Professional Documents

Culture Documents

Welding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel Code

Welding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel Code

Uploaded by

Nuwan RanaweeraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel Code

Welding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel Code

Uploaded by

Nuwan RanaweeraCopyright:

Available Formats

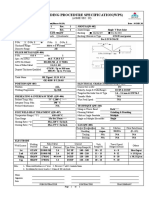

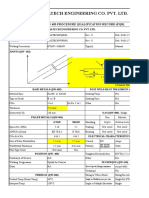

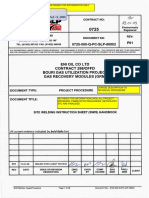

WEC ENGINEERS & CONSTRUCTORS PTE LTD,

CHINA NATIONAL CHEMICAL ENGINEERING NO.14

CONSTRUCTION CO., LTD (CNCEC.14) AND

PT WIJAYA KARYA (PERSERO) TBK WIKA (THE JV PARTNERS)

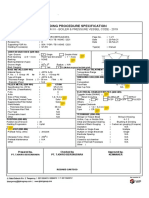

WELDING PROCEDURE SPECIFICATION ( WPS )

ASME SEC IX, 2017 BOILER AND PRESSURE VESSEL CODE Page 1 of 2

WPS No. WPS-054 Date 18 July 2019

Revision No. 0

Supporting PQR No. PQR-054 Rev.0 Code ASME IX 2010__________

Welding Process GTAW Type Manual____________

JOINTS ( QW 402 ) JOINT DETAILS

Joint Design Butt, Tee, Corner, Fillet

Backing Yes No

Backing Mat'l (Type) N.A.

1-1.5 mm

2-3 mm

BASE METALS ( QW 403 )

P No. 8 Gr. No. 1 to P No. 8 Gr. No. 1______

Or

Specification type and grade 304,304L,304H,304LN,TP305,CF3A,CF8A,WP304,CPF8A,CPF3A and Equal

to Specification type and grade 304,304L,304H,304LN,TP305,CF3A,CF8A,WP304,CPF8A,CPF3A and Equal

Qualified Thickness Range of Base Metal

Groove 1.5mm to 5.54.mm

Fillet Unlimited

Max. Pass Thickness Limit: GTAW: 2.4Ø - 4.0 mm),

Note : 50 mm Dia and below shall be made using the Gas Tungsten Arc Welding (GTAW) as per RIS 11-01

FILLER METALS ( QW 404 ) POSTWELD HEAT TREATMENT ( QW 407 )

Spec. No. ( SFA ) SFA 5.9 AWS Temp. Range Not required

No. ( Class ) ER308L Time Range n/a

F No. 6 GAS ( QW 408 )

A No. 1

Size of Filler Metal 2.4mmØ Shielding Gas(es) Argon

Percent Composition( Mixture ) 99.997%

Weld Metal Flow Rate 10 to 15 LPM

Thickness Range: Gas Backing n/a

Groove 5.54 mm Flow Rate n/a

Fillet Unlimited Trailing Gas n/a

Electrode Flux ( Class ) n/a

Flux Trade Name n/a

Consumable Insert: Kiswel

Others None

POSITION ( QW 405 ) ELECTRICAL CHARACTERISTICS ( QW 409 )

Position (s) of Groove All Current AC or DC Direct Current

Welding Progression: Up Yes Down No Polarity Straight

Position (s) of Fillet All Amps ( Range ) see page 2 of 2

PREHEAT ( QW 406 ) Preheat Temp. Min Ambient Volts ( Range ) see page 2 of 2

(15°C minimum) Interpass Temp. Max. 250°C Tungsten Electrode Size and Type 2.4mm, 2% EWTH

maximum Preheat Maintenance n/a Mode of Metal Transfer for GMAW n/a

Electrode Wire Feed Speed Range n/a

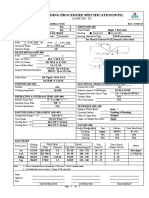

WEC ENGINEERS & CONSTRUCTORS PTE LTD,

CHINA NATIONAL CHEMICAL ENGINEERING NO.14

CONSTRUCTION CO., LTD (CNCEC.14) AND

PT WIJAYA KARYA (PERSERO) TBK WIKA (THE JV PARTNERS)

WELDING PROCEDURE SPECIFICATION ( WPS )

