Professional Documents

Culture Documents

Fosroc Nitocote HT120: Constructive Solutions

Fosroc Nitocote HT120: Constructive Solutions

Uploaded by

Vincent JavateOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fosroc Nitocote HT120: Constructive Solutions

Fosroc Nitocote HT120: Constructive Solutions

Uploaded by

Vincent JavateCopyright:

Available Formats

Fosroc Nitocote HT120 constructive solutions

Solvent free, novel resin coating, resistant to

temperatures up to 120°C

Uses Properties

Protective coating for concrete and steel used for high Solids by weight : 100%

temperature service conditions up to 120°C. It is particularly Specific gravity : approx. 1.55 (mixed)

useful to resist boiling water under continuous or partial Pot life : 180 mins @ 23°C

service conditions in areas like: : 90 mins @ 35°C

Power stations : 40 mins @ 45°C

Drying time @ 23°C @ 35°C

Water treatment plants Touch dry : 6-8 hours 3 hours

Desalination plants Recoatable : 8-20 hours 4-14 hours

Full cure : 7 days 4 days

Boiling water tanks Bond strength after 600

hours water boil

Advantages ASTM D4541 : 4.5 N/mm2 concrete failure

Resistant to boiling water under continuous service Physical effects after

conditions 600 hours water boil : No cracking, chalking,

softening, blistering or

Resistant to thermal shocks and freeze-thaw cycles

debonding

Abrasion and corrosion resistant

Chemical resistance :

Resistant to sea water

Alkalis

Resistant to oils Sodium hydroxide (sat.) : Excellent

Can be applied directly on prepared substrate without

Aqueous solutions

using a primer

Chlorinated water : Excellent

High build application

Tap water : Excellent

Smooth, glossy, easy to clean surface Distilled water : Excellent

Low cost service life - resistant to mould growth Sea water : Excellent

Easy to apply, solvent free formulation makes it suitable Sugar solution (sat.) : Excellent

for use in confined spaces Glucose syrup (80%) : Excellent

Salt solution (sat.) : Excellent

Description Starch solution : Excellent

Nitocote HT120 is a two pack, solvent free, resin material. It Others

is supplied in pre-measured quantities ready for site mixing Sewage water : Excellent

and use. The material cures to provide a smooth, tough and Marsh water : Excellent

resistant finish. It is available in dark grey colour.

Please consult your local Fosroc office for details on various

chemicals and operating conditions.

Design criteria

Nitocote HT120 is designed to be applied in two coats to

achieve a minimum total dry film thickness of 400 microns.

To achieve the correct protective properties, Nitocote HT120

must be applied on to the substrate at the coverage rates

recommended.

Nitocote HT120

Fosroc Nitocote HT120

Instructions for use Application

Preparation The minimum application temperature is 5°C.

Concrete surfaces All surfaces should be treated with two coats of Nitocote HT120.

All surfaces must be smooth, sound and free from debris, The thoroughly mixed material should be applied with a

loose or flaking material and areas of standing water. Surfaces suitable brush, roller or spray.

must be free from contamination such as oil, grease and

The first coat must be firmly applied and be well scrubbed into

organic growth. Concrete surfaces must be fully cured, laitance

the surface, ensuring a uniform coating with a wet film

free and free from any traces of shutter release oils and curing

thickness not less than 200 microns. The first coat should be

compounds.

allowed to dry for not less than 3 hours and not more than 14

To achieve the above it is recommended that the substrate hours at 35°C.

should be grit blasted which will also provide a suitable key for

The second coat should be applied exactly as above, again

Nitocote HT120.

achieving a wet film thickness not less than 200 microns.

All blow holes and imperfections should be filled with

For cold weather working, it is recommended that Nitocote

Nitomortar FC*† or Nitomortar FC(B)*†. Consult the local data

HT120 be stored in a heated building and removed

sheet for pot life and overcoating time.

immediately before use, as workability deteriorates and curing

Steel surfaces times increase at lower temperatures.

All surfaces should be grit blasted to meet the requirements of Cleaning

BS 4232, First Quality. The lining work should be programmed

Nitocote HT120 should be removed from tools and equipment

so that newly cleaned steel is coated as soon as possible

with Fosroc Solvent 102 immediately after use. Cured material

before the formation of rust or scale.

can only be removed mechanically.

