagesProcess Enginnering FundamentalsMeng KiatNo ratings yet

- Practice Makes Perfect in Chemistry: Organic Chemistry with AnswersFrom EverandPractice Makes Perfect in Chemistry: Organic Chemistry with AnswersNo ratings yet

- Practice Makes Perfect in Chemistry: Acids, Bases, and Salts with AnswersFrom EverandPractice Makes Perfect in Chemistry: Acids, Bases, and Salts with AnswersNo ratings yet

- Plastic Mold Steels High Quality: HI-PM SeriesDocument6 pagesPlastic Mold Steels High Quality: HI-PM SeriestaknevNo ratings yet

- Chapter 18 BQDocument10 pagesChapter 18 BQTarek GhaddarNo ratings yet

- DPG 482Document6 pagesDPG 482Krittika ChandranNo ratings yet

- Chestnut Oak Shells Activated CarbonDocument41 pagesChestnut Oak Shells Activated CarbonVũ Văn NguyênNo ratings yet

- CHEM 403L Module 5 - Post-Laboratory QuestionsDocument3 pagesCHEM 403L Module 5 - Post-Laboratory QuestionsjustinNo ratings yet

- Swarrnim Startup and Innovation University Department of Civil Engineering Semester: 3 Sub: Concrete TechnologyDocument6 pagesSwarrnim Startup and Innovation University Department of Civil Engineering Semester: 3 Sub: Concrete TechnologyAkshay Kumar SutariyaNo ratings yet

- One Step Synthesis of Mn3O4 NanoparticlesDocument6 pagesOne Step Synthesis of Mn3O4 Nanoparticlessiti fatimahNo ratings yet

- P-ISSN 2722-1334 E-ISSN 2721-1894: 1. PendahuluanDocument14 pagesP-ISSN 2722-1334 E-ISSN 2721-1894: 1. PendahuluanNorma SafitriNo ratings yet

- To Study The Performance and Emission Characteristics of 5% Hydrogen Blend in Diesel EngineDocument6 pagesTo Study The Performance and Emission Characteristics of 5% Hydrogen Blend in Diesel EnginePravin nitnawareNo ratings yet

- Welding Procedure Specification (WPS) : (Applicable Code/Standard: ISO 15614-2 Edition 2005)Document2 pagesWelding Procedure Specification (WPS) : (Applicable Code/Standard: ISO 15614-2 Edition 2005)saioman100% (7)

- Hardness, Conductivity, TDS MeasurementDocument2 pagesHardness, Conductivity, TDS Measurementdiego calleNo ratings yet

- HCL PDFDocument13 pagesHCL PDFjoycepeterNo ratings yet

- 1052 Emulsion Bulk (5.1)Document3 pages1052 Emulsion Bulk (5.1)tarek aneesNo ratings yet

- Piercan Tradeshow PresentationDocument23 pagesPiercan Tradeshow PresentationDangthieuhoi VuNo ratings yet

- AM ECOHANCE Remo XPDocument11 pagesAM ECOHANCE Remo XPHồ NghĩaNo ratings yet

- Theme: Technology in Chemistry Chapter: Polymer Title of Project: Stationery HolderDocument30 pagesTheme: Technology in Chemistry Chapter: Polymer Title of Project: Stationery HolderTecky JerryNo ratings yet

- Lanolin 6ppDocument6 pagesLanolin 6ppicrao100% (1)

- A Review On Current Research Trends in Electrical Discharge Machining (EDM)Document15 pagesA Review On Current Research Trends in Electrical Discharge Machining (EDM)dinesh veerNo ratings yet

- Mineral PDFDocument57 pagesMineral PDFMasuda SultanaNo ratings yet

- Chem Project - Pari GuptaDocument8 pagesChem Project - Pari GuptaPari GuptaNo ratings yet

- Tabel VCDocument1 pageTabel VCgame downloadNo ratings yet

- Mil PRF 5606JDocument13 pagesMil PRF 5606JDNo ratings yet

- Multi-Purpose Cleaner/Degreaser: FeaturesDocument2 pagesMulti-Purpose Cleaner/Degreaser: FeaturesJivendra KumarNo ratings yet

- Chemtreat Challenges of Industrial Boiler Water TreatmentDocument17 pagesChemtreat Challenges of Industrial Boiler Water TreatmentKhondoker Nayeem ul haqueNo ratings yet

- June 2012 MS - Paper 1C Edexcel Chemistry IGCSEDocument32 pagesJune 2012 MS - Paper 1C Edexcel Chemistry IGCSEVideesha AmunugamaNo ratings yet

- Karbol WangiDocument2 pagesKarbol WangicendraNo ratings yet

- Corrosion Problems Associated With Stainless SteelDocument11 pagesCorrosion Problems Associated With Stainless SteelVivek RathodNo ratings yet