Professional Documents

Culture Documents

Sauter Vug032f304

Sauter Vug032f304

Uploaded by

NORODDINEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sauter Vug032f304

Sauter Vug032f304

Uploaded by

NORODDINECopyright:

Available Formats

Product data sheet 10.1 56.

120

VUG: 2-way flanged valve, PN 25/16 (el.)

How energy efficiency is improved

Efficiency means precise and reliable control

Features

• Continuous control of cold and hot water in closed circuits, and of steam

• In combination with valve actuators AVM 322(S), AVM 234S, AVN 224S and AVF 234S as a control

unit

• Water quality as per VDI 2035

• Valve with flange connection as per EN 1092-2, seal form B

• Nominal pressure 25 bar, except VUG065F316, nominal pressure 16 bar

• Not suitable for drinking water

• Complies with standard for control units as per DIN EN 145971)

VUG032F304

• Regulating valve, free of silicone grease, painted black

• Equal-percentage characteristic, can be set with SUT (SAUTER Universal Technology) valve actua-

tors to linear or quadratic

• The valve is closed when the spindle is moved out

• Closing procedure against the pressure or with the pressure

• Valve body made of ductile cast iron; seat and spindle of stainless steel

• Plugs of nominal diameter DN 15...50 made of stainless steel with glass-fibre-reinforced PTFE seal-

ing ring

• Plugs of nominal diameter DN 65...150 made of stainless steel with metal-to-metal seal

• Maintenance-free stuffing box in brass with spring-loaded PTFE washer

Technical data

Parameters

Nominal pressure PN 16/25

Connection Flange as per EN 1092-2, form B

Valve characteristic Equal-percentage

Control ratio of valve > 50:1

Leakage rate at max. ∆ps ≤ 0.05% of Kvs value

Admissible ambient conditions

Operating temperature2) -20...200 °C

Operating pressure3) PN 16:

30 °C, 16 bar

At 120 °C, 16 bar

At 200 °C, 14 bar

PN 25:

30 °C, 25 bar

At 120 °C, 25 bar

At 200 °C, 21.7 bar

Standards and directives

Pressure and temperature data EN 764, EN 1333

1)

The VUG065F316 valve does not have TÜV approval. It does not bear the test institute code and

is classified under category I of the Directive on Pressure Equipment. This valve can be used with

the AVN224SF*** actuator, but not as a safety device. Use stuffing box heater at temperatures be-

low 0 °C; use the relevant adapter (accessory) at temperatures above 130 °C or 180 °C. Down to

-10 °C, as per AD code of practice W 10, use water with anti-freeze and brine solution. For use as

per DIN EN 14597. When valve is combined with AVN 224S, admissible media temperature is >

0 °C.

2) For cold water applications from -20...30 °C, the versions VUG***F3**S with a stuffing box containing silicone

(e.g.: VUG015F304S) must be used. The valves VUG***F3**S do not comply with the standard for regulating

units as per DIN EN 14597. VUG***F3**S are only available up to DN 125.

Use stuffing box heater at temperatures below 0 °C; use the relevant adapter (accessory) at temperatures

above 130 °C or 180 °C. Down to -10 °C, as per AD code of practice W 10, use water with anti-freeze and brine