Mixing

Limitations

The contents of the base can should be stirred thoroughly to

disperse any settlement. The entire contents of the hardener - Nitocote HT120 is formulated for application to clean, sound

can should be added to the base container and mixed concrete and steel.

thoroughly until a uniform consistency is obtained, taking

- Nitocote HT120 should not be applied over existing

particular care to scrape the sides and bottom of the container.

coatings.

It is recommended that mechanical mixing be employed, using

a Fosroc Mixing Paddle (MR2) on a heavy duty, slow speed - Application should not be undertaken if the temperature is

electric drill. Mixing should be carried out continuously for a below 5°C, or is 5°C and falling.

minimum of 3 minutes.

- In conditions of high relative humidity i.e. 85-90% good

ventilation conditions are essential. Substrate temperature

should be at least 3ºC above dew point.

- Although Nitocote HT120 may be applied to damp concrete,

there must be no standing or running water.

- Nitocote HT120 is not colour stable when exposed to direct

sunlight or when in contact with some chemicals such

as acids and oxidising agents.

Nitocote HT120 - Page 2 of 4

Fosroc Nitocote HT120

Technical support Precautions

Fosroc offers a comprehensive technical support service to Health and safety

specifiers, end users and contractors. It is also able to offer on-

Nitocote HT120 and Fosroc Solvent 102 should not come in

site technical assistance, an AutoCAD facility and dedicated

contact with the skin and eyes, or be swallowed. When using

specification assistance in locations all over the world.

Fosroc Solvent 102 ensure adequate ventilation and avoid

inhalation of vapour. Some people are sensitive to resins,

Estimating

hardeners and solvent.

Supply

Wear suitable protective clothing, gloves and eye protection.

Nitocote HT120 : 4 litre packs

The use of barrier creams provides additional skin protection.

Fosroc Solvent 102 : 5 litre cans

In case of contact with the skin, rinse with plenty of clean

Coverage water, then cleanse with soap and water. Do not use solvent.

Nitocote HT120 : 5.00 m2/litre In case of contact with eyes, rinse immediately with plenty of

@ 200 microns wft per coat clean water and seek medical advice. If swallowed, seek

Note: The coverage figure is theoretical – due to wastage medical attention immediately – do not induce vomiting.

factors and the variety and nature of substrates, practical Fire

coverage figures may be substantially reduced.

Nitocote HT120 is non-flammable.

Storage Fosroc Solvent 102 is flammable. Keep away from sources of

Shelf life ignition. No smoking. In the event of fire, extinguish with CO2

or foam. Do not use a water jet.

All products have a shelf life of 12 months if kept in a dry, air

conditioned store between 5°C and 30°C in the original, Flash point

unopened containers. Fosroc Solvent 102 : 33°C

Storage conditions For further information, refer to the Product Material Safety

Data Sheet.

Store in dry conditions at temperatures between 5°C and 30°C

in the original, unopened containers. If stored at high

temperatures the shelf life will be reduced. Air conditioned

storage at high ambient temperatures is recommended.

Nitocote HT120 - Page 3 of 4

Fosroc Nitocote HT120

Additional Information

Fosroc manufactures a wide range of complementary

products which include :

waterproofing membranes & waterstops

joint sealants & filler boards

cementitious & epoxy grouts

specialised flooring materials

Fosroc additionally offers a comprehensive package of

products specifically designed for the repair and

refurbishment of damaged concrete. Fosroc’s ‘Systematic

Approach’ to concrete repair features the following :

hand-placed repair mortars

spray grade repair mortars

fluid micro-concretes

chemically resistant epoxy mortars

anti-carbonation/anti-chloride protective coatings

chemical and abrasion resistant coatings

For further information on any of the above, please consult

your local Fosroc office - as below.

* Denotes the trademark of Fosroc International Limited

†

See separate data sheet

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard Conditions for

the Supply of Goods and Service. All Fosroc datasheets are updated on a regular basis. It is the user’s responsibility to

obtain the latest version.

