Professional Documents

Culture Documents

Mpi 44444286 ..

Mpi 44444286 ..

Uploaded by

Khalil Chabbouh0 ratings0% found this document useful (0 votes)

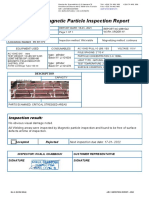

73 views1 pageThe magnetic particle inspection report summarizes the inspection of a vessel separator. Key details include:

- The inspection was performed on October 2nd, 2021 at Weatherford Base II.

- The areas inspected were the 4 lifting point weldment areas of the vessel separator with serial number 44444286.

- No visible defect indications were found, so the welds were considered acceptable.

- The next MPI inspection is scheduled for September 2nd, 2022.

Original Description:

Original Title

MPI 44444286 ..--

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe magnetic particle inspection report summarizes the inspection of a vessel separator. Key details include:

- The inspection was performed on October 2nd, 2021 at Weatherford Base II.

- The areas inspected were the 4 lifting point weldment areas of the vessel separator with serial number 44444286.

- No visible defect indications were found, so the welds were considered acceptable.

- The next MPI inspection is scheduled for September 2nd, 2022.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

73 views1 pageMpi 44444286 ..

Mpi 44444286 ..

Uploaded by

Khalil ChabbouhThe magnetic particle inspection report summarizes the inspection of a vessel separator. Key details include:

- The inspection was performed on October 2nd, 2021 at Weatherford Base II.

- The areas inspected were the 4 lifting point weldment areas of the vessel separator with serial number 44444286.

- No visible defect indications were found, so the welds were considered acceptable.

- The next MPI inspection is scheduled for September 2nd, 2022.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 1

MAGNETIC PARTICLE INSPECTION REPORT

Customer: WEATHERFORD. Report No:125487456

Rig: N-A Date: 10/02/ 2021

Next MPI inspection date: 09/02/ 2022

Test Location: weatherford Base II W.O N:19593

PAGE: 1 OF 1

TEM INSPECTED: VESSEL SEPARETOR

SERIAL / ID NO: 44444286

AREAS INSPECTED Surface Condition: Cleaned to Bare Metal

o

Test Temperature: Ambient 23 C

Illumination: Minimum 1000Lx

4 LIFTING POINTS WELDMENT AREAS 2

Black Intensity: 1000 μ watts/cm min

Materials Used for Magnetic Particle Test / Inspection

Equipment Ser No. Equipment X Ser No. Magnetizing Process : Continuous Residual

AC YOKE 7973 UV METER: X 1320005430 Magnetizing Current : Alternating Direct

DC COIL 176 LIGHT METER: 1320005430 Equipment Ser No. AC YOKE 4.5kg Test Weight OK

BLACK LIGH 180 YOKE TEST WEIGHT A205 Magnetic Field Strength Indicator M1159 COIL 1200 AMP TURNS

Consumables Type Batch

X No. Magnetizing Coil Prods Yoke

Method : Permanent Magnet

WHITE CONTRAST PAINT PFINDER L1 102932 Magnetic Field Indicator: Burmah Castrol Strip

BLACK MAGNETIC INK PFINDER L1 029065 Light Intensity:Illumination before inspection 1000 Lx

Demagnetization: YES No

WET FLUORESECENT PFINDER

X L1 165526

DRY POWDER N-A N-A Particle consontration : black ink 2.4/100ml

Particle consontration : fluorescent 0.4/100ml

Specifications: : ASTM 709-08 Magnetic Particles Dry Wet

OTHER: Weatherford WT 811

Visible Fluorescent

Scope of Work: 100% Magnetic Particle Inspection ON lifting points were inspected

Results: At the time of examination no visible defect indications were apparent, therefore the weld examined were considered acceptable to

specification.

