Professional Documents

Culture Documents

Design of Beam

Design of Beam

Uploaded by

pobre3nga3bataOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Beam

Design of Beam

Uploaded by

pobre3nga3bataCopyright:

Available Formats

5CD2_E439_91C0_4CB4.

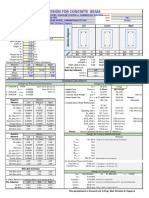

Project : RHC Design by : RHC

Owner : Mark : B1

LOGO Location :

Check by : Engr. Ruel H. Cepeda

Date : 2/12/2021

Material Properties Left Center Right

Concrete f'c = 20.70 Mpa

Section Diagram

Reinforcing fy = 414.00 Mpa

Stirrup fy = 276.00 Mpa

Beam Data

Span type = Simply supported

Span Length = 3.00 m

width, b = 0.25 m

height, h = 0.40 m

d' = 0.06 m

d= 0.34 m Top: 1.000 ok Top: 1.000 ok Top: 1.345 ok

io

at

flexure bar Ø= 16.00 mm Bot: 1.000 ok Bot: 1.000 ok Bot: 1.000 ok

R

shear bar Ø= 10.00 mm ● Check Minimum Depth of Beam

Torsion bar Ø= 16.00 mm Depth = 0.19 Depth use is ok NSCP 2015 409.3.1.1

Stress Result (Any FEA or Frame Analysis) 4xDepth = 1.36 Depth use is ok NSCP 2015 418.6.2

Moment Left *Midspan Right Width (200 or 0.3h) = 0.20 Width use is ok NSCP 2015 418.6.2

TB 60.93 12.36 57.43 ● Main Bar Summary

BB 42.51 32.40 36.88 Main Bar Adjusted Left *Mid Right

Left *Midspan Right Top Bars = 2 pcs 2 pcs 3 pcs

Shear

74.08 - 72.82 Bot Bars = 2 pcs 2 pcs 2 pcs

Torsion

Detailed Calculations

Design for Flexural Reinforcement Design for Stirrups

● Compute β 1 Value NSCP 2015 422.2.2.4.3 Vu = 74.1 kN 2 Legs

β1 = 0.85000 Table 422.2.2.4.3 ● Applied Force Distance = @ 50mm @ 2●Height

● Compute ρ min 0.00338 409.6.1.2 ● Applied Force Vu = 70.4 kN 34.6 kN

● Compute ρ max = 0.01603 ● Concrete Shear Strength - φVc = 49.3 kN 49.3 kN 409.6.3.1

● Check Section Size Vs max = φ▪ ⅔ ▪ sqrt(f'c)▪b▪h 191.4 kN Remark

Negative Section Vmax = 240.7 kN 240.7 kN Adequate

Moment Left *Midspan Right ● Compute Area of Shear Reinforcement

Mu (kN.m) = 60.928524 12.3573813 57.432726 Vs = 28.1 kN

Ru (Mpa) = 0.04 0.00 0.20 Vs = 127.6 kN 127.6 kN Table 409.7.6.2.2

r, req = 0.00338 0.00338 0.00457 Spacing_max = 170.0 mm 170.0 mm Table 409.7.6.2.2

Remarks = Singly! Singly! Singly! Av_used = 157.1 mm² 157.1 mm²

As, neg (mm 2 ) = 331.40 331.40 448.05 Av/S_req = 0.30 mm²/mm

As, pos (mm 2 ) = 0.00 0.00000 0.00000 Av/S_min1 = 0.26 mm²/mm 0.26 mm²/mm 409.6.3.3(a)

Reduction Factor = 0.90000 0.90000 0.90000 Av/S_min2 = 0.32 mm²/mm 0.32 mm²/mm 409.6.3.3(b)

Tensile Strain = 0.02905 0.02905 0.02070 Av/S_used = 0.32 mm²/mm 0.32 mm²/mm

Top Bars (pcs) = 2.00 2.00 2.23 S_req = 495.5 mm 495.5 mm

Bot Bars (pcs) = 0.00 0.00 0.00 S_used = 150.0 mm 150.0 mm

Remark 10mm Ø 1@50MM, 6@150mm, REST @ 150MM O.C.

