Professional Documents

Culture Documents

Gelled Acid Diverter-Technical Data Sheet

Gelled Acid Diverter-Technical Data Sheet

Uploaded by

wesam tetouhaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gelled Acid Diverter-Technical Data Sheet

Gelled Acid Diverter-Technical Data Sheet

Uploaded by

wesam tetouhaCopyright:

Available Formats

< Back

CLEARWATER

Engineered Chemistry T e c h n i c a l D a t a

AGA-400ME

Viscosity Enhanced Acid Gelling System

DESCRIPTION ADVANTAGES

AGA-400ME is a cationic, high-molecular weight, • Acid penetrates deeper before spending

polyacrylamide copolymer that viscosifies hydrochloric (HCl) • Cross-linking lowers fluid leak-off to the formation by

acid for use in carbonate acidizing treatments. Being plugging wormholes

acrylamide based, AGA-400ME works to temperatures of • Base gel viscosity is retained as acid spends

149°C (300°F). • Excellent friction reduction

• Residual viscosity helps remove insoluble fines

AGA-400ME is the main component of a cross-linked acid • Creates longer, more conductive fractures

system. When combined with AGA-Buffer-1, AGA-XL-1 and

ICA-720, a self-diverting, cross-linked acid system is USAGE

developed. The cross-link forms as the acid spends and the pH The typical concentration range for AGA-400ME is 15-40

rises. The cross-linked acid greatly reduces fluid loss to the gal/1000 gallons (15-40 L/m3). The cross-linked acid system

existing permeability and therefore creates longer, higher also utilizes an iron control agent, ICA-720, at 3-10 lbs/1000

conductivity fractures in fracture acidizing treatments or gallons (0.36-1.2 kg/m3), a pH buffer, AGA-Buffer-1, at 1-2

improved etching in matrix acid applications. gal/1000 gallons (1-2 L/m3), and the cross-linker, AGA-XL-1, at

4-5 gal/1000 gallons (4-5 L/m3).

APPLICATION

AGA-400ME requires a premix time of at least 30 minutes prior AGA-400ME is also an excellent friction reducer for acid when

to pumping to ensure complete mixing and viscosity used at relatively low dosages of 1-2 gal/1000 gallons (1-2

development. For low strength acids (<10% HCl) and in cold L/m3).

water, the premix time required is increased to at least 1 hour.

VISCOSITY DATA, 15% HCl, 1.5% AGA-400ME

AGA-400ME must be mixed with high shear to achieve FANN 35 @ 170/sec and 24°C (75°F) ..............................48 cps

maximum viscosity development. This can best be achieved by FANN 35 @ 511/sec and 24°C (75°F) ..............................32 cps

injecting the polymer into the eye of the blender's centrifugal

pump. To prevent rapid gellation and lumping (fisheyes), add PHYSICAL PROPERTIES

AGA-400ME only after the strong acid has been mixed with the Appearance .....................................Milky-White, Viscous Liquid

water containing the chemical additives, not earlier to the make Specific Gravity ............................................................1.01-1.04

up water. Adding such a polymer to water will result in Density..............................................................8.41-8.66 lbs/gal

lumping. Solubility in Water ..................................................................5%

pH (neat) ..........................................................................5.0-8.0

AGA-400 ME is compatible with both cationic and non-ionic Ionic Charge....................................................................Cationic

surfactants and corrosion inhibitors. Use with caution with Freeze Point.................................................................0°C (32°F)

anionic surfactants, such as anionic anti-sludge agents.

Compatibility problems can diminish the effectiveness of the

overall acidizing package.

This material is supplied solely for informational purposes and Clearwater makes no guarantees or warranties, either expressed or implied, with respect to the accuracy

and the use of this data. All product warranties and guarantees shall be governed by the Standard Terms of Sale. 2003/08

ISO 9001 Certified

Clearwater 713/693-4844 Headquarters www.cwichem.com

515 Post Oak Blvd., Suite 200 713/693-4490 Fax

Houston, Texas 77027 USA

< Back

CLEARWATER

Engineered Chemistry T e c h n i c a l D a t a

AGA-Buffer-1

pH Buffer for AGA-400 ME System

DESCRIPTION ADVANTAGES

AGA-Buffer-1 is a low pH solution of a proprietary organic • Buffers the pH so that cross-linking can place

buffer that provides pH control for the AGA-400ME cross-linked • Effective at temperatures <149°C (<300°F)

acid system. As the gelled acid spends and the pH rises to 2.5- • Concentrated buffer

3, AGA-Buffer-1 temporarily locks the pH there to allow for • Readily soluble in hydrochloric acid

complete cross-link viscosity development. Without this pH

control additive, the AGA-400ME system would not be USAGE

possible. AGA-Buffer-1 is used at a concentration of 1-2 gal/1000 gallons

(1-2 L/m3) of gelled acid.