Tool OK, Ready to Ship Needs Repair Tool Rejected, Do Not Use

Inspectors Name khalil chabbouh Customer

Qualification: ASNT INSPECTOR LEVEL II

signature

You might also like

- Dominik, William EditorDocument24 pagesDominik, William EditorRajib Chowdhury0% (3)

- Desert Magazine 1968 MarchDocument44 pagesDesert Magazine 1968 Marchdm1937100% (2)

- DBMS Project 2020Document14 pagesDBMS Project 2020Aman AgarwalNo ratings yet

- APA 7th Edition LLC 2020Document10 pagesAPA 7th Edition LLC 2020Juliana Giraldo Rivera100% (3)

- Robert Morris The Mind: Body ProblemDocument364 pagesRobert Morris The Mind: Body ProblemAriel Baron-Robbins73% (11)

- Magnetic Particle Inspection Report: TEM INSPECTED: Assembly (X Over 2",pipes 2",elbows)Document2 pagesMagnetic Particle Inspection Report: TEM INSPECTED: Assembly (X Over 2",pipes 2",elbows)Khalil ChabbouhNo ratings yet

- 1588-1326 Hyd Jar ...Document1 page1588-1326 Hyd Jar ...khalilNo ratings yet

- Fishing Jar 285204 .Document1 pageFishing Jar 285204 .Khalil ChabbouhNo ratings yet

- Lifting Plug New Report 10Document1 pageLifting Plug New Report 10Khalil ChabbouhNo ratings yet

- MPI Report - M250 - 127mm DiaDocument1 pageMPI Report - M250 - 127mm DiaGyanendraNo ratings yet

- Mpi Pipe Rack PR 03-1.Document1 pageMpi Pipe Rack PR 03-1.Khalil ChabbouhNo ratings yet

- H-18 MpiDocument2 pagesH-18 Mpisushanto.mtbdNo ratings yet

- MPI Report SWL 5 Ton BoxDocument2 pagesMPI Report SWL 5 Ton BoxYusuf bagewadiNo ratings yet

- Ibop 101801720Document2 pagesIbop 101801720André da SilvaNo ratings yet

- Techno NDT Services: Ultrasonic Flaw Detection ReportDocument1 pageTechno NDT Services: Ultrasonic Flaw Detection Reportram dreamsNo ratings yet

- 02 Spiral Drill Collar Slip Groove 6 1-2 4 1-2 IfDocument2 pages02 Spiral Drill Collar Slip Groove 6 1-2 4 1-2 IfKhalil ChabbouhNo ratings yet

- Non Destructive Testing: As Recieve Final Solvent Cleaning Others Black Ink Fluorescent RepairDocument3 pagesNon Destructive Testing: As Recieve Final Solvent Cleaning Others Black Ink Fluorescent RepairAkhmad RamdaniNo ratings yet

- NDT-TEC-M101-12 MPI Colour Contrast Electromagnet ASME VDocument2 pagesNDT-TEC-M101-12 MPI Colour Contrast Electromagnet ASME VkorichiNo ratings yet

- 04 Spiral Drill Collar Slip Groove 4 3-4Document2 pages04 Spiral Drill Collar Slip Groove 4 3-4Khalil ChabbouhNo ratings yet

- WO1831 - Arabtec 09.02.2020.Document1 pageWO1831 - Arabtec 09.02.2020.Pradeep ManivannanNo ratings yet

- MI Barite Tank 2 Mpi RepDocument7 pagesMI Barite Tank 2 Mpi RepChristopher Jones100% (1)

- 75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Document1 page75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Mohamed El-SawahNo ratings yet

- MT02Document1 pageMT02اسران احمدNo ratings yet

- Magnetic Particle Examination ReportDocument1 pageMagnetic Particle Examination ReportNadia Suci Rahma PutriNo ratings yet

- New Report 13 3-8 Inch Slips Sa 1402Document1 pageNew Report 13 3-8 Inch Slips Sa 1402Khalil ChabbouhNo ratings yet

- MT PipaDocument70 pagesMT PipaDani Madrid12No ratings yet

- NDT Report - Dovetail WheelsDocument4 pagesNDT Report - Dovetail WheelsOm Ar TanNo ratings yet

- 01.10.2021 BKC MPTDocument1 page01.10.2021 BKC MPTMN AliNo ratings yet

- CB-043 Mpi Exp-02 Apr 2024Document1 pageCB-043 Mpi Exp-02 Apr 2024Ahmed Abu EleninNo ratings yet

