Professional Documents

Culture Documents

Section 5: 7 Corrosion Protection

Section 5: 7 Corrosion Protection

Uploaded by

murtada adamCopyright:

Available Formats

You might also like

- Method Statement For Prefabrication and Erection-PipingDocument10 pagesMethod Statement For Prefabrication and Erection-PipingAhmed Gomaa92% (61)

- Method Statement For Installation of Overhead CraneDocument88 pagesMethod Statement For Installation of Overhead CraneJohn100% (5)

- Electrical Feeder Method StatementDocument3 pagesElectrical Feeder Method StatementAngelo Castro100% (1)

- M 111 Tank Weld Repair ProcedureDocument8 pagesM 111 Tank Weld Repair ProcedureAAISATNo ratings yet

- Crude Manual 001 PDFDocument433 pagesCrude Manual 001 PDFJay Bhamre100% (1)

- Barrafer ADocument2 pagesBarrafer ADoby YuniardiNo ratings yet

- Ms For Demin Water Tank Modification Rev 1 Feb. 28 2011lastDocument9 pagesMs For Demin Water Tank Modification Rev 1 Feb. 28 2011lastsharif339100% (1)

- Cleaning Gauging Hydrautesting and Chemical CleaningDocument2 pagesCleaning Gauging Hydrautesting and Chemical CleaningJosephKaren LorzanoIlaganNo ratings yet

- OSHA Technical Manual PDFDocument102 pagesOSHA Technical Manual PDFAshish PatelNo ratings yet

- 2 Welding Procedure 2 PDFDocument6 pages2 Welding Procedure 2 PDFMustafa MubderNo ratings yet

- QYD-QCP-MS-001 Tank Shell Weld Repair Procedure-Method StatementDocument6 pagesQYD-QCP-MS-001 Tank Shell Weld Repair Procedure-Method StatementAbdul Khaleem KhanNo ratings yet

- Method Statement TrayDocument38 pagesMethod Statement Traywaseem kausar100% (1)

- Rotating Equip Installation Procedure - Method StatementDocument14 pagesRotating Equip Installation Procedure - Method StatementSonu Vakkayil MathewNo ratings yet

- MOS AG Drainage SystemDocument22 pagesMOS AG Drainage SystemAdrianaChivuNo ratings yet

- Method Statement For BACKFILLING WORKSDocument12 pagesMethod Statement For BACKFILLING WORKSYash Sharma50% (2)

- QCP-E-04 - Cable Install Proc - Issue 1Document10 pagesQCP-E-04 - Cable Install Proc - Issue 1Mohamed AliNo ratings yet

- Saes L 470Document9 pagesSaes L 470Jaseel KanhirathingalNo ratings yet

- Contractor Safety-OMR 2017 PDFDocument13 pagesContractor Safety-OMR 2017 PDFvaibhavharigarh100% (1)

- DCC T&C Ms-PlumbingDocument11 pagesDCC T&C Ms-Plumbing721917114 47100% (1)

- Cathodic Protection Galvanic Sacrificial SpecificationDocument6 pagesCathodic Protection Galvanic Sacrificial SpecificationMohamed Alkhawaga100% (1)

- Wick Drain SpecsDocument7 pagesWick Drain SpecsBiraj GautamNo ratings yet

- Saic H 2023Document2 pagesSaic H 2023Anish V NairNo ratings yet

- Gse Ms Ug 001 Rev 0 - Method Statement For Underground PipingDocument7 pagesGse Ms Ug 001 Rev 0 - Method Statement For Underground PipingsugumarNo ratings yet

- TS of Travelling TripperDocument10 pagesTS of Travelling TripperShashank HegdeNo ratings yet

- 40 05 57 23 - ELECTRIC MOTOR ACTUATORS - Rev02Document7 pages40 05 57 23 - ELECTRIC MOTOR ACTUATORS - Rev02adnanyaseenzrgrNo ratings yet

- Cathodic Protection Clarifier Specification-Jun 2010Document7 pagesCathodic Protection Clarifier Specification-Jun 2010656665665No ratings yet

- Field Sampling and Testing Manual Section 700 Miscellaneous ConstructionDocument34 pagesField Sampling and Testing Manual Section 700 Miscellaneous ConstructionFaruk AtalarNo ratings yet

- Saes L 470Document10 pagesSaes L 470abaanNo ratings yet

- Method Statement For CW INTAKE SCREEN WASH WATER SYSTEM FLUSHING BL.1 5 PDFDocument8 pagesMethod Statement For CW INTAKE SCREEN WASH WATER SYSTEM FLUSHING BL.1 5 PDFFredie UnabiaNo ratings yet

- Working Procedure of PipelineDocument12 pagesWorking Procedure of Pipelinevishal bailurNo ratings yet

- Method Statement For Fabrication and Erection of Demineralized Water TankDocument12 pagesMethod Statement For Fabrication and Erection of Demineralized Water TanksomiqatarNo ratings yet

- 03 38 16 - Post-Tensioned ConcreteDocument9 pages03 38 16 - Post-Tensioned ConcreteAnonymous swFolM3gXNo ratings yet

- Enk-Fab-Pg-006-Design and Fabrication of Metallic Vertical Storage TanksDocument16 pagesEnk-Fab-Pg-006-Design and Fabrication of Metallic Vertical Storage TanksEmic Fotografía y VideoNo ratings yet

- Saes H 204Document34 pagesSaes H 204heartbreakkid132No ratings yet

- POWERGRID Tech Spec For 765kV Reactor Rev 06Document70 pagesPOWERGRID Tech Spec For 765kV Reactor Rev 06sitam_nitj4202No ratings yet

- Rumaila Project: Document NumberDocument12 pagesRumaila Project: Document Numbernoor.albseerawiNo ratings yet

