Professional Documents

Culture Documents

FNC Brochure English 08 03

FNC Brochure English 08 03

Uploaded by

Vembi DwiCopyright:

Available Formats

You might also like

- Mitsubishi Lancer Evolution VII Workshop ManualDocument1,642 pagesMitsubishi Lancer Evolution VII Workshop ManualDiego Hernan PiñeiroNo ratings yet

- Tundish Cover Ladle NodularizingDocument2 pagesTundish Cover Ladle Nodularizingarnaldorcr8646No ratings yet

- Structure Works: R4 / BBR111, Bandar Bukit Raja 2, Klang, Selangor. 12. Structure WorksDocument3 pagesStructure Works: R4 / BBR111, Bandar Bukit Raja 2, Klang, Selangor. 12. Structure WorksRafee PieNo ratings yet

- USTER HVI Spectrum Measuring PrinciplesDocument45 pagesUSTER HVI Spectrum Measuring PrinciplesRAMARAMRAM100% (2)

- BS en Iso 16148-2016 PDFDocument38 pagesBS en Iso 16148-2016 PDFVuong Tran Van100% (1)

- Instruments Question BankDocument50 pagesInstruments Question Bankmomanbh100% (4)

- Propery of Indian SectionsDocument26 pagesPropery of Indian SectionsVasanthakumarNo ratings yet

- 1.isolated Foundation (Decon 2) Factor LoadDocument37 pages1.isolated Foundation (Decon 2) Factor LoadSrishti Project ConsultantsNo ratings yet

- Schrader - Hydraulic Cylinders ISO 6020-1Document9 pagesSchrader - Hydraulic Cylinders ISO 6020-1alvaromviegas_191514No ratings yet

- Concreto Armado 2: Predimensionamiento de ColumnasDocument7 pagesConcreto Armado 2: Predimensionamiento de ColumnasEdward Mejia LeonNo ratings yet

- Insert Bearing Flanged Unit With Round 4-Bolt Flange Housing, Set Screws, For Metric ShaftsDocument4 pagesInsert Bearing Flanged Unit With Round 4-Bolt Flange Housing, Set Screws, For Metric Shaftsmohamadelsb3No ratings yet

- Magnetic Coupling Torque Vs Air GapDocument4 pagesMagnetic Coupling Torque Vs Air GapDallie KurniawanNo ratings yet

- Wind Pressure and Load 55.55Document7 pagesWind Pressure and Load 55.55ethjetjetNo ratings yet

- DLKR Perairan RealDocument6 pagesDLKR Perairan RealuliNo ratings yet

- BS (85T 125T) JIS CatalogueDocument6 pagesBS (85T 125T) JIS CatalogueJONHHY NGUYEN DANGNo ratings yet

- Wind Pressure and Load 39Document7 pagesWind Pressure and Load 39ethjetjetNo ratings yet

- Torque Settings: Section 1 - General InformationDocument1 pageTorque Settings: Section 1 - General InformationNikNo ratings yet

- Alpha Marathon M12V70 Data SheetDocument2 pagesAlpha Marathon M12V70 Data SheetMontgomery George DentNo ratings yet

- Catalogo Da TEEJETDocument22 pagesCatalogo Da TEEJETRodrigoNo ratings yet

- Fit Current 25c 4Document2 pagesFit Current 25c 4xuyen tranNo ratings yet

- BLN 2022 Quo4Document3 pagesBLN 2022 Quo4Phyo Ko OoNo ratings yet

- Hitungan Mekanika Fluida Rev01Document19 pagesHitungan Mekanika Fluida Rev01misfat nawalNo ratings yet

- Ub H BeamsDocument6 pagesUb H BeamsKamal Elumalai100% (1)

- Universal Beam PropertiesDocument4 pagesUniversal Beam PropertiesniroshniroshNo ratings yet

- Insert Ball BearingsDocument26 pagesInsert Ball BearingsJason ZhouNo ratings yet

- SO 1550 F3 User ManualDocument18 pagesSO 1550 F3 User ManualLidya SukendroNo ratings yet

- Scooters India Limited, Lucknow Spare Part Price List (Two Wheeler) W.E.F. 25.02-2017Document23 pagesScooters India Limited, Lucknow Spare Part Price List (Two Wheeler) W.E.F. 25.02-2017Sk.Abdul NaveedNo ratings yet

- Beoncy ValveDocument20 pagesBeoncy Valvefirman harianjaNo ratings yet

- JIS ChannelsDocument5 pagesJIS ChannelsRuri IswadiNo ratings yet

- Deutz GeradoresDocument1 pageDeutz GeradoresDANE80No ratings yet

- Flange: 규격표 (ANSI Code)Document12 pagesFlange: 규격표 (ANSI Code)aliNo ratings yet