- 10-03-2020 C1 Gland Steam Superheater - MTDocument6 pages10-03-2020 C1 Gland Steam Superheater - MTDave CheungNo ratings yet

- C6 Turbine LP Cylinder Casing (Bottom Half) - MPIDocument7 pagesC6 Turbine LP Cylinder Casing (Bottom Half) - MPIDave CheungNo ratings yet

- Installation of Padeyes Ad Load Test: Front CoverDocument40 pagesInstallation of Padeyes Ad Load Test: Front CoverAhmedA.HassanNo ratings yet

- IRM3427 Ensco Ensco5002 Installation of Padeyes Ad Load TestDocument40 pagesIRM3427 Ensco Ensco5002 Installation of Padeyes Ad Load TestAfzaalUmairNo ratings yet

- Berhad I Endurance Anchorage: Non-Destructive TestDocument2 pagesBerhad I Endurance Anchorage: Non-Destructive TestNua JamilNo ratings yet

- Mpi Report With Uv Trdi1 Spacer Can New1Document2 pagesMpi Report With Uv Trdi1 Spacer Can New1Khalil ChabbouhNo ratings yet

- A-Star Testing & Inspection (S) Pte LTD No 5, Soon Lee Street #03-37 - Pioneer Point Singapore 627607 - Tel: +65 62616162 / +65 62616169Document8 pagesA-Star Testing & Inspection (S) Pte LTD No 5, Soon Lee Street #03-37 - Pioneer Point Singapore 627607 - Tel: +65 62616162 / +65 62616169Hari KarthickNo ratings yet

- Hil Renukoot Ut 2022-2023Document249 pagesHil Renukoot Ut 2022-2023duttcon engineeringNo ratings yet

- CNT230022-5 C3 HRSG LP Drum - MTreportDocument6 pagesCNT230022-5 C3 HRSG LP Drum - MTreportDave CheungNo ratings yet

- Magnetic Examination Report: SketchDocument69 pagesMagnetic Examination Report: SketchSeret BroNo ratings yet

- Ensco 5002. NDT Inspection Handling Tools and Wall Thickness Survey. Version - Original P.Document167 pagesEnsco 5002. NDT Inspection Handling Tools and Wall Thickness Survey. Version - Original P.mohamed fahsNo ratings yet

- MIghty Machine RejectDocument1 pageMIghty Machine RejectMohammad Shanawaz MNo ratings yet

- Int-Aim-231861 MT 06-08-23Document4 pagesInt-Aim-231861 MT 06-08-23Joshua ClaytonNo ratings yet

- CNT200020-3 C3 HRSG HP Drum - MT ReportDocument6 pagesCNT200020-3 C3 HRSG HP Drum - MT ReportDave CheungNo ratings yet

- MT RSDocument37 pagesMT RSdeari nur azisNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- MPI Report 013 5inch DP Elevator A109-2Document1 pageMPI Report 013 5inch DP Elevator A109-2John DolanNo ratings yet

- Annual Vg7076Document2 pagesAnnual Vg7076Emmanuel SanthanasamyNo ratings yet

- MPI Report 012 5inch DP Elevator A109-1Document1 pageMPI Report 012 5inch DP Elevator A109-1John DolanNo ratings yet

- 01 Warm GearDocument21 pages01 Warm GearAndri SaputraNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument4 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- MPI Report 002 Mast 002 R.1Document1 pageMPI Report 002 Mast 002 R.1John DolanNo ratings yet

- 3-2-NDT-SOIS-21 AirWinch ENF#40 MW-004314Document1 page3-2-NDT-SOIS-21 AirWinch ENF#40 MW-004314Abdou BoucheritNo ratings yet

- Control Panel FMS SN CP0001 MpiDocument1 pageControl Panel FMS SN CP0001 MpiKhalil ChabbouhNo ratings yet

- Dead Line AnchorDocument1 pageDead Line AnchorGamal AbelmaksoudNo ratings yet

- Journal BeringDocument8 pagesJournal BeringpelakupasarNo ratings yet

- 07 Mpi Report - 1Document12 pages07 Mpi Report - 1Abdou BoucheritNo ratings yet