Section Design for Torsion

Positive Moment

Left *Midspan Right Left Mid Right

Mu (kN.m) = 42.505992 32.4022638 36.882361 Tn >= Tu / φ >= 0.00 0.00 0.00

Ru (Mpa) = 0.00 0.08 0.00 Ao = 0.85 Aoh = 0.00 0.00 0.00

r, req = 0.00338 0.00338 0.00338 At/s = (Tn/2Aofyt) = 0.00 0.00 0.00

Remarks = Singly! Singly! Singly! Provide stirrup Al = 0.00 0.00 0.00

As, pos (mm 2 ) = 0.00000 0.00000 0.00000 (pcs) = 0.00 0.00 0.00

As, neg (mm 2 ) = 331.40 331.40 331.40 NSCP 2015 Section 418.6.3

Reduction Factor = 0.90000 0.90000 0.90000 a.) 1 Least 2.00 at both top and bot

Tensile Strain = 0.02905 0.02905 0.02905 2 Min bar 1.00 (0.25*√fc)*bd/fy

Top Bars (pcs) = 0.00 0.00 0.00 1.00 1.4*bd/fy

Bot Bars (pcs) = 2.00 2.00 2.00 3 Max bar 11.00 0.025*bd

Top Bars (pcs) = 2.00 2.00 3.00

Main Bar Summary Bot Bars (pcs) = 2.00 2.00 2.00

Top Bars (pcs) = 2.00 2.00 2.23 b.) Positive moment at joint face shall be at least one half the negative moment strength

Bot Bars (pcs) = 2.00 2.00 2.00 provided at that face of the joint Both the negative and positive moment strength at any

section along member length shall be at least one fourth the maximum moment strength

● Check Minimum according to NSCP 2015 Section 418.6.3 provided at face of either joint

Bar Adjusted Left *Mid Right Top Bars (pcs) = 2.00 2.00 3.00

Top Bars = 2 pcs 2 pcs 3 pcs Bot Bars (pcs) = 2.00 2.00 2.00

Bot Bars = 2 pcs 2 pcs 2 pcs

This spreadsheets is licensed only to Engr. Ruel H. Cepeda

You might also like

- 21dj0024 PowDocument55 pages21dj0024 Powelisha cyril maxinoNo ratings yet

- Price ListDocument33 pagesPrice ListAllen MendozaNo ratings yet

- Bolts and Nuts PricesDocument3 pagesBolts and Nuts PricesRenalyn AndradeNo ratings yet

- MEPF Detailed Design PDFDocument2 pagesMEPF Detailed Design PDFElcid Del RosarioNo ratings yet

- Purlins (LC) Section PropertiesDocument4 pagesPurlins (LC) Section Propertiespobre3nga3bata100% (1)

- York Chiller Log SheetDocument4 pagesYork Chiller Log SheetEngr Fazal AkbarNo ratings yet

- DPWH Weather Chart CompressDocument3 pagesDPWH Weather Chart CompressLei SantiagoNo ratings yet

- Office of The Land Use and Zoning Administration: VisionDocument6 pagesOffice of The Land Use and Zoning Administration: VisionSick FreakNo ratings yet

- DPWH Brgy. 227, Tondo, ManilaDocument11 pagesDPWH Brgy. 227, Tondo, ManilaAllison GetubigNo ratings yet

- Final S-CurveDocument30 pagesFinal S-CurveErwin Macapinlac MabutiNo ratings yet

- Regional Office Iv-B: Itemized Quantities and Cost Estimates On Other SheetDocument50 pagesRegional Office Iv-B: Itemized Quantities and Cost Estimates On Other SheetKevin Suerte CanillaNo ratings yet

- Footing Reinforcement: For FOOTING Using 6m Long 16 MM Diameter REINFORCING BARDocument11 pagesFooting Reinforcement: For FOOTING Using 6m Long 16 MM Diameter REINFORCING BARJef Junio AlvarezNo ratings yet

- MLM Engineering Sample Two Storey Residential Building-WBS Item/Description 1 General RequirementsDocument12 pagesMLM Engineering Sample Two Storey Residential Building-WBS Item/Description 1 General RequirementsNiño EvangelioNo ratings yet

- Purlins Analysis and DesignDocument6 pagesPurlins Analysis and DesignJestoni Gonzales TortolaNo ratings yet

- Application For Building Permit (For Building Permit)Document1 pageApplication For Building Permit (For Building Permit)Brandon L ApilsNo ratings yet

- 21pe50 Plan 3Document24 pages21pe50 Plan 3nhiyzhar monimoNo ratings yet

- Gaddani Covered CourtDocument136 pagesGaddani Covered CourtErnestNo ratings yet

- FSED 001 - Application Form FSECDocument1 pageFSED 001 - Application Form FSECMacabebe Fire StationNo ratings yet

- VERDANA SPECIFICATIONS UpdatedDocument32 pagesVERDANA SPECIFICATIONS UpdatedPrinces Jecyvhel De LeonNo ratings yet

