Professional Documents

Culture Documents

Machine Design P2-1

Machine Design P2-1

Uploaded by

Alexander MugabeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Machine Design P2-1

Machine Design P2-1

Uploaded by

Alexander MugabeCopyright:

Available Formats

MINISTRY OF HIGHER AND TERTIARY EDUCATION

HIGHER EDUCATION EXAMINATIONS COUNCIL

NATIONAL DIDLOMA

IN

MECHANICAL ENGINEERING

SUBJECT: Machine Design PAPER NO: 539/S09

FigQ7

1. A chain is to actuate a compressor from an electric motor rated at 11.2𝑘𝑊 at 970𝑟𝑝𝑚,

the

compressor speed being 350𝑟𝑝𝑚. If the minimum centre distance should be 550𝑚𝑚.

The

pitch 19.05𝑚𝑚, the roller diameter 12.07𝑚𝑚, the minimum width of roller 11.68𝑚𝑚,

the

maximum (breaking) load 5900𝑘𝑔 and the sprocket pinion has 25 teeth, calculate;

a) the pitch diameters of the pinion and wheel sprockets [4]

b) the factor of safety [4]

c) the bearing pressure (or stress) on the roller [2]

d) the length of the chain [3]

e) the actual centre distance [7]

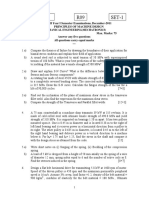

2. A nickel steel shaft carries two gears, C and D located at distances 250mm and 400mm

respectively as shown in Fig Q7. Gear C is 600mm in diameter and gear D is 200mm

in diameter. The distance between the centre lines of bearings is 2.4m. The shaft

transmits

15kW at 100rpm. The power is delivered to the shaft at gear C and taken out at gear D

in

such a manner that the tooth pressures Pt c and Pt d which become loads supported by

the

shaft, act vertically downward as shown in the end view. Find the diameter of shaft, if

the

ultimate shear stress is 900mpa and the factor of safety is 8 and gears C and D weigh

20kg

and 7kg respectively. [20]

3. a) Give 4 advantages of welded joints [4]

b) A 105x95x10 mm angle iron is welded to its support by two 10mm fillet welds. A

load

of 1575kg is applied normal to the gravity axis at a distance of 300mm from the C.G. of

the

welds. Determine the maximum shear stress in the welds, assuming each weld to be

100mm long and parallel to the axis of the angle iron. [16]

1

Cal de Mag

You might also like

- Massey Ferguson 50e Industrial Tractor Service ManualDocument38 pagesMassey Ferguson 50e Industrial Tractor Service ManualAlexander Mugabe0% (2)

- MF 6190Document674 pagesMF 6190hanganu constantin100% (1)

- 2022 MDSP With AnswersDocument101 pages2022 MDSP With AnswersMarc Citcian Gatinao67% (3)

- Problem Based Learning - MM1Document3 pagesProblem Based Learning - MM1Muhammad Ali HaiderNo ratings yet

- Mech-nd-2020-Me 8593-Design of Machine Elements-334300796-X10703 (Me8593) Design of Machine ElementsDocument5 pagesMech-nd-2020-Me 8593-Design of Machine Elements-334300796-X10703 (Me8593) Design of Machine ElementsARIGARAN SNo ratings yet

- Me6503 Dme023Document4 pagesMe6503 Dme023Bakkiya RajNo ratings yet

- 15ume503 1Document4 pages15ume503 1Sathis kumar0% (1)

- Tutorial Chapter 1Document1 pageTutorial Chapter 1Melvin Shady PereiraNo ratings yet

- 4363 111 Machine Design IDocument6 pages4363 111 Machine Design Iyogesh_b_k100% (2)

- 07a6ec05 Designofmachinemembers IIDocument11 pages07a6ec05 Designofmachinemembers IIzahid_polyNo ratings yet

- 12ME5DCDM2Document3 pages12ME5DCDM2Abhyudaya SinghNo ratings yet

- 08 r05310305 Design of Machine Members IDocument9 pages08 r05310305 Design of Machine Members IKrupanandareddyYarragudiNo ratings yet

- Me1302 Dme 2Document4 pagesMe1302 Dme 2sumikannu100% (1)

- Me201 2017 06-1 PDFDocument5 pagesMe201 2017 06-1 PDFPromise GwaindepiNo ratings yet