APPLICATION

A cross-linked acid system provides better fluid loss control PHYSICAL PROPERTIES

and diverts live acid to another part of the formation face to Appearance...............................................................Clear Liquid

prevent “wormhole” development. It allows the acid to Specific gravity ................................................................1.2-1.3

concentrate on the full area of the formation. Clearwater's AGA- Solubility,

400ME is a self-diverting acid system because the fluid cross- water, 25°C (77°F)........................................................Complete

links as the pH of the system rises (pH=2.5-3.0) and then acid, 25°C (77°F) ..........................................................Complete

breaks back to its original viscosity as the pH continues to rise pH (neat).............................................................................<1.0

(pH=4.0-5.0). Freeze Point...............................................................10°C (50°F)

Flash Point........................................................>93°C (>200°F)

A strong pH buffer is needed to allow for a complete cross-link

to occur and divert the live acid. AGA-Buffer-1 provides this pH

stability in the AGA-400ME system.

This material is supplied solely for informational purposes and Clearwater makes no guarantees or warranties, either expressed or implied, with respect to the accuracy

and the use of this data. All product warranties and guarantees shall be governed by the Standard Terms of Sale. 2003/08

ISO 9001 Certified

Clearwater 713/693-4844 Headquarters www.cwichem.com

515 Post Oak Blvd., Suite 200 713/693-4490 Fax

Houston, Texas 77027 USA

< Back

CLEARWATER

Engineered Chemistry T e c h n i c a l D a t a

AGA-XL-1

Cross-Linker for AGA-400ME System

DESCRIPTION ADVANTAGES

AGA-XL-1 is a low pH solution of a proprietary metal chloride • Forms stable cross-link acid gels

cross-linker for Clearwater's AGA-400ME cross-linked acid • Effective at temperatures <149°C (<300°F)

system. The metal supplies the means for the acid gelling • Highly concentrated cross-linker

polymer to form longer polymer chains, increasing the apparent • Readily soluble in hydrochloric acid

viscosity of the cross-linked gel.

USAGE

APPLICATION AGA-XL-1 is used at a concentration of 4-5 ga/1000 gallons (4-

A cross-linked acid system provides better fluid loss control 5 L/m3) of gelled acid.

and diverts live acid to another part of the formation face to

prevent “wormhole” development. It allows the acid to PHYSICAL PROPERTIES

concentrate on the full area of the formation. Clearwater's AGA- Appearance...............................................Reddish-Brown Liquid

400ME is a self-diverting acid system because the fluid cross- Specific gravity ............................................................1.41-1.46

links as the pH of the system rises (pH=2.5-3.0) and then Density..........................................................11.75-12.16 lbs/gal

breaks back to its original viscosity as the pH continues to rise Freeze Point, ...........................................................-50°C (-58°F)

(pH=4.0-5.0). pH (neat).............................................................................<2.0

Solubility,

AGA-XL-1 reacts with the polymer in AGA-400ME as the pH water, 25°C (77°F)........................................................Complete

increases to create a cross-link and divert the live acid. acid, 25°C (77°F) ..........................................................Complete

This material is supplied solely for informational purposes and Clearwater makes no guarantees or warranties, either expressed or implied, with respect to the accuracy

and the use of this data. All product warranties and guarantees shall be governed by the Standard Terms of Sale. 2003/08

ISO 9001 Certified

Clearwater 713/693-4844 Headquarters www.cwichem.com

515 Post Oak Blvd., Suite 200 713/693-4490 Fax

Houston, Texas 77027 USA

< Back

CLEARWATER

Engineered Chemistry T e c h n i c a l D a t a

ICA-720

Iron Reducing Agent

DESCRIPTION ADVANTAGES

ICA-720 is an organic acid sodium salt that functions as an iron • Prevents iron precipitation from spent acid solutions

reducing agent and oxygen scavenger for fracturing and • Removes free oxygen from stimulation fluids

acidizing fluids. ICA-720 also functions as an anti-oxidant and • Effective at temperatures >149°C (>300°F)

weak chelating agent. • Prevents ferric iron compatibility problems in gelled/cross-

