Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Jul-18 Weld

Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Jul-18 Weld

Uploaded by

m4metzOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Jul-18 Weld

Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Jul-18 Weld

Uploaded by

m4metzCopyright:

Available Formats

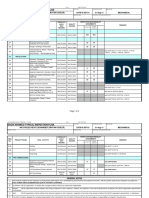

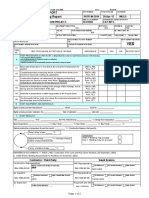

SAUDI ARAMCO ID/PIEU-15-July-2018-REV. 2018.05.00(Standards Cutoff - May 31,2018) Rev.2018.05.

00 31-May-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Post Weld Heat Treatment (PWHT) for On-Plot Piping SAIC-W-2004 15-Jul-18 WELD-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A General Requirements (Pre-Work)

A written procedure describing the general PWHT requirements of ASME

SAES-W-011,

A1 B31.3, has been reviewed and approved by CSD and has been verified

Para. 13.1

using SAIC-W-2013 and accepted by PID.

Contractor has prepared a Table listing following info for each joint or

component requiring heat treatment reviewed and approved by PID .

a) location

b) drawing number

c) diameter

d) wall thickness e)

SAES-W-011,

A2 material f)

Para. 13.2

heating rate g)

cooling rate h)

soak temperature i)

soak time

Verify that code and SA requirements have been met.

"Carbon & low alloy steel butt welds requiring PWHT for Process

Conditions & Services are as listed:

A) All caustic soda (NaOH) solutions, incl. conditions where caustic

carryover may occur (e.g. downstream of caustic injection points).

B) All monoethanolamine (MEA) solutions (all temperatures).

C) All diglycol amine (DGA) solutions above 138°C design temp.

D) Rich amino diisoprop (ADIP) solutions above 90°C design temp.

E) All lean ADIP solutions above 60°C design temperature. SAES-W-011,

A3

F) Boiler Deaerator serv (ambient temp vacuum deaerator = exempt) Para. 13.3

G) Hydrogen service for P-No. 3, 4, and 5A/B/C base materials.

H) All diethanolamine (DEA) solutions.

I) All MDEA / aMDEA solutions

These reqmts also apply to external welds to attach non-pressure

containing component to piping (e.g., reinforcement pad or sleeve

attached to the pipe) and to seal welds. Seal welds on threaded valves

may be exempt if PWHT will damage valve internals."

For applications where PWHT is required by service fluid (Item A3 above)

" OR " where hardness limits are specified:

a) Reductions in PWHT temperature or alternative temperatures

below normal holding temps listed in ASME B31.3 are not permitted. SAES-W-011,

A4

b) Minimum PWHT soak time shall be 1 hour. Para. 13.9

c) If hardness limits are specified, production weld soak time shall not be

less than 80% of PQR soak time unless approved by CSD.

Saudi Aramco: Company General Use

You might also like

- 01 Coordination Complex Compounds Plus2 2nd YearDocument61 pages01 Coordination Complex Compounds Plus2 2nd YearJosephine TorresNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldManoj KumarNo ratings yet

- Process Industry Practices Machinery: Pip Resp73V Application of ASME B73.2 - 2003Document31 pagesProcess Industry Practices Machinery: Pip Resp73V Application of ASME B73.2 - 2003m4metzNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistm4metzNo ratings yet

- Maboumine Process - Example of A Promising Process For Developing A Polymetallic Ore DepositDocument7 pagesMaboumine Process - Example of A Promising Process For Developing A Polymetallic Ore DepositLuis Anza100% (1)

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- SAIC-A-2008 Rev 6 Verify Test Medium For Hydrostatic Testing and Lay UpDocument2 pagesSAIC-A-2008 Rev 6 Verify Test Medium For Hydrostatic Testing and Lay UpAhdal NoushadNo ratings yet

- SATIP-W-011-01 Rev 8Document10 pagesSATIP-W-011-01 Rev 8saravananmenmathiNo ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- Weld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020Document3 pagesWeld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020bishalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistkartik_harwani4387No ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportEswari AnandNo ratings yet

- Welder Job Clearance Card: Nesma/TanmiaDocument8 pagesWelder Job Clearance Card: Nesma/TanmiaMohamed Reda Hussein SengarNo ratings yet

- Saudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 WeldMAZHARULNo ratings yet

- Welder Repair Assessment and Tracer Weld Report-Weekly SATR-W-2018 22-Jan-18 WeldDocument2 pagesWelder Repair Assessment and Tracer Weld Report-Weekly SATR-W-2018 22-Jan-18 Weldkarthi51289No ratings yet

- Portacabin Inspection ChecklistDocument2 pagesPortacabin Inspection ChecklistApm FoumilNo ratings yet

- Incr - XXXDocument2 pagesIncr - XXXsadik coolsadyNo ratings yet

- F-035 (Valve Erection Format)Document1 pageF-035 (Valve Erection Format)Rajeev Kumar100% (1)

- QMIS LBE Rev Mech Final OldDocument683 pagesQMIS LBE Rev Mech Final OldprabakaranNo ratings yet