- r05321403 Principles of Machine DesignDocument8 pagesr05321403 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- No of Pages Course Code:: Fig.1 Fig 2Document4 pagesNo of Pages Course Code:: Fig.1 Fig 2CRAZY PIANO PLAYERNo ratings yet

- Dme Model 2Document6 pagesDme Model 2YashwanthI-StyleKuttiNo ratings yet

- Supp Nov 2009Document10 pagesSupp Nov 2009prk74No ratings yet

- r05320305 Design of Machine Members IIDocument11 pagesr05320305 Design of Machine Members IISrinivasa Rao G100% (4)

- Unit IDocument3 pagesUnit Imahendra babu mekalaNo ratings yet

- Tutorial Sheet-II MEC3110/317 (Machine Design II)Document4 pagesTutorial Sheet-II MEC3110/317 (Machine Design II)Prateeksha ShakyaNo ratings yet

- Machine Design BDocument7 pagesMachine Design BNicole MikesellNo ratings yet

- rr320305 Design of Machine Members IIDocument8 pagesrr320305 Design of Machine Members IISrinivasa Rao GNo ratings yet

- Dmm2 Mar2006Document8 pagesDmm2 Mar2006Abdul Saleem MohammedNo ratings yet

- ImportantDocument3 pagesImportantapi-386873483No ratings yet

- Objective QuestionsDocument3 pagesObjective QuestionsAnonymous YkDJkSqNo ratings yet

- Design of Machine Element-IIDocument53 pagesDesign of Machine Element-IIPramod R Bidve100% (1)

- 9A14503 Principles of Machine DesignDocument8 pages9A14503 Principles of Machine DesignsivabharathamurthyNo ratings yet

- DME Model QuesDocument3 pagesDME Model QuesSiva RamanNo ratings yet

- MD ConventionalDocument8 pagesMD ConventionalBipin KumarNo ratings yet

- Dme Model QuestionDocument2 pagesDme Model QuestiondharaniventhanNo ratings yet

- 12 Me 5dcdm2Document3 pages12 Me 5dcdm2Abhyudaya SinghNo ratings yet

- Me8593 - Dme - Model QPDocument3 pagesMe8593 - Dme - Model QPChandrasekhar PrabhakaranNo ratings yet

- Assignment QuestionDocument15 pagesAssignment QuestionPratik WalimbeNo ratings yet

- 13 ME AssignmentDocument2 pages13 ME AssignmentMuhammad Sharif JamaliNo ratings yet

- DME Chapter Three: or (Summer 15)Document7 pagesDME Chapter Three: or (Summer 15)honeyfunnyNo ratings yet

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.lavanya babuNo ratings yet

- DomeDocument3 pagesDomevikaskumar1986No ratings yet

- Me 2303 Imp QnsDocument3 pagesMe 2303 Imp QnsAJAY63No ratings yet

- Question Paper Code:: Reg. NoDocument3 pagesQuestion Paper Code:: Reg. NoSURESH KUMAR APNo ratings yet

- Time Allowed: 1.5 Hours Full Marks: 70: 604 (S) August 2021Document3 pagesTime Allowed: 1.5 Hours Full Marks: 70: 604 (S) August 2021Sourav BhowmikNo ratings yet

- 16mu315 - Machine Design Question Bank: Ut Yt B TDocument3 pages16mu315 - Machine Design Question Bank: Ut Yt B THarishNo ratings yet

- Snist Dom Previous PaperDocument9 pagesSnist Dom Previous PaperKapil Siddhant DevulapalliNo ratings yet

- Dme Model Key 2019Document25 pagesDme Model Key 2019Siva RamanNo ratings yet

- Question PapersDocument89 pagesQuestion PapersDreamer ChavanNo ratings yet

- Addis Ababa Science and Technology University Electromechanical Engineering Design Machine Element I WorksheetDocument3 pagesAddis Ababa Science and Technology University Electromechanical Engineering Design Machine Element I WorksheetHanan ShayiboNo ratings yet

- Design of Machine ElementDocument11 pagesDesign of Machine ElementVenkat RajaNo ratings yet