- Diagramas Columnas ETBAS2016Document152 pagesDiagramas Columnas ETBAS2016David GoñiNo ratings yet

- Format Log SheetDocument6 pagesFormat Log SheetAndika MfNo ratings yet

- Sharekhan LimitedDocument3 pagesSharekhan LimitedAnurag DandriyalNo ratings yet

- ABS BucklingDocument7 pagesABS BucklingOwoseni DareNo ratings yet

- Bulkling Check (P1420)Document3 pagesBulkling Check (P1420)ding liuNo ratings yet

- Cata - Flange ANSIDocument48 pagesCata - Flange ANSIZohaib RafiqNo ratings yet

- Cata - Flange ANSI - pdf1299758077 PDFDocument48 pagesCata - Flange ANSI - pdf1299758077 PDFNikhil PanchalNo ratings yet

- Stand 1HDocument30 pagesStand 1HSADMAN AOWALNo ratings yet

- MOTOR SUN3105E2 MTP 36 KW AT 2300RPM - 67C-P/23: 8574 NW 61 Street MIAMI FL 33166Document38 pagesMOTOR SUN3105E2 MTP 36 KW AT 2300RPM - 67C-P/23: 8574 NW 61 Street MIAMI FL 33166Angel Mendoza RodríguezNo ratings yet

- W Steel SheatDocument1 pageW Steel Sheatmohamed salahNo ratings yet

- Fairchild Medium Power MosfetsDocument1 pageFairchild Medium Power MosfetsAmirNo ratings yet

- Conn10a - Id MarkupDocument1 pageConn10a - Id MarkupAbdul basithNo ratings yet

- Z-Section Dimensions & Properties - MetsecDocument3 pagesZ-Section Dimensions & Properties - Metsecadil_khan648No ratings yet

- Calculo de Conductores E Interruptores Termomagneticos 380V, 60HzDocument7 pagesCalculo de Conductores E Interruptores Termomagneticos 380V, 60HzGUTARRA QUISPE OSCAR ALEXANDERNo ratings yet

- Batteries Ni-CD Saft SCL P - SCMDocument6 pagesBatteries Ni-CD Saft SCL P - SCMULTG T3GALNo ratings yet

- PIle Capacity Alpha Beta MethodDocument4 pagesPIle Capacity Alpha Beta Methodmasud parvegNo ratings yet

- Thread Pitch Chart PDFDocument2 pagesThread Pitch Chart PDFDarkvaderNo ratings yet

- C Purlin Data SheetDocument6 pagesC Purlin Data SheetAkhil VN100% (1)

- Aframax DataDocument2 pagesAframax DataVivek GuptaNo ratings yet

- Adani Steel Takeoff1Document10 pagesAdani Steel Takeoff1ranjitNo ratings yet

- Leeson - IEC Motor DataDocument4 pagesLeeson - IEC Motor DataEdderson NT100% (1)

- VerificationDocument10 pagesVerificationOmar OubahaNo ratings yet

- Dimensions Setional Properties Designation Mass (M) D B t T Sectional Area (a) Flange Slope (α) R R C I I rDocument4 pagesDimensions Setional Properties Designation Mass (M) D B t T Sectional Area (a) Flange Slope (α) R R C I I rRahul SolankiNo ratings yet

- Alc07 OffreDocument3 pagesAlc07 OffreCititoare NecunoscutăNo ratings yet

- Surge Tank Calculation (Optional)Document69 pagesSurge Tank Calculation (Optional)Laskar PejuangNo ratings yet

- General - Jacking PDFDocument1 pageGeneral - Jacking PDFCarlos Gaston Varrenti (LATAM)No ratings yet

- Inventario de ParabrisasDocument18 pagesInventario de ParabrisasDomo StoreNo ratings yet

- TATA Apron Feeder Main Frame TADocument14 pagesTATA Apron Feeder Main Frame TAMohammad AdilNo ratings yet

- KYK Pillow Block UCP & UCF PDFDocument1 pageKYK Pillow Block UCP & UCF PDFlaaliNo ratings yet

- Kyk Pillow Block Ucp & UcfDocument1 pageKyk Pillow Block Ucp & UcflaaliNo ratings yet

- Watchlist ExampleDocument1,406 pagesWatchlist Examplesourabh6chakrabort-1No ratings yet

- Master CatalougeDocument20 pagesMaster CatalougeCnzNo ratings yet

- United States Census Figures Back to 1630From EverandUnited States Census Figures Back to 1630No ratings yet

- UntitledDocument314 pagesUntitledVembi DwiNo ratings yet

- HRNT 95Document4 pagesHRNT 95Vembi DwiNo ratings yet

- Testing LA BatteriesDocument5 pagesTesting LA BatteriesVembi DwiNo ratings yet

- DR 101 - FNC 180M X 49cells X 2 RackDocument1 pageDR 101 - FNC 180M X 49cells X 2 RackVembi DwiNo ratings yet