- 24KC0079 - Construction of Multipurpose Building (Tribal Tulugan)Document57 pages24KC0079 - Construction of Multipurpose Building (Tribal Tulugan)Marco RoaNo ratings yet

- Two Storey Structural DesignDocument9 pagesTwo Storey Structural Designking taugNo ratings yet

- 2022.0227 Notice To Proceed To Engineering DesignDocument1 page2022.0227 Notice To Proceed To Engineering DesignRaachel Anne CastroNo ratings yet

- Tondo Residence Plumbing EstimateDocument2 pagesTondo Residence Plumbing EstimateEvans CorpNo ratings yet

- Day 1-Wind Loading NSCP 2015Document77 pagesDay 1-Wind Loading NSCP 2015Nick OperarioNo ratings yet

- Construction of Quezon City Archival Center - PaligsahanDocument47 pagesConstruction of Quezon City Archival Center - PaligsahanBobbles D LittlelionNo ratings yet

- Length Excavated (M) Width Excavated (M) Depth Excavated (M)Document15 pagesLength Excavated (M) Width Excavated (M) Depth Excavated (M)anthonyNo ratings yet

- Plumbing Permit (FRONT)Document1 pagePlumbing Permit (FRONT)Mark Anthony FolleroNo ratings yet

- Ee 23 Miscellaneous Details EeDocument1 pageEe 23 Miscellaneous Details EeGarduque AngreysNo ratings yet

- Proposed 3-Storey Residential Building: Roof Deck Floor PlanDocument1 pageProposed 3-Storey Residential Building: Roof Deck Floor Planmichael jan de celisNo ratings yet

- 22BJ0060Document27 pages22BJ0060Jervin BragadoNo ratings yet

- Table ListDocument16 pagesTable ListMavelyn TolentinoNo ratings yet

- Office Blow Up Plan: W-5 WC FAUDocument1 pageOffice Blow Up Plan: W-5 WC FAUmichael jan de celisNo ratings yet

- Acel Rate From DPWH 2011 PDFDocument1 pageAcel Rate From DPWH 2011 PDFreynoldNo ratings yet

- Remar Construction: Brgy. Tadao, Pasuquin, Ilocos Norte and Brgy. Saricao, Vintar, Ilocos NorteDocument1 pageRemar Construction: Brgy. Tadao, Pasuquin, Ilocos Norte and Brgy. Saricao, Vintar, Ilocos NorteNix GabrielNo ratings yet

- Standard Classroom Building - DPWH As of 021524 A1Document1 pageStandard Classroom Building - DPWH As of 021524 A1designers.starlightNo ratings yet

- PL Boq of A 2-Storey HouseDocument18 pagesPL Boq of A 2-Storey HouseAILA TABRILLANo ratings yet

- Description/Materials Quantity: Detailed EstimatesDocument1 pageDescription/Materials Quantity: Detailed EstimatesJohn Harvy JoseNo ratings yet

- Estimating Calculator Based On Max PajardoDocument26 pagesEstimating Calculator Based On Max Pajardofred anthony UeraNo ratings yet

- Sample POWDocument31 pagesSample POWJitherDoromalDelaCruzNo ratings yet

- 20dj0115 PowDocument83 pages20dj0115 PowJule LobresNo ratings yet

- Architectural Permit: Office of The Building OfficialDocument2 pagesArchitectural Permit: Office of The Building Officialrmrv valdezNo ratings yet

- ComputationsDocument7 pagesComputationsGintokiNo ratings yet

- Bureau of Design: Three (3) Storey, Fifteen (15) Classroom School BuildingDocument1 pageBureau of Design: Three (3) Storey, Fifteen (15) Classroom School BuildingDominador Ladot Heraña Jr.No ratings yet

- Detailed Plan & Isometric of Genset & Electrical RoomDocument10 pagesDetailed Plan & Isometric of Genset & Electrical RoomjdvalmontNo ratings yet

- Canal II Layout1Document1 pageCanal II Layout1Xan KulitzNo ratings yet

- 1 A-2 Construction of One-Storey Residential Building: Floor Plan Magnolia Joy C. Tan Magnolia Joy C. TanDocument1 page1 A-2 Construction of One-Storey Residential Building: Floor Plan Magnolia Joy C. Tan Magnolia Joy C. TanPaul SuicoNo ratings yet

- Construction Methodslayog NiaDocument1 pageConstruction Methodslayog NiarrpenolioNo ratings yet