- SATR-W-2020 Rev 8Document4 pagesSATR-W-2020 Rev 8محمد علي النويصرNo ratings yet

- 175 022503Document2 pages175 022503Abu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanJagdishNo ratings yet

- SATR-W-2005 Rev 6 PWHT ReportDocument1 pageSATR-W-2005 Rev 6 PWHT ReportAWAIS RAJANo ratings yet

- Satr W 2013Document8 pagesSatr W 2013Rijwan MohammadNo ratings yet

- Table - Qw-416 Welding Variables For Welder PerformanceDocument1 pageTable - Qw-416 Welding Variables For Welder PerformanceAnonymous VohpMtUSN100% (1)

- Cold Tap Coating Report 2Document1 pageCold Tap Coating Report 2Jamal BakhtNo ratings yet

- SATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)Document2 pagesSATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)deepa narayanNo ratings yet

- SATR-W-2007 Rev 7Document4 pagesSATR-W-2007 Rev 7QA QCNo ratings yet

- STD-InSP-0004 (Material Identification Proceudre)Document3 pagesSTD-InSP-0004 (Material Identification Proceudre)airbroomNo ratings yet

- Satr-W-2008 Atyb TRDocument6 pagesSatr-W-2008 Atyb TRDeo MNo ratings yet

- Saudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 24-Mar-16 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 24-Mar-16 CivilSajid ShaikhNo ratings yet

- 175-Ir171300, (850146), 11.30.2015Document2 pages175-Ir171300, (850146), 11.30.2015Rami ELLOUMINo ratings yet

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapNo ratings yet

- 7.2-WI-54-ITSD Inspectors Qualification Requirements Rev-05Document28 pages7.2-WI-54-ITSD Inspectors Qualification Requirements Rev-05Ksn HariNo ratings yet

- 0002 - 102 - Pressure Testing SafelyDocument17 pages0002 - 102 - Pressure Testing Safelytarique100% (1)

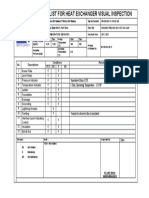

- Checklist For Heat Exchanger Visual Inspection: No. Descriptions Conditions Remarks YES NO S NSDocument1 pageChecklist For Heat Exchanger Visual Inspection: No. Descriptions Conditions Remarks YES NO S NSRizqiNo ratings yet

- SATR-A-2009 Rev 2 - System Lay-Up Report (Certificate)Document2 pagesSATR-A-2009 Rev 2 - System Lay-Up Report (Certificate)deepa narayan100% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- WPS FGPDocument1 pageWPS FGPShabbir HussainNo ratings yet

- Saudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportDocument2 pagesSaudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportJoni Carino Suni100% (1)

- Inspectable MaterialsDocument2 pagesInspectable MaterialsMohamed RedaNo ratings yet

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 MechDocument4 pagesSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 Mechkarthi51289No ratings yet

- Internal NCR Log For Satellite 30aug18Document4 pagesInternal NCR Log For Satellite 30aug18GA JonNo ratings yet

- WPS-Shell To Tubesheet (CS-SS)Document1 pageWPS-Shell To Tubesheet (CS-SS)suria qaqcNo ratings yet

- 175 100100 PDFDocument2 pages175 100100 PDFThaksenNo ratings yet

- Saic L 2008 PDFDocument4 pagesSaic L 2008 PDFHesham HelalNo ratings yet

- QW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Document1 pageQW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Deepanshu KhatriNo ratings yet

- SATIP-L-450-03 Mechanical Ne: Saudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliDocument13 pagesSATIP-L-450-03 Mechanical Ne: Saudi Aramco Typical Inspection Plan Cross Country Above Ground Pipelikarthi51289No ratings yet

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- Saic-P-3003 Rev 0 PDFDocument4 pagesSaic-P-3003 Rev 0 PDFHesham HelalNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument1 pageInspection & Testing Requirements Scope:: Test and Inspection PerEagle SpiritNo ratings yet

- Saes W 013Document8 pagesSaes W 013Dhaval Patel100% (1)

- PDS Hempadur Hi-Build 45200 en-GBDocument2 pagesPDS Hempadur Hi-Build 45200 en-GBvitharvanNo ratings yet

- CBT QuestionsDocument17 pagesCBT QuestionsNaseer Ahmed SokhalNo ratings yet

- Satip e 007 01Document2 pagesSatip e 007 01Anonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Test Report Temperature Tie-In Welding ReportDocument2 pagesSaudi Aramco Test Report Temperature Tie-In Welding ReportManoj Kumar100% (2)

- 175 018200 PDFDocument2 pages175 018200 PDFAbu Anas M.SalaheldinNo ratings yet

- MST Gravity Test OwsDocument5 pagesMST Gravity Test OwsJenson T VNo ratings yet

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldDocument19 pagesSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldIrshad IqbalNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Process Industry Practices Machinery: Pip Resp73H Application of ASME B73.1 - 2001Document15 pagesProcess Industry Practices Machinery: Pip Resp73H Application of ASME B73.1 - 2001m4metzNo ratings yet