- FNC VR BrochureDocument4 pagesFNC VR BrochureVembi DwiNo ratings yet

- Commissioning: of Stationary Nickel-Cadmium Batteries With FNC CellsDocument10 pagesCommissioning: of Stationary Nickel-Cadmium Batteries With FNC CellsVembi DwiNo ratings yet

- Abb Acs355 PDFDocument2 pagesAbb Acs355 PDFVembi DwiNo ratings yet

- Ds 404 ManualDocument25 pagesDs 404 ManualRoberto Padrino Garcia100% (1)

- General Description of Afbc BoilerDocument8 pagesGeneral Description of Afbc BoilerSaurabh Barange100% (1)

- AL-210 Technical Bulletin: VerSA-Flow™ Can and Drum Dispensing SystemsDocument15 pagesAL-210 Technical Bulletin: VerSA-Flow™ Can and Drum Dispensing SystemsSigma-AldrichNo ratings yet

- Aux Relay NRDocument5 pagesAux Relay NRSibolis NaburjuNo ratings yet

- Abap PDF ViewerDocument6 pagesAbap PDF Viewerccnicola2No ratings yet

- Joucomatic Ersatzteiliste 2010Document46 pagesJoucomatic Ersatzteiliste 2010Enrique MurgiaNo ratings yet

- Superinsulated Houses: William ShurcliffDocument24 pagesSuperinsulated Houses: William ShurcliffKnot NairNo ratings yet

- 2013 1357 Wang 02 WDocument15 pages2013 1357 Wang 02 WReinaldo Side JuniorNo ratings yet

- SOE - Sequence of EventsDocument9 pagesSOE - Sequence of EventsEdo AdityaNo ratings yet

- FCC 17 166a1Document539 pagesFCC 17 166a1Recode100% (1)

- Paper - 1: All India Open Test (Aiot) Jee AdvancedDocument24 pagesPaper - 1: All India Open Test (Aiot) Jee AdvancedNinad Akolekar100% (5)

- Used Water Submission ProceduresDocument26 pagesUsed Water Submission Procedurescloud6521100% (1)

- How To Claim Land and Not BuyDocument36 pagesHow To Claim Land and Not BuyJoshua Sygnal GutierrezNo ratings yet

- Precast/ Prestressed Concrete BuildingsDocument0 pagesPrecast/ Prestressed Concrete BuildingsDinh Tuat Trieu100% (1)

- CT, CVT, La IiDocument73 pagesCT, CVT, La IiSayender Yadav E100% (1)

- Hydro Crane Checlist PDFDocument1 pageHydro Crane Checlist PDFFandy AgitaNo ratings yet

- RFI-3409Daily Welding Inspection ReportDocument12 pagesRFI-3409Daily Welding Inspection ReportnguyennamxmNo ratings yet

- Document Management - White Paper (M-Files)Document46 pagesDocument Management - White Paper (M-Files)optical420100% (1)

- 348 - 38835 - BA124 - 2018 - 4 - 2 - 1 - Area and VolumeDocument13 pages348 - 38835 - BA124 - 2018 - 4 - 2 - 1 - Area and Volumephysics a2No ratings yet

- TeamViewer For Remote Control APK v10.0.2938 PDFDocument13 pagesTeamViewer For Remote Control APK v10.0.2938 PDFAnonymous LUIwju87ARNo ratings yet

- Comparision Between The PT and Normal Slab - by Aaqib ShoukatDocument13 pagesComparision Between The PT and Normal Slab - by Aaqib ShoukatAaqib ShoukatNo ratings yet

- 2007-Semi-Automatic Development of The Wbs For Construction ProjectDocument13 pages2007-Semi-Automatic Development of The Wbs For Construction ProjectariesNo ratings yet

- Primus FX-180-240-280 SpecificationsDocument2 pagesPrimus FX-180-240-280 Specificationsmairimsp2003No ratings yet

- A B C D E: Floor Plan Scale: 1:100MtsDocument5 pagesA B C D E: Floor Plan Scale: 1:100MtsMichaela Francess Abrasado AbalosNo ratings yet

FNC Brochure English 08 03

FNC Brochure English 08 03

Uploaded by

Vembi DwiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FNC Brochure English 08 03

FNC Brochure English 08 03

Uploaded by

Vembi DwiCopyright:

Available Formats

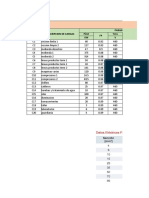

FNC® C A PA C I T I E S , D I M E N S I O N S A N D W E I G H T S

Capa- Dimensions Cell Cell Weight Electro- Capa- Dimensions Cell Cell Weight Electro-

city weight weight solid lyte city weight weight solid lyte

C5 with without electro- quantity C5 with without electro- quantity

electro- electro- lyte electro- electro- lyte

Type Length Width H eight lyte lyte Type Length Width H eight lyte lyte

Ah mm mm mm kg kg kg ltr. Ah mm mm mm kg kg kg ltr.

