Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 Weld

Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 Weld

Uploaded by

m4metzCopyright:

Available Formats

You might also like

- Guidance To The Verification of Runway BeamsDocument42 pagesGuidance To The Verification of Runway BeamsTiago CastelaniNo ratings yet

- 09 Samss 070Document11 pages09 Samss 070NASIR SYEDNo ratings yet

- AWS D1.1 Quick Reference Guide Prequalified WeldsDocument29 pagesAWS D1.1 Quick Reference Guide Prequalified Weldstylerstearns100% (2)

- 175 045600Document2 pages175 045600Abu Anas M.Salaheldin0% (1)

- Process Industry Practices Machinery: Pip Resp73V Application of ASME B73.2 - 2003Document31 pagesProcess Industry Practices Machinery: Pip Resp73V Application of ASME B73.2 - 2003m4metzNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistm4metzNo ratings yet

- Asme Viii QC ManualDocument70 pagesAsme Viii QC Manualneurolepsia3790No ratings yet

- API 653 CalculationDocument29 pagesAPI 653 Calculationsheikmoin100% (2)

- As-NZS 1554.1-2014 Welding Procedure Specification (WPS)Document1 pageAs-NZS 1554.1-2014 Welding Procedure Specification (WPS)Bobby CurrieNo ratings yet

- Welding Inspection CSWIP GudDocument637 pagesWelding Inspection CSWIP GudAbdul Muneer A75% (4)

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldDocument27 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldIrshad IqbalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument19 pagesSaudi Aramco Inspection ChecklistIrshad IqbalNo ratings yet

- Saic W 2011Document3 pagesSaic W 2011munnaNo ratings yet

- Saic e 2002Document10 pagesSaic e 2002jerinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument21 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saic L 2004Document18 pagesSaic L 2004ejazNo ratings yet

- Saic RT 2001Document24 pagesSaic RT 2001munnaNo ratings yet

- Saic MPT 2004 Rev 0Document6 pagesSaic MPT 2004 Rev 0philipyapNo ratings yet

- 7.2-WI-54-ITSD Inspectors Qualification Requirements Rev-05Document28 pages7.2-WI-54-ITSD Inspectors Qualification Requirements Rev-05Ksn HariNo ratings yet

- Saudi Aramco Inspection Checklist: Pre Welding Inspection - Offshore Structures SAIC-W-1312 WeldDocument1 pageSaudi Aramco Inspection Checklist: Pre Welding Inspection - Offshore Structures SAIC-W-1312 Weldkartik_harwani4387No ratings yet

- SATR-W-2020 Rev 8Document4 pagesSATR-W-2020 Rev 8محمد علي النويصرNo ratings yet

- Saep 324Document13 pagesSaep 324Up WeldNo ratings yet

- Saic RT 2007Document9 pagesSaic RT 2007munnaNo ratings yet

- Welding Procedure Qualification Record (WPQR)Document8 pagesWelding Procedure Qualification Record (WPQR)Belin InversoNo ratings yet

- SAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingDocument5 pagesSAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingFiras AlbaweiNo ratings yet

- Saudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechDocument3 pagesSaudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechmominNo ratings yet

- Saic W 2036Document2 pagesSaic W 2036Neelam AhmadNo ratings yet

- WWR 500-R-10 - Manual of Standard PracticeDocument38 pagesWWR 500-R-10 - Manual of Standard PracticePeterWayNo ratings yet

- SAIC-X-3104 Rev 3Document4 pagesSAIC-X-3104 Rev 3Imran khanNo ratings yet

- NCR - ATF Accredited Testing FacilityDocument5 pagesNCR - ATF Accredited Testing FacilityjesycubanNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 MechDocument4 pagesSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 Mechkarthi51289No ratings yet

- 175 012300Document2 pages175 012300Abu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection ChecklistAli AhmedNo ratings yet