ASME SEC IX, 2017 BOILER AND PRESSURE VESSEL CODE Page 2 of 2

WPS No. WPS-054 Revision No. 0

WELDING TECHNIQUE ( QW 410 )

String or Weave Bead Both - Contact Tube to Work Distance n/a

Orifice or Gas Cup size n/ a Single or Multiple Pass ( per side ) Both

Initial or Inter pass Cleaning Brushing / Grinding Single or Multiple Electrode Single

Method of Back Gouging Grinding / Arc Gouging Peening n/a

Oscillation None Welding in Closed or Out Chamber Out Chamber

Others None

CHARACTERISTICS ELECTRODE DETAILS

Directio Speed Heat input Size

Pass no Process Polarity Amps Volts Spec no Name.

n mm/min Kj/mm (mm)

1-Root GTAW Vert up DCSP 40-60 11-15 60-80 0.44-0.67 2.4 mm ER308L Kiswel

2-Hot 0.88- ER308

Pass

GTAW Vert up DCSP 40-60 11-15 30-50 2.4 mm Kiswel

1.08 L

118- 01.1- ER308

Cap SMAW Vert up DCSP 11-20 30-50 2.4 mm Kiswel

130 1.26 L

ADDITIONAL INSTRUCTIONS:

1) Welding machine for GTAW process shall be high frequency starting equipment equal.

2) Radial misalignment or hi-lo shall be limited, max 1.5 mm.

3) Number of passes will vary with change in the thickness.

4) Change of electrode and filler wire(refer to mill certificate and if equivalent can be used)

5) Tack weld technique shall be same as with root pass and minimum 25mm, except where not practical.

6) Weld reinforcement should be 3.0mm maximum.

PREPARED BY: APPROVED BY: REVIEWED BY:

Lakshmanan Srinivasan Steven Seow

THIRD PARTY/CLIENT

JV PARTNERS JV PARTNERS QA / QC REPRESENTATIVE

QA / QC ENGINEER QA / QC MANAGER

You might also like

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (6)

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Helmut Zander, Anthroposophie in DeutschlandDocument14 pagesHelmut Zander, Anthroposophie in DeutschlandBibliorare100% (1)

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- Smaw Wps FinalDocument3 pagesSmaw Wps FinalsheikmoinNo ratings yet

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- ITP (Inspection Test Plan) For Tank ConstructionDocument6 pagesITP (Inspection Test Plan) For Tank ConstructionNuwan RanaweeraNo ratings yet

- NPP Education PolicyDocument20 pagesNPP Education PolicyNuwan RanaweeraNo ratings yet

- WPS MCC 001 PDFDocument1 pageWPS MCC 001 PDFNuwan RanaweeraNo ratings yet

- 011 WPS ASME TOP F 2022 - Rev.0Document8 pages011 WPS ASME TOP F 2022 - Rev.0megantara maromNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- WPS-ASME-009-1 Rev1Document1 pageWPS-ASME-009-1 Rev1Ahmed LepdaNo ratings yet

- WPS-ASME-007-1 Rev0Document1 pageWPS-ASME-007-1 Rev0Ahmed LepdaNo ratings yet

- PQR 77Document14 pagesPQR 77BIIS QAQC Babu SivaNo ratings yet

- Final PQRDocument130 pagesFinal PQRAhamed Naufal CaNo ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- Asme IxDocument1 pageAsme IxAxel Navarro AlbinesNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (2)

- WpsDocument3 pagesWpsPankaj KumarNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- PQR 03 2014Document2 pagesPQR 03 2014vinuNo ratings yet

- Wps PQR PipexlsxDocument190 pagesWps PQR PipexlsxIshwarNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- WPS CuNiDocument4 pagesWPS CuNiSripathyNo ratings yet

- 4 2WPSDocument2 pages4 2WPSsaravanans18910% (1)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- Wps Aws d1.1 Ss400 To Ss400 Gmaw-RevDocument2 pagesWps Aws d1.1 Ss400 To Ss400 Gmaw-RevAnonymous zfC1zo9C100% (2)

- WPS Dissimilar 11.08 MM Max.Document4 pagesWPS Dissimilar 11.08 MM Max.Sripathy50% (2)

- (Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Document6 pages(Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Saifulla CmpNo ratings yet

- Wps Magi Tig Exemple PDFDocument6 pagesWps Magi Tig Exemple PDFJaime PatrónNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (3)