- Prelim 2022 SMDocument4 pagesPrelim 2022 SMARJUNANo ratings yet

- No of Pages: 4 Course Code: 12M502: Fig.1 Fig 2Document4 pagesNo of Pages: 4 Course Code: 12M502: Fig.1 Fig 2CRAZY PIANO PLAYERNo ratings yet

- 107503MEDocument7 pages107503MEPrathamNo ratings yet

- EMD Question Bank II 2Document4 pagesEMD Question Bank II 2Soham MisalNo ratings yet

- DME Question BankDocument4 pagesDME Question BankILAYAPERUMAL KNo ratings yet

- 7 Dts Question Bank-1Document22 pages7 Dts Question Bank-1Placements DhaanishNo ratings yet

- PMD ModelDocument8 pagesPMD ModelDamodara SatyaDeva MadhukarNo ratings yet

- Dec 2019 ME304 - Dynamics of Machinery (S) - Ktu QbankDocument3 pagesDec 2019 ME304 - Dynamics of Machinery (S) - Ktu QbankMidhun SukumaranNo ratings yet

- ME2303Document5 pagesME2303balameckNo ratings yet

- GATE - IES QuestionsDocument4 pagesGATE - IES QuestionsMahesh Chandrabhan ShindeNo ratings yet

- Unit 4 AssignmentsDocument5 pagesUnit 4 AssignmentsbattuarunNo ratings yet

- ME-6503 Design of Machine Elements - 16 MarksDocument12 pagesME-6503 Design of Machine Elements - 16 MarksMadhu MithaNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Blocked Ears Wax Self Guidelines For PatientsDocument2 pagesBlocked Ears Wax Self Guidelines For PatientsAlexander MugabeNo ratings yet

- Blocked Ears Wax Self Guidelines For PatientsDocument2 pagesBlocked Ears Wax Self Guidelines For PatientsAlexander MugabeNo ratings yet

- Membership Rules BookletDocument8 pagesMembership Rules BookletAlexander MugabeNo ratings yet

- Career Engineering UnisaDocument41 pagesCareer Engineering Unisaabubakr fingerNo ratings yet

- UNIT-III Steam TurbineDocument51 pagesUNIT-III Steam TurbineAlexander MugabeNo ratings yet

- Diesel Engine Timing and Injection Pump Setting & Locking SetDocument1 pageDiesel Engine Timing and Injection Pump Setting & Locking SetAlexander MugabeNo ratings yet

- GEC 117 Module 9-10 Lecture Note (Repaired)Document19 pagesGEC 117 Module 9-10 Lecture Note (Repaired)Alexander MugabeNo ratings yet

- Fluid MechanicsDocument2 pagesFluid MechanicsAlexander MugabeNo ratings yet

- Unit 1 Electrical Control ComponentsDocument13 pagesUnit 1 Electrical Control ComponentsAlexander MugabeNo ratings yet

- Requirements For The May 2021 Students 1. Automotive Department 2. Information Technology DepartmentDocument21 pagesRequirements For The May 2021 Students 1. Automotive Department 2. Information Technology DepartmentAlexander MugabeNo ratings yet

- Reverse Modulated Wet Disc Brake System: SectionDocument7 pagesReverse Modulated Wet Disc Brake System: SectionAlexander MugabeNo ratings yet

- AdhesionDocument10 pagesAdhesionAlexander MugabeNo ratings yet

- Island Job InterviewDocument2 pagesIsland Job InterviewAlexander MugabeNo ratings yet

- Brake Schematic.: N.R.Z. DRAWING No. D - 9722A Drawer No. L - 3 D.E. 10A & 11A Class LocomotivesDocument1 pageBrake Schematic.: N.R.Z. DRAWING No. D - 9722A Drawer No. L - 3 D.E. 10A & 11A Class LocomotivesAlexander MugabeNo ratings yet

- Chapter One Fluid MechanicsDocument29 pagesChapter One Fluid MechanicsAlexander MugabeNo ratings yet

- SOM - Fieldwork 02Document1 pageSOM - Fieldwork 02Alexander MugabeNo ratings yet

- EXPLODEDDocument1 pageEXPLODEDAlexander MugabeNo ratings yet

- Strength of Materials Question PaperDocument3 pagesStrength of Materials Question PaperAlexander MugabeNo ratings yet