- SAES-M-005 PDF Download - Design and Construction of Fixed Offshore Platforms - PDFYARDocument8 pagesSAES-M-005 PDF Download - Design and Construction of Fixed Offshore Platforms - PDFYARZahidRafiqueNo ratings yet

- Saudi Aramco Test Report: Internal Tank Bottom Testing 15-Jul-18 CP-SATR-X-3205Document7 pagesSaudi Aramco Test Report: Internal Tank Bottom Testing 15-Jul-18 CP-SATR-X-3205Sreni Excel MacrosNo ratings yet

- Saic A 1002Document2 pagesSaic A 1002karthi51289No ratings yet

- 5.3. 402020-01391-08-PI-SPC-0002 Rev0 PDFDocument136 pages5.3. 402020-01391-08-PI-SPC-0002 Rev0 PDFsumit kumarNo ratings yet

- PQR Editable SampleDocument2 pagesPQR Editable SampleKoya ThangalNo ratings yet

- Thermax Limited: Inspection Procedure For GalvanizingDocument14 pagesThermax Limited: Inspection Procedure For GalvanizingNsidibe Michael EtimNo ratings yet

- Demagnetization: BSS Non Destructive Testing PVT - LTDDocument18 pagesDemagnetization: BSS Non Destructive Testing PVT - LTDSANU100% (1)

- Section Subject: Shaybah CPF Expansion ProjectDocument21 pagesSection Subject: Shaybah CPF Expansion ProjectAdhie Waelacxh100% (1)

- 01-SAMSS-048 PDF Download - CRA Clad or Lined Steel PipeDocument4 pages01-SAMSS-048 PDF Download - CRA Clad or Lined Steel PipeZahidRafiqueNo ratings yet

- Office: Printout Sample - ASME WPSDocument2 pagesOffice: Printout Sample - ASME WPSDanem HalasNo ratings yet

- B H e L Limited RTDocument13 pagesB H e L Limited RTbhavin17850% (2)

- Saep 323 PDFDocument8 pagesSaep 323 PDFthanga balanNo ratings yet

- Saudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 WeldMAZHARULNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Finishing and Curing Inspection SAIC-Q-1015 15-Nov-17 MAH-SA-CDocument4 pagesSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Finishing and Curing Inspection SAIC-Q-1015 15-Nov-17 MAH-SA-CAbdul HannanNo ratings yet

- Guide To Weld Inspection For Structure SteelDocument12 pagesGuide To Weld Inspection For Structure SteelRakesh MenonNo ratings yet

- Saudi Arabian Oil Company: Instrument Specification Sheet - Pressure and Differential Pressure GaugesDocument2 pagesSaudi Arabian Oil Company: Instrument Specification Sheet - Pressure and Differential Pressure GaugesMuhammad ShahidNo ratings yet

- Part2 Notice 1Document21 pagesPart2 Notice 1Danem Halas100% (1)

- Code For Offshore Personnel Transfer Systems July 2022Document92 pagesCode For Offshore Personnel Transfer Systems July 2022Ozan DurmazogluNo ratings yet

- S1450401-Execution and Inspection of Welding WorkDocument26 pagesS1450401-Execution and Inspection of Welding Workkeeoraon4No ratings yet

- Nozzle Fit-Up Inspection Report: Inspected & Prepared byDocument9 pagesNozzle Fit-Up Inspection Report: Inspected & Prepared byDaison PaulNo ratings yet

- ABS - PipelineDocument186 pagesABS - Pipelineap1948No ratings yet

- 16 Samss 512Document40 pages16 Samss 512HatemS.MashaGbehNo ratings yet

- Rapid p0030 CPP U0030 Qac Mom 0024 Quality MeetingDocument13 pagesRapid p0030 CPP U0030 Qac Mom 0024 Quality MeetingAtuk Safiz100% (1)