solution

3) For operating pressure, see table: Pressure / temperature assignment

Right of amendment reserved © 2017 Fr. Sauter AG 1/10

Product data sheet 10.1 56.120

Flow parameters EN 60534

Test marks TÜV

ID: 13556

Overview of types

Type Nominal diameter Kvs value Valve stroke Connection Weight

VUG015F374 DN 15 0.16 m³/h 20 mm PN 25/16 4 kg

VUG015F364 DN 15 0.25 m³/h 20 mm PN 25/16 4 kg

VUG015F354 DN 15 0.4 m³/h 20 mm PN 25/16 4 kg

VUG015F344 DN 15 0.63 m³/h 20 mm PN 25/16 4 kg

VUG015F334 DN 15 1 m³/h 20 mm PN 25/16 4 kg

VUG015F324 DN 15 1.6 m³/h 20 mm PN 25/16 4 kg

VUG015F314 DN 15 2.5 m³/h 20 mm PN 25/16 4 kg

VUG015F304 DN 15 4 m³/h 20 mm PN 25/16 4 kg

VUG020F304 DN 20 6.3 m³/h 20 mm PN 25/16 5 kg

VUG025F304 DN 25 10 m³/h 20 mm PN 25/16 5.6 kg

VUG032F304 DN 32 16 m³/h 20 mm PN 25/16 9.1 kg

VUG040F304 DN 40 25 m³/h 20 mm PN 25/16 11.2 kg

VUG050F304 DN 50 40 m³/h 20 mm PN 25/16 13.8 kg

VUG065F316 DN 65 63 m³/h 40 mm PN 16 25 kg

VUG065F304 DN 65 63 m³/h 40 mm PN 25 25 kg

VUG080F304 DN 80 100 m³/h 40 mm PN 25/16 37 kg

VUG100F304 DN 100 160 m³/h 40 mm PN 25 50 kg

VUG125F304 DN 125 250 m³/h 40 mm PN 25 75 kg

VUG150F304 DN 150 340 m³/h 40 mm PN 25 100 kg

Accessories

Type Description

0372336180 Adapter (required when temperature of the medium is 130...180 °C)

0372336240 Adaptor (required when temperature of the medium is 180...200 °C)

0378284100 Stuffing box heater 230V~, 15 W for medium below 0 °C

0378284102 Stuffing box heater 24V~, 15 W for medium below 0 °C

0378384001 Torsion protection DN 65...150

0560260001 Stuffing box for VUG/BUG for cold water application with grease containing silicone

2/10 Right of amendment reserved © 2017 Fr. Sauter AG

Product data sheet 10.1 56.120

Combination of VUG with electric actuators

/ Warranty: The technical data and pressure differences indicated here are applicable only in com-

bination with SAUTER valve actuators. The warranty does not apply if used with valve actuators

from other manufacturers.

/ Definition of ∆p s: Maximum admissible pressure drop in the event of a malfunction (pipe break

after the valve) at which the actuator reliably closes the valve by means of a return spring.

/ Definition of ∆p max: Maximum admissible pressure drop in control mode at which the actuator

reliably opens and closes the valve.

Pressure differences

Actuator AVM322F120 AVM322SF132 AVM234SF132 AVF234SF132 AVF234SF232 AVN224SF132

AVM322F122 AVN224SF232

Actuating power 1000 N 1000 N 2500 N 2000 N 2000 N 1100 N

2-/3-

2-/3-point, 0...10 V, 2-/3-point, 0...10 V, 2-/3-point, 0...10 V, 2-/3-point, 0...10 V,

Control signal 2-/3-point pt., 0...10 V, 4...20 m

4...20 mA 4...20 mA 4...20 mA 4...20 mA

A

Running time DN

120/240 s 80/120 s 40/80/120 s 40/80/120 s 40/80/120 s 40/80/120 s

15...50

Running time for

– – 80/160/240 s 80/160/240 s 80/160/240 s 80/160/240 s

DN 65...150

∆p [bar]

