Professional Documents

Culture Documents

Technical Data Sheet Y Plastic Filters: Ydv YDV: Product Description

Technical Data Sheet Y Plastic Filters: Ydv YDV: Product Description

Uploaded by

mujeebscribdCopyright:

Available Formats

You might also like

- Anchor Handling Tug Pre-Mob InspectionDocument8 pagesAnchor Handling Tug Pre-Mob Inspectiondndudc100% (1)

- Cajas Portavalvulas IrritecDocument3 pagesCajas Portavalvulas IrritecFrot OrellanaNo ratings yet

- 001.17033.000230 - Da001 - Rev 01 - CDocument70 pages001.17033.000230 - Da001 - Rev 01 - CSérgio RibeiroNo ratings yet

- Test Report: Dilip Buildcon LimitedDocument5 pagesTest Report: Dilip Buildcon LimitedRitesh TiwariNo ratings yet

- CM-04&05 Flow MeterDocument10 pagesCM-04&05 Flow MeterPortfolio TrackerNo ratings yet

- 7S10LEN00839 - Single Round 5 Adapter 25 I - TypeDocument4 pages7S10LEN00839 - Single Round 5 Adapter 25 I - TypeDen TseNo ratings yet

- 29.3 - A33760US-01-VDS - Rev 1Document3 pages29.3 - A33760US-01-VDS - Rev 1manuelarranoNo ratings yet

- L&t-Ut-Se-1678 - R1 30-03-2023Document1 pageL&t-Ut-Se-1678 - R1 30-03-2023SamirNo ratings yet

- FORJADOS S.A. (100536) : No. 2019 678/CC/1 Rev.0 DTD 16 Apr 2019Document13 pagesFORJADOS S.A. (100536) : No. 2019 678/CC/1 Rev.0 DTD 16 Apr 2019claudio veas cortesNo ratings yet

- Customer Information: Consolidated ReportDocument12 pagesCustomer Information: Consolidated Reportst.fernandez.ana78No ratings yet

- Material Test ReportDocument5 pagesMaterial Test ReportJuan Carlos Sua SuaNo ratings yet

- 1H18B0 - Water Accessories Booklet Rev. 2A PDFDocument258 pages1H18B0 - Water Accessories Booklet Rev. 2A PDFcnl filesNo ratings yet

- Valvulas de Compuerta 3-4 X 800Document3 pagesValvulas de Compuerta 3-4 X 800danielsalcedomringenierosNo ratings yet

- Pump-Out Plug: A) DescriptionDocument13 pagesPump-Out Plug: A) DescriptionROBERTO ANDRES SIZA REYNo ratings yet

- 15.0 IFU - Volumetric SetDocument2 pages15.0 IFU - Volumetric SetMamdouhNo ratings yet

- NT2-L3-M-000!21!00010 MS For Cleaning & Flushing of BOP Piping SystemDocument7 pagesNT2-L3-M-000!21!00010 MS For Cleaning & Flushing of BOP Piping SystemHuynh Thanh TamNo ratings yet

- Ydf Globo 1 PDFDocument3 pagesYdf Globo 1 PDFArnoldo Huertas garzonNo ratings yet

- Al-Iris E-25a-02-003 PDFDocument12 pagesAl-Iris E-25a-02-003 PDFHao TranNo ratings yet

- MountainShilajitresin Lab Reports 2019 SpectroDocument3 pagesMountainShilajitresin Lab Reports 2019 SpectroMayur PatelNo ratings yet

- Customer Information: Consolidated ReportDocument12 pagesCustomer Information: Consolidated Reportst.fernandez.ana78No ratings yet

- Manufacturing Certificate and MDR & DOSH Documentation TPI Certificate, Calculation and Drawing CertifiedDocument17 pagesManufacturing Certificate and MDR & DOSH Documentation TPI Certificate, Calculation and Drawing CertifiedNasrul HazimNo ratings yet

- ZQ200X200X 8 K S355 - 730229708 - 72 M - CorinthDocument3 pagesZQ200X200X 8 K S355 - 730229708 - 72 M - CorinthIonela Ionela100% (1)