FNC 103 X 10 30 122 250 1.4 1.1 0.06 0.25 FNC 201 M 20 30 122 309 1.5 1.0 0.11 0.44

FNC 106 X 19 47 122 250 2.5 1.9 0.12 0.48 FNC 202 M 40 47 122 309 2.6 1.7 0.20 0.76

All details in this brochure are based on state-of-the-art technology. Our products are subject to constant development. We therefore reserve the right to make changes.

FNC 110 X 33 72 122 250 3.7 2.9 0.18 0.75 FNC 203 M 60 47 122 309 2.8 2.2 0.14 0.54

FNC 114 X 45 92 122 250 5.0 3.9 0.24 0.99 FNC 204 M 80 72 122 309 4.2 2.9 0.28 1.09

FNC 118 X 58 115 122 250 6.2 4.8 0.29 1.18 FNC 205 M 100 72 122 309 4.5 3.5 0.21 0.80

FNC 203 X 13 30 122 309 1.8 1.3 0.10 0.40 FNC 206 M 120 92 122 309 5.6 4.1 0.32 1.24

FNC 206 X 25 47 122 309 3.2 2.4 0.23 0.93 FNC 207 M 140 92 122 309 5.9 4.5 0.30 1.18

FNC 210 X 43 72 122 309 4.8 3.6 0.26 1.06 FNC 208 M 160 115 122 309 7.1 5.2 0.42 1.64

FNC 214 X 60 92 122 309 6.3 4.8 0.30 1.25 FNC 209 M 180 115 122 309 7.4 5.8 0.35 1.34

FNC 218 X 77 115 122 309 7.8 5.4 0.49 2.02 FNC 306 M 200 92 194 309 8.5 6.0 0.54 2.10

FNC 307 M 233 92 194 309 9.2 7.4 0.40 1.56

FNC 201 H 12 30 122 309 1.5 1.0 0.12 0.48 FNC 308 M 266 115 194 309 10.0 7.1 0.63 2.44

FNC 202 H 23 30 122 309 1.8 1.3 0.09 0.37 FNC 309 M 300 115 194 309 10.9 8.4 0.53 2.05

FNC 203 H 35 47 122 309 2.7 1.8 0.17 0.71 FNC 404 M 150 77 157 405 7.5 4.2 0.72 2.78

FNC 204 H 46 47 122 309 3.0 2.3 0.15 0.63 FNC 405 M 185 77 157 405 7.8 4.6 0.69 2.68

FNC 205 H 58 72 122 309 4.2 2.8 0.29 1.17 FNC 406 M 225 109 157 405 10.5 7.0 0.76 2.94

FNC 206 H 69 72 122 309 4.4 3.1 0.27 1.10 FNC 407 M 265 109 157 405 10.5 7.5 0.65 2.52

FNC 207 H 80 72 122 309 4.6 3.5 0.23 0.93 FNC 408 M 300 109 157 405 12.0 8.5 0.57 2.20

FNC 208 H 93 92 122 309 5.6 4.0 0.33 1.34 FNC 409 M 340 157 157 405 15.5 10.0 1.19 4.62

FNC 209 H 104 92 122 309 5.8 4.4 0.29 1.18 FNC 410 M 375 157 157 405 16.0 11.0 1.09 4.20

FNC 210 H 115 115 122 309 6.9 4.9 0.42 1.73 FNC 411 M 415 157 157 405 16.2 11.6 1.00 3.87

FNC 211 H 125 115 122 309 7.2 5.3 0.39 1.60 FNC 412 M 450 157 157 405 16.8 12.6 0.91 3.53

FNC 307 H 140 92 194 309 8.6 6.0 0.52 2.14

FNC 308 H 160 92 194 309 9.2 6.7 0.50 2.06

FNC 309 H 180 92 194 309 9.2 7.2 0.43 1.76 Capacities above 490 Ah to 1300 Ah available on request.