- S0600 Aa Pro 070Document44 pagesS0600 Aa Pro 070opruzhak-boxNo ratings yet

- Application Form For CSWIP 5 Year Renewal (Overseas) - v3 1Document7 pagesApplication Form For CSWIP 5 Year Renewal (Overseas) - v3 1Bamarasan ArasanNo ratings yet

- SATIP-W-011-01 Rev 8Document10 pagesSATIP-W-011-01 Rev 8saravananmenmathiNo ratings yet

- 175 011100Document2 pages175 011100Abu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 24-Mar-16 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 24-Mar-16 CivilSajid ShaikhNo ratings yet

- G16S-0202-07 - Two Layer PaintingDocument7 pagesG16S-0202-07 - Two Layer Paintingpuwarin naja100% (1)

- Compex International CentresDocument2 pagesCompex International CentresnjennsNo ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldDocument32 pagesSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldIrshad Iqbal100% (2)

- SABP G 003 AramcoDocument9 pagesSABP G 003 Aramcom4metz100% (1)

- SABP G 002 AramcoDocument7 pagesSABP G 002 Aramcom4metz100% (1)

- Dhiraj Dhirendra KumarDocument6 pagesDhiraj Dhirendra Kumarm4metz100% (1)

- Process Industry Practices Machinery: Pip Resp73H Application of ASME B73.1 - 2001Document15 pagesProcess Industry Practices Machinery: Pip Resp73H Application of ASME B73.1 - 2001m4metzNo ratings yet

- Sabp F 004Document19 pagesSabp F 004m4metzNo ratings yet

- Sabp G 001Document12 pagesSabp G 001m4metz100% (1)

- Best Practice: Quick Energy Assessment Methodology For Energy Efficiency OptimizationDocument66 pagesBest Practice: Quick Energy Assessment Methodology For Energy Efficiency Optimizationm4metzNo ratings yet

- Saudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 15-Jul-18 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 Weldm4metz100% (1)

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistm4metzNo ratings yet

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Jul-18 Weldm4metzNo ratings yet

- Quality and Inspection: D.DHANASEKAR M.E.,Mem.A.S.M.E., Design Engineer - MechanicalDocument45 pagesQuality and Inspection: D.DHANASEKAR M.E.,Mem.A.S.M.E., Design Engineer - MechanicalRUDHRA DHANASEKARNo ratings yet

- Material Take Off: Client OGC Project IAC Upgrade Project Location Sultanate of OmanDocument13 pagesMaterial Take Off: Client OGC Project IAC Upgrade Project Location Sultanate of OmanDeepak RajanNo ratings yet

- Seimens PS 555Document26 pagesSeimens PS 555HoangNo ratings yet

- En Iso 15609-1-2004Document10 pagesEn Iso 15609-1-2004Marija IvanovskaNo ratings yet

- 2294E2-0000-DA00-SPC-0002 Rev 0Document14 pages2294E2-0000-DA00-SPC-0002 Rev 0amirNo ratings yet

- Welding Management As A Tool For Innovative, Competitive and Sustainable Manufacturing: Case Study - West AfricaDocument12 pagesWelding Management As A Tool For Innovative, Competitive and Sustainable Manufacturing: Case Study - West AfricaAlex MazabuelNo ratings yet

- Guidelines For Specification, Welding and Inspection of Stainless Alloy Piping Craig Reid, P.EngDocument19 pagesGuidelines For Specification, Welding and Inspection of Stainless Alloy Piping Craig Reid, P.EngFinnFan8No ratings yet

- Appendix T - Weld Metal - Welding Procedure Specification Notch Toughness Verification Test - BNBC 2020 CommentaryDocument2 pagesAppendix T - Weld Metal - Welding Procedure Specification Notch Toughness Verification Test - BNBC 2020 CommentaryTarif Aziz MarufNo ratings yet

- Attachment-20 - STN-00-Z21-V-SP-0007 P01 - ENDocument36 pagesAttachment-20 - STN-00-Z21-V-SP-0007 P01 - ENrameshqcNo ratings yet

