Professional Documents

Culture Documents

Astm A653a 653M 3

Astm A653a 653M 3

Uploaded by

Barbado BlancoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm A653a 653M 3

Astm A653a 653M 3

Uploaded by

Barbado BlancoCopyright:

Available Formats

A 653/A 653M

pattern that is produced on hot-dip zinc-coated steel sheet. tolerances in Specification A 924/A 924M that applies to the

3.2.7.1 Discussion—Zinc-iron alloy coating is composed order, that is, the table of thickness tolerances for 3⁄8-in.

entirely of inter-metallic alloys. It is typically produced by [10-mm] edge distance, or the table of thickness tolerances for

subjecting the hot-dip zinc-coated steel sheet to a thermal 1-in. [25-mm] edge distance.

treatment after it emerges from the molten zinc bath. This type 5.2.12 Coil size requirements (specify maximum outside

of coating is suitable for immediate painting without further diameter (OD), acceptable inside diameter (ID), and maximum

treatment except normal cleaning (refer to Guide D 2092). The weight [mass]),

lack of ductility of the alloy coating presents a potential for 5.2.13 Packaging,

powdering, etc. 5.2.14 Certification, if required, heat analysis and mechani-

cal property report,

4. Classification 5.2.15 Application (part identification and description), and

4.1 The material is available in several designations as 5.2.16 Special requirements (if any).

follows: 5.2.16.1 If required, the product may be ordered to a

4.1.1 Commercial steel (CS Types A, B, and C), specified base metal thickness (see Supplementary Require-

4.1.2 Forming steel (FS Types A and B), ment S1.)

4.1.3 Deep drawing steel (DDS),

NOTE 1—Typical ordering descriptions are as follows: steel sheet,

4.1.4 Extra deep drawing steel (EDDS), zinc-coated, commercial steel Type A, ASTM A 653, Coating Designation

4.1.5 Structural steel (SS), G 115, chemically treated, oiled, minimum 0.040 by 34 by 117 in., for

4.1.6 High strength low alloy steel (HSLAS Type A), and stock tanks, or steel sheet, zinc-coated, high strength low alloy steel Type

4.1.7 High strength low alloy steel (HSLAS Type B). A Grade 340, ASTM A 653M, Coating Designation Z275, minimized

4.2 Structural steel and high strength low alloy steel are spangle, not chemically treated, oiled, minimum 1.00 by 920 mm by coil,

available in several grades based on mechanical properties. 1520-mm maximum OD, 600-mm ID, 10 000-kg maximum, for tractor

inner fender.

Structural Steel Grade 50 [340] is available in three classes

NOTE 2—The purchaser should be aware that there are variations in

based on tensile strength. manufacturing practices among the producers and therefore is advised to

4.3 The material is available as either zinc-coated or zinc- establish the producer’s standard (or default) procedures for thickness

iron alloy-coated in several coating weights [masses] or tolerances.

coating designations as shown in Table 1, and

4.3.1 The material is available with the same or different 6. Chemical Composition

coating designations on each surface. 6.1 Base Metal:

6.1.1 The heat analysis of the base metal shall conform to

5. Ordering Information

the requirements shown in Table 2 for CS (Types A, B, and C),

5.1 Zinc-coated or zinc-iron alloy-coated sheet in coils and FS (Types A and B), DDS, and EDDS, and Table 3 for SS and

cut lengths is produced to thickness requirements expressed to HSLAS (Types A and B).

0.001 in. [0.01 mm]. The thickness of the sheet includes both 6.1.2 Each of the elements listed in Tables 2 and 3 shall be

the base metal and the coating. included in the report of heat analysis. When the amount of

5.2 Orders for product to this specification shall include the copper, nickel, chromium, or molybdenum is less than 0.02 %,

following information, as necessary, to adequately describe the report the analysis as either <0.02 % or the actual determined

desired product: value. When the amount of vanadium, titanium, or columbium

5.2.1 Name of product (steel sheet, zinc-coated (galvanized) is less than 0.008 %, report the analysis as either <0.008 % or

or zinc-iron alloy-coated (galvannealed)), the actual determined value.