FNC 310 H 200 115 194 309 11.1 8.1 0.62 2.52

FNC 311 H 220 115 194 309 11.6 8.7 0.60 2.44

FNC 201 L 20 30 122 309 1.6 1.0 0.12 0.49

FNC 202 L 40 47 122 309 2.6 1.6 0.19 0.80

FNC 203 L 60 47 122 309 2.7 2.1 0.15 0.58

FNC 204 L 80 72 122 309 4.1 2.7 0.30 1.15

FNC 205 L 100 72 122 309 4.3 3.2 0.25 0.95

FNC 206 L 120 92 122 309 5.2 3.7 0.34 1.30

FNC 207 L 140 92 122 309 5.6 4.2 0.31 1.18

FNC 208 L 160 115 122 309 6.8 4.8 0.45 1.74

FNC 209 L 180 115 122 309 6.9 5.0 0.41 1.58

FNC 306 L 200 92 194 309 8.5 6.0 0.54 2.08

FNC 307 L 233 92 194 309 9.2 7.1 0.45 1.74

FNC 308 L 266 115 194 309 10.7 7.7 0.65 2.53

FNC 309 L 300 115 194 309 10.9 8.2 0.58 2.25

FNC 404 L 150 77 157 405 7.3 4.7 0.58 2.25

FNC 405 L 185 77 157 405 7.8 5.4 0.51 1.99

FNC 406 L 225 109 157 405 10.3 6.6 0.80 3.11

FNC 407 L 265 109 157 405 10.9 7.4 0.77 2.98

FNC 408 L 300 109 157 405 12.0 8.9 0.68 2.65

FNC 409 L 340 109 157 405 13.1 10.4 0.59 2.30

Form FNC® /02.2001/08.2003/3 H

FNC 410 L 375 157 157 405 15.3 10.0 1.15 4.45

FNC 411 L 415 157 157 405 15.8 10.6 1.13 4.37

FNC 412 L 450 157 157 405 16.5 11.7 1.05 4.08

FNC 413 L 490 157 157 405 17.1 12.8 0.94 3.66

Sales & Administration

HOPPECKE Batterien GmbH & Co. KG

P.O.Box 11 40 • D-59914 Brilon • Hotline 02961/97 06-2 14 • Fax 02961/97 06-2 51

POWER FROM INNOVATION e-mail: HOPPECKE.AB@t-online.de • www.hoppecke.com

Te l e c o m / I T B a t t e r y S y s t e m s

AGV Battery Systems

Motive Power Systems

Railway Battery Systems

Power Supply

®

FNC VENTED NICKEL-CADMIUM BAT TERIES Standby

POWER FROM INNOVATION

FNC® VENTED NICKEL-CADMIUM-BAT TERIES

Applications

FNC® batteries are used in a great variety of applications:

• In power stations and transformer plants

• In emergency power supply

• In telecommunication installations

• In off-the-line power supply plants and when using regenerative energies

• In signalling and control systems

• In starting emergency power units

Product features

Electrodes

The positive and negative electrodes consist of nickel fibre-structured elements with

graphite-free active material. The three-dimensional fibre structure comprising a nickel

fibre composite is extremely elastic. Mechanical stresses and volume changes during

charge/discharge cycles are therefore absorbed by the electrodes.

Separators

The positive electrodes are enveloped in microporous separators. The separators are

designed to ensure that the electrodes are properly separated and that they show low

internal resistance corresponding to the level of stress they are subjected to.

Cell connectors

The cell connectors are screwed onto the cells. This makes it easy to fit the connec-

tors. Fully insulated connectors are supplied on request. The connectors consist of

nickel-plated copper with a very low resistance.

Electrolyte

The electrolyte comprises diluted potassium hydroxide with a density of 1.19 kg/I at

20°C. The cells are delivered in a filled and charged state. For sea or air transport,

delivery in a dry, discharged condition is recommended. The electrolyte is then delive-

red separately packed and ready to fill or as dry electrolyte.

Container

The battery container is made of high resistant translucent polypropylene (PP). This

facilitates checking the electrolyte level. Material variations are possible. Container and

lid are welded together to prevent gas and electrolyte escaping. Special O-rings ensure

that the pole bushings are sealed properly.

FNC ® cells come in different

designs and are often used in Vent plugs

UPS stations. Back-fire resistant flip-top vent plugs are standard delivery.

Attributes

With continuous battery power supply with float charge FNC® batteries have a service

life of up to 20 years. Because of the graphite-free electrodes, no electrolyte change

is necessary during their entire service life. The FNC ® battery is also distinguished by

its cycle resistance (over 2000 cycles under DIN), its extremely low internal resistance

and a high energy density.

Advantages

Apart from long maintenance intervals and low life-cycle costs, the optional AquaGen®

vent plug provides an added advantage: At the corresponding charge voltage water

need only be topped up once during the entire service life.

The FNC® electrode structure with an active fibre length of more than 300 m per m3

with a free volume of 90% for the active material leads to low internal resistance and Dieser Text ist ein Blindtext. Wir

thus longer free maintenance intervals, high current loads and the option of applying möchten Ihnen damit einen Ein-

lower capacities in comparison to other systems. druck von der Gestaltung und

Wirkung des Werbemittels genau

The FNC® electrodes comprise pure active materials without any additives which makes vermitteln, ohne dabei bereits

an electrolyte change superfluous. This leads to a significant reduction in operating eine Diskussion über Textdetails

costs and a minimal burden on the environment. The high elasticity of the conducting auszulösen und weiter.

material ensures a high cycle resistance as well as a long service life. The thickness of

the electrodes can be varied from 0.8 to 10 mm, so all different performance types of

batteries (X, H, M, L according to IEC 623) can be built based on the fibre structured

electrode. Therefore the FNC® cell is the best choice for the best battery for every

application.