- SABP G 003 AramcoDocument9 pagesSABP G 003 Aramcom4metz100% (1)

- SABP G 002 AramcoDocument7 pagesSABP G 002 Aramcom4metz100% (1)

- Sabp F 004Document19 pagesSabp F 004m4metzNo ratings yet

- Sabp G 001Document12 pagesSabp G 001m4metz100% (1)

- Best Practice: Quick Energy Assessment Methodology For Energy Efficiency OptimizationDocument66 pagesBest Practice: Quick Energy Assessment Methodology For Energy Efficiency Optimizationm4metzNo ratings yet

- Dhiraj Dhirendra KumarDocument6 pagesDhiraj Dhirendra Kumarm4metz100% (1)

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 15-Jul-18 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 Weldm4metz100% (1)

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistm4metzNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 Weldm4metzNo ratings yet

- Atmospheric Corrosion of Copper and The Colour Structure and Composition of Natural Patinas On Copper 2006 Corrosion ScienceDocument30 pagesAtmospheric Corrosion of Copper and The Colour Structure and Composition of Natural Patinas On Copper 2006 Corrosion ScienceEmanuela Leite FragosoNo ratings yet

- Lab Report Chem 7Document5 pagesLab Report Chem 7NURUL AIN SOFINo ratings yet

- Parr - Zirconium Corrosion Info PDFDocument25 pagesParr - Zirconium Corrosion Info PDFPhineas sehoanaNo ratings yet

- AmalgamDocument45 pagesAmalgamAhmed OsamaNo ratings yet

- Chemistry: Foundation Tier Paper 1Document40 pagesChemistry: Foundation Tier Paper 1karuneshnNo ratings yet

- Chapter 1 IntroductionDocument41 pagesChapter 1 IntroductionertNo ratings yet

- Viscose Fiber Production ProcessDocument6 pagesViscose Fiber Production Processadityasirawale100% (1)

- High Speed CastingDocument7 pagesHigh Speed Castingferdlh9No ratings yet

- Lesson 9 Reactions of Carbonyl CompoundsDocument18 pagesLesson 9 Reactions of Carbonyl Compoundsdela2No ratings yet

- Chemistry MCQs SSBCrack PDFDocument18 pagesChemistry MCQs SSBCrack PDFutkarsh chaturvediNo ratings yet

- Good, Bad and Ugly Process Burner FlamesDocument3 pagesGood, Bad and Ugly Process Burner Flamesratninp9368No ratings yet

- Mechanochemical Synthesis of Nanocrystalline Hydroxyapatite From CaO and CaHPODocument8 pagesMechanochemical Synthesis of Nanocrystalline Hydroxyapatite From CaO and CaHPOAngelNo ratings yet

- Pasi Rousu - Revenues From ResiduesDocument20 pagesPasi Rousu - Revenues From ResiduesAsia Clean Energy ForumNo ratings yet

- Ion NotesDocument3 pagesIon Notesyeetespeetes04No ratings yet

- Measure Measure Pour Measure Set Up: Efficiency of Alkanols As FuelsDocument2 pagesMeasure Measure Pour Measure Set Up: Efficiency of Alkanols As FuelsSara LeeNo ratings yet

- A Final Tablas 1Document22 pagesA Final Tablas 1hanni86No ratings yet

- Industrial Chemistry PP TDocument16 pagesIndustrial Chemistry PP TIqbal Ridalta PutraNo ratings yet

- Cepsa Xtar Super Coolant Hybrid NFDocument2 pagesCepsa Xtar Super Coolant Hybrid NFRamonNo ratings yet

- Morlina OilDocument2 pagesMorlina OilpetrofacumarNo ratings yet

- Solutions - AIATS Medical-2020 (XI Studying) - Test-6 (Code-C - D) - (17!02!2019)Document32 pagesSolutions - AIATS Medical-2020 (XI Studying) - Test-6 (Code-C - D) - (17!02!2019)Sanskruti ChavanNo ratings yet

- Proofex Torchseal PrimerDocument2 pagesProofex Torchseal PrimerSetyo poernomoNo ratings yet

- Best Practices For Aromatics Extractive Distillation in Integrated ComplexesDocument8 pagesBest Practices For Aromatics Extractive Distillation in Integrated ComplexesNaiduJagarapuNo ratings yet

- Aerospace Material SpecificationDocument6 pagesAerospace Material SpecificationadiNo ratings yet

- Chemical Engineers DictionaryDocument77 pagesChemical Engineers DictionaryAnonymous b9fcR5100% (1)

- Flame Retardants - Clariant PDFDocument28 pagesFlame Retardants - Clariant PDFShushil Kumar100% (1)

- Polyvinyl ChlorideDocument6 pagesPolyvinyl ChlorideMohsin KhanNo ratings yet

- Strip Teas' - Solubility Data For The Removal (And Application) Picture VarnishesDocument9 pagesStrip Teas' - Solubility Data For The Removal (And Application) Picture Varnishesmp77No ratings yet

- Topic 3,4,5&6 CH 4 Class 11thDocument3 pagesTopic 3,4,5&6 CH 4 Class 11thLakshaya SainiNo ratings yet