- En Scheme of Welder Certification ENGDocument4 pagesEn Scheme of Welder Certification ENGHoque Anamul100% (1)

- Documentation of Welding Procedure TestDocument5 pagesDocumentation of Welding Procedure Testrty2No ratings yet

- 175 011100Document2 pages175 011100Abu Anas M.SalaheldinNo ratings yet

- Updated Quality PlanDocument23 pagesUpdated Quality PlanThi PhamNo ratings yet

- Process Industry Practices Piping: PIP PNSC0001 Fabrication and Examination Specification For ASME B31.3 Metallic PipingDocument17 pagesProcess Industry Practices Piping: PIP PNSC0001 Fabrication and Examination Specification For ASME B31.3 Metallic PipingMidhun K Chandrabose100% (3)

- DNV-Fabrication and Testing of Offshore Structures PDFDocument44 pagesDNV-Fabrication and Testing of Offshore Structures PDFgelo_17No ratings yet

- Ex A-Weld 24'' 5 KMDocument12 pagesEx A-Weld 24'' 5 KMJabel Oil Services Technical DPTNo ratings yet

- Inspection Test Plan For Fabrication PDF FreeDocument4 pagesInspection Test Plan For Fabrication PDF Freesam paulNo ratings yet

- DKSKV Welding Technology MTK 201Document8 pagesDKSKV Welding Technology MTK 201Eizanie MuhamadNo ratings yet

- 175 010800Document3 pages175 010800Abu Anas M.Salaheldin100% (1)

- Fracture TestDocument1 pageFracture TestYuvaraj SathishNo ratings yet

- Wps Sp14 Reva PDFDocument9 pagesWps Sp14 Reva PDFravi00098No ratings yet

- 2 5418388499906691582 PDFDocument12 pages2 5418388499906691582 PDFrezaNo ratings yet

- Summary of Changes in ASME Section IX, 1998 EditionDocument5 pagesSummary of Changes in ASME Section IX, 1998 EditionTeguh Setiono100% (1)

- Aws American Welding Society ﺎﻜﯾﺮﻣآ شﻮﺟ ﻦﻤﺠﻧا دراﺪﻧﺎﺘﺳا: Pdf Created With Pdffactory Pro Trial VersionDocument33 pagesAws American Welding Society ﺎﻜﯾﺮﻣآ شﻮﺟ ﻦﻤﺠﻧا دراﺪﻧﺎﺘﺳا: Pdf Created With Pdffactory Pro Trial VersionAli SASSINo ratings yet

Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 Weld

Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 Weld

Uploaded by

m4metzOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 Weld

Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 Weld

Uploaded by

m4metzCopyright:

Available Formats

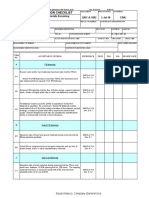

SAUDI ARAMCO ID/PIEU-15-July-2018-REV. 2018.05.00(Standards Cutoff - May 31,2018) Rev.2018.05.

00 31-May-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 WELD-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A Welding Procedure Requirements

All welding procedures to be used shall be submitted as a complete

package to Saudi Aramco CSD for technical approval prior to the start of

work.The Package shall include:

A) Welding Procedure Request Form (Attachment A) SAES-W-011,

B) Welding Procedure Specifications (WPS) Para. 7.1.1 &

A1

C) Qualification Test Records (PQR) SAEP-352

D) Weld and Line Description Tables (Attachment B). Table -1

Note: Refer to SAEP-352 Table-1 for the welding Procedures to be

submitted for CSD review.

All procedures shall be submitted to PMT in clear and legible scanned pdf

format for onward transmittal to CSD through the Engineering Service

Request (ESR) using Customer Relationship Management (CRM)

system.

NOTE: CSD will issue a review sheet for each welding procedure

SAES-W-011,

A2 indicating the review status. If a welding procedure is approved, the

Para. 7.1.1

official approval stamp will be on the approved digital copy of the WPS

which will be sent back to PMT through CRM system.