- Test Rapport RTB30Document18 pagesTest Rapport RTB30Thomas Birch HansenNo ratings yet

- A3 Approved For Fabrication: Instrument ListDocument8 pagesA3 Approved For Fabrication: Instrument ListJuan Portilla cortezNo ratings yet

- DNV GL Certificate For Halton FDLDocument3 pagesDNV GL Certificate For Halton FDLNguyễn Tất ĐôngNo ratings yet

- PHTP-HT-4T07-26-835 Manual Sitrans TS500 PDFDocument394 pagesPHTP-HT-4T07-26-835 Manual Sitrans TS500 PDFAndres Mauricio GaleanoNo ratings yet

- DNV Accesory Approval 2023 02Document3 pagesDNV Accesory Approval 2023 02Jorge JuanNo ratings yet

- Certificado DNF HCB TANK 12423612Document1 pageCertificado DNF HCB TANK 12423612Ricardo VillarNo ratings yet

- Used Drill Pipe BuggyDocument4 pagesUsed Drill Pipe BuggyJohn DolanNo ratings yet

- Taf00000jm 3Document3 pagesTaf00000jm 3Will SohNo ratings yet

- SAILOR 6222 VHF DSC Class A EC Type Examination Module B NEMKO PDFDocument3 pagesSAILOR 6222 VHF DSC Class A EC Type Examination Module B NEMKO PDFlucas barriosNo ratings yet

- Pmi ReportDocument5 pagesPmi ReportMANIMARAN QCNo ratings yet

- Certificate of Approval NMI 14/3/1Document21 pagesCertificate of Approval NMI 14/3/1MjeriteljXNo ratings yet

- 7734 14 T6734R5Document22 pages7734 14 T6734R5Alexandre MorelNo ratings yet

- 27100-C Air PadsDocument16 pages27100-C Air PadsJason MaNo ratings yet

- 35.0 IFU - Buretta With NeedleDocument3 pages35.0 IFU - Buretta With NeedleMamdouhNo ratings yet

- Stress Calculation Stress Engineering Cover SheetDocument7 pagesStress Calculation Stress Engineering Cover SheetPappu Kishore KumarNo ratings yet

- EEW17.3.9.Pressure Test ReportDocument6 pagesEEW17.3.9.Pressure Test Reportmecon bhilaiNo ratings yet

- 1033 - 2018 Adt e All Air Conditioner Fin Temperature Sensor Kit (00000002)Document5 pages1033 - 2018 Adt e All Air Conditioner Fin Temperature Sensor Kit (00000002)JUAN MANUEL RUIZ BERMEJONo ratings yet

- Hazardous Waste Filtration System User Guide: Millipore Cat. No. YT30 142 HWDocument11 pagesHazardous Waste Filtration System User Guide: Millipore Cat. No. YT30 142 HWJUAN RAMIREZ MARTINEZNo ratings yet

- Ansul R-102 ManualDocument215 pagesAnsul R-102 ManualIvana NovitaNo ratings yet

- Line Traveler PHOENIXDocument21 pagesLine Traveler PHOENIXRuth DiazNo ratings yet

- Spirax Sarco - Non Return Valve Type DCV3Document4 pagesSpirax Sarco - Non Return Valve Type DCV3jimmiilongNo ratings yet

- R902447420 Trator JD 63CM Re240475Document21 pagesR902447420 Trator JD 63CM Re240475Rodrigues de OliveiraNo ratings yet

- 151VORILTCCertificate FullDocument3 pages151VORILTCCertificate Fullk ONo ratings yet

- 9368-18 Ges (Inox) 3fti-3 Aisi316l PN6 PDFDocument84 pages9368-18 Ges (Inox) 3fti-3 Aisi316l PN6 PDFFELIXENGIPLASCOMNo ratings yet

- Series TSW 210-310: SUCTION FILTER, Horizontal Tank Mounted Sheet No. 1905 JDocument4 pagesSeries TSW 210-310: SUCTION FILTER, Horizontal Tank Mounted Sheet No. 1905 Jsanjay0910No ratings yet

- L&t-Ut-Se-1675 - R1 30-03-2023Document1 pageL&t-Ut-Se-1675 - R1 30-03-2023SamirNo ratings yet