Closes against

∆pmax ∆pmax ∆pmax ∆pmax ∆ps ∆pmax ∆ps ∆pmax ∆ps

the pressure

VUG015F374

VUG015F364

VUG015F354

VUG015F344

VUG015F334 16.0 16.0 16.0 16.0 25.0 16.0 25.0 16.0 25.0

VUG015F324

VUG015F314

VUG015F304

VUG020F304

VUG025F304 15.2 15.2 16.0 16.0 25.0 16.0 25.0 16.0 17.0

VUG032F304 9.4 9.4 16.0 16.0 21.0 16.0 21.0 10.5 10.5

VUG040F304 6.1 6.1 16.0 13.5 13.5 13.5 13.5 6.5 6.5

VUG050F304 4.0 4.0 11.0 8.5 8.5 8.5 8.5 4.0 4.0

VUG065F316 – – 7.1 5.6 5.6 5.6 5.6 – –

VUG065F304 – – 7.1 5.6 5.6 5.6 5.6 3.0 3.0

VUG080F304 – – 4.7 3.4 3.4 3.4 3.4 2.0 2.0

VUG100F304 – – 3.0 2.2 2.2 2.2 2.2 1.1 1.1

VUG125F304 – – 2.0 1.6 1.6 1.6 1.6 0.8 0.8

VUG150F304 – – 1.5 1.2 1.2 1.2 1.2 0.6 0.6

Closes with the

∆pmax ∆pmax ∆pmax ∆pmax ∆ps ∆pmax ∆ps ∆pmax ∆ps

pressure

VUG015F374

VUG015F364

VUG015F354

VUG015F344

VUG015F334

VUG015F324 6.0 6.0 6.0 6.0 25.0 6.0 25.0 6.0 25.0

VUG015F314

VUG015F304

VUG020F304

VUG025F304

VUG032F304

VUG040F304 5.5 5.5 6.0 6.0 25.0 6.0 25.0 6.0 25.0

VUG050F304 3.5 3.5 6.0 6.0 25.0 6.0 25.0 4.0 25.0

VUG065F316 – – 4.5 4.5 25.0 4.5 25.0 – –

VUG065F304 – – 4.5 4.5 25.0 4.5 25.0 2.6 25.0

VUG080F304 – – 3.5 3.4 25.0 3.4 25.0 1.7 25.0

VUG100F304 – – 3.0 2.2 25.0 2.2 25.0 1.1 25.0

Right of amendment reserved © 2017 Fr. Sauter AG 3/10

Product data sheet 10.1 56.120

Actuator AVM322F120 AVM322SF132 AVM234SF132 AVF234SF132 AVF234SF232 AVN224SF132

AVM322F122 AVN224SF232

VUG125F304 – – – 1.6 25.0 1.6 25.0 0.8 25.0

VUG150F304 – – – 1.0 25.0 1.0 25.0 0.6 25.0

A At temperatures above 130 °C, accessories are required

A Combination with AVN 224S: with safety function as per DIN EN 14597

Description of operation

The valve can be moved to any intermediate position with an electric actuator. When the spindle is

moved out, the control passage of the valve is closed. These valves may be used in the “against the

pressure” and “with the pressure” closing procedures. The direction of flow on the valve must be con-

sidered, or must be pasted over when using “with the pressure” (adhesive to be found in fitting in-

structions). The flow parameters correspond to EN 60534.

Closing procedure against the pressure Closing procedure with the pressure

These regulating valves are characterised by their reliability and precision and make an important

contribution towards efficient regulation. They meet difficult challenges such as safety functions, over-

coming high differential pressures, controlling media temperatures and performing the shut-off func-

tion, all with a low noise level.

The valve spindle is automatically and firmly connected to the actuator spindle. The de luxe stainless

steel SAUTER plug controls the equal-percentage flow rate in the control passage. The tightness of

the valve is ensured by the stainless steel ring pressed in the housing and the corresponding plug.

The stuffing box is maintenance-free. This consists of 6 tapered PTFE rings and a spring. The spring

ensures permanent tension on the seals, thus guaranteeing that they are leaktight against the spin-

dle. In addition, a grease reserve ensures that the spindle is constantly lubricated. The grease re-

serve also stops particles that are present in the medium from penetrating to the PTFE seal.

Intended use

This product is only suitable for the purpose intended by the manufacturer, as described in the “De-

scription of operation” section.

All related product regulations must also be adhered to. Changing or converting the product is not ad-

missible.

Engineering and fitting notes

The valves are combined with the AVM 322(S) or AVM 234S valve actuators without a spring return

or with the AVF 234S or AVN 224S valve actuators with a spring return. The actuator is mounted di-

rectly on the valve and fastened with screws. The actuator is connected with the valve spindle auto-

matically. When the system is commissioned, the AVM 322(S), AVM 234S and AVF 234S actuator

moves out and the connector automatically closes the connection to the valve when it reaches the

lower valve seat. The stroke of the valve is also detected by the actuator, and no further adjustments

are required. Therefore the force on the seat is always the same and the smallest amount of leakage

is ensured. With the SUT actuators, the characteristic can be set to linear or quadratic as required.

When using AVN 224S valve actuators, the actuator must be initialised manually. For a more detailed

description, see PDS 51.379 “Initialisation and feedback signal”.

Additional technical data

SAUTER slide rule for valve sizing P100013496

Technical manual on control units 7 000477 001

Parameters, fitting notes, control, general information Applicable EN, DIN, AD, TRD and accident prevention regu-

lations

CE conformity: PED 2014/68/EU

Fluid group II, liquid or with steam pressure

VUG065F316: CE label Category I

VUG with AVN224SF132: CE-0035 label Category IV

VUG without AVN224SF132: CE-0035 label Category II

Fitting instructions:

4/10 Right of amendment reserved © 2017 Fr. Sauter AG

Product data sheet 10.1 56.120

DN 15…50 MV 505947

DN 65…150 MV 505973

AVM 322 P100011900

AVM 234S MV 505919

AVF 234S MV 505920

AVN 224S MV 505927

Declaration on materials and the environment MD 56.120

Fitting position

The control unit can be fitted in any position, but the hanging position is not recommended. Conden-

sate, drops of water, etc. must be prevented from entering the actuator. With horizontal installation

and no structural support for the actuator, the maximum admissible weight on the valve is 25 kg.

At a media temperature

• Up to 130 °C:

• In any position except suspended.