Weld & Line Description Table (Attach. B) shall include:

A) Matls, thickness, & weld joint type for

individual line designations. B) A welding procedure shall be

listed for each different weld type and line designation.

C) All base SAES-W-011,

A3

materials (by spec, grade, P-No, Piping Diameter range) and wall Para. 7.1.3

thicknesses to be used shall be included in the Weld Table.

D) Weld Table shall only be reviewed with WPSs and

PQRs and and vice-versa.

Each Weld Table shall be completed & show all line designations to be

used for the entire complete job or contract.

Note : Line Service designation ("sour", non-sour, Internal FBE

SAES-W-011,

A4 Coated, Impact tested CS, Severe Cycle or Category M service, & other

Para. 7.1.4

special service considerations such as Hardness Testing & PWHT shall

be so designated in the Attachment B. Utilize the Remarks Section as

needed.

All Welding Procedure Specifications and Welding Procedure SAES-W-011,

A5

Qualification Records shall be written in English. Para. 7.1.9

Saudi Aramco: Company General Use

For shop fabrication In-Kingdom and all field fabrication and installation,

the Welding Procedure Specifications (WPSs) and Procedure

Qualification Records (PQRs) shall be prepared as per the suggested

SAES-W-011,

A6 format of ASME SEC IX.

Para. 7.1.2

NOTE: Standardized PQR forms from an approved independent test

laboratory are acceptable. Equivalent WPS forms from a contractor may

be acceptable if approved by CSD.

Saudi Aramco: Company General Use

You might also like

- Guidance To The Verification of Runway BeamsDocument42 pagesGuidance To The Verification of Runway BeamsTiago CastelaniNo ratings yet

- 09 Samss 070Document11 pages09 Samss 070NASIR SYEDNo ratings yet

- AWS D1.1 Quick Reference Guide Prequalified WeldsDocument29 pagesAWS D1.1 Quick Reference Guide Prequalified Weldstylerstearns100% (2)

- 175 045600Document2 pages175 045600Abu Anas M.Salaheldin0% (1)

- Process Industry Practices Machinery: Pip Resp73V Application of ASME B73.2 - 2003Document31 pagesProcess Industry Practices Machinery: Pip Resp73V Application of ASME B73.2 - 2003m4metzNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistm4metzNo ratings yet

- Asme Viii QC ManualDocument70 pagesAsme Viii QC Manualneurolepsia3790No ratings yet

- API 653 CalculationDocument29 pagesAPI 653 Calculationsheikmoin100% (2)

- As-NZS 1554.1-2014 Welding Procedure Specification (WPS)Document1 pageAs-NZS 1554.1-2014 Welding Procedure Specification (WPS)Bobby CurrieNo ratings yet

- Welding Inspection CSWIP GudDocument637 pagesWelding Inspection CSWIP GudAbdul Muneer A75% (4)

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldDocument27 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldIrshad IqbalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument19 pagesSaudi Aramco Inspection ChecklistIrshad IqbalNo ratings yet

- Saic W 2011Document3 pagesSaic W 2011munnaNo ratings yet

- Saic e 2002Document10 pagesSaic e 2002jerinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument21 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saic L 2004Document18 pagesSaic L 2004ejazNo ratings yet

- Saic RT 2001Document24 pagesSaic RT 2001munnaNo ratings yet

- Saic MPT 2004 Rev 0Document6 pagesSaic MPT 2004 Rev 0philipyapNo ratings yet

- 7.2-WI-54-ITSD Inspectors Qualification Requirements Rev-05Document28 pages7.2-WI-54-ITSD Inspectors Qualification Requirements Rev-05Ksn HariNo ratings yet

- Saudi Aramco Inspection Checklist: Pre Welding Inspection - Offshore Structures SAIC-W-1312 WeldDocument1 pageSaudi Aramco Inspection Checklist: Pre Welding Inspection - Offshore Structures SAIC-W-1312 Weldkartik_harwani4387No ratings yet