- File 1477563820Document10 pagesFile 1477563820QuintusNo ratings yet

- DNV GL enDocument2 pagesDNV GL enronaldusjansen1994No ratings yet

- 9 13 317 0aDocument6 pages9 13 317 0aPeerasut ChaisrimaneepanNo ratings yet

- EMC Pro1040 Pro1050 2182013 ODCùl ENDocument75 pagesEMC Pro1040 Pro1050 2182013 ODCùl ENTayfun SezişNo ratings yet

- WS 059Document4 pagesWS 059san2inNo ratings yet

- Infomation Wds Flow Controls TaiwanDocument8 pagesInfomation Wds Flow Controls TaiwanjuanrosonNo ratings yet

- DNV 3xxx Taa00001rwDocument4 pagesDNV 3xxx Taa00001rwtom7132414No ratings yet

- D62 - 691 - 5 - C4-Specification Sheets PDFDocument26 pagesD62 - 691 - 5 - C4-Specification Sheets PDFSoumiyaNo ratings yet

- ATEX Ex H ITS16ATEX101534X KM26Document4 pagesATEX Ex H ITS16ATEX101534X KM26ROGELIO QUIJANONo ratings yet

- Code of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7From EverandCode of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7No ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Adm Std. Specs-part2-Road StructuresDocument2 pagesAdm Std. Specs-part2-Road StructuresmujeebscribdNo ratings yet

- Multiply and Divide Polynomials, Distributive Property, and SubstitutionsDocument7 pagesMultiply and Divide Polynomials, Distributive Property, and SubstitutionsmujeebscribdNo ratings yet

- Gulf Precast GRCDocument12 pagesGulf Precast GRCmujeebscribdNo ratings yet

- Instructions - DM TestDocument1 pageInstructions - DM TestmujeebscribdNo ratings yet

- HDPE Lining Case StudyDocument9 pagesHDPE Lining Case StudymujeebscribdNo ratings yet

- PE-hydraulic Design of Liquid or Water Piping SystemDocument16 pagesPE-hydraulic Design of Liquid or Water Piping SystemmujeebscribdNo ratings yet

- Rotomolding Manholes - 2333Document20 pagesRotomolding Manholes - 2333mujeebscribdNo ratings yet

- PP For Generations - BorougeDocument30 pagesPP For Generations - BorougemujeebscribdNo ratings yet

- Rotomoulding Presentation PDFDocument80 pagesRotomoulding Presentation PDFmujeebscribdNo ratings yet

- A 703 - A 703M - 01 Qtcwmy0wmueDocument14 pagesA 703 - A 703M - 01 Qtcwmy0wmueJuan Sebastián Londoño MartínezNo ratings yet

- Astm A789Document6 pagesAstm A789shahid khan100% (1)

- AstmDocument6 pagesAstmJeetendra MhatreNo ratings yet

- STD 900Document16 pagesSTD 900Diego CondeNo ratings yet

- Bearing Number Id (MM) Od (MM) Width (MM) ID (Inch) OD (Inch) Width (Inch)Document12 pagesBearing Number Id (MM) Od (MM) Width (MM) ID (Inch) OD (Inch) Width (Inch)Bv Rao100% (3)

- Engineering Manual Expansion JointsDocument24 pagesEngineering Manual Expansion JointsbrockNo ratings yet

- ASTM A213 T22 ASME SA213 T22 Specification - 3 PDFDocument6 pagesASTM A213 T22 ASME SA213 T22 Specification - 3 PDFbagus asmoroNo ratings yet

- Heaton Valves BrochureDocument16 pagesHeaton Valves BrochureRian HilmawanNo ratings yet

- Cor Cote HTDocument4 pagesCor Cote HTlovaldes62No ratings yet

- Appendix E1 Ages SP 09 002Document13 pagesAppendix E1 Ages SP 09 002SandeepNBabuNo ratings yet

- Fig F611 F621 F626 Butterfly CraneFS DS 1702 P77 PDFDocument1 pageFig F611 F621 F626 Butterfly CraneFS DS 1702 P77 PDFmarchus09No ratings yet