Head Office

telephone: (+9714) 2039699 fax: (+9714) 2859649 email: agf@fosroc.com

Al Gurg Fosroc LLC

Regional offices

Post Box 657, Dubai Abu Dhabi, Al Gurg Fosroc telephone: 673 1779 fax: 673 1449 email: abudhabi@fosroc.com

United Arab Emirates Bahrain, YBA Kanoo telephone: 17738200 fax: 17732828 email: bahrain@fosroc.com

Kuwait, Boodai telephone: 4817618 fax: 4832124 email: kuwait@fosroc.com

www.fosroc.com

Oman, Al Amana telephone: 24815080 fax: 24817554 email: oman@fosroc.com

Qatar, Tadmur telephone: 4432365 fax: 4419517 email: qatar@fosroc.com

UAE/0386/11/E

You might also like

- Durapol UHT (Spray Grade) - 2014 PDFDocument2 pagesDurapol UHT (Spray Grade) - 2014 PDFEngTamerNo ratings yet

- Nitocote HT120: Constructive SolutionsDocument3 pagesNitocote HT120: Constructive SolutionsSHAIK ASIMUDDINNo ratings yet

- Fosroc Nitocote ET402: Constructive SolutionsDocument4 pagesFosroc Nitocote ET402: Constructive SolutionsVJ QatarNo ratings yet

- Nitocote ET402 : Constructive SolutionsDocument4 pagesNitocote ET402 : Constructive Solutionsnoto.sugiartoNo ratings yet

- Nitocote ET402 : Coal Tar Extended Epoxy Resin CoatingDocument4 pagesNitocote ET402 : Coal Tar Extended Epoxy Resin CoatingmaninambiramNo ratings yet

- Nitocote EP405: Constructive SolutionsDocument4 pagesNitocote EP405: Constructive SolutionsrayNo ratings yet

- Nitocote EP405: Constructive SolutionsDocument4 pagesNitocote EP405: Constructive SolutionsAdil Budiyanto SiagianNo ratings yet

- TDS Fosroc Nitocote EP405 SEADocument4 pagesTDS Fosroc Nitocote EP405 SEAPT PP BIH SanurNo ratings yet

- Diaoxy Hi-Build Amine Cured EpoxyDocument4 pagesDiaoxy Hi-Build Amine Cured Epoxybublooo123No ratings yet

- Quick Dry SatinwoodDocument3 pagesQuick Dry SatinwoodAMER SALEEMNo ratings yet

- 1.DiaAcryl 2K Polyurethane Finish (3.8+0.8)Document4 pages1.DiaAcryl 2K Polyurethane Finish (3.8+0.8)bublooo123No ratings yet

- Nitocote EP405Document4 pagesNitocote EP405mangjitNo ratings yet

- Epoxy Coating K Sir 88Document2 pagesEpoxy Coating K Sir 88ANIBALLOPEZVEGANo ratings yet

- Fosroc Nitomortar S: Constructive SolutionsDocument4 pagesFosroc Nitomortar S: Constructive SolutionsVincent JavateNo ratings yet

- Durapol Coating For Amines EtcDocument2 pagesDurapol Coating For Amines EtckermadaxNo ratings yet

- Epoxy Repair PDFDocument1 pageEpoxy Repair PDFASTAM DEVNo ratings yet

- Diaoxy Hi-Build Zinc Phosphate Epoxy PrimerDocument4 pagesDiaoxy Hi-Build Zinc Phosphate Epoxy Primerbublooo123No ratings yet

- Strongcoat HB400Document4 pagesStrongcoat HB400osama mohNo ratings yet

- Fosroc Nitoflor TF120 UB: Constructive SolutionsDocument4 pagesFosroc Nitoflor TF120 UB: Constructive SolutionstalatzahoorNo ratings yet

- Nitomortar SDocument4 pagesNitomortar SMansoor AliNo ratings yet

- Sika Poxitar MyDocument3 pagesSika Poxitar Myhijur ChenNo ratings yet

- Datasheet File Nitoflor FC150Document4 pagesDatasheet File Nitoflor FC150hendra wahyuNo ratings yet

- Strongcoat HB400Document53 pagesStrongcoat HB400irfan shafiqueNo ratings yet

- Nitocote PE135 UAEDocument2 pagesNitocote PE135 UAESanthosh ParanjothiNo ratings yet