- SATR-W-2020 Rev 8Document4 pagesSATR-W-2020 Rev 8محمد علي النويصرNo ratings yet

- Saep 324Document13 pagesSaep 324Up WeldNo ratings yet

- Saic RT 2007Document9 pagesSaic RT 2007munnaNo ratings yet

- Welding Procedure Qualification Record (WPQR)Document8 pagesWelding Procedure Qualification Record (WPQR)Belin InversoNo ratings yet

- SAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingDocument5 pagesSAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingFiras AlbaweiNo ratings yet

- Saudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechDocument3 pagesSaudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechmominNo ratings yet

- Saic W 2036Document2 pagesSaic W 2036Neelam AhmadNo ratings yet

- WWR 500-R-10 - Manual of Standard PracticeDocument38 pagesWWR 500-R-10 - Manual of Standard PracticePeterWayNo ratings yet

- SAIC-X-3104 Rev 3Document4 pagesSAIC-X-3104 Rev 3Imran khanNo ratings yet

- NCR - ATF Accredited Testing FacilityDocument5 pagesNCR - ATF Accredited Testing FacilityjesycubanNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 MechDocument4 pagesSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 Mechkarthi51289No ratings yet

- 175 012300Document2 pages175 012300Abu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection ChecklistAli AhmedNo ratings yet

- SAES-M-005 PDF Download - Design and Construction of Fixed Offshore Platforms - PDFYARDocument8 pagesSAES-M-005 PDF Download - Design and Construction of Fixed Offshore Platforms - PDFYARZahidRafiqueNo ratings yet

- Saudi Aramco Test Report: Internal Tank Bottom Testing 15-Jul-18 CP-SATR-X-3205Document7 pagesSaudi Aramco Test Report: Internal Tank Bottom Testing 15-Jul-18 CP-SATR-X-3205Sreni Excel MacrosNo ratings yet

- Saic A 1002Document2 pagesSaic A 1002karthi51289No ratings yet

- 5.3. 402020-01391-08-PI-SPC-0002 Rev0 PDFDocument136 pages5.3. 402020-01391-08-PI-SPC-0002 Rev0 PDFsumit kumarNo ratings yet

- PQR Editable SampleDocument2 pagesPQR Editable SampleKoya ThangalNo ratings yet

- Thermax Limited: Inspection Procedure For GalvanizingDocument14 pagesThermax Limited: Inspection Procedure For GalvanizingNsidibe Michael EtimNo ratings yet

- Demagnetization: BSS Non Destructive Testing PVT - LTDDocument18 pagesDemagnetization: BSS Non Destructive Testing PVT - LTDSANU100% (1)

- Section Subject: Shaybah CPF Expansion ProjectDocument21 pagesSection Subject: Shaybah CPF Expansion ProjectAdhie Waelacxh100% (1)

- 01-SAMSS-048 PDF Download - CRA Clad or Lined Steel PipeDocument4 pages01-SAMSS-048 PDF Download - CRA Clad or Lined Steel PipeZahidRafiqueNo ratings yet

- Office: Printout Sample - ASME WPSDocument2 pagesOffice: Printout Sample - ASME WPSDanem HalasNo ratings yet

- B H e L Limited RTDocument13 pagesB H e L Limited RTbhavin17850% (2)

- Saep 323 PDFDocument8 pagesSaep 323 PDFthanga balanNo ratings yet

- Saudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 WeldMAZHARULNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Finishing and Curing Inspection SAIC-Q-1015 15-Nov-17 MAH-SA-CDocument4 pagesSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Finishing and Curing Inspection SAIC-Q-1015 15-Nov-17 MAH-SA-CAbdul HannanNo ratings yet

- Guide To Weld Inspection For Structure SteelDocument12 pagesGuide To Weld Inspection For Structure SteelRakesh MenonNo ratings yet