5.2.2 Designation of sheet [CS (Types A, B, and C), FS 6.1.3 See Specification A 924/A 924M for chemical analy-

(Types A and B), DDS, EDDS, SS, or HSLAS (Types A and sis procedures and product analysis tolerances.

B)]. 6.2 Zinc Bath Analysis—The bath metal used in continuous

5.2.2.1 When a CS type is not specified, Type B will be hot-dip galvanizing shall contain not less than 99 % zinc.

furnished. When a FS type is not specified, FS Type B will be

furnished. NOTE 3—To control alloy formation and promote adhesion of the zinc

coating with the steel base metal, the molten coating metal composition

5.2.3 When a SS or HSLAS designation is specified, state normally contains a percentage of aluminum usually in the range from

the type, grade, or class, or combination thereof. 0.05 to 0.25. This aluminum is purposely supplied to the molten coating

5.2.4 ASTM designation number and year of issue, as A 653 bath, either as a specified ingredient in the zinc spelter or by the addition

for inch-pound units or A 653M for SI units. of a master alloy containing aluminum.

5.2.5 Coating designation,

5.2.6 Chemically treated or not chemically treated, 7. Mechanical Properties

5.2.7 Oiled or not oiled, 7.1 Structural steel and high-strength low-alloy steel shall

5.2.8 Minimized spangle (if required), conform to the mechanical property requirements in Table 4 for

5.2.9 Extra smooth (if required), the type, grade, or class, or all, specified.

5.2.10 Phosphatized (if required), 7.2 The typical mechanical properties for CS (Types A, B,

5.2.11 Dimensions (show thickness, minimum or nominal, and C), FS (Types A and B), DDS, and EDDS sheet designa-

width, flatness requirements, and length, if cut lengths). The tions are listed in Table 5. These mechanical property values

purchaser shall specify the appropriate table of thickness are nonmandatory. They are intended solely to provide the

3

COPYRIGHT ASTM International

Licensed by Information Handling Services

You might also like

- ASTM A792-10 Specification GalvalumeDocument6 pagesASTM A792-10 Specification GalvalumeSaurabh Gupta0% (1)

- Siemens Axiom Iconos X-Ray System - User ManualDocument238 pagesSiemens Axiom Iconos X-Ray System - User ManualЮрий ОгаревNo ratings yet

- Astm A653 1Document13 pagesAstm A653 1AlbertoNo ratings yet

- Asme Section Ii A-2 Sa-1008 Sa-1008mDocument10 pagesAsme Section Ii A-2 Sa-1008 Sa-1008mAnonymous GhPzn1xNo ratings yet

- Astm A792Document7 pagesAstm A792MJ100% (2)

- Astm A792 - A792m-09Document5 pagesAstm A792 - A792m-09masaud akhtar100% (1)

- Steel Sheet, 55 % Aluminum-Zinc Alloy-Coated by The Hot-Dip ProcessDocument6 pagesSteel Sheet, 55 % Aluminum-Zinc Alloy-Coated by The Hot-Dip ProcessJosé Ramón GutierrezNo ratings yet

- ASTM A 1008 A 1008M REV A 2006Document10 pagesASTM A 1008 A 1008M REV A 2006Jorge ToribioNo ratings yet

- Astm-A79210pdf PDFDocument6 pagesAstm-A79210pdf PDFLian HoaNo ratings yet

- STANDARD - ASTM A792 - Brief DescriptionDocument3 pagesSTANDARD - ASTM A792 - Brief DescriptionSeyong ParkNo ratings yet

- Steel, Sheet, Cold-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-Strength Low-Alloy With Improved Formability, Solution Hardened, and Bake HardenableDocument9 pagesSteel, Sheet, Cold-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-Strength Low-Alloy With Improved Formability, Solution Hardened, and Bake HardenableCarlos Ramirez BaltazarNo ratings yet

- A 1008 - A 1008M - 02 Qtewmdgtmdjfmq - PDFDocument7 pagesA 1008 - A 1008M - 02 Qtewmdgtmdjfmq - PDFTiến Lượng NguyễnNo ratings yet