- MPI Report 004 Mast Axis 002Document1 pageMPI Report 004 Mast Axis 002John DolanNo ratings yet

- Doosan Power Systems Indai PVT Limited: System CalibrationDocument3 pagesDoosan Power Systems Indai PVT Limited: System CalibrationBalkishan DyavanapellyNo ratings yet

- MT ReportDocument11 pagesMT Reportel_sharkawy2011100% (1)

- Gpti Qicl 032Document2 pagesGpti Qicl 032uselessinstaid52No ratings yet

- TRF 39905 Test ReportDocument4 pagesTRF 39905 Test ReportAbhishek RajputNo ratings yet

- Magnetic Particle Test Report: Observation & ResultDocument1 pageMagnetic Particle Test Report: Observation & ResultAdarsh ChaturvediNo ratings yet

- Mpi Report With Ac Yoke Lifting Eyes and Sje AdapterDocument2 pagesMpi Report With Ac Yoke Lifting Eyes and Sje AdapterKhalil ChabbouhNo ratings yet

- Rp-20-Ut-011-Tcr-Saudi CementDocument1 pageRp-20-Ut-011-Tcr-Saudi CementRonel John Rodriguez CustodioNo ratings yet

- 0026 Lifting PlugDocument1 page0026 Lifting PlugKhalil ChabbouhNo ratings yet

- 2370 Cross OverDocument1 page2370 Cross OverKhalil ChabbouhNo ratings yet

- Mpi Report With Uv Trdi1 Spacer Can New1Document2 pagesMpi Report With Uv Trdi1 Spacer Can New1Khalil ChabbouhNo ratings yet

- 0011 Lifting PlugDocument1 page0011 Lifting PlugKhalil ChabbouhNo ratings yet

- TB 5003,, (New4Document1 pageTB 5003,, (New4Khalil ChabbouhNo ratings yet

- X Over 8Document1 pageX Over 8Khalil ChabbouhNo ratings yet

- Magnetic Particle Inspection Report: TEM INSPECTED: Assembly (X Over 2",pipes 2",elbows)Document2 pagesMagnetic Particle Inspection Report: TEM INSPECTED: Assembly (X Over 2",pipes 2",elbows)Khalil ChabbouhNo ratings yet

- Bushing Drive Sub 31766Document1 pageBushing Drive Sub 31766Khalil ChabbouhNo ratings yet

- Fishing Jar 285204 .Document1 pageFishing Jar 285204 .Khalil ChabbouhNo ratings yet

- TB0084Document1 pageTB0084Khalil ChabbouhNo ratings yet

- 02 Spiral Drill Collar Slip Groove 6 1-2 4 1-2 IfDocument2 pages02 Spiral Drill Collar Slip Groove 6 1-2 4 1-2 IfKhalil ChabbouhNo ratings yet

- Mpi Pipe Rack PR 03-1.Document1 pageMpi Pipe Rack PR 03-1.Khalil ChabbouhNo ratings yet

- 04 Spiral Drill Collar Slip Groove 4 3-4Document2 pages04 Spiral Drill Collar Slip Groove 4 3-4Khalil ChabbouhNo ratings yet

- Hp013 Lifting SubDocument1 pageHp013 Lifting SubKhalil ChabbouhNo ratings yet

- 03 HWDP Spiral 3 1-2 New ReportDocument2 pages03 HWDP Spiral 3 1-2 New ReportKhalil ChabbouhNo ratings yet

- 4 Legs Sling INA 182-1.Document1 page4 Legs Sling INA 182-1.Khalil ChabbouhNo ratings yet

- Ip RRLDocument4 pagesIp RRLysabellanicoleNo ratings yet

- Wat Arunratchawararam Ratchaworamahawihan (Temple of Dawn) HistoryDocument8 pagesWat Arunratchawararam Ratchaworamahawihan (Temple of Dawn) HistoryninjazaNo ratings yet

- Getting Started With Mapp Documentation Br3o23xbDocument42 pagesGetting Started With Mapp Documentation Br3o23xbFrancescoNo ratings yet

- Cathodic CorrosionDocument16 pagesCathodic CorrosionDavid KanuNo ratings yet

- English For Grade 2Document39 pagesEnglish For Grade 2Prince Louie Morte100% (1)