• Over 130 °C:

• At temperatures of over 130 °C or over 180 °C, a horizontal fitting position is recommended, and

the appropriate adapter for the temperature must be used. The adapter can also be used as an

extension to come out of the pipe insulation with the actuator. To protect the actuator from exces-

sive heat, the piping must be insulated.

When the actuator is mounted on the valve, make sure the plug is not twisted on the stainless steel

seat (this can damage the sealing surface). When insulating the valve, it may only be insulated up to

the connecting clip of the actuator.

To increase the functional reliability of the valves, the system should conform to DIN EN 14336 (heat-

ing systems in buildings). DIN EN 14336 states, amongst other things, that the system has to be

flushed through before being put into service.

Using with steam

The valves can be used for steam applications up to 200 °C with the same ∆pmax values as listed in

the combination tables. When using the valve, make sure that it does not operate mainly on the lower

third of its stroke range. This position leads to an extremely high flow speed, which greatly reduces

the serviceable life of the valve.

Using with water

So that impurities are retained in the water (welding beads, rust particles, etc.) and the spindle seal is

not damaged, we recommend installing collecting filters, for example one for each floor or pipe run.

Requirements for water quality as per VDI 2035.

When using an additive in the water, the compatibility of the valve materials must be checked with the

manufacturer of the medium. The materials table shown below may be used. When using glycol we

recommend a concentration between 20% and 55%.

Approval for DIN EN 14597

With the exception of the VUG065F316, the valves can be used together with the valve actuator with

emergency function AVN 224S as per DIN EN 14597.

Other information regarding hydraulics and noise in systems

The valves can be used in a low-noise environment. To prevent noise, the pressure differences ∆pmax

listed below should not be exceeded. These are listed as recommended values in the table of pres-

sure losses.

The pressure difference ∆pv is the maximum pressure that may act on the valve regardless of the

stroke position, in order that the risk of cavitation and erosion is limited. These values are irrespective

of the actuator force. The cavitation accelerates wear on the plug and seat in the valve and causes

noises. To prevent cavitation, the differential pressure on the valve should not exceed the value ∆pcrit:

∆pcrit = (p1 – pv) × 0.5

p1 = upstream pressure before the valve (bar)

pv = steam pressure at operating temperature (bar)

The calculation works with absolute pressure.

For the spring return, the stated ∆ps values are also the permissible differential pressure up to which

the actuator can guarantee that the valve is closed in the event of an incident. Because this is an

emergency function with a fast stroke movement (using a spring), this value can exceed ∆pmax.

Right of amendment reserved © 2017 Fr. Sauter AG 5/10

Product data sheet 10.1 56.120

VUG flow-rate chart

Type ∆pv

Against the pressure [bar] With the pressure [bar]

VUG015F374 16 6

6/10 Right of amendment reserved © 2017 Fr. Sauter AG

Product data sheet 10.1 56.120

Type ∆pv

VUG015F364 16 6

VUG015F354 16 6

VUG015F344 16 6

VUG015F334 16 6

VUG015F324 16 6

VUG015F314 16 6

VUG015F304 16 6

VUG020F304 16 6

VUG025F304 16 6

VUG032F304 16 6

VUG040F304 16 6

VUG050F304 12 6

VUG065F304 10 4.5

VUG065F316 10 4.5

VUG080F304 7 3.5

VUG100F304 4.5 3

VUG125F304 3 2

VUG150F304 2 1

Additional version information

Valve body made of ductile cast iron as per EN 1563, code EN-GJS-400-18-LT, material number EN-

JS 1025 with smooth drilled flanges as per EN 1092-2, seal form B. Valve body protected by matt

paint RAL 9005 jet black. Recommended for the welding flange as per EN 1092-1. Valve fitting length

as per EN 558-1, basic series 1. Flat seal on valve body made of asbestos-free material.

Material numbers as per DIN

DIN material no. DIN designation

Valve body EN-JS1025 EN-GJS-400-18-LT (GGG40.3)

Valve seat 1.4021 X20Cr13

Spindle 1.4305 X8CrNiS18-9

Plug 1.4305 X8CrNiS18-9

Plug seal PTFE Glass-fibre reinforced

Stuffing box CW617N CuZn40Pb2

Seal under stuffing box CW024A Cu-DHP

Pressure / temperature assignment

p[bar]

PN 25

25

21,7

18 PN 16

16

14

0

-20 -10 2 120 200 °C

- 4 14 35,6 248 392 °F

0378284 102; 24 V~

0378284 100; 230 V~

Additional details on the definitions of pressure difference

∆pv:

Maximum admissible pressure difference over the valve at every stroke position, limited by noise level

and erosion.

With this parameter, the valve is characterised as a flow element with specific hydraulic behaviour.