linked acid systems

APPLICATION • Readily soluble in hydrochloric acid

Iron control is required for any acidizing treatment. Iron control

agents react with dissolved iron and other dissolved metal ions DISADVANTAGES

to inhibit solids precipitation as acid spends and pH rises. The • Not recommended for batch mixing

iron control agents function by preventing the re-precipitation of • Effectiveness degrades with time and temperature in HCl acid

iron compounds through maintaining the iron cations in

solution. USAGE

ICA-720 is normally used at 3-10 lbs/1000 gallons (0.36-1.2

The formation of sludge during stimulation treatments is often kg/m3) in 15% or 28% HCl acid or 5-20 lbs/1000 gallons (0.6-2.4

enhanced or stabilized by the presence of iron. Therefore, kg/m3) in fracturing fluids.

effective iron control may also control/reduce sludge formation.

PHYSICAL PROPERTIES

The presence of ICA-720 in acidizing solutions prevents the Appearance ......................................White to Off-White Powder

precipitation of gelatinous ferric hydroxide from spent acid pH (10%) ..........................................................................5.0-8.0

primarily by reducing ferric iron to the more soluble ferrous iron. Bulk Density .............................................................60-64 lbs/ft3

Because ICA-720 does not spend itself on the already soluble Solubility, 15% in Water................................................Complete

ferrous iron, it controls ferric iron precipitation at much lower Solubility, >25% in Acid...............................................Complete

concentrations than competitive materials.

This material is supplied solely for informational purposes and Clearwater makes no guarantees or warranties, either expressed or implied, with respect to the accuracy

and the use of this data. All product warranties and guarantees shall be governed by the Standard Terms of Sale. 2003/08

ISO 9001 Certified

Clearwater 713/693-4844 Headquarters www.cwichem.com

515 Post Oak Blvd., Suite 200 713/693-4490 Fax

Houston, Texas 77027 USA

< Back

CLEARWATER

Engineered Chemistry T e c h n i c a l D a t a

AI-600

High-Temperature Acid Corrosion Inhibitor

DESCRIPTION ADVANTAGES

AI-600 contains a quinoline quat surfactant, an synergistic • Contains no propargyl alcohol

blend of an acetylenic alcohol replacement, solvents and a • Non-Hazardous for DOT purposes

highly effective dispersion package that enable it to inhibit • High-temperature performance

corrosion in all hydrochloric (HCl) and hydrochloric-hydrofluoric • Compatible with intensifiers: AII-F90, AII-240, AII-241 &

(HCl-HF) acid concentrations up to 177°C (350°F). The upper AII-245

temperature limit can be increased by the use of inhibitor • Eliminates sulfide scaling, hydrogen embrittlement

intensifiers. • Compatible with refinery catalyst

• Disperses easily in acid and water

AI-600 contains no propargyl alcohol and has a high flash point,

making the product non-hazardous for DOT purposes. USAGE

The typical concentration range for AI-600 is 1-20 gal/1000

APPLICATION gallons (1-20 L/m3) depending on acid strength, acid type,

Uninhibited hydrochloric acid of various strengths will react to temperature and contact time. Please refer to the following

corrode steel. The amount of damage to assets coming in charts for performance information.

contact with the acid is a function of contact time, acid

strength, and temperature. As the temperature goes up, the PHYSICAL PROPERTIES

effectiveness of many acid inhibitors drops below desirable Appearance..............................................Dark Red/Purple Liquid

protection levels. Specific Gravity ............................................................1.03-1.07

Density..............................................................8.58-8.91 lbs/gal

Although AI-600 is compatible with most surfactants, Solubility in Water..........................................................Miscible

demulsifiers and mutual solvents, care should be taken when Compatibility .............................................Cationic and nonionic

designing acid treatments. Corrosion rates are tripled or Flash Point (TCC).....................................................77°C (170°F)

quadrupled when anionic anti-sludging agents are added to the pH (neat) ..........................................................................2.0-4.0

inhibited acid. Mutual solvents, cationic gelling agents and Freeze Point......................................................<-30°C (<-22°F)

nonionic surfactants increase the corrosion rate of the inhibited

acid package only slightly. Laboratory tests are highly

recommended to determine the upper temperature limits of any

acid system.

Anionic anti-sludging agents and water-wetting surfactants

should be mixed continuously and run “on-the-fly”. Always

thoroughly mix the acid additives in the acid prior to leaving the

service center and again before pumping downhole.

AI-600 is compatible with intensifiers such as organic acids

(AII-F90), metal halides (AII-240 & AII-241) and antimony

compounds (AII-245).