- Vacuum Chambers: Installation and Operating GuideDocument9 pagesVacuum Chambers: Installation and Operating GuideMiie EmiieNo ratings yet

- Af Concrete Screw Anchor Tds 022018Document6 pagesAf Concrete Screw Anchor Tds 022018Orlando LopesNo ratings yet

- Welding Engineer Qa/Qc DepartmentDocument2 pagesWelding Engineer Qa/Qc DepartmentSendy MaulanaNo ratings yet

- J Matpr 2019 10 018Document4 pagesJ Matpr 2019 10 018Alagar SamyNo ratings yet

- Plastering Bead & Mesh: Stainless Steel and PvcuDocument12 pagesPlastering Bead & Mesh: Stainless Steel and PvcuSami LouisNo ratings yet

- Ivc Single Faced Sluice Gate Valve Valvula de CompuertaDocument14 pagesIvc Single Faced Sluice Gate Valve Valvula de CompuertaSurendra ReddyNo ratings yet

- 345 PDFDocument32 pages345 PDFTuntunNo ratings yet

- Invima Fonendoscopio RiesterDocument2 pagesInvima Fonendoscopio RiesterVanessa SalinasNo ratings yet

- Catalog + Fiber Laser Welding Machine + XT Laser AbelDocument13 pagesCatalog + Fiber Laser Welding Machine + XT Laser AbelLuciano Añorga ArmestarNo ratings yet

- Valve Series 33 MS-01-61Document6 pagesValve Series 33 MS-01-61kicsnerNo ratings yet

- XCO Drive Package - The Alternative To Stainless SteelDocument4 pagesXCO Drive Package - The Alternative To Stainless SteelSEW-Eurodrive PortugalNo ratings yet

- Nicored 182 PDFDocument1 pageNicored 182 PDFDương Quang KhánhNo ratings yet

- Brosur FontaDocument8 pagesBrosur FontaKawat Las FontaNo ratings yet

- BE19F02F012-Industrial Interaction ReportDocument38 pagesBE19F02F012-Industrial Interaction ReportSubodh DanaoNo ratings yet

- 17-4 Fi Us enDocument10 pages17-4 Fi Us ennaeem akramNo ratings yet

- Cladding & Overlay - Ni InstituteDocument24 pagesCladding & Overlay - Ni Institutesajid aslamNo ratings yet

- Suneal Pergola Brochure /PUIGMETAL®Document7 pagesSuneal Pergola Brochure /PUIGMETAL®PUIGMETAL®No ratings yet

- Astm A182Document6 pagesAstm A182Rayan AlfredNo ratings yet

- Welding Journal 1961 10Document157 pagesWelding Journal 1961 10AlexeyNo ratings yet

Technical Data Sheet Y Plastic Filters: Ydv YDV: Product Description

Technical Data Sheet Y Plastic Filters: Ydv YDV: Product Description

Uploaded by

mujeebscribdOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Data Sheet Y Plastic Filters: Ydv YDV: Product Description

Technical Data Sheet Y Plastic Filters: Ydv YDV: Product Description

Uploaded by

mujeebscribdCopyright:

Available Formats

TDS n°: TDS17353IT

Rev. n°: 00

dated: 04/07/2019

Approved by: UTSCLN

Page 1/3

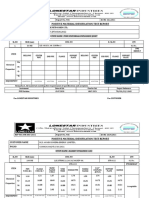

TECHNICAL DATA SHEET

Y PLASTIC FILTERS: YDV YDV

Product description

Online filter, model “D”, male threaded connections.

Product picture

Characteristics

Nominal flow rate: 5 m3/h.

Filtration area: 160 cm2.

Available filtration grade: 20, 30, 50, 75, 100, 155, 200 mesh stainless steel or polyester screen; 120 mesh stainless steel

or polyester screen and disks.

Preset pressure gauge connections, ¼” male thread, no hole.

Maximum working pressure according to temperature as per Table 1.

Table 1. – PN

from +5 to +25 °C from +26 to +40 °C from +41 to +60 °C

10 9 8

Applications

Secondary and safety filtration. This filter can be installed both in valve boxes and open areas.

It is also used in fertigation systems thanks to its resistance to common acids and fertilizers used in agriculture.