Recycling of old battery installations The section of the FNC® cell

clearly shows the corrugated

Lead and NC battery installations are recycled in Germany by Hoppecke according separator between the positive

to the corresponding environmental protection requirements. and negative plate.

The Hoppecke branches are happy to provide information.

You might also like

- Mitsubishi Lancer Evolution VII Workshop ManualDocument1,642 pagesMitsubishi Lancer Evolution VII Workshop ManualDiego Hernan PiñeiroNo ratings yet

- Tundish Cover Ladle NodularizingDocument2 pagesTundish Cover Ladle Nodularizingarnaldorcr8646No ratings yet

- Structure Works: R4 / BBR111, Bandar Bukit Raja 2, Klang, Selangor. 12. Structure WorksDocument3 pagesStructure Works: R4 / BBR111, Bandar Bukit Raja 2, Klang, Selangor. 12. Structure WorksRafee PieNo ratings yet

- USTER HVI Spectrum Measuring PrinciplesDocument45 pagesUSTER HVI Spectrum Measuring PrinciplesRAMARAMRAM100% (2)

- BS en Iso 16148-2016 PDFDocument38 pagesBS en Iso 16148-2016 PDFVuong Tran Van100% (1)

- Instruments Question BankDocument50 pagesInstruments Question Bankmomanbh100% (4)

- Propery of Indian SectionsDocument26 pagesPropery of Indian SectionsVasanthakumarNo ratings yet

- 1.isolated Foundation (Decon 2) Factor LoadDocument37 pages1.isolated Foundation (Decon 2) Factor LoadSrishti Project ConsultantsNo ratings yet

- Schrader - Hydraulic Cylinders ISO 6020-1Document9 pagesSchrader - Hydraulic Cylinders ISO 6020-1alvaromviegas_191514No ratings yet

- Concreto Armado 2: Predimensionamiento de ColumnasDocument7 pagesConcreto Armado 2: Predimensionamiento de ColumnasEdward Mejia LeonNo ratings yet

- Insert Bearing Flanged Unit With Round 4-Bolt Flange Housing, Set Screws, For Metric ShaftsDocument4 pagesInsert Bearing Flanged Unit With Round 4-Bolt Flange Housing, Set Screws, For Metric Shaftsmohamadelsb3No ratings yet

- Magnetic Coupling Torque Vs Air GapDocument4 pagesMagnetic Coupling Torque Vs Air GapDallie KurniawanNo ratings yet

- Wind Pressure and Load 55.55Document7 pagesWind Pressure and Load 55.55ethjetjetNo ratings yet

- DLKR Perairan RealDocument6 pagesDLKR Perairan RealuliNo ratings yet

- BS (85T 125T) JIS CatalogueDocument6 pagesBS (85T 125T) JIS CatalogueJONHHY NGUYEN DANGNo ratings yet

- Wind Pressure and Load 39Document7 pagesWind Pressure and Load 39ethjetjetNo ratings yet

- Torque Settings: Section 1 - General InformationDocument1 pageTorque Settings: Section 1 - General InformationNikNo ratings yet

- Alpha Marathon M12V70 Data SheetDocument2 pagesAlpha Marathon M12V70 Data SheetMontgomery George DentNo ratings yet

- Catalogo Da TEEJETDocument22 pagesCatalogo Da TEEJETRodrigoNo ratings yet

- Fit Current 25c 4Document2 pagesFit Current 25c 4xuyen tranNo ratings yet

- BLN 2022 Quo4Document3 pagesBLN 2022 Quo4Phyo Ko OoNo ratings yet

- Hitungan Mekanika Fluida Rev01Document19 pagesHitungan Mekanika Fluida Rev01misfat nawalNo ratings yet

- Ub H BeamsDocument6 pagesUb H BeamsKamal Elumalai100% (1)

- Universal Beam PropertiesDocument4 pagesUniversal Beam PropertiesniroshniroshNo ratings yet

- Insert Ball BearingsDocument26 pagesInsert Ball BearingsJason ZhouNo ratings yet

- SO 1550 F3 User ManualDocument18 pagesSO 1550 F3 User ManualLidya SukendroNo ratings yet

- Scooters India Limited, Lucknow Spare Part Price List (Two Wheeler) W.E.F. 25.02-2017Document23 pagesScooters India Limited, Lucknow Spare Part Price List (Two Wheeler) W.E.F. 25.02-2017Sk.Abdul NaveedNo ratings yet