(Continued)

This material is supplied solely for informational purposes and Clearwater makes no guarantees or warranties, either expressed or implied, with respect to the accuracy

and the use of this data. All product warranties and guarantees shall be governed by the Standard Terms of Sale. 2003/08

ISO 9001 Certified

Clearwater 713/693-4844 Headquarters www.cwichem.com

515 Post Oak Blvd., Suite 200 713/693-4490 Fax

Houston, Texas 77027 USA

< Back

CLEARWATER

Engineered Chemistry T e c h n i c a l D a t a

AI-600

Corrosion Testing

Table 1

Conditions: N-80 Steel 15% HCl @ 22.2 mls/in2

% AI-600 % AII-F90 Intensifier Time, hrs. Temp, °F / °C Corr. Rate, #/ft2 Pit

0.2 --- 24 150 / 66 0.0081 0

0.2 --- 16 175 / 79 0.0048 0

0.4 --- 16 200 / 93 0.0132 0

0.6 2.0 6 225 / 107 0.0140 3,0,0

0.6 3.0 6 250 / 121 0.0133 0,1,0

0.6 3.0 6 275 / 135 0.0141 3,0,0

0.6 4.0 6 300 / 149 0.0217 1,1,1

1.0 6.0 2 350 / 177 0.0240 0,0,0

Table 2

Conditions: N-80 Steel 28% HCl @ 22.2 mls/in2

% AI-600 % AII-F90 Intensifier Time, hrs. Temp, °F / °C Corr. Rate, #/ft2 Pit

0.4 --- 24 150 / 66 0.0107 0,0,0

0.8 --- 16 175 / 79 0.0155 0,0,3

1.0 --- 16 200 / 93 0.0321 0,0,0

0.6 4.0 6 225 / 107 0.0115 1,0,0

0.6 6.0 6 250 / 121 0.0169 0,0,0

0.6 6.0 6 275 / 135 0.0165 0,0,0

1.0 6.0 6 300 / 149 0.0221 0,0,0

Table 3

Conditions: N-80 Steel 12-3 Mud Acid @ 22.2 mls/in2

% AI-600 % AII-F90 Intensifier Time, hrs. Temp, °F / °C Corr. Rate, #/ft2 Pit

0.1 --- 24 150 / 66 0.0161 0,3

0.2 --- 24 150 / 66 0.0085 0,1,0

0.3 --- 24 175 / 79 0.0089 0,0,0

0.4 --- 16 200 / 93 0.0114 0,0

0.4 3.0 6 225 / 107 0.0151 4,3

0.6 3.0 6 250 / 121 0.0157 3,0,3

0.6 4.0 6 275 / 135 0.0162 0,0

0.8 4.0 6 300 / 149 0.0233 3,3

(Continued)

This material is supplied solely for informational purposes and Clearwater makes no guarantees or warranties, either expressed or implied, with respect to the accuracy

and the use of this data. All product warranties and guarantees shall be governed by the Standard Terms of Sale. 2003/08

ISO 9001 Certified

Clearwater 713/693-4844 Headquarters www.cwichem.com

515 Post Oak Blvd., Suite 200 713/693-4490 Fax

Houston, Texas 77027 USA

< Back

CLEARWATER

Engineered Chemistry T e c h n i c a l D a t a

AI-600

Corrosion Testing

Table 4

Conditions: J-55 Steel 15% HCl & 12-3 Mud Acid @ 22.2 mls/in2

% AI-600 % AII-F90, Intensifier Acid Type Time, hrs. Temp, °F / °C Corr. Rate, #/ft2 Pit

0.2 --- 15% HCl 24 150 / 66 0.0110 0,0,0

0.2 --- 12-3 Mud 24 150 / 66 0.0086 0,0,0

0.6 --- 15% HCl 16 200 / 93 0.0143 0,0,0

0.4 --- 12-3 Mud 16 200 / 93 0.0127 0,0,0

0.6 4.0 15% HCl 6 300 / 149 0.0174 0,0,0

Table 5

Conditions: CR-13 15% & 28% HCl and 12-3 Mud Acid @ 22.2 mls/in2

% AI-600 % AII-F90, Intensifier Acid Type Time, hrs. Temp, °F / °C Corr. Rate, #/ft2 Pit