- Muhammad Arasy 10 IPA 3 A Look Back at The Life of Steve JobsDocument2 pagesMuhammad Arasy 10 IPA 3 A Look Back at The Life of Steve JobsMuhammad ArasyNo ratings yet

- Colour Psychology in BrandingDocument4 pagesColour Psychology in Brandingvinayjain221100% (2)

- Representation of A Crime DramaDocument6 pagesRepresentation of A Crime Dramaejbrooky_1509No ratings yet

- Blood Sacrifice in Ancient and Medieval Greece: A ComparisonDocument8 pagesBlood Sacrifice in Ancient and Medieval Greece: A ComparisonBasil DokosNo ratings yet

- Concepcion Gomez de Jacoby Tarregas Enig-3Document1 pageConcepcion Gomez de Jacoby Tarregas Enig-3Laureano DomínguezNo ratings yet

- Tree of Life PDFDocument35 pagesTree of Life PDFAnonymous 4LWvm3F100% (1)

- Invitation Letter For LC's BOL'18Document8 pagesInvitation Letter For LC's BOL'18Asad RehanNo ratings yet

- Pokémon: The Beginning and Gold and Silver: Ash KetchumDocument2 pagesPokémon: The Beginning and Gold and Silver: Ash KetchumJank kantNo ratings yet

- Jo Nesbø WikiDocument4 pagesJo Nesbø Wikianimihiout100% (2)

- Arundhati Roy: Made By: Martin Pavlov, XIIDocument9 pagesArundhati Roy: Made By: Martin Pavlov, XIIMartin PavlovNo ratings yet

- Formwor K: A Study of Its Various Types, Materials AND Construction TechniquesDocument60 pagesFormwor K: A Study of Its Various Types, Materials AND Construction TechniquesDeep GuptaNo ratings yet

- It Was The MidDocument1 pageIt Was The MidZaara ZaveriNo ratings yet

- Chapter 05 Lesson 1 Quiz Origins of Hindu IndiaDocument4 pagesChapter 05 Lesson 1 Quiz Origins of Hindu IndiaLouie Jay Cañada AbarquezNo ratings yet

- Pronoun Case and Usage Notes and Exercises With AnswersDocument20 pagesPronoun Case and Usage Notes and Exercises With AnswersMitch-ChedyLanoriaNo ratings yet

- Practice Test 5 Use of English I. Select The Best AnswerDocument5 pagesPractice Test 5 Use of English I. Select The Best AnswerJack NguyễnNo ratings yet

- Interior Design Decoration.157171807Document15 pagesInterior Design Decoration.157171807swami061009No ratings yet

- Sixth English Exam Vi Parcial: FULL NAME: Aguilar Ramirez Jesus DATE:16 /05 /2020Document3 pagesSixth English Exam Vi Parcial: FULL NAME: Aguilar Ramirez Jesus DATE:16 /05 /2020Jesus Aguilar RamirezNo ratings yet

- ACFrOgBQyl710Yl 0NqLIUm4nu oGKiPGZsRvbGsDg50L49FRSkqOIolKJ0HrGA3WuyqkNIiUcKmFRe7Bj7O4mjz9e83cYLY4HTLtDoEfwromoBS14Xj75SfJljak8CMDRXAPC-7TO6wa69-1pZDocument3 pagesACFrOgBQyl710Yl 0NqLIUm4nu oGKiPGZsRvbGsDg50L49FRSkqOIolKJ0HrGA3WuyqkNIiUcKmFRe7Bj7O4mjz9e83cYLY4HTLtDoEfwromoBS14Xj75SfJljak8CMDRXAPC-7TO6wa69-1pZDlu DiazNo ratings yet

- (1955) Soldiers Without Swords: A History of The Salvation ArmyDocument272 pages(1955) Soldiers Without Swords: A History of The Salvation ArmyHerbert Hillary Booker 2nd100% (1)

- Churches and Symbolic Power in The Irish LanscapeDocument24 pagesChurches and Symbolic Power in The Irish LanscapeErdei Iván MárkNo ratings yet