- LU72WZ1Document8 pagesLU72WZ1hobolghaniNo ratings yet

- Hydrostatic Reservoir Sensors For Double-Wall Fiberglass TanksDocument12 pagesHydrostatic Reservoir Sensors For Double-Wall Fiberglass TanksShalvaTavdgiridzeNo ratings yet

- 101 Greseli de Lexic Si de SemanticaDocument24 pages101 Greseli de Lexic Si de Semanticaradu70No ratings yet

- Datasheet OPCom Particle Monitor 10051 EN USDocument4 pagesDatasheet OPCom Particle Monitor 10051 EN USmetinNo ratings yet

- Design and Analysis of Central Air-Conditioning System With Air Cooled Chiller of Multi-Storey Office BuildingDocument16 pagesDesign and Analysis of Central Air-Conditioning System With Air Cooled Chiller of Multi-Storey Office BuildingSajjad HasanNo ratings yet

- Densimetric TableDocument6 pagesDensimetric TablexzarrandikoNo ratings yet

- Cage Code ReferenceDocument8 pagesCage Code ReferenceBarbara MartinNo ratings yet

- Easy UPS On-Line - SRV1KI-EDocument3 pagesEasy UPS On-Line - SRV1KI-EAnh nguyen tran minh namNo ratings yet

- Shidae e CatalogueDocument20 pagesShidae e CatalogueNaveen ParthasarathyNo ratings yet

- 201 23-nm2Document326 pages201 23-nm2Kavi SaikrishnaNo ratings yet

- Gearbox SelectionDocument4 pagesGearbox SelectionsanjushaNo ratings yet

- JANARDDocument4 pagesJANARDirinuca12No ratings yet

- Motoman - Yaskawa - MPX2600 Robot - Maintenance ManuaklDocument100 pagesMotoman - Yaskawa - MPX2600 Robot - Maintenance ManuaklJesseNo ratings yet

- Genadvisor Shaft Volt Current Mon PSPG b10244 00 7600 en LR Fina PDFDocument2 pagesGenadvisor Shaft Volt Current Mon PSPG b10244 00 7600 en LR Fina PDFSourav RanaNo ratings yet

- S.M.A.R.T. Service Material and Reference TipsDocument10 pagesS.M.A.R.T. Service Material and Reference TipsAlejandro AlcubierreNo ratings yet

- Introduciton of MTM Mill and MTW Mill: We Pursue The Zenith of Technology and QualityDocument9 pagesIntroduciton of MTM Mill and MTW Mill: We Pursue The Zenith of Technology and QualityArdi NalNo ratings yet

- Dexretail-Capo-LED ColourDocument8 pagesDexretail-Capo-LED ColourFarag MohamedNo ratings yet

- Compendium of Registered Vendors Upto 30th Sep 2021Document13 pagesCompendium of Registered Vendors Upto 30th Sep 2021Aman DubeyNo ratings yet

- CRN-Infinera 7080R445 V2Document14 pagesCRN-Infinera 7080R445 V2ThomasNo ratings yet

- d8b ControllerDocument2 pagesd8b ControllerNew Age Productions MarseilleNo ratings yet

- Computer Technology INGLES IIDocument3 pagesComputer Technology INGLES IImicaela bernacheaNo ratings yet

- Ferm FHB-940 Wood LatheDocument26 pagesFerm FHB-940 Wood LatheLuke McNeilageNo ratings yet

- Datasheet MCO enDocument1 pageDatasheet MCO entuan triNo ratings yet

- Lenco LS-55WA TurntableDocument99 pagesLenco LS-55WA Turntablevaiaane.coNo ratings yet

- L17B6681 DS311 Machine Card PDFDocument6 pagesL17B6681 DS311 Machine Card PDFeduamaNo ratings yet

- Types in Incandescent LampDocument12 pagesTypes in Incandescent LampALVIN MAMITAGNo ratings yet

- Engineering Utilities 1 (Chapt4) - Student'sDocument16 pagesEngineering Utilities 1 (Chapt4) - Student'sLevine VivaNo ratings yet

- Low-Voltage Single-Phase Isolating and Safety Transformers - Class FDocument1 pageLow-Voltage Single-Phase Isolating and Safety Transformers - Class FDario PekeljevicNo ratings yet

- Design Procedure of A Push Pull Current-Fed DC-DCDocument8 pagesDesign Procedure of A Push Pull Current-Fed DC-DCIhya UlumuddinNo ratings yet