0.4 --- 15% HCl 24 150 / 66 0.0317 0,0,4

0.8 --- 28% HCl 24 150 / 66 0.0237 0,3,0

0.4 --- 12-3 Mud 24 150 / 66 0.0136 0

0.6 --- 15% HCl 24 175 / 79 0.0246 0

1.2 --- 28% HCl 24 175 / 79 0.0798 2,5

0.4 --- 12-3 Mud 24 175 / 79 0.0177 0

0.8 --- 15% HCl 16 200 / 93 0.0400 3,0,3

1.0 --- 28% HCl 16 200 / 93 0.0723 1,3

0.8 --- 12-3 Mud 16 200 / 93 0.0212 0,0,0

1.0 3.0 15% HCl 6 225 / 107 0.0384 1,1,1

2.0 6.0 15% HCl 6 250 / 121 0.0249 1,1,1

(Continued)

This material is supplied solely for informational purposes and Clearwater makes no guarantees or warranties, either expressed or implied, with respect to the accuracy

and the use of this data. All product warranties and guarantees shall be governed by the Standard Terms of Sale. 2003/08

ISO 9001 Certified

Clearwater 713/693-4844 Headquarters www.cwichem.com

515 Post Oak Blvd., Suite 200 713/693-4490 Fax

Houston, Texas 77027 USA

< Back

CLEARWATER

Engineered Chemistry T e c h n i c a l D a t a

AI-600

Corrosion Testing

Table 6

Conditions: QT-700 15% & 28% HCl and 12-3 Mud Acid @ 22.2 mls/in2

% AI-600 % AII-F90, Intensifier Acid Type Time, hrs. Temp, °F / °C Corr. Rate, #/ft2 Pit

0.1 --- 15% HCl 24 150 / 66 0.0039 0

0.3 --- 28% HCl 24 150 / 66 0.0107 4

0.1 --- 12-3 Mud 24 150 / 66 0.0045 0

0.2 --- 15% HCl 24 175 / 79 0.0037 0,0,0

0.4 --- 28% HCl 24 175 / 79 0.0177 0,1,1

0.1 --- 12-3 Mud 24 175 / 79 0.0074 0

0.3 --- 15% HCl 16 200 / 93 0.0075 0,0,0

0.4 --- 28% HCl 16 200 / 93 0.0288 3,3

0.2 --- 12-3 Mud 16 200 / 93 0.0090 1,1,0

0.4 2.0 15% HCl 6 225 / 107 0.0054 0

0.6 2.0 28% HCl 6 225 / 107 0.0061 0

0.4 2.0 12-3 Mud 6 225 / 107 0.0057 0

1.0 2.0 15% HCl 6 250 / 121 0.0076 0,0,0

0.8 2.0 15% HCl 6 275 / 135 0.0097 0,0,0

1.0 3.0 28% HCl 6 275 / 135 0.0129 0,0,0

0.8 2.0 12-3 Mud 6 275 / 135 0.0168 0,0,0

1.0 2.0 15% HCl 6 300 / 149 0.0111 0,0,0

1.0 3.0 28% HCl 6 300 / 149 0.0223 0,0,0

0.8 2.0 12-3 Mud 6 300 / 149 0.0145 0,0,0

Pit Ranking*

Rank Description of Pitting

0 No pits. Surface same as for original untreated coupon.

1 Intergranular corrosion on cut edge of coupon, giving a sintered effect; no pits on major surfaces.

2 Small, shallow pits on cut edges; no pits on major surfaces.

3 Scattered, very shallow pin point pits, less than 25 pits on either surface.

4 More than 25 pits of Rank 3 on either surface.

5 Ten or less pits of 1/32” to 1/16” diameter, 1/64” to 1/32” deep.

6 11-25 pits of Rank 5.

7 More than 25 pits of Rank 5.

8 Pits larger than 1/16” but less than 1/8” in diameter, greater than 1/32” deep, 100 or less in number.

9 Any pitting more severe than Rank 8.

Pitting represented by Ranks 1, 2, 3 and 4 are usually not considered serious. Ranks 1 and 2 are on surfaces that normally do not occur

in oil well tubular goods.

* - SPE 5644, C.F. Smith, F.E. Dollarhide & Nancy J. Byth; Dowell. Presented at 50th Annual Meeting of SPE, Dallas, TX 9/28 10/1/75.