- Beoncy ValveDocument20 pagesBeoncy Valvefirman harianjaNo ratings yet

- JIS ChannelsDocument5 pagesJIS ChannelsRuri IswadiNo ratings yet

- Deutz GeradoresDocument1 pageDeutz GeradoresDANE80No ratings yet

- Flange: 규격표 (ANSI Code)Document12 pagesFlange: 규격표 (ANSI Code)aliNo ratings yet

- Diagramas Columnas ETBAS2016Document152 pagesDiagramas Columnas ETBAS2016David GoñiNo ratings yet

- Format Log SheetDocument6 pagesFormat Log SheetAndika MfNo ratings yet

- Sharekhan LimitedDocument3 pagesSharekhan LimitedAnurag DandriyalNo ratings yet

- ABS BucklingDocument7 pagesABS BucklingOwoseni DareNo ratings yet

- Bulkling Check (P1420)Document3 pagesBulkling Check (P1420)ding liuNo ratings yet

- Cata - Flange ANSIDocument48 pagesCata - Flange ANSIZohaib RafiqNo ratings yet

- Cata - Flange ANSI - pdf1299758077 PDFDocument48 pagesCata - Flange ANSI - pdf1299758077 PDFNikhil PanchalNo ratings yet

- Stand 1HDocument30 pagesStand 1HSADMAN AOWALNo ratings yet

- MOTOR SUN3105E2 MTP 36 KW AT 2300RPM - 67C-P/23: 8574 NW 61 Street MIAMI FL 33166Document38 pagesMOTOR SUN3105E2 MTP 36 KW AT 2300RPM - 67C-P/23: 8574 NW 61 Street MIAMI FL 33166Angel Mendoza RodríguezNo ratings yet

- W Steel SheatDocument1 pageW Steel Sheatmohamed salahNo ratings yet

- Fairchild Medium Power MosfetsDocument1 pageFairchild Medium Power MosfetsAmirNo ratings yet

- Conn10a - Id MarkupDocument1 pageConn10a - Id MarkupAbdul basithNo ratings yet

- Z-Section Dimensions & Properties - MetsecDocument3 pagesZ-Section Dimensions & Properties - Metsecadil_khan648No ratings yet

- Calculo de Conductores E Interruptores Termomagneticos 380V, 60HzDocument7 pagesCalculo de Conductores E Interruptores Termomagneticos 380V, 60HzGUTARRA QUISPE OSCAR ALEXANDERNo ratings yet

- Batteries Ni-CD Saft SCL P - SCMDocument6 pagesBatteries Ni-CD Saft SCL P - SCMULTG T3GALNo ratings yet

- PIle Capacity Alpha Beta MethodDocument4 pagesPIle Capacity Alpha Beta Methodmasud parvegNo ratings yet

- Thread Pitch Chart PDFDocument2 pagesThread Pitch Chart PDFDarkvaderNo ratings yet

- C Purlin Data SheetDocument6 pagesC Purlin Data SheetAkhil VN100% (1)

- Aframax DataDocument2 pagesAframax DataVivek GuptaNo ratings yet

- Adani Steel Takeoff1Document10 pagesAdani Steel Takeoff1ranjitNo ratings yet

- Leeson - IEC Motor DataDocument4 pagesLeeson - IEC Motor DataEdderson NT100% (1)

- VerificationDocument10 pagesVerificationOmar OubahaNo ratings yet

- Dimensions Setional Properties Designation Mass (M) D B t T Sectional Area (a) Flange Slope (α) R R C I I rDocument4 pagesDimensions Setional Properties Designation Mass (M) D B t T Sectional Area (a) Flange Slope (α) R R C I I rRahul SolankiNo ratings yet

- Alc07 OffreDocument3 pagesAlc07 OffreCititoare NecunoscutăNo ratings yet

- Surge Tank Calculation (Optional)Document69 pagesSurge Tank Calculation (Optional)Laskar PejuangNo ratings yet

- General - Jacking PDFDocument1 pageGeneral - Jacking PDFCarlos Gaston Varrenti (LATAM)No ratings yet

- Inventario de ParabrisasDocument18 pagesInventario de ParabrisasDomo StoreNo ratings yet

- TATA Apron Feeder Main Frame TADocument14 pagesTATA Apron Feeder Main Frame TAMohammad AdilNo ratings yet

- KYK Pillow Block UCP & UCF PDFDocument1 pageKYK Pillow Block UCP & UCF PDFlaaliNo ratings yet

- Kyk Pillow Block Ucp & UcfDocument1 pageKyk Pillow Block Ucp & UcflaaliNo ratings yet