- Saudi Arabian Oil Company: Instrument Specification Sheet - Pressure and Differential Pressure GaugesDocument2 pagesSaudi Arabian Oil Company: Instrument Specification Sheet - Pressure and Differential Pressure GaugesMuhammad ShahidNo ratings yet

- Part2 Notice 1Document21 pagesPart2 Notice 1Danem Halas100% (1)

- Code For Offshore Personnel Transfer Systems July 2022Document92 pagesCode For Offshore Personnel Transfer Systems July 2022Ozan DurmazogluNo ratings yet

- S1450401-Execution and Inspection of Welding WorkDocument26 pagesS1450401-Execution and Inspection of Welding Workkeeoraon4No ratings yet

- Nozzle Fit-Up Inspection Report: Inspected & Prepared byDocument9 pagesNozzle Fit-Up Inspection Report: Inspected & Prepared byDaison PaulNo ratings yet

- ABS - PipelineDocument186 pagesABS - Pipelineap1948No ratings yet

- 16 Samss 512Document40 pages16 Samss 512HatemS.MashaGbehNo ratings yet

- Rapid p0030 CPP U0030 Qac Mom 0024 Quality MeetingDocument13 pagesRapid p0030 CPP U0030 Qac Mom 0024 Quality MeetingAtuk Safiz100% (1)

- S0600 Aa Pro 070Document44 pagesS0600 Aa Pro 070opruzhak-boxNo ratings yet

- Application Form For CSWIP 5 Year Renewal (Overseas) - v3 1Document7 pagesApplication Form For CSWIP 5 Year Renewal (Overseas) - v3 1Bamarasan ArasanNo ratings yet

- SATIP-W-011-01 Rev 8Document10 pagesSATIP-W-011-01 Rev 8saravananmenmathiNo ratings yet

- 175 011100Document2 pages175 011100Abu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 24-Mar-16 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 24-Mar-16 CivilSajid ShaikhNo ratings yet

- G16S-0202-07 - Two Layer PaintingDocument7 pagesG16S-0202-07 - Two Layer Paintingpuwarin naja100% (1)

- Compex International CentresDocument2 pagesCompex International CentresnjennsNo ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldDocument32 pagesSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldIrshad Iqbal100% (2)

- SABP G 003 AramcoDocument9 pagesSABP G 003 Aramcom4metz100% (1)

- SABP G 002 AramcoDocument7 pagesSABP G 002 Aramcom4metz100% (1)

- Dhiraj Dhirendra KumarDocument6 pagesDhiraj Dhirendra Kumarm4metz100% (1)

- Process Industry Practices Machinery: Pip Resp73H Application of ASME B73.1 - 2001Document15 pagesProcess Industry Practices Machinery: Pip Resp73H Application of ASME B73.1 - 2001m4metzNo ratings yet

- Sabp F 004Document19 pagesSabp F 004m4metzNo ratings yet

- Sabp G 001Document12 pagesSabp G 001m4metz100% (1)

- Best Practice: Quick Energy Assessment Methodology For Energy Efficiency OptimizationDocument66 pagesBest Practice: Quick Energy Assessment Methodology For Energy Efficiency Optimizationm4metzNo ratings yet

- Saudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 15-Jul-18 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 Weldm4metz100% (1)

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistm4metzNo ratings yet

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Jul-18 Weldm4metzNo ratings yet

- Quality and Inspection: D.DHANASEKAR M.E.,Mem.A.S.M.E., Design Engineer - MechanicalDocument45 pagesQuality and Inspection: D.DHANASEKAR M.E.,Mem.A.S.M.E., Design Engineer - MechanicalRUDHRA DHANASEKARNo ratings yet

- Material Take Off: Client OGC Project IAC Upgrade Project Location Sultanate of OmanDocument13 pagesMaterial Take Off: Client OGC Project IAC Upgrade Project Location Sultanate of OmanDeepak RajanNo ratings yet