- Revised PWPS 001Document2 pagesRevised PWPS 001stdshopNo ratings yet

- Form No. 101 - 401 Bharat Heavy Electricals Limited Tiruchirappalli-620014 Welding Technology Centre Page 1 of 2Document10 pagesForm No. 101 - 401 Bharat Heavy Electricals Limited Tiruchirappalli-620014 Welding Technology Centre Page 1 of 2JithinAbrahamNo ratings yet

- Rep WPS 02Document2 pagesRep WPS 02shaniraj BirajdarNo ratings yet

- Tips Wps FormatDocument5 pagesTips Wps FormatWaqas WaqasNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- PQR A106 HAL-1Document1 pagePQR A106 HAL-1Budi Setia RahmanNo ratings yet

- QW 483 - PQR (Gtaw+smaw) 04.01.17Document8 pagesQW 483 - PQR (Gtaw+smaw) 04.01.17Srikant GanjiNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- WCBDocument5 pagesWCBSuresh KrishnanNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)attaullaNo ratings yet

- 07-02-PQRDocument2 pages07-02-PQRMo ZeroNo ratings yet

- Wps 18Document2 pagesWps 18Avishek GuptaNo ratings yet

- Wps For Akbtpl E-6013 - ModifiedDocument13 pagesWps For Akbtpl E-6013 - ModifiedvinayNo ratings yet

- Toaz - Info Wps PQR Saw PRDocument6 pagesToaz - Info Wps PQR Saw PRMustafaNo ratings yet

- Welding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Document3 pagesWelding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Budi Setia RahmanNo ratings yet

- Piping WpsDocument37 pagesPiping WpsZulfokar FahdawiNo ratings yet

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- WC9Document5 pagesWC9Suresh KrishnanNo ratings yet

- Wps LCC Gt6 Cs GT 001Document3 pagesWps LCC Gt6 Cs GT 001AhedNo ratings yet

- GMCo - WPSDocument8 pagesGMCo - WPSMohamed AtefNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Nanoelectronic Devices and ApplicationsFrom EverandNanoelectronic Devices and ApplicationsTrupti Ranjan LenkaNo ratings yet

- Definitions: Source: Australian Pump Technical Handbook 3 Edition and Reproduced in Entirety With Permission From P/ADocument10 pagesDefinitions: Source: Australian Pump Technical Handbook 3 Edition and Reproduced in Entirety With Permission From P/ANuwan RanaweeraNo ratings yet

- Blushing of Amines in Coal Tar Epoxy (Amine Adduct)Document7 pagesBlushing of Amines in Coal Tar Epoxy (Amine Adduct)Nuwan RanaweeraNo ratings yet

- Hydraulic Surge Analysis ReportDocument15 pagesHydraulic Surge Analysis ReportNuwan RanaweeraNo ratings yet

- Relief Valves ProcedureDocument15 pagesRelief Valves ProcedureNuwan RanaweeraNo ratings yet

- Is Living in Sweden A Pleasure or A TormentDocument17 pagesIs Living in Sweden A Pleasure or A TormentNuwan RanaweeraNo ratings yet

- KD Aul Ôú Hla Fkdief, K WD ÓlhlaDocument32 pagesKD Aul Ôú Hla Fkdief, K WD ÓlhlaNuwan RanaweeraNo ratings yet

- Occupational Safety Health - Professional EthicsDocument10 pagesOccupational Safety Health - Professional EthicsNuwan RanaweeraNo ratings yet

- Site Welding Instruction Sheet (SWIS) HandbookDocument36 pagesSite Welding Instruction Sheet (SWIS) HandbookNuwan RanaweeraNo ratings yet

- Heat Stress!!!: Explain Dangers SymptomsDocument1 pageHeat Stress!!!: Explain Dangers SymptomsNuwan RanaweeraNo ratings yet

- Preliminary Welding Procedure Specification No.: MCC/WF/pWPS/002Document1 pagePreliminary Welding Procedure Specification No.: MCC/WF/pWPS/002Nuwan RanaweeraNo ratings yet

- Welding Procedure Qualification Record Form (WPQR) : Range of Qualification Test PieceDocument5 pagesWelding Procedure Qualification Record Form (WPQR) : Range of Qualification Test PieceNuwan RanaweeraNo ratings yet