- C Users PC Desktop 2 Storey Residential House Architectural TemplateDocument1 pageC Users PC Desktop 2 Storey Residential House Architectural TemplateRoque CapaqueNo ratings yet

- Eng U2 Module 3 - PlumbingDocument27 pagesEng U2 Module 3 - PlumbingNovelyn Butih-lingNo ratings yet

- Roof Deck Design and Analysis of SlabsDocument11 pagesRoof Deck Design and Analysis of SlabsJt ManaoisNo ratings yet

- Full Truss Diagram (Ft1)Document1 pageFull Truss Diagram (Ft1)SimjanNo ratings yet

- Structural PlansDocument23 pagesStructural PlansDiane de OcampoNo ratings yet

- Jet Grouting Dupa D.O. 197 S. 2016Document1 pageJet Grouting Dupa D.O. 197 S. 2016john paul larozaNo ratings yet

- Perspective: CriselleDocument11 pagesPerspective: CriselleEngr RicardoNo ratings yet

- X'WELL Company Profile 2017Document35 pagesX'WELL Company Profile 2017francis pacaigueNo ratings yet

- Summary of Punchlist Need To Closed OutDocument7 pagesSummary of Punchlist Need To Closed OutJan Lawrence Alberto100% (1)

- Perimeter Fence eDocument1 pagePerimeter Fence eAlbert Christian BesmanosNo ratings yet

- Prepared By: - Francis M, Pacaigue - Engineer I (J.O.) Checked/Reviewed By: - Domingo P. Villaruel - Engineer IIDocument21 pagesPrepared By: - Francis M, Pacaigue - Engineer I (J.O.) Checked/Reviewed By: - Domingo P. Villaruel - Engineer IIfrancis pacaigueNo ratings yet

- Contractor's Billing of Const of Mullti-Purpose Bldg. (Covered Court), Brgy. Hilub-Ang, Calatrava, Neg. Occ. (17RB0208)Document15 pagesContractor's Billing of Const of Mullti-Purpose Bldg. (Covered Court), Brgy. Hilub-Ang, Calatrava, Neg. Occ. (17RB0208)Mae Ann GonzalesNo ratings yet

- 5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesDocument1 page5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesMark Christian EsguerraNo ratings yet

- 5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesDocument1 page5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesMark Christian EsguerraNo ratings yet

- Roof BeamDocument7 pagesRoof BeamNick OperarioNo ratings yet

- Beam DetailsDocument5 pagesBeam Detailspobre3nga3bataNo ratings yet

- Beam DesignDocument4 pagesBeam Designpobre3nga3bataNo ratings yet

- Footing Design UIDocument1 pageFooting Design UIpobre3nga3bataNo ratings yet

- Column Design UIDocument1 pageColumn Design UIpobre3nga3bataNo ratings yet

- Deflection Calculation - Part1Document1 pageDeflection Calculation - Part1pobre3nga3bataNo ratings yet

- Struc Ex Pro Rectangular Column Design CalculationDocument4 pagesStruc Ex Pro Rectangular Column Design Calculationpobre3nga3bataNo ratings yet

- Struc Ex Pro Rectangular Beam Design CalculationDocument1 pageStruc Ex Pro Rectangular Beam Design Calculationpobre3nga3bataNo ratings yet

- Design of Column Using StrucExPro.Document1 pageDesign of Column Using StrucExPro.pobre3nga3bataNo ratings yet

- Area of A Rectangle - VBA CodeDocument1 pageArea of A Rectangle - VBA Codepobre3nga3bataNo ratings yet

- Minimum Rebar Development and Splice Lengths (MM)Document1 pageMinimum Rebar Development and Splice Lengths (MM)pobre3nga3bataNo ratings yet

- RHC Singly Beam Design ToolDocument1 pageRHC Singly Beam Design Toolpobre3nga3bataNo ratings yet

- PAUBAYA CHORDS by Moira Dela Torre at Ultimate-GuitarDocument3 pagesPAUBAYA CHORDS by Moira Dela Torre at Ultimate-Guitarpobre3nga3bataNo ratings yet

- Design of Combined FootingDocument2 pagesDesign of Combined Footingpobre3nga3bataNo ratings yet

- RHC Fixed Beam Shear+moment+deflection CheckerDocument1 pageRHC Fixed Beam Shear+moment+deflection Checkerpobre3nga3bataNo ratings yet

- Design of Two-Way SlabDocument1 pageDesign of Two-Way Slabpobre3nga3bataNo ratings yet