- ASTM A 1008 A 1008M 2007a CanceladaDocument9 pagesASTM A 1008 A 1008M 2007a CanceladaHABEEB RAHMANNo ratings yet

- A 1008 - A 1008M - 04 Qtewmdgvqtewmdhnlvjfra - PDFDocument9 pagesA 1008 - A 1008M - 04 Qtewmdgvqtewmdhnlvjfra - PDFMarcos Verissimo Juca de PaulaNo ratings yet

- Steel Sheet, 55 % Aluminum-Zinc Alloy-Coated by The Hot-Dip ProcessDocument6 pagesSteel Sheet, 55 % Aluminum-Zinc Alloy-Coated by The Hot-Dip ProcessNilton Santillan OrtegaNo ratings yet

- Astm A 1008 Acero Al CarbonDocument9 pagesAstm A 1008 Acero Al CarbonMajo BárcenasNo ratings yet

- Astm A1008 Crc-CrsDocument9 pagesAstm A1008 Crc-CrshdierkeNo ratings yet

- Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip ProcessDocument13 pagesSteel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip ProcessjleikNo ratings yet

- A1008A1008M-03 (Replacing A 611)Document7 pagesA1008A1008M-03 (Replacing A 611)Thiên LongNo ratings yet

- A1008 373465-1Document9 pagesA1008 373465-1Jorge Andrés QuinteroNo ratings yet

- Astm A1008a1008m - 08Document9 pagesAstm A1008a1008m - 08Laboratório MateriaisNo ratings yet

- A 1008 - A 1008M - 00 Qtewmdgtmda - PDFDocument7 pagesA 1008 - A 1008M - 00 Qtewmdgtmda - PDFTiến Lượng NguyễnNo ratings yet

- A917 PDFDocument3 pagesA917 PDFSy Nguyen VietNo ratings yet

- 10-15961 2012 AMD2 Reff2022 Fixed.Document11 pages10-15961 2012 AMD2 Reff2022 Fixed.Duong Phuong DuyNo ratings yet

- Steel, Sheet, Cold-Rolled, Carbon, Structural, High-Strength Low-Alloy and High-Strength Low-Alloy With Improved FormabilityDocument7 pagesSteel, Sheet, Cold-Rolled, Carbon, Structural, High-Strength Low-Alloy and High-Strength Low-Alloy With Improved Formabilitynicole pampangaNo ratings yet

- A 929Document4 pagesA 929José Ramón GutierrezNo ratings yet

- Astm A 1008-A 1008M-04Document7 pagesAstm A 1008-A 1008M-04NilüferKarayel0% (1)

- Astm A 792Document6 pagesAstm A 792Mafer FbaNo ratings yet

- A792a792m 28998Document6 pagesA792a792m 28998sasdfsadasdasNo ratings yet

- Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip ProcessDocument13 pagesSteel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by The Hot-Dip ProcessKannanNo ratings yet

- Astm A 463-A 463M-02Document6 pagesAstm A 463-A 463M-02Anton Thomas Punzalan100% (4)

- Astm A653Document9 pagesAstm A653MEPNo ratings yet

- SDI, Steel Deck.Document13 pagesSDI, Steel Deck.Miguel LuqueNo ratings yet

- ASTM 653A Specification For Steel GalvanizedDocument9 pagesASTM 653A Specification For Steel GalvanizedCarlos, O BatistaNo ratings yet

- A 1008 - A 1008M - 01 Qtewmdgtmdfb PDFDocument7 pagesA 1008 - A 1008M - 01 Qtewmdgtmdfb PDFTiến Lượng NguyễnNo ratings yet

- Astm A 1008 - 2004 PDFDocument8 pagesAstm A 1008 - 2004 PDFdeepan govindasamyNo ratings yet

- Steel Sheet, Aluminum-Coated, by The Hot-Dip Process: Standard Specification ForDocument6 pagesSteel Sheet, Aluminum-Coated, by The Hot-Dip Process: Standard Specification ForOmar Marghani SalmaNo ratings yet