Monitoring the cavitation and erosion along with the associated noise increases the service life and

the operational capacity.

∆pmax:

Maximum admissible pressure difference over the valve at which the actuator can reliably open and

close the valve.

Static pressure and flow effects are considered. This value ensures trouble-free stroke movement and

closing of the valve. The value ∆pv of the valve is never exceeded.

Right of amendment reserved © 2017 Fr. Sauter AG 7/10

Product data sheet 10.1 56.120

∆ps:

Maximum admissible pressure difference over the valve in the event of a malfunction (e.g. power fail-

ure, excessive temperature or pressure, pipe break) at which the actuator can close the valve tightly

and, if necessary, maintain the entire operating pressure against atmospheric pressure. Because this

is a quick-closing function with a rapid stroke movement, ∆ps can be greater than ∆pmax or ∆pv. The

disruptive flow effects that arise here are quickly passed through and are of minor importance in this

method of operation.

For 3-way valves, the values only apply to the control passage.

∆pstat:

Line pressure behind the valve. This essentially corresponds to the idle pressure when the pump is

switched off, caused for example by the fluid level in the system, increased pressure due to pressure

tanks, steam pressure, etc.

For valves that close with pressure, the static pressure plus the pump pressure are used.

Characteristic for actuators with positioner (only 24 V)

On actuator AVM 322 (S), AVM 234 S, AVF 234 S or AVN 224 S

Equal-percentage/linear/quadratic

Can be set using coding switch

Disposal

When disposing of the product, observe the currently applicable local laws.

More information on materials can be found in the Declaration on materials and the environment for

this product.

8/10 Right of amendment reserved © 2017 Fr. Sauter AG

Product data sheet 10.1 56.120

Dimension drawing

[mm] [mm]

H

H

72,5

72,5

44,5

44,5

d b

d

c

DN

Øk

DN

Øk

A

b

A

L

L

VUG DN A c L H k d b

015 15 84 54 130 20 65 14 x 4 14 VUG DN A c L H k d b

020 20 94 48 150 20 75 14 x 4 16 065 65/PN25 144 163 290 40 145 19 x 8 19

025 25 97 50 160 20 85 14 x 4 16 080 80 156 182 310 40 160 19 x 8 19

032 32 110 59 180 20 100 19 x 4 18 100 100 176 183 350 40 190 23 x 8 19

040 40 116 63 200 20 110 19 x 4 19 125 125 228 223 400 40 220 28 x 8 19

050 50 126 67 230 20 125 19 x 4 19 150 150 242 257 480 40 250 28 x 8 20

065 65/ PN16 144 163 290 40 145 19 x 4 19

Combinations

AVM 322(S) AVM 234S

[mm] [mm]

57 60 230 57 73 230

289

> 150 > 150

289

c

c

K10416 K10421

Right of amendment reserved © 2017 Fr. Sauter AG 9/10

Product data sheet 10.1 56.120

AVF 234S AVN 224S

[mm] [mm]

60 73 230

>150

44 44 160

289

> 150

241

c

K10422

Accessories

[mm]

0372336 180 0378284 100 71

0372336 240 0378284 102 36

? 40,9

a

70

14,5

0372336 T (°C) a (mm) b (mm)

1000

180 180 69,4 60

240 240 109,4 100

Fr. Sauter AG

Im Surinam 55

CH-4016 Basel

Tel. +41 61 - 695 55 55

www.sauter-controls.com

10/10 Right of amendment reserved © 2017 Fr. Sauter AG

You might also like

- LG843Ⅱ.00 (CDM843N) 《Spare Parts Manual》2015-12-30 PDFDocument231 pagesLG843Ⅱ.00 (CDM843N) 《Spare Parts Manual》2015-12-30 PDFMohammadazmy Sobursyakur100% (1)

- Is 14539 - 1998Document11 pagesIs 14539 - 1998Sumit LakhotiaNo ratings yet

- Sauter BugDocument11 pagesSauter BugMarko TurkovicNo ratings yet

- BUL: 3-Way Unit Valve, PN 16: FeaturesDocument8 pagesBUL: 3-Way Unit Valve, PN 16: FeaturesDiego Felipe Orellana AravenaNo ratings yet

- 3 81 e pv15 Pneumatic On Off Globe Valves dn15 100 enDocument6 pages3 81 e pv15 Pneumatic On Off Globe Valves dn15 100 enQuyết Bạch ĐìnhNo ratings yet

- Valvula de Control de 2 Vias dn15 100 en pv25 - 0Document6 pagesValvula de Control de 2 Vias dn15 100 en pv25 - 0Layton DfcNo ratings yet