Benefits, operation and materials

Materials used:

• Body: black polypropylene.

• Filtering cartridge:

o Inox (mesh in stainless steel AISI 304 with polypropylene structure);

o Polyester (polyester mesh with polypropylene structure);

o Disks (polypropylene structure and disks).

• Gaskets: nitrile rubber (NBR).

Cover: Black polypropylene.

Technical design

TDS17304IT – rev.00 dated 04/07/2019

TDS n°: TDS17353IT

Rev. n°: 00

dated: 04/07/2019

Approved by: UTSCLN

Page 2/3

Technical data

Table 2. – Dimensions

R E E’ E’’ D D’ R’ A B H

inch mm mm mm mm mm inch mm mm mm

3/4’’ 155 29 85 20 18 3/4’’ 148 46 152

1’’ 155 29 85 23 18 3/4’’ 148 46 152

Diagram 1. – Head loss

Head loss data resulting from a laboratory test carried out with clean water and 120 mesh filtration element.

TDS17304IT – rev.00 dated 04/07/2019

TDS n°: TDS17353IT

Rev. n°: 00

dated: 04/07/2019

Approved by: UTSCLN

Page 3/3

Applicable standards

Code Title Edition Certificate

Pipe threads where pressure tight joints are made on the threads - Part 1: Taper

UNI EN 10226-1 external threads and parallel internal threads - Dimensions, tolerances and 2006 ❑

designation

Use and/or assembly instructions

Threaded offtake:

1. In order to avoid leakage at low pressure, fasten the thread by using the Teflon (two rounds).

N.B. Place the filter in the flow direction shown by the body arrow.

Packaging

Table 3

Ref. Box Type

YDV 20 C

Notes and annexes

TDS17304IT – rev.00 dated 04/07/2019

You might also like

- Anchor Handling Tug Pre-Mob InspectionDocument8 pagesAnchor Handling Tug Pre-Mob Inspectiondndudc100% (1)

- Cajas Portavalvulas IrritecDocument3 pagesCajas Portavalvulas IrritecFrot OrellanaNo ratings yet

- 001.17033.000230 - Da001 - Rev 01 - CDocument70 pages001.17033.000230 - Da001 - Rev 01 - CSérgio RibeiroNo ratings yet

- Test Report: Dilip Buildcon LimitedDocument5 pagesTest Report: Dilip Buildcon LimitedRitesh TiwariNo ratings yet

- CM-04&05 Flow MeterDocument10 pagesCM-04&05 Flow MeterPortfolio TrackerNo ratings yet

- 7S10LEN00839 - Single Round 5 Adapter 25 I - TypeDocument4 pages7S10LEN00839 - Single Round 5 Adapter 25 I - TypeDen TseNo ratings yet

- 29.3 - A33760US-01-VDS - Rev 1Document3 pages29.3 - A33760US-01-VDS - Rev 1manuelarranoNo ratings yet

- L&t-Ut-Se-1678 - R1 30-03-2023Document1 pageL&t-Ut-Se-1678 - R1 30-03-2023SamirNo ratings yet

- FORJADOS S.A. (100536) : No. 2019 678/CC/1 Rev.0 DTD 16 Apr 2019Document13 pagesFORJADOS S.A. (100536) : No. 2019 678/CC/1 Rev.0 DTD 16 Apr 2019claudio veas cortesNo ratings yet

- Customer Information: Consolidated ReportDocument12 pagesCustomer Information: Consolidated Reportst.fernandez.ana78No ratings yet

- Material Test ReportDocument5 pagesMaterial Test ReportJuan Carlos Sua SuaNo ratings yet

- 1H18B0 - Water Accessories Booklet Rev. 2A PDFDocument258 pages1H18B0 - Water Accessories Booklet Rev. 2A PDFcnl filesNo ratings yet

- Valvulas de Compuerta 3-4 X 800Document3 pagesValvulas de Compuerta 3-4 X 800danielsalcedomringenierosNo ratings yet

- Pump-Out Plug: A) DescriptionDocument13 pagesPump-Out Plug: A) DescriptionROBERTO ANDRES SIZA REYNo ratings yet