- Cold Rolled Steels - AK SteelDocument8 pagesCold Rolled Steels - AK SteelRuben HernandezNo ratings yet

- Astm A1011-A1011mDocument6 pagesAstm A1011-A1011mRAMIL100% (1)

- A 792 GalvalumeDocument5 pagesA 792 GalvalumeKapa SandeepNo ratings yet

- ASTM A653 - Standard Pec. For Steel, Galvanized by Hot Deep ProcessDocument9 pagesASTM A653 - Standard Pec. For Steel, Galvanized by Hot Deep ProcessibrahimNo ratings yet

- Norma AstmDocument8 pagesNorma AstmmaryconejoNo ratings yet

- Hot Dip Galvan Neal EdDocument6 pagesHot Dip Galvan Neal EdEstuardoANo ratings yet

- A 463 - A 463M - 02 - Qtq2my9bndyztqDocument7 pagesA 463 - A 463M - 02 - Qtq2my9bndyztqJOSE DE LA TORRENo ratings yet

- Astm A 366 (A1008)Document7 pagesAstm A 366 (A1008)Felipe De la cruzNo ratings yet

- A 463 - A 463M - 00 - Qtq2my0wmaDocument6 pagesA 463 - A 463M - 00 - Qtq2my0wmaJOSE DE LA TORRENo ratings yet

- Astm A1008 CRC Crs PDFDocument9 pagesAstm A1008 CRC Crs PDFArul Edwin VijayNo ratings yet

- Astm A101 PDFDocument8 pagesAstm A101 PDFtrjithinrajNo ratings yet

- Steel Sheet, Aluminum-Coated, by The Hot-Dip Process: Standard Specification ForDocument6 pagesSteel Sheet, Aluminum-Coated, by The Hot-Dip Process: Standard Specification ForRafael CossolinoNo ratings yet

- A308Document4 pagesA308alirioNo ratings yet

- Carbon and Alloy Steel Bars For SpringsDocument4 pagesCarbon and Alloy Steel Bars For Springsbb bamNo ratings yet

- Sheet Material Untuk Proses PressingDocument4 pagesSheet Material Untuk Proses PressingeltonNo ratings yet

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesFrom EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonRating: 4 out of 5 stars4/5 (1)

- 4 Canadian Wood-Frame House ConstructionDocument3 pages4 Canadian Wood-Frame House ConstructionBarbado BlancoNo ratings yet

- 5 Canadian Wood-Frame House ConstructionDocument3 pages5 Canadian Wood-Frame House ConstructionBarbado BlancoNo ratings yet

- Application Menu: Quick Access Toolbar:: RibbonDocument10 pagesApplication Menu: Quick Access Toolbar:: RibbonBarbado BlancoNo ratings yet

- Chapter Summary Chapter Test Questions Chapter Drawing ProjectsDocument10 pagesChapter Summary Chapter Test Questions Chapter Drawing ProjectsBarbado BlancoNo ratings yet

- Chapter Two: Circles and Drawing Aids Chapter Two: Circles and Drawing AidsDocument10 pagesChapter Two: Circles and Drawing Aids Chapter Two: Circles and Drawing AidsBarbado BlancoNo ratings yet

- Figure 1-26: Relative CoordinatesDocument10 pagesFigure 1-26: Relative CoordinatesBarbado BlancoNo ratings yet

- Subsection B: T-180 EvaluationDocument1 pageSubsection B: T-180 EvaluationBarbado BlancoNo ratings yet

- A360 16 Spec and Commentary 8Document1 pageA360 16 Spec and Commentary 8Barbado BlancoNo ratings yet

- Creating Flat and Complex Internal Tables Dynamically Using RTTI - Code Gallery - SCN WikiDocument3 pagesCreating Flat and Complex Internal Tables Dynamically Using RTTI - Code Gallery - SCN Wikiabdul.shaikNo ratings yet

- Temperature Humidity Sensor ChartDocument64 pagesTemperature Humidity Sensor Chartvyhtran4731100% (1)