ISO 9001 Certified

Clearwater 713/693-4844 Headquarters www.cwichem.com

515 Post Oak Blvd., Suite 200 713/693-4490 Fax

Houston, Texas 77027 USA

You might also like

- JSA - Electrical Testing - Circuit Breaker Field TestDocument4 pagesJSA - Electrical Testing - Circuit Breaker Field TestTawfik Mohamed Abu Zaid0% (1)

- PT Chemco Webinar at Surabaya Indinesia 18022023Document116 pagesPT Chemco Webinar at Surabaya Indinesia 18022023Lisa H. K100% (2)

- Nitinol Af Testing StrategiesDocument5 pagesNitinol Af Testing StrategiesTodd DicksonNo ratings yet

- The Model Joint Venture AgreementDocument222 pagesThe Model Joint Venture AgreementWael LotfyNo ratings yet

- Alketerge EDocument4 pagesAlketerge EYohanes OktavianusNo ratings yet

- Escaid High Performance Base Fluids LR PDFDocument4 pagesEscaid High Performance Base Fluids LR PDFLê CôngNo ratings yet

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisFrom EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisRating: 5 out of 5 stars5/5 (1)

- Caregiving TG - 10Document31 pagesCaregiving TG - 10Amer Dalanda100% (2)

- E1817 PDFDocument3 pagesE1817 PDFalfonso_comimsaNo ratings yet

- Alpacon ALTREAT 400Document2 pagesAlpacon ALTREAT 400ECO Green and BlueNo ratings yet

- Boiler AUTOTREAT - 25 LTRDocument2 pagesBoiler AUTOTREAT - 25 LTRBINIT SINGHNo ratings yet

- Aquatreat Selection GuideDocument3 pagesAquatreat Selection GuideMustafa KareemiNo ratings yet

- Coolant OAT Bulletin LT32533Document2 pagesCoolant OAT Bulletin LT32533Castro RicardoNo ratings yet

- 419 - Composites Catalogue-AtulDocument12 pages419 - Composites Catalogue-AtulVaittianathan Mahavapillai100% (1)

- Treat: Koch 275 AntiscalantDocument2 pagesTreat: Koch 275 Antiscalantdalton2004No ratings yet

- Filtro Carbon ActivadoDocument3 pagesFiltro Carbon ActivadoPepe CarreraNo ratings yet

- Epoxy Curing Agent BrochureDocument9 pagesEpoxy Curing Agent Brochureavinash3285No ratings yet

- Apogee Flash ColumnsDocument8 pagesApogee Flash ColumnsResolution Systems, Inc.No ratings yet

- AutotreatDocument2 pagesAutotreatAne SierasNo ratings yet

- Coventya Cooling Water LinecardDocument3 pagesCoventya Cooling Water Linecarddalton2003No ratings yet

- Ag HR Seri S: High Rejection Brackish Water RO ElementsDocument2 pagesAg HR Seri S: High Rejection Brackish Water RO ElementsPraveen KumarNo ratings yet

- 02-WTS Storage Tank PWC10111D10Document3 pages02-WTS Storage Tank PWC10111D10LuisNo ratings yet

- TDS - Glenium Ace 340Document3 pagesTDS - Glenium Ace 340Alexi ALfred H. TagoNo ratings yet

- Hydrogen Generators: Hydrogen On Demand Up To 1,300 Ml/minDocument2 pagesHydrogen Generators: Hydrogen On Demand Up To 1,300 Ml/minAnish KarthikeyanNo ratings yet

- Primal Ac337 Emulsione Acrilica 890029 TdsDocument18 pagesPrimal Ac337 Emulsione Acrilica 890029 TdsForeverNo ratings yet

- SGL ScaleBuster 970 TDS v2Document3 pagesSGL ScaleBuster 970 TDS v2Luis HenriqueNo ratings yet

- TDS - Glenium Ace 415Document3 pagesTDS - Glenium Ace 415Alexi ALfred H. TagoNo ratings yet

- Autotreat - 25 LTRDocument2 pagesAutotreat - 25 LTRMichael SimplicioNo ratings yet

- 05chemicalDocument2 pages05chemicaldalton2004No ratings yet

- Oil and Gas: Application Focus: Condensate Stabilization /fractionationDocument2 pagesOil and Gas: Application Focus: Condensate Stabilization /fractionationSomar AdamNo ratings yet

- Coolant For EngineDocument27 pagesCoolant For EnginemunhNo ratings yet

- Pelletizer Gala 12S EN SDocument12 pagesPelletizer Gala 12S EN SJR De la PazNo ratings yet

- Blueworks ChlorinatorDocument30 pagesBlueworks ChlorinatorerniewatersNo ratings yet

- Application Engineering Bulletin: Automotive Industrial Marine G-Drive Genset Powergen Antifreeze in Warm ClimatesDocument3 pagesApplication Engineering Bulletin: Automotive Industrial Marine G-Drive Genset Powergen Antifreeze in Warm ClimatesCesar G.No ratings yet