- PDS Hempadur Multi-Strength 35842 en-GBDocument2 pagesPDS Hempadur Multi-Strength 35842 en-GBIfrahimNo ratings yet

- Nitocote PE135 PDFDocument2 pagesNitocote PE135 PDFSuresh BabuNo ratings yet

- Bipigard Coaltar Finish PDFDocument2 pagesBipigard Coaltar Finish PDFKhirod KroutNo ratings yet

- Ultra Cote 401 HsDocument3 pagesUltra Cote 401 HsGilbert Dela Serna IINo ratings yet

- Fosroc Nitomortar 908 TDSDocument2 pagesFosroc Nitomortar 908 TDSmrameshceNo ratings yet

- Wearing CompoundsDocument6 pagesWearing Compoundsfadlywirawan7No ratings yet

- ROYALPOXY UW 410-tdsDocument3 pagesROYALPOXY UW 410-tdsSyed FaridNo ratings yet

- Fosroc Nitomortar EL-HB TDSDocument2 pagesFosroc Nitomortar EL-HB TDSabdelsalamassarNo ratings yet

- Bipigard Coaltar FinishDocument2 pagesBipigard Coaltar FinishKhirod Krout100% (1)

- CarbolineDocument18 pagesCarbolineimaduddinshaNo ratings yet

- Strongcoat 400 - TDSDocument4 pagesStrongcoat 400 - TDSOsama Abu ShalthamNo ratings yet

- O Ring Viton Vs NitrileDocument3 pagesO Ring Viton Vs NitrileIrfanmaulana ardiansyahNo ratings yet

- Duremax GPE: General Purpose Epoxy CoatingDocument4 pagesDuremax GPE: General Purpose Epoxy CoatinglivefreakNo ratings yet

- Nitoproof 600 UAEDocument4 pagesNitoproof 600 UAECharles FernandesNo ratings yet

- Nitoflor FC150: Constructive SolutionsDocument3 pagesNitoflor FC150: Constructive SolutionstalatzahoorNo ratings yet

- Royale Play Ironic: Product FeaturesDocument2 pagesRoyale Play Ironic: Product FeaturesAcro PaintsNo ratings yet

- 2-Nitoflor FC150Document4 pages2-Nitoflor FC150Ahmed I. GhallabNo ratings yet

- Water-Based Single Component High Gloss Acrylic For DTM and Topcoat ApplicationsDocument6 pagesWater-Based Single Component High Gloss Acrylic For DTM and Topcoat ApplicationsamitNo ratings yet

- Durepox 2K Primer TDSDocument4 pagesDurepox 2K Primer TDSOswaldo Manuel Ramirez MarinNo ratings yet

- Samtech 200 Epoxy Grout: Three Component Rapid Cure High Strength Epoxy GroutDocument3 pagesSamtech 200 Epoxy Grout: Three Component Rapid Cure High Strength Epoxy GroutFrancois-No ratings yet

- Luxafloor ECO: Water Borne Epoxy Floor CoatingDocument2 pagesLuxafloor ECO: Water Borne Epoxy Floor CoatinglivefreakNo ratings yet

- Strongcoat PE350 - TDS PDFDocument4 pagesStrongcoat PE350 - TDS PDFMohamed AlhadidyNo ratings yet

- Strongcoat Epoxy FDocument4 pagesStrongcoat Epoxy Fosama mohNo ratings yet

- All Purpose Paint Remover - Dipping Grade: PRODUCT CODE: RRA 200-SeriesDocument2 pagesAll Purpose Paint Remover - Dipping Grade: PRODUCT CODE: RRA 200-SeriesPieter FourieNo ratings yet

- Bariline Express Datasheet enDocument3 pagesBariline Express Datasheet entamariNo ratings yet

- Strongcoat PE350Document48 pagesStrongcoat PE350Ahmad ElghazolyNo ratings yet

- Dekguard PUDocument4 pagesDekguard PUSyed HassaanNo ratings yet

- Bituguard Pu 70Document3 pagesBituguard Pu 70ahmedyahea181No ratings yet

- Nitoproof PU AromaticDocument3 pagesNitoproof PU AromaticSharookhan ShajahanNo ratings yet