- Seimens PS 555Document26 pagesSeimens PS 555HoangNo ratings yet

- En Iso 15609-1-2004Document10 pagesEn Iso 15609-1-2004Marija IvanovskaNo ratings yet

- 2294E2-0000-DA00-SPC-0002 Rev 0Document14 pages2294E2-0000-DA00-SPC-0002 Rev 0amirNo ratings yet

- Welding Management As A Tool For Innovative, Competitive and Sustainable Manufacturing: Case Study - West AfricaDocument12 pagesWelding Management As A Tool For Innovative, Competitive and Sustainable Manufacturing: Case Study - West AfricaAlex MazabuelNo ratings yet

- Guidelines For Specification, Welding and Inspection of Stainless Alloy Piping Craig Reid, P.EngDocument19 pagesGuidelines For Specification, Welding and Inspection of Stainless Alloy Piping Craig Reid, P.EngFinnFan8No ratings yet

- Appendix T - Weld Metal - Welding Procedure Specification Notch Toughness Verification Test - BNBC 2020 CommentaryDocument2 pagesAppendix T - Weld Metal - Welding Procedure Specification Notch Toughness Verification Test - BNBC 2020 CommentaryTarif Aziz MarufNo ratings yet

- Attachment-20 - STN-00-Z21-V-SP-0007 P01 - ENDocument36 pagesAttachment-20 - STN-00-Z21-V-SP-0007 P01 - ENrameshqcNo ratings yet

- En Scheme of Welder Certification ENGDocument4 pagesEn Scheme of Welder Certification ENGHoque Anamul100% (1)

- Documentation of Welding Procedure TestDocument5 pagesDocumentation of Welding Procedure Testrty2No ratings yet

- 175 011100Document2 pages175 011100Abu Anas M.SalaheldinNo ratings yet

- Updated Quality PlanDocument23 pagesUpdated Quality PlanThi PhamNo ratings yet

- Process Industry Practices Piping: PIP PNSC0001 Fabrication and Examination Specification For ASME B31.3 Metallic PipingDocument17 pagesProcess Industry Practices Piping: PIP PNSC0001 Fabrication and Examination Specification For ASME B31.3 Metallic PipingMidhun K Chandrabose100% (3)

- DNV-Fabrication and Testing of Offshore Structures PDFDocument44 pagesDNV-Fabrication and Testing of Offshore Structures PDFgelo_17No ratings yet

- Ex A-Weld 24'' 5 KMDocument12 pagesEx A-Weld 24'' 5 KMJabel Oil Services Technical DPTNo ratings yet

- Inspection Test Plan For Fabrication PDF FreeDocument4 pagesInspection Test Plan For Fabrication PDF Freesam paulNo ratings yet

- DKSKV Welding Technology MTK 201Document8 pagesDKSKV Welding Technology MTK 201Eizanie MuhamadNo ratings yet

- 175 010800Document3 pages175 010800Abu Anas M.Salaheldin100% (1)

- Fracture TestDocument1 pageFracture TestYuvaraj SathishNo ratings yet

- Wps Sp14 Reva PDFDocument9 pagesWps Sp14 Reva PDFravi00098No ratings yet

- 2 5418388499906691582 PDFDocument12 pages2 5418388499906691582 PDFrezaNo ratings yet

- Summary of Changes in ASME Section IX, 1998 EditionDocument5 pagesSummary of Changes in ASME Section IX, 1998 EditionTeguh Setiono100% (1)

- Aws American Welding Society ﺎﻜﯾﺮﻣآ شﻮﺟ ﻦﻤﺠﻧا دراﺪﻧﺎﺘﺳا: Pdf Created With Pdffactory Pro Trial VersionDocument33 pagesAws American Welding Society ﺎﻜﯾﺮﻣآ شﻮﺟ ﻦﻤﺠﻧا دراﺪﻧﺎﺘﺳا: Pdf Created With Pdffactory Pro Trial VersionAli SASSINo ratings yet