- Watchlist ExampleDocument1,406 pagesWatchlist Examplesourabh6chakrabort-1No ratings yet

- Master CatalougeDocument20 pagesMaster CatalougeCnzNo ratings yet

- United States Census Figures Back to 1630From EverandUnited States Census Figures Back to 1630No ratings yet

- UntitledDocument314 pagesUntitledVembi DwiNo ratings yet

- HRNT 95Document4 pagesHRNT 95Vembi DwiNo ratings yet

- Testing LA BatteriesDocument5 pagesTesting LA BatteriesVembi DwiNo ratings yet

- DR 101 - FNC 180M X 49cells X 2 RackDocument1 pageDR 101 - FNC 180M X 49cells X 2 RackVembi DwiNo ratings yet

- FNC VR BrochureDocument4 pagesFNC VR BrochureVembi DwiNo ratings yet

- Commissioning: of Stationary Nickel-Cadmium Batteries With FNC CellsDocument10 pagesCommissioning: of Stationary Nickel-Cadmium Batteries With FNC CellsVembi DwiNo ratings yet

- Abb Acs355 PDFDocument2 pagesAbb Acs355 PDFVembi DwiNo ratings yet

- Ds 404 ManualDocument25 pagesDs 404 ManualRoberto Padrino Garcia100% (1)

- General Description of Afbc BoilerDocument8 pagesGeneral Description of Afbc BoilerSaurabh Barange100% (1)

- AL-210 Technical Bulletin: VerSA-Flow™ Can and Drum Dispensing SystemsDocument15 pagesAL-210 Technical Bulletin: VerSA-Flow™ Can and Drum Dispensing SystemsSigma-AldrichNo ratings yet

- Aux Relay NRDocument5 pagesAux Relay NRSibolis NaburjuNo ratings yet

- Abap PDF ViewerDocument6 pagesAbap PDF Viewerccnicola2No ratings yet

- Joucomatic Ersatzteiliste 2010Document46 pagesJoucomatic Ersatzteiliste 2010Enrique MurgiaNo ratings yet

- Superinsulated Houses: William ShurcliffDocument24 pagesSuperinsulated Houses: William ShurcliffKnot NairNo ratings yet

- 2013 1357 Wang 02 WDocument15 pages2013 1357 Wang 02 WReinaldo Side JuniorNo ratings yet

- SOE - Sequence of EventsDocument9 pagesSOE - Sequence of EventsEdo AdityaNo ratings yet

- FCC 17 166a1Document539 pagesFCC 17 166a1Recode100% (1)

- Paper - 1: All India Open Test (Aiot) Jee AdvancedDocument24 pagesPaper - 1: All India Open Test (Aiot) Jee AdvancedNinad Akolekar100% (5)

- Used Water Submission ProceduresDocument26 pagesUsed Water Submission Procedurescloud6521100% (1)

- How To Claim Land and Not BuyDocument36 pagesHow To Claim Land and Not BuyJoshua Sygnal GutierrezNo ratings yet

- Precast/ Prestressed Concrete BuildingsDocument0 pagesPrecast/ Prestressed Concrete BuildingsDinh Tuat Trieu100% (1)

- CT, CVT, La IiDocument73 pagesCT, CVT, La IiSayender Yadav E100% (1)

- Hydro Crane Checlist PDFDocument1 pageHydro Crane Checlist PDFFandy AgitaNo ratings yet

- RFI-3409Daily Welding Inspection ReportDocument12 pagesRFI-3409Daily Welding Inspection ReportnguyennamxmNo ratings yet

- Document Management - White Paper (M-Files)Document46 pagesDocument Management - White Paper (M-Files)optical420100% (1)

- 348 - 38835 - BA124 - 2018 - 4 - 2 - 1 - Area and VolumeDocument13 pages348 - 38835 - BA124 - 2018 - 4 - 2 - 1 - Area and Volumephysics a2No ratings yet

- TeamViewer For Remote Control APK v10.0.2938 PDFDocument13 pagesTeamViewer For Remote Control APK v10.0.2938 PDFAnonymous LUIwju87ARNo ratings yet

- Comparision Between The PT and Normal Slab - by Aaqib ShoukatDocument13 pagesComparision Between The PT and Normal Slab - by Aaqib ShoukatAaqib ShoukatNo ratings yet

- 2007-Semi-Automatic Development of The Wbs For Construction ProjectDocument13 pages2007-Semi-Automatic Development of The Wbs For Construction ProjectariesNo ratings yet

- Primus FX-180-240-280 SpecificationsDocument2 pagesPrimus FX-180-240-280 Specificationsmairimsp2003No ratings yet

- A B C D E: Floor Plan Scale: 1:100MtsDocument5 pagesA B C D E: Floor Plan Scale: 1:100MtsMichaela Francess Abrasado AbalosNo ratings yet