- KVDN../2/ : Unit Through Valve (Regulating), PN 16Document5 pagesKVDN../2/ : Unit Through Valve (Regulating), PN 16Jonathan GrechNo ratings yet

- Diaphragm-Seal Type Pressure Gauges: OutlineDocument40 pagesDiaphragm-Seal Type Pressure Gauges: OutlineFadlul Akbar HerfiantoNo ratings yet

- Changde Cigarette Factory - Parts EnquiryDocument4 pagesChangde Cigarette Factory - Parts Enquiry樊瞳No ratings yet

- VFDH PRSH enDocument3 pagesVFDH PRSH enOmar JarwanNo ratings yet

- Pressure Reducing Valves enDocument41 pagesPressure Reducing Valves enkelvinNo ratings yet

- 3 Way Sauter ValveDocument8 pages3 Way Sauter ValverkssNo ratings yet

- VDP Series: Dynamic Differential Pressure Control Valves (DPCV)Document3 pagesVDP Series: Dynamic Differential Pressure Control Valves (DPCV)Muhammad MuslimNo ratings yet

- 2/2 & 3/2 Solenoid Valves: High Pressure Pneumatic Applications - 40 BarDocument12 pages2/2 & 3/2 Solenoid Valves: High Pressure Pneumatic Applications - 40 Barhoussem houssemNo ratings yet

- C2..QFL-.. R2..FL-.. Datasheet En-GbDocument4 pagesC2..QFL-.. R2..FL-.. Datasheet En-GbROGER CHNo ratings yet

- SAMSON Control Valves Type 3213 Type 3214 t5868Document12 pagesSAMSON Control Valves Type 3213 Type 3214 t5868Sai SarihadduNo ratings yet

- VCLDocument5 pagesVCLoutlander2008No ratings yet

- Medidor Caudal Kobold Flotador UrkDocument4 pagesMedidor Caudal Kobold Flotador UrkBase SistemasNo ratings yet

- Datový List - Smyčkové Regulační Ventily - PřírubovéDocument16 pagesDatový List - Smyčkové Regulační Ventily - PřírubovéMoe KimoNo ratings yet

- Herion N - 201 Valvulas SOFT SEAL 3V2P 5V2PDocument4 pagesHerion N - 201 Valvulas SOFT SEAL 3V2P 5V2PECO Green and BlueNo ratings yet

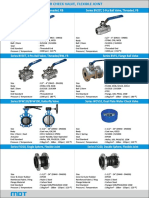

- Product Range - MDT Valve 2017Document2 pagesProduct Range - MDT Valve 2017heru hsNo ratings yet

- Externally Operated Valves: Type AV210Document12 pagesExternally Operated Valves: Type AV210usinagem arfusionNo ratings yet

- Pneumatic Valve Metalwork-10ser70valvesDocument0 pagesPneumatic Valve Metalwork-10ser70valvesRoga29No ratings yet

- Sauter VqeDocument8 pagesSauter VqeMarko TurkovicNo ratings yet

- Vann Air ValveDocument4 pagesVann Air ValveDedeLesmanaNo ratings yet

- Strainers enDocument51 pagesStrainers enmohamadNo ratings yet

- 3 80 e pv25g Pneumatic On Off Valves dn15 100Document4 pages3 80 e pv25g Pneumatic On Off Valves dn15 100Layton DfcNo ratings yet

- BS-HWC4 - Butterfly ValveDocument10 pagesBS-HWC4 - Butterfly Valvesidparikh254No ratings yet

- Data - Sheet Hora CV Act DetailsDocument2 pagesData - Sheet Hora CV Act DetailsAnand K. MouryaNo ratings yet

- Flow and Level MeterDocument16 pagesFlow and Level MeterDimas Ady PratamaNo ratings yet

- Control Valves: Slaney Direct LTDDocument15 pagesControl Valves: Slaney Direct LTDParis AnabelNo ratings yet

- Data Sheets 1301 Series High Pressure Regulators Bulletin Fisher en en 6106236Document8 pagesData Sheets 1301 Series High Pressure Regulators Bulletin Fisher en en 6106236Abdeldjalil AchourNo ratings yet

- Catalog VaneDocument16 pagesCatalog VanehbcbmwtuningNo ratings yet

- 7b-Bg-Gas ValveDocument60 pages7b-Bg-Gas Valvettiinneell8932100% (1)

- Uniworld: Series Pneumatic ValvesDocument2 pagesUniworld: Series Pneumatic ValvesSyarif Mutsaqqif100% (1)