- 15.0 IFU - Volumetric SetDocument2 pages15.0 IFU - Volumetric SetMamdouhNo ratings yet

- NT2-L3-M-000!21!00010 MS For Cleaning & Flushing of BOP Piping SystemDocument7 pagesNT2-L3-M-000!21!00010 MS For Cleaning & Flushing of BOP Piping SystemHuynh Thanh TamNo ratings yet

- Ydf Globo 1 PDFDocument3 pagesYdf Globo 1 PDFArnoldo Huertas garzonNo ratings yet

- Al-Iris E-25a-02-003 PDFDocument12 pagesAl-Iris E-25a-02-003 PDFHao TranNo ratings yet

- MountainShilajitresin Lab Reports 2019 SpectroDocument3 pagesMountainShilajitresin Lab Reports 2019 SpectroMayur PatelNo ratings yet

- Customer Information: Consolidated ReportDocument12 pagesCustomer Information: Consolidated Reportst.fernandez.ana78No ratings yet

- Manufacturing Certificate and MDR & DOSH Documentation TPI Certificate, Calculation and Drawing CertifiedDocument17 pagesManufacturing Certificate and MDR & DOSH Documentation TPI Certificate, Calculation and Drawing CertifiedNasrul HazimNo ratings yet

- ZQ200X200X 8 K S355 - 730229708 - 72 M - CorinthDocument3 pagesZQ200X200X 8 K S355 - 730229708 - 72 M - CorinthIonela Ionela100% (1)

- Test Rapport RTB30Document18 pagesTest Rapport RTB30Thomas Birch HansenNo ratings yet

- A3 Approved For Fabrication: Instrument ListDocument8 pagesA3 Approved For Fabrication: Instrument ListJuan Portilla cortezNo ratings yet

- DNV GL Certificate For Halton FDLDocument3 pagesDNV GL Certificate For Halton FDLNguyễn Tất ĐôngNo ratings yet

- PHTP-HT-4T07-26-835 Manual Sitrans TS500 PDFDocument394 pagesPHTP-HT-4T07-26-835 Manual Sitrans TS500 PDFAndres Mauricio GaleanoNo ratings yet

- DNV Accesory Approval 2023 02Document3 pagesDNV Accesory Approval 2023 02Jorge JuanNo ratings yet

- Certificado DNF HCB TANK 12423612Document1 pageCertificado DNF HCB TANK 12423612Ricardo VillarNo ratings yet

- Used Drill Pipe BuggyDocument4 pagesUsed Drill Pipe BuggyJohn DolanNo ratings yet

- Taf00000jm 3Document3 pagesTaf00000jm 3Will SohNo ratings yet

- SAILOR 6222 VHF DSC Class A EC Type Examination Module B NEMKO PDFDocument3 pagesSAILOR 6222 VHF DSC Class A EC Type Examination Module B NEMKO PDFlucas barriosNo ratings yet

- Pmi ReportDocument5 pagesPmi ReportMANIMARAN QCNo ratings yet

- Certificate of Approval NMI 14/3/1Document21 pagesCertificate of Approval NMI 14/3/1MjeriteljXNo ratings yet

- 7734 14 T6734R5Document22 pages7734 14 T6734R5Alexandre MorelNo ratings yet

- 27100-C Air PadsDocument16 pages27100-C Air PadsJason MaNo ratings yet

- 35.0 IFU - Buretta With NeedleDocument3 pages35.0 IFU - Buretta With NeedleMamdouhNo ratings yet

- Stress Calculation Stress Engineering Cover SheetDocument7 pagesStress Calculation Stress Engineering Cover SheetPappu Kishore KumarNo ratings yet

- EEW17.3.9.Pressure Test ReportDocument6 pagesEEW17.3.9.Pressure Test Reportmecon bhilaiNo ratings yet

- 1033 - 2018 Adt e All Air Conditioner Fin Temperature Sensor Kit (00000002)Document5 pages1033 - 2018 Adt e All Air Conditioner Fin Temperature Sensor Kit (00000002)JUAN MANUEL RUIZ BERMEJONo ratings yet