- Sqlloader For OracleDocument10 pagesSqlloader For OraclehariprasathdbaNo ratings yet

- IEC 60400 - Tubos FluorecentesDocument82 pagesIEC 60400 - Tubos FluorecentesemilianoNo ratings yet

- Illustrated Parts List: 324 South Service Road, Unit 104 Melville NY 11747 TEL (631) 815-5520 FAX (631) 815-5526Document51 pagesIllustrated Parts List: 324 South Service Road, Unit 104 Melville NY 11747 TEL (631) 815-5520 FAX (631) 815-5526iwancalwohotmail.comNo ratings yet

- UENR2631-01 CDocument15 pagesUENR2631-01 CShanmuga PrakashNo ratings yet

- Lean Systems (Abridged)Document24 pagesLean Systems (Abridged)gttrans111No ratings yet

- FPL Brochure (2019!06!14 Final)Document2 pagesFPL Brochure (2019!06!14 Final)Sofia ForeroNo ratings yet

- MainBridge - Design ReportDocument18 pagesMainBridge - Design ReportWan100% (1)

- Periodical Maintenance When Using A VJ 1638 1638XDocument19 pagesPeriodical Maintenance When Using A VJ 1638 1638XAgence 3RNo ratings yet

- 3rd Quarter Summative TestDocument2 pages3rd Quarter Summative Testmaricel_ayingNo ratings yet

- THIELE Lashing ProductsDocument28 pagesTHIELE Lashing ProductsNixNo ratings yet

- EngineeringDocument7 pagesEngineeringapi-546649921No ratings yet

- Servo Motor ControlDocument72 pagesServo Motor ControlTien-Thinh NguyenNo ratings yet

- CATÁLOGO ACOPLES RÁPIDOS OPW LDocument2 pagesCATÁLOGO ACOPLES RÁPIDOS OPW LFRANCISCO BADILLONo ratings yet

- Chapter 7 - Stress - TransformationsDocument21 pagesChapter 7 - Stress - TransformationsroselleNo ratings yet

- Venturi Medium Sized (VMS) : ApplicationDocument8 pagesVenturi Medium Sized (VMS) : ApplicationChn TutkunNo ratings yet

- Introduction To Astronautics: Sissejuhatus KosmonautikasseDocument37 pagesIntroduction To Astronautics: Sissejuhatus Kosmonautikassegirithik14No ratings yet

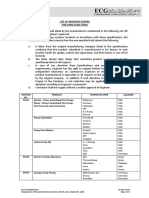

- Ecg Long Lead Items Vendor ListDocument2 pagesEcg Long Lead Items Vendor Listamr abdelmageedNo ratings yet

- Chapter 7 - Timber DesignDocument97 pagesChapter 7 - Timber DesignIqbarMaliki100% (2)

- Hyundai Hd-78 (Ремонт Китайского Редуктора Harbin)Document28 pagesHyundai Hd-78 (Ремонт Китайского Редуктора Harbin)Bigfair HD78100% (2)

- Thermal Expansion Loop - ML Loops ALLDocument6 pagesThermal Expansion Loop - ML Loops ALLPamela De Melo-LangfordNo ratings yet

- Cylindrical Cube WorksheetsDocument1 pageCylindrical Cube WorksheetsmarilenaamtestNo ratings yet

- CFD - Concept and ApplicationsDocument27 pagesCFD - Concept and ApplicationsTejas ShahNo ratings yet

- Relative VelocityDocument5 pagesRelative VelocityspreemouseNo ratings yet

- Curriculum VitaeDocument12 pagesCurriculum Vitaeاحمد العبيديNo ratings yet

- Coal Stockyard Storm Water TreatmentDocument23 pagesCoal Stockyard Storm Water TreatmentRajaram Jayaraman100% (1)

- Job Title: Software Development & Support Reports To: Senior Manager Location: Toronto, ONDocument1 pageJob Title: Software Development & Support Reports To: Senior Manager Location: Toronto, ONThomas RosickyNo ratings yet

- Oe 2Document2 pagesOe 2samratshergillNo ratings yet