- Medallist Softener Inst Op PartsDocument31 pagesMedallist Softener Inst Op PartsmountaintreeNo ratings yet

- Econtrol Web 4 PDFDocument10 pagesEcontrol Web 4 PDFJeyaraj KLNo ratings yet

- Catalogue Water Conformance Water Shutoff Rev02 SKRDocument7 pagesCatalogue Water Conformance Water Shutoff Rev02 SKRMehrez AssidyNo ratings yet

- Amberlite™ Ira958 CL: Ion Exchange ResinsDocument2 pagesAmberlite™ Ira958 CL: Ion Exchange ResinsLuisAlbertoRendónNo ratings yet

- On-Site Hypochlorite Generation System OSEC® B-Pak: Product SheetDocument2 pagesOn-Site Hypochlorite Generation System OSEC® B-Pak: Product SheetNguyễn NgọcNo ratings yet

- Agc-40 CS AwDocument2 pagesAgc-40 CS AwlartarorNo ratings yet

- Accu-Tab Aquatics CapBrochureDocument12 pagesAccu-Tab Aquatics CapBrochureJay SuguitanNo ratings yet

- PERI Arctic3x3ATC FoamConcentrate Datasheet v1-1Document2 pagesPERI Arctic3x3ATC FoamConcentrate Datasheet v1-1Luis Alberto Serrano MesaNo ratings yet

- Ap 954 TDS EnglishDocument2 pagesAp 954 TDS EnglishHUANG StevenNo ratings yet

- Atotech Cupracid Ultra ADocument11 pagesAtotech Cupracid Ultra AKodagnanaso kodagNo ratings yet

- Echo Pure - RFSDocument1 pageEcho Pure - RFSCameron AirdNo ratings yet

- Economical Chemical RecoveryDocument5 pagesEconomical Chemical Recoveryroohollah13No ratings yet

- Silcolapse 426R: DescriptionDocument2 pagesSilcolapse 426R: DescriptionherryNo ratings yet

- Anslurry PDFDocument4 pagesAnslurry PDFraul_beronNo ratings yet

- PRIMAL™ AC-2337: Pure Acrylic Emulsion PolymerDocument6 pagesPRIMAL™ AC-2337: Pure Acrylic Emulsion PolymerSameer AhmedNo ratings yet

- Techsheet AuDocument2 pagesTechsheet AuidrisssoftNo ratings yet

- Dow MetalworkingDocument6 pagesDow MetalworkingBen Karthiben NathanNo ratings yet

- Technical Datasheet: AME™ 6001 INF-135 Premium Marine Resin InfusionDocument2 pagesTechnical Datasheet: AME™ 6001 INF-135 Premium Marine Resin InfusionMarjan ArhNo ratings yet

- Racor FiltryDocument32 pagesRacor FiltryMuhammadObaidullahNo ratings yet

- User Guide For Organic Acids Analysis Columns: The Power of DiscoveryDocument17 pagesUser Guide For Organic Acids Analysis Columns: The Power of DiscoveryGeetha ThiruvengadamNo ratings yet

- ES COMPLEAT™ AntifreezeCoolant - LT15548Document2 pagesES COMPLEAT™ AntifreezeCoolant - LT15548Cesar G.No ratings yet

- Alkaline Non-Cyanide ZincDocument4 pagesAlkaline Non-Cyanide ZincSuraj RawatNo ratings yet

- Angus Amp 90 TdsDocument2 pagesAngus Amp 90 TdsTomek DekaNo ratings yet

- Technical Datasheet: Acrylate Gel For Structure Leak SealDocument7 pagesTechnical Datasheet: Acrylate Gel For Structure Leak SealAyman ElMawardyNo ratings yet

- Albatex Sa-200 NewDocument5 pagesAlbatex Sa-200 NewruestchivaNo ratings yet

- 700 Series Portable: Reverse Osmosis System 650 To 2600 Ml/minDocument2 pages700 Series Portable: Reverse Osmosis System 650 To 2600 Ml/mineduardoNo ratings yet

- SVR® GT - XT RO Product Bulletin - UP24 - WebDocument4 pagesSVR® GT - XT RO Product Bulletin - UP24 - WebconfidentialaroundNo ratings yet

- ACUMER 3100 Boiler FormulationDocument12 pagesACUMER 3100 Boiler FormulationAlfonso Dominguez GonzalezNo ratings yet

- Resistance: Guide To ChemicalDocument32 pagesResistance: Guide To ChemicaleragornNo ratings yet