- Hazardous Waste Filtration System User Guide: Millipore Cat. No. YT30 142 HWDocument11 pagesHazardous Waste Filtration System User Guide: Millipore Cat. No. YT30 142 HWJUAN RAMIREZ MARTINEZNo ratings yet

- Ansul R-102 ManualDocument215 pagesAnsul R-102 ManualIvana NovitaNo ratings yet

- Line Traveler PHOENIXDocument21 pagesLine Traveler PHOENIXRuth DiazNo ratings yet

- Spirax Sarco - Non Return Valve Type DCV3Document4 pagesSpirax Sarco - Non Return Valve Type DCV3jimmiilongNo ratings yet

- R902447420 Trator JD 63CM Re240475Document21 pagesR902447420 Trator JD 63CM Re240475Rodrigues de OliveiraNo ratings yet

- 151VORILTCCertificate FullDocument3 pages151VORILTCCertificate Fullk ONo ratings yet

- 9368-18 Ges (Inox) 3fti-3 Aisi316l PN6 PDFDocument84 pages9368-18 Ges (Inox) 3fti-3 Aisi316l PN6 PDFFELIXENGIPLASCOMNo ratings yet

- Series TSW 210-310: SUCTION FILTER, Horizontal Tank Mounted Sheet No. 1905 JDocument4 pagesSeries TSW 210-310: SUCTION FILTER, Horizontal Tank Mounted Sheet No. 1905 Jsanjay0910No ratings yet

- L&t-Ut-Se-1675 - R1 30-03-2023Document1 pageL&t-Ut-Se-1675 - R1 30-03-2023SamirNo ratings yet

- File 1477563820Document10 pagesFile 1477563820QuintusNo ratings yet

- DNV GL enDocument2 pagesDNV GL enronaldusjansen1994No ratings yet

- 9 13 317 0aDocument6 pages9 13 317 0aPeerasut ChaisrimaneepanNo ratings yet

- EMC Pro1040 Pro1050 2182013 ODCùl ENDocument75 pagesEMC Pro1040 Pro1050 2182013 ODCùl ENTayfun SezişNo ratings yet

- WS 059Document4 pagesWS 059san2inNo ratings yet

- Infomation Wds Flow Controls TaiwanDocument8 pagesInfomation Wds Flow Controls TaiwanjuanrosonNo ratings yet

- DNV 3xxx Taa00001rwDocument4 pagesDNV 3xxx Taa00001rwtom7132414No ratings yet

- D62 - 691 - 5 - C4-Specification Sheets PDFDocument26 pagesD62 - 691 - 5 - C4-Specification Sheets PDFSoumiyaNo ratings yet

- ATEX Ex H ITS16ATEX101534X KM26Document4 pagesATEX Ex H ITS16ATEX101534X KM26ROGELIO QUIJANONo ratings yet

- Code of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7From EverandCode of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7No ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Adm Std. Specs-part2-Road StructuresDocument2 pagesAdm Std. Specs-part2-Road StructuresmujeebscribdNo ratings yet

- Multiply and Divide Polynomials, Distributive Property, and SubstitutionsDocument7 pagesMultiply and Divide Polynomials, Distributive Property, and SubstitutionsmujeebscribdNo ratings yet

- Gulf Precast GRCDocument12 pagesGulf Precast GRCmujeebscribdNo ratings yet

- Instructions - DM TestDocument1 pageInstructions - DM TestmujeebscribdNo ratings yet

- HDPE Lining Case StudyDocument9 pagesHDPE Lining Case StudymujeebscribdNo ratings yet

- PE-hydraulic Design of Liquid or Water Piping SystemDocument16 pagesPE-hydraulic Design of Liquid or Water Piping SystemmujeebscribdNo ratings yet

- Rotomolding Manholes - 2333Document20 pagesRotomolding Manholes - 2333mujeebscribdNo ratings yet

- PP For Generations - BorougeDocument30 pagesPP For Generations - BorougemujeebscribdNo ratings yet

- Rotomoulding Presentation PDFDocument80 pagesRotomoulding Presentation PDFmujeebscribdNo ratings yet

- A 703 - A 703M - 01 Qtcwmy0wmueDocument14 pagesA 703 - A 703M - 01 Qtcwmy0wmueJuan Sebastián Londoño MartínezNo ratings yet