- RHC Simple Beam Shear+moment+deflection CheckerDocument1 pageRHC Simple Beam Shear+moment+deflection Checkerpobre3nga3bataNo ratings yet

- Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel PipesDocument13 pagesSeamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipesandrea assanelliNo ratings yet

- Haumek - Non Stick CookwareDocument16 pagesHaumek - Non Stick CookwareDeepak JhaNo ratings yet

- Chapter 2Document18 pagesChapter 2Lucy BrownNo ratings yet

- XHHW 2 PDFDocument2 pagesXHHW 2 PDFNaveedNo ratings yet

- Attendees: Anc: ETA PMC Sr. No. A Civil WorksDocument2 pagesAttendees: Anc: ETA PMC Sr. No. A Civil WorksNedunuri.Madhav MurthyNo ratings yet

- Armatec CeilcoteCoatingsDocument2 pagesArmatec CeilcoteCoatingschusnadiantyNo ratings yet

- Dokumen Jenis KabelDocument5 pagesDokumen Jenis KabeljujurNo ratings yet

- Sa 335 PDFDocument12 pagesSa 335 PDFAnilNo ratings yet

- Chapter 1 - Engineering Materials and Their Proper - 2012 - Engineering MaterialDocument12 pagesChapter 1 - Engineering Materials and Their Proper - 2012 - Engineering MaterialDavidNo ratings yet

- Bollhoff Rivkle Elastic - Blind Rivet Nuts For Vibration DampingDocument4 pagesBollhoff Rivkle Elastic - Blind Rivet Nuts For Vibration DampingAce Industrial SuppliesNo ratings yet

- Chapter: Bill of Quantities: 1 Provisional SumDocument12 pagesChapter: Bill of Quantities: 1 Provisional SumRam Prasad AwasthiNo ratings yet

- Def Stan 00-970Document11 pagesDef Stan 00-970stefan.vince536No ratings yet

- BR PDF AD G 2015 With 2016 AmendmentsDocument55 pagesBR PDF AD G 2015 With 2016 AmendmentsGeorgeNo ratings yet

- Momentsstressesi00westiala PDFDocument132 pagesMomentsstressesi00westiala PDFVarun KumarNo ratings yet

- Scope of WorksDocument2 pagesScope of WorksBernard QuiboyNo ratings yet

- Victaulic Modeling by AutoPipe PDFDocument18 pagesVictaulic Modeling by AutoPipe PDFlimin zhangNo ratings yet

- BS en 13230-6-2020 - (2023-05-31 - 08-25-53 PM)Document64 pagesBS en 13230-6-2020 - (2023-05-31 - 08-25-53 PM)Alireza MashhadizadehNo ratings yet

- Vee Packing PDFDocument10 pagesVee Packing PDFMehdi SoltaniNo ratings yet

- Branching of Pipes, Pipes in Series or Parallel, Pipe NetworksDocument53 pagesBranching of Pipes, Pipes in Series or Parallel, Pipe NetworksTahir KhanNo ratings yet

- Rule - Vi Fire-Resistive Requirements in ConstructionDocument31 pagesRule - Vi Fire-Resistive Requirements in Constructionhobi jungNo ratings yet

- 4.determination of Clay, Silt & Dust in Fine AggregateDocument1 page4.determination of Clay, Silt & Dust in Fine AggregateLakshithaGonapinuwalaWithanageNo ratings yet

- Structural Analysis - I Unit-IDocument22 pagesStructural Analysis - I Unit-ITamizhan_KNo ratings yet

- Experimental Study of Bituminous Concrete Containg Plastic Waste MaterialDocument9 pagesExperimental Study of Bituminous Concrete Containg Plastic Waste MaterialCivil StructureNo ratings yet

- A Presentation On: Non-Linear Analysis of Arch Bridge Subjected To Ground MotionDocument27 pagesA Presentation On: Non-Linear Analysis of Arch Bridge Subjected To Ground MotionPratik KaleNo ratings yet

- BPI Zap TLok Headed Bar InstructionsDocument3 pagesBPI Zap TLok Headed Bar InstructionshectoriturbeNo ratings yet

- YAR104-2-1 WaterDocument42 pagesYAR104-2-1 WaterNancy TessNo ratings yet

- Zapucavajuci EkseriDocument194 pagesZapucavajuci EkseriМилан БурсаћNo ratings yet

- SVWRF 2 5Document4 pagesSVWRF 2 5邱瑋No ratings yet

- Chemical Engineering Objective Questions by OP Gupta PDFDocument875 pagesChemical Engineering Objective Questions by OP Gupta PDFIbrahim Khalid50% (2)