- Abecote 320: Epoxy Enamel CoatingDocument2 pagesAbecote 320: Epoxy Enamel CoatingAshvin ParmessurNo ratings yet

- NCI Tds Datass SheetDocument6 pagesNCI Tds Datass Sheetcad camNo ratings yet

- High Build Epoxy Coating Epigen 1311: Potable Water SuitabilityDocument2 pagesHigh Build Epoxy Coating Epigen 1311: Potable Water Suitabilityjulius hasan33No ratings yet

- Nitoseal Debonding Tape AgfDocument1 pageNitoseal Debonding Tape AgfVincent JavateNo ratings yet

- Hydrocell XLDocument2 pagesHydrocell XLVincent JavateNo ratings yet

- Fosroc Nitocote NT550: Constructive SolutionsDocument4 pagesFosroc Nitocote NT550: Constructive SolutionsVincent JavateNo ratings yet

- Barrel GunDocument1 pageBarrel GunVincent JavateNo ratings yet

- Fosroc Structuro W435: (Formerly Structuro RX Plus)Document2 pagesFosroc Structuro W435: (Formerly Structuro RX Plus)Vincent JavateNo ratings yet

- Fosroc Dekguard Filler: Acrylic, Intercoat Pin Hole FillerDocument2 pagesFosroc Dekguard Filler: Acrylic, Intercoat Pin Hole FillerVincent JavateNo ratings yet

- Fosroc Brushbond FLXIII: Constructive SolutionsDocument2 pagesFosroc Brushbond FLXIII: Constructive SolutionsVincent JavateNo ratings yet

- Fosroc Structuro W450: Constructive SolutionsDocument2 pagesFosroc Structuro W450: Constructive SolutionsVincent JavateNo ratings yet

- Fosroc Sprayset SL: Wet / Dry Process High Performance Shotcrete AcceleratorDocument2 pagesFosroc Sprayset SL: Wet / Dry Process High Performance Shotcrete AcceleratorVincent JavateNo ratings yet

- Fosroc Structuro W415: A Superior High Performance Concrete Hyperplasticiser Based On Polycarboxylate TechnologyDocument2 pagesFosroc Structuro W415: A Superior High Performance Concrete Hyperplasticiser Based On Polycarboxylate TechnologyVincent JavateNo ratings yet

- Fosroc Structuro W425: A Superior High Performance Concrete Hyperplasticiser Based On Polycarboxylate TechnologyDocument2 pagesFosroc Structuro W425: A Superior High Performance Concrete Hyperplasticiser Based On Polycarboxylate TechnologyVincent JavateNo ratings yet

- Structuro w440Document2 pagesStructuro w440Vincent JavateNo ratings yet

- Sprayset hbl42Document2 pagesSprayset hbl42Vincent JavateNo ratings yet

- Fosroc Conplast SP472: Constructive SolutionsDocument2 pagesFosroc Conplast SP472: Constructive SolutionsVincent JavateNo ratings yet

- Fosroc Structuro W420: A Superior High Performance Concrete Hyperplasticiser Based On Polycarboxylate TechnologyDocument2 pagesFosroc Structuro W420: A Superior High Performance Concrete Hyperplasticiser Based On Polycarboxylate TechnologyVincent JavateNo ratings yet

- Fosroc Conplast WP400: Hydrophobic Pore-Blocking Waterproofing Admixture Effects of OverdosingDocument2 pagesFosroc Conplast WP400: Hydrophobic Pore-Blocking Waterproofing Admixture Effects of OverdosingVincent JavateNo ratings yet

- Smart Materials and Technologies For Sustainable Concrete Construction - 2023Document19 pagesSmart Materials and Technologies For Sustainable Concrete Construction - 2023JuanNo ratings yet

- ASHRAE - Design Conditions - 2013 - 2Document2 pagesASHRAE - Design Conditions - 2013 - 2Ing Peter CucchiNo ratings yet

- Dealing With Pre-Erection and Erection Issues of Segmental Bridge (S Rastogi AECOM)Document49 pagesDealing With Pre-Erection and Erection Issues of Segmental Bridge (S Rastogi AECOM)ShaileshRastogiNo ratings yet

- 15.checklist For Interior PlasteringDocument4 pages15.checklist For Interior PlasteringPradeep MalhotraNo ratings yet