- Astm A789Document6 pagesAstm A789shahid khan100% (1)

- AstmDocument6 pagesAstmJeetendra MhatreNo ratings yet

- STD 900Document16 pagesSTD 900Diego CondeNo ratings yet

- Bearing Number Id (MM) Od (MM) Width (MM) ID (Inch) OD (Inch) Width (Inch)Document12 pagesBearing Number Id (MM) Od (MM) Width (MM) ID (Inch) OD (Inch) Width (Inch)Bv Rao100% (3)

- Engineering Manual Expansion JointsDocument24 pagesEngineering Manual Expansion JointsbrockNo ratings yet

- ASTM A213 T22 ASME SA213 T22 Specification - 3 PDFDocument6 pagesASTM A213 T22 ASME SA213 T22 Specification - 3 PDFbagus asmoroNo ratings yet

- Heaton Valves BrochureDocument16 pagesHeaton Valves BrochureRian HilmawanNo ratings yet

- Cor Cote HTDocument4 pagesCor Cote HTlovaldes62No ratings yet

- Appendix E1 Ages SP 09 002Document13 pagesAppendix E1 Ages SP 09 002SandeepNBabuNo ratings yet

- Fig F611 F621 F626 Butterfly CraneFS DS 1702 P77 PDFDocument1 pageFig F611 F621 F626 Butterfly CraneFS DS 1702 P77 PDFmarchus09No ratings yet

- Vacuum Chambers: Installation and Operating GuideDocument9 pagesVacuum Chambers: Installation and Operating GuideMiie EmiieNo ratings yet

- Af Concrete Screw Anchor Tds 022018Document6 pagesAf Concrete Screw Anchor Tds 022018Orlando LopesNo ratings yet

- Welding Engineer Qa/Qc DepartmentDocument2 pagesWelding Engineer Qa/Qc DepartmentSendy MaulanaNo ratings yet

- J Matpr 2019 10 018Document4 pagesJ Matpr 2019 10 018Alagar SamyNo ratings yet

- Plastering Bead & Mesh: Stainless Steel and PvcuDocument12 pagesPlastering Bead & Mesh: Stainless Steel and PvcuSami LouisNo ratings yet

- Ivc Single Faced Sluice Gate Valve Valvula de CompuertaDocument14 pagesIvc Single Faced Sluice Gate Valve Valvula de CompuertaSurendra ReddyNo ratings yet

- 345 PDFDocument32 pages345 PDFTuntunNo ratings yet

- Invima Fonendoscopio RiesterDocument2 pagesInvima Fonendoscopio RiesterVanessa SalinasNo ratings yet

- Catalog + Fiber Laser Welding Machine + XT Laser AbelDocument13 pagesCatalog + Fiber Laser Welding Machine + XT Laser AbelLuciano Añorga ArmestarNo ratings yet

- Valve Series 33 MS-01-61Document6 pagesValve Series 33 MS-01-61kicsnerNo ratings yet

- XCO Drive Package - The Alternative To Stainless SteelDocument4 pagesXCO Drive Package - The Alternative To Stainless SteelSEW-Eurodrive PortugalNo ratings yet

- Nicored 182 PDFDocument1 pageNicored 182 PDFDương Quang KhánhNo ratings yet

- Brosur FontaDocument8 pagesBrosur FontaKawat Las FontaNo ratings yet

- BE19F02F012-Industrial Interaction ReportDocument38 pagesBE19F02F012-Industrial Interaction ReportSubodh DanaoNo ratings yet

- 17-4 Fi Us enDocument10 pages17-4 Fi Us ennaeem akramNo ratings yet

- Cladding & Overlay - Ni InstituteDocument24 pagesCladding & Overlay - Ni Institutesajid aslamNo ratings yet

- Suneal Pergola Brochure /PUIGMETAL®Document7 pagesSuneal Pergola Brochure /PUIGMETAL®PUIGMETAL®No ratings yet

- Astm A182Document6 pagesAstm A182Rayan AlfredNo ratings yet

- Welding Journal 1961 10Document157 pagesWelding Journal 1961 10AlexeyNo ratings yet