- Welding Procedure Qualification Record Form (WPQR) : Range of Qualification Test PieceDocument5 pagesWelding Procedure Qualification Record Form (WPQR) : Range of Qualification Test PieceNuwan RanaweeraNo ratings yet

- TPP Steel PlantDocument25 pagesTPP Steel PlantPRASANTHNo ratings yet

- Solution of Assignment 5Document5 pagesSolution of Assignment 5Reza Borah100% (1)

- Start With Why SummaryDocument6 pagesStart With Why SummaryAnurag100% (1)

- Simultaneous Equations O/LDocument13 pagesSimultaneous Equations O/LVenuja De SilvaNo ratings yet

- Appositives and AdjectiveDocument2 pagesAppositives and AdjectiveRinda RiztyaNo ratings yet

- TL Files Struktol Content Maerkte-Produkte Kautschuk-Additive en Technische-Merkblaetter 01032 WB16FLAKES GB TECHDocument2 pagesTL Files Struktol Content Maerkte-Produkte Kautschuk-Additive en Technische-Merkblaetter 01032 WB16FLAKES GB TECHJoban AroraNo ratings yet

- Anggaran ElektronikaDocument12 pagesAnggaran ElektronikaSeptian IswanjayaNo ratings yet

- List Product YellowDocument10 pagesList Product YellowfitriNo ratings yet

- Office of The President: Bicol UniversityDocument1 pageOffice of The President: Bicol UniversityElmer BelgaNo ratings yet

- Chapter 9: TidesDocument40 pagesChapter 9: TidesCarol GirottoNo ratings yet

- Frampton AntithesispedagogyDocument2 pagesFrampton AntithesispedagogyJohann WieseNo ratings yet

- Barreramora Fernando Linear Algebra A Minimal Polynomial AppDocument313 pagesBarreramora Fernando Linear Algebra A Minimal Polynomial AppStrahinja DonicNo ratings yet

- Earth Dams Foundation & Earth Material InvestigationDocument111 pagesEarth Dams Foundation & Earth Material Investigationmustafurade1No ratings yet

- CCE Catalogue DetailedDocument28 pagesCCE Catalogue DetailedIshaan SinghNo ratings yet

- GattaniDocument18 pagesGattaniKhushbu NovhalNo ratings yet

- Measurement GER NER GPI - Version 1.0Document8 pagesMeasurement GER NER GPI - Version 1.0Wouter RijneveldNo ratings yet

- 14 Sept Quiz Chapter 1 SoalanDocument5 pages14 Sept Quiz Chapter 1 SoalanLukman MansorNo ratings yet

- Oxford Thesis CollectionDocument5 pagesOxford Thesis Collectionkimberlybundypittsburgh100% (2)

- Michigan Strategic Compliance Plan FINALDocument22 pagesMichigan Strategic Compliance Plan FINALbcap-oceanNo ratings yet

- Al Boury Oil FieldDocument11 pagesAl Boury Oil FieldSherif MohammedNo ratings yet

- Brac Bank LimitedDocument1 pageBrac Bank LimitedMd Mojibar RahmanNo ratings yet

- Revised Copy of Wartsila 18V220SG ProjectDocument3 pagesRevised Copy of Wartsila 18V220SG ProjectZohaib AlamNo ratings yet

- Process Flow ChartDocument22 pagesProcess Flow ChartKumar Ashutosh100% (1)

- Benstones Instruments IMPAQ ELITE 4 CanalesDocument8 pagesBenstones Instruments IMPAQ ELITE 4 CanalesmauriciojjNo ratings yet

- Catalog Stationary Screw Compressors F en V 1 3 WebDocument28 pagesCatalog Stationary Screw Compressors F en V 1 3 WebcristiNo ratings yet

- Volume AdministrationDocument264 pagesVolume AdministrationeviyipyipNo ratings yet

- 21st Century Skills PaperDocument8 pages21st Century Skills PaperemilyraleyNo ratings yet

- ECE 5325/6325 Fall 2009: Exam 1 SolutionsDocument2 pagesECE 5325/6325 Fall 2009: Exam 1 Solutionswilfred godfreyNo ratings yet

- Practical Research 2: Data Gathering ProceduresDocument8 pagesPractical Research 2: Data Gathering ProceduresJosua GarciaNo ratings yet