- Final EWS NotificationDocument19 pagesFinal EWS NotificationGill GillNo ratings yet

- Blank Check List Fire Hose Reel - 2Document2 pagesBlank Check List Fire Hose Reel - 2mohammad AshrafNo ratings yet

- Afss FP 01Document1 pageAfss FP 01Rolly DumbriqueNo ratings yet

- ADA, Building Codes, and Standards Relating To Handrails and GuardsDocument77 pagesADA, Building Codes, and Standards Relating To Handrails and GuardsAntónio FontesNo ratings yet

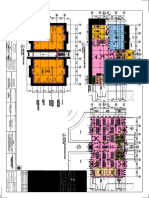

- 26076-110-V12-HEGS-00049 SC Heavy Equipment Transportation Plan (R3)Document20 pages26076-110-V12-HEGS-00049 SC Heavy Equipment Transportation Plan (R3)bangunNo ratings yet

- FSED 24F Fire Safety Inspection Checklist Small General Business Establishment Rev.02Document2 pagesFSED 24F Fire Safety Inspection Checklist Small General Business Establishment Rev.02april oyardoNo ratings yet

- Slump Test REPORTDocument5 pagesSlump Test REPORTLove Rosiee100% (1)

- 2018 Guideline For Bridge Design of LGEDDocument12 pages2018 Guideline For Bridge Design of LGEDParvez Syed RafiNo ratings yet

- Arc 206 History2Document27 pagesArc 206 History2almustapha abdullahiNo ratings yet

- Design of An Integrated Port Passenger Terminal Building in The Port of Iloilo City, Iloilo PDFDocument312 pagesDesign of An Integrated Port Passenger Terminal Building in The Port of Iloilo City, Iloilo PDFspccosain100% (1)

- Alex G. Pacalangot: Position Desired: Finishing Carpenter Formworks CarpenterDocument2 pagesAlex G. Pacalangot: Position Desired: Finishing Carpenter Formworks CarpenterRon Jonel DumlaoNo ratings yet

- Hiab Xs 177KDocument12 pagesHiab Xs 177KJoaquín TodhinNo ratings yet

- 169 172, Tesma407, IJEASTDocument4 pages169 172, Tesma407, IJEASTAr Aayush GoelNo ratings yet

- 2020 08 01 Plan and ElevationsDocument2 pages2020 08 01 Plan and ElevationsZachary DeLucaNo ratings yet

- JSA IndexDocument2 pagesJSA IndexDie HArdNo ratings yet

- Avantika RBDocument14 pagesAvantika RBMansi RathiNo ratings yet

- 8351 - L&T Arch CommentsDocument1 page8351 - L&T Arch CommentsVarunn VelNo ratings yet

- Protastructure Design Guide RC Beam Design To Sni284Document26 pagesProtastructure Design Guide RC Beam Design To Sni284chong fung yunNo ratings yet

- Optimal Deign of Pile FoundationDocument13 pagesOptimal Deign of Pile FoundationJustin Johnson100% (1)

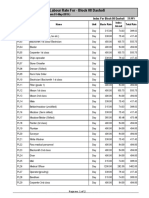

- Block 08 Dasholi - ResourceRate - LabourDocument2 pagesBlock 08 Dasholi - ResourceRate - LabourManojNo ratings yet

- Komatsu Pc200 7 Shop Manual 1Document20 pagesKomatsu Pc200 7 Shop Manual 1james100% (55)

- Underwater Construction: Civil AddaDocument8 pagesUnderwater Construction: Civil AddatonskieNo ratings yet

- Permit To Work: No Work Is So Urgent That We Cannot Take Time To Do It Safely 0072429Document2 pagesPermit To Work: No Work Is So Urgent That We Cannot Take Time To Do It Safely 0072429maldisaNo ratings yet

- GSO Floor PlanDocument1 pageGSO Floor PlanRomel DecenillaNo ratings yet

- Specification A10 Ips FlooringDocument1 pageSpecification A10 Ips Flooringharishram123456No ratings yet

- Specification For InstrumentationDocument39 pagesSpecification For InstrumentationEagle Engineering & Trading Sdn BhdNo ratings yet