- Technical Data Sheet: Performa 560Document10 pagesTechnical Data Sheet: Performa 560Diego NavaNo ratings yet

- How Reverse Osmosis Works: A Look at Industrial ROFrom EverandHow Reverse Osmosis Works: A Look at Industrial RORating: 2.5 out of 5 stars2.5/5 (2)

- (Welding) ANSI-AWS Standard A5.5-96 Specification For Low-Alloy Steel Electrodes For Shielded Metal Arc Welding (Ebook, 55 Pages)Document55 pages(Welding) ANSI-AWS Standard A5.5-96 Specification For Low-Alloy Steel Electrodes For Shielded Metal Arc Welding (Ebook, 55 Pages)hammadNo ratings yet

- Salesforce Pages Developers GuideDocument810 pagesSalesforce Pages Developers GuideanynameNo ratings yet

- Paypal SecurityDocument5 pagesPaypal SecurityNazer Mo GNo ratings yet

- Ethics QuizDocument2 pagesEthics QuizLegogie Moses AnoghenaNo ratings yet

- Wordsearch Fruits Fun Activities Games Games Icebreakers Oneonone Ac - 109759Document2 pagesWordsearch Fruits Fun Activities Games Games Icebreakers Oneonone Ac - 109759raquel lujanNo ratings yet

- Project Eagle QualitativeDocument188 pagesProject Eagle QualitativeCheriel Anne EsnardoNo ratings yet

- 2011-10-07 - Hand Out - Ithaca - Harm. of Interpr. en 15512Document19 pages2011-10-07 - Hand Out - Ithaca - Harm. of Interpr. en 15512alfonxxlNo ratings yet

- Final Health EducDocument139 pagesFinal Health EducsprrwgoldenNo ratings yet

- SACH Tooth Brush - Launch Docket PDFDocument13 pagesSACH Tooth Brush - Launch Docket PDFSami ShaikhNo ratings yet

- A Critical Literature Review of World-Class Universities Characteristics, Enablers, and StrategiesDocument9 pagesA Critical Literature Review of World-Class Universities Characteristics, Enablers, and StrategiesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 4understanding Calculations in Tableau - TableauDocument4 pages4understanding Calculations in Tableau - TableauChanakya ChanuNo ratings yet

- Motor Nuron Disease and The Life of Motor Neurones.Document1 pageMotor Nuron Disease and The Life of Motor Neurones.mjkenneallyNo ratings yet

- 01 - EN - Why Invest in Tribe - Accor Global Development - FEB2020Document66 pages01 - EN - Why Invest in Tribe - Accor Global Development - FEB2020Ivan DidiNo ratings yet

- An Argument For Working Capital AdjustmentsDocument4 pagesAn Argument For Working Capital AdjustmentschristianNo ratings yet

- Lesson Plan 14Document3 pagesLesson Plan 14api-268829047No ratings yet

- Acid Rain: Kingdom of Saudi Arabia Ministry of Higher Education King Faisal University Dept. of ScienceDocument7 pagesAcid Rain: Kingdom of Saudi Arabia Ministry of Higher Education King Faisal University Dept. of ScienceAl HasaNo ratings yet

- Suryaputhran Sasidharan CVDocument4 pagesSuryaputhran Sasidharan CVSuryaputhran SasidharanNo ratings yet

- SF - SafeFlame Data Sheet UVIRDocument2 pagesSF - SafeFlame Data Sheet UVIRVincent GabrielNo ratings yet

- Foreign Currency TranactionDocument11 pagesForeign Currency TranactionAngelieNo ratings yet

- IGTM-CT Gas Turbine Meter: Documentation and Technical SpecificationsDocument12 pagesIGTM-CT Gas Turbine Meter: Documentation and Technical Specificationsajitp123No ratings yet

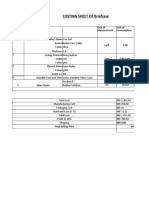

- Costing Breif CaseDocument2 pagesCosting Breif Casehema varshiniNo ratings yet

- Geophysics & Remote SensingDocument5 pagesGeophysics & Remote SensingHaris Eko SetyawanNo ratings yet

- Cityscope Sports and LeisureDocument7 pagesCityscope Sports and LeisurePD HoàngNo ratings yet

- Bandas PDFDocument3 pagesBandas PDFClaudia DiazNo ratings yet

- A Seminar Report On: An International Study On A Risk of Cyber TerrorismDocument7 pagesA Seminar Report On: An International Study On A Risk of Cyber TerrorismManish SakalkarNo ratings yet