- 3way ValveDocument8 pages3way Valveahmed ezzelarabNo ratings yet

- SveDocument28 pagesSveseaqu3stNo ratings yet

- Consiltant ToolsDocument16 pagesConsiltant ToolsOlusegun OyebanjiNo ratings yet

- CAT MANUAL-VALVES PVC-U EN ElrDocument362 pagesCAT MANUAL-VALVES PVC-U EN ElrBruno ManestarNo ratings yet

- PRV DRV RangeDocument7 pagesPRV DRV RangeSharon LambertNo ratings yet

- Inline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLDDocument11 pagesInline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLDAllan ArraisNo ratings yet

- SWV CatalogDocument48 pagesSWV Catalogtpelly7No ratings yet

- Pneumatic PosisionerDocument10 pagesPneumatic Posisionerwong_arifNo ratings yet

- SRV66 Ti P186 08 enDocument5 pagesSRV66 Ti P186 08 enGeorgeNo ratings yet

- PRV C 101 Data SheetDocument1 pagePRV C 101 Data SheetDevit FitriyantoNo ratings yet

- CLORIOUS - Pressure Reducing Valves Type G1PR (PN 25)Document2 pagesCLORIOUS - Pressure Reducing Valves Type G1PR (PN 25)RM HaroonNo ratings yet

- GSR Data Sheet Solenoid Valve Type 27Document4 pagesGSR Data Sheet Solenoid Valve Type 27BaoLCNo ratings yet

- KDF-KDG Variable Area Flow MeterDocument4 pagesKDF-KDG Variable Area Flow MeterprannoyNo ratings yet

- RAKD - GS01R01B30 00E E - Ed15 - Pub2020 07 01Document16 pagesRAKD - GS01R01B30 00E E - Ed15 - Pub2020 07 01azlanNo ratings yet

- Pressure Control Valves: Backpressure Regulators UV 1.6, 2.6Document2 pagesPressure Control Valves: Backpressure Regulators UV 1.6, 2.6cartarNo ratings yet

- Krohne Optiflux 1000 Electromagnetic Flow SensDocument12 pagesKrohne Optiflux 1000 Electromagnetic Flow SensAlejandro DallosNo ratings yet

- Fisatehnica533251 7908 41 1706926566Document6 pagesFisatehnica533251 7908 41 1706926566Gina VNo ratings yet

- Catalogue Pressure GaugesDocument50 pagesCatalogue Pressure GaugesIra MartianiNo ratings yet

- FK 21.63 (3) GB Wedge Gate Valves: Primary CharacteristicsDocument2 pagesFK 21.63 (3) GB Wedge Gate Valves: Primary CharacteristicsNguyen KhaNo ratings yet

- BHDT Fertilizer Engl Neu Online PDFDocument8 pagesBHDT Fertilizer Engl Neu Online PDFRAVINDR.KNo ratings yet

- Industrial Solenoid ValvesDocument36 pagesIndustrial Solenoid Valvesศตวรรษ ฉิมวัยNo ratings yet

- Dissolved O2 AnalyzersDocument3 pagesDissolved O2 AnalyzerssolbahiaNo ratings yet

- FF Side Mounting Float Switch - B0Document15 pagesFF Side Mounting Float Switch - B0giathinh123456789No ratings yet

- Spirax Sarco Ball Float PDFDocument12 pagesSpirax Sarco Ball Float PDFchanayireNo ratings yet

- vffg2-vffg3 PRSH enDocument7 pagesvffg2-vffg3 PRSH enOmar JarwanNo ratings yet

- Combined Hvac Edcl-PeniDocument56 pagesCombined Hvac Edcl-PeniNORODDINENo ratings yet

- 2º Eso Possesive Adj & PronDocument10 pages2º Eso Possesive Adj & PronNORODDINENo ratings yet

- SiemensDocument108 pagesSiemensNORODDINE100% (1)

- Jumo Heattherm-At and Jumo Heattherm-Dr: Type 603070, Surface-Mounted or Room Thermostat VersionsDocument15 pagesJumo Heattherm-At and Jumo Heattherm-Dr: Type 603070, Surface-Mounted or Room Thermostat VersionsNORODDINENo ratings yet

- Energies 12 00693Document21 pagesEnergies 12 00693NORODDINENo ratings yet

- Bag In/Bag Out: A Multi-Stage High Efficiency Filtration SystemDocument2 pagesBag In/Bag Out: A Multi-Stage High Efficiency Filtration SystemNORODDINENo ratings yet

- AVF 234S: SUT Valve Actuator With Spring Return: FeaturesDocument8 pagesAVF 234S: SUT Valve Actuator With Spring Return: FeaturesNORODDINENo ratings yet

- S+S Regeltechnik TF54 PT1000 400mm + MF-06-MDocument6 pagesS+S Regeltechnik TF54 PT1000 400mm + MF-06-MNORODDINENo ratings yet

- At The Fire Station - Unit 4Document10 pagesAt The Fire Station - Unit 4NORODDINENo ratings yet

- Huba Control 604 - Pressure - SwitchDocument4 pagesHuba Control 604 - Pressure - SwitchNORODDINENo ratings yet

- F9NN 04 - Install, Test and Commission Compressed Air SystemsDocument29 pagesF9NN 04 - Install, Test and Commission Compressed Air SystemsNORODDINENo ratings yet

- At Rooftops School - Unit 3Document8 pagesAt Rooftops School - Unit 3NORODDINENo ratings yet

- 2 Shell and Tube ExchangerDocument8 pages2 Shell and Tube ExchangerarulrakkNo ratings yet

- Grúa Tadano Faun ATF 130 G5Document93 pagesGrúa Tadano Faun ATF 130 G5Reinaldo ZorrillaNo ratings yet

- Wat 14Document48 pagesWat 14kky chanNo ratings yet

- Peter Savage CastingsDocument32 pagesPeter Savage CastingsggrapsasNo ratings yet

- Various Bs Astm German Rsa StandardsDocument40 pagesVarious Bs Astm German Rsa StandardsRahul KhoslaNo ratings yet

- BR Prepump A4 Eng 201106Document12 pagesBR Prepump A4 Eng 201106GrundfosEgyptNo ratings yet

- Phed BSR 2020Document68 pagesPhed BSR 2020Anil saini100% (2)

- Bridge PlugsDocument9 pagesBridge PlugsAtamoraofficeNo ratings yet

- Manual Coning Tool: Instruction SheetDocument4 pagesManual Coning Tool: Instruction Sheetanon_177818888No ratings yet

- Sfze Q 000114078Document17 pagesSfze Q 000114078Waqar KhanNo ratings yet

- Calorised Pipes Petrochemical W-UpDocument6 pagesCalorised Pipes Petrochemical W-UpSunil Gupta100% (1)

- Rotary DrillingDocument63 pagesRotary Drillingayan100% (2)

- Ch-38 Plinth Area RateDocument7 pagesCh-38 Plinth Area RateAchinta_b11No ratings yet

- Types of Flanges-Definition of FlangesDocument4 pagesTypes of Flanges-Definition of FlangesindikumaNo ratings yet

- Welded and Seamless Steel Pipe Piles: Standard Specification ForDocument7 pagesWelded and Seamless Steel Pipe Piles: Standard Specification Forsharon blushteinNo ratings yet

- Eziline Mortar Mix - Linings PDFDocument1 pageEziline Mortar Mix - Linings PDFMatthew ButlerNo ratings yet

- Butterfly TrainingDocument24 pagesButterfly TrainingOlawale John AdeotiNo ratings yet

- Lethal Service - Quick Guide - Pressure Vessel EngineeringDocument8 pagesLethal Service - Quick Guide - Pressure Vessel EngineeringIara NascimentoNo ratings yet

- Watsonmarlow 520 Ip66 ManualDocument93 pagesWatsonmarlow 520 Ip66 Manualch tcNo ratings yet

- 13L00501A - 7P-A: General NotesDocument7 pages13L00501A - 7P-A: General NotesCLS AKNo ratings yet

- Techno Commercial Part IIDocument9 pagesTechno Commercial Part IImalaya tripathyNo ratings yet

- Installation, Operation & Maintenance Manual Coro Vane Pump IC101 PDFDocument40 pagesInstallation, Operation & Maintenance Manual Coro Vane Pump IC101 PDFSergio Muñoz OjedaNo ratings yet

- Din en 25817Document1 pageDin en 25817vietduchbkNo ratings yet

- VESDA For COLD STORAGE - SMOKE DETECTION System PDFDocument15 pagesVESDA For COLD STORAGE - SMOKE DETECTION System PDFjayakrishna_2009No ratings yet

- Catalog BondstrandDocument6 pagesCatalog Bondstrandgigiphi1No ratings yet

- Company Profile PT Guna Teguh AbadiDocument23 pagesCompany Profile PT Guna Teguh AbadialfiansputraNo ratings yet

- Masonry Work Productivity RateDocument13 pagesMasonry Work Productivity RateLito EstimosNo ratings yet

- Tomoe Valve-ManualDocument2 pagesTomoe Valve-Manualphuc nguyenNo ratings yet