- NSH KBR Skop e 007 - Junction Boxes InstallationDocument6 pagesNSH KBR Skop e 007 - Junction Boxes InstallationFrancisco Severino Gatoc Jr.No ratings yet

- B2020-TDC-VF-009 Vessel Fabrication R0Document5 pagesB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam PrabhakaranNo ratings yet

- Saep 135Document8 pagesSaep 135Anonymous 4IpmN7OnNo ratings yet

- RTR Pipe Hydrotest ProcedureDocument13 pagesRTR Pipe Hydrotest ProcedureMohammad Rizwan0% (1)

- Saes B 057Document9 pagesSaes B 057HaleemUrRashidBangashNo ratings yet

- 4.1 - ANX-1 Definition of Mechanical Completion PDFDocument18 pages4.1 - ANX-1 Definition of Mechanical Completion PDFLegend AnbuNo ratings yet

- Saes B 064Document14 pagesSaes B 064Engr HafeezullahNo ratings yet

- Saep 35Document6 pagesSaep 35hendraox3996No ratings yet

- p103-Stts-gec-Asi-ms-ele-004 - Method Statement For Cable Laying On Cable TrayDocument6 pagesp103-Stts-gec-Asi-ms-ele-004 - Method Statement For Cable Laying On Cable TrayAnandu AshokanNo ratings yet

- Quick Guide To Saudi Aramco Standards and ProceduresDocument18 pagesQuick Guide To Saudi Aramco Standards and ProceduresJeck MaquitedNo ratings yet

- ASME B31.4 - 2006 (Excerpt - Pgs. 39, 40 & 41)Document3 pagesASME B31.4 - 2006 (Excerpt - Pgs. 39, 40 & 41)Paul CassellsNo ratings yet

- Method Statement For Installation of Emt Conduit-OldDocument13 pagesMethod Statement For Installation of Emt Conduit-OldSalman SaifuddinNo ratings yet

- Earthing and Lightning ProtectionDocument10 pagesEarthing and Lightning ProtectionqaqcmepteamNo ratings yet

- METHOD STATEMENT - PipingDocument12 pagesMETHOD STATEMENT - PipingAnonymous M5rHHKNo ratings yet

- Bridge Crane & Hoist InstallationDocument7 pagesBridge Crane & Hoist Installationnike_y2kNo ratings yet

- Method Statement For Scaffolding Works and Installation of Acoustic PanelsDocument8 pagesMethod Statement For Scaffolding Works and Installation of Acoustic PanelsSujan AugustinNo ratings yet

- Method Statement For Prefabrication and Erection PipingDocument10 pagesMethod Statement For Prefabrication and Erection PipingMidhun K ChandraboseNo ratings yet

- NSH KBR Skop e 009 - Bus Duct Installation and TestingDocument7 pagesNSH KBR Skop e 009 - Bus Duct Installation and TestingFrancisco Severino Gatoc Jr.No ratings yet

- Installation of Chain Link FenceDocument10 pagesInstallation of Chain Link FencevitamkupaNo ratings yet

- QCP-S-000-5520-176 Rev A (Elect - Power & Control Cable)Document15 pagesQCP-S-000-5520-176 Rev A (Elect - Power & Control Cable)arockiyathassNo ratings yet

- Catalyst Loading by Sock Method Single Bed Reactor Normal AtmosphereDocument5 pagesCatalyst Loading by Sock Method Single Bed Reactor Normal Atmospherevishal bailurNo ratings yet

- Saudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1Document6 pagesSaudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1sureshNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Denso-Protal-7200 Rev - 1607.22Document2 pagesDenso-Protal-7200 Rev - 1607.22gabriel PantojaNo ratings yet

- Quickmast 341Document2 pagesQuickmast 341rakeshNo ratings yet

- Reasoned Document IRS M-39-2020Document42 pagesReasoned Document IRS M-39-2020Metal deptNo ratings yet

- Fading of InoculationDocument2 pagesFading of Inoculationarnaldorcr8646No ratings yet

- Berger Decorative Price List March 2020Document1 pageBerger Decorative Price List March 2020Muskaan ZahraNo ratings yet

- Assignment/ Tugasan - Occupational SafetyDocument20 pagesAssignment/ Tugasan - Occupational SafetyAerein SylvesterNo ratings yet

- Procurement Request 01032021 1Document3 pagesProcurement Request 01032021 1Christine Benito EstebanNo ratings yet

- Guide For The Gas Shielded Arc Welding of Aluminum and Aluminum Alloy PipeDocument38 pagesGuide For The Gas Shielded Arc Welding of Aluminum and Aluminum Alloy PipeCGRRNo ratings yet

- 440C 1Document4 pages440C 1svk1234No ratings yet

- Introduction To Ductile IronDocument8 pagesIntroduction To Ductile IronNatalino FonsecaNo ratings yet

- Finkelstein Metals Black - WebDocument6 pagesFinkelstein Metals Black - WebFernando RomeroNo ratings yet

- BME RFI Template - Supplier Profile - 2021Document30 pagesBME RFI Template - Supplier Profile - 2021Amir KaračićNo ratings yet

- Tolerance Notes: VFA12-HD VFA12-HDDocument5 pagesTolerance Notes: VFA12-HD VFA12-HDneil gonzalesNo ratings yet

- Lectures 20,21 and 22Document20 pagesLectures 20,21 and 22viky kavaNo ratings yet

- Venkatesh. B Asst. Prof Textile TechnologyDocument14 pagesVenkatesh. B Asst. Prof Textile TechnologyVenkatesh BairabathinaNo ratings yet

- Brochure WEBDocument6 pagesBrochure WEBManivannanMudhaliarNo ratings yet

- KNER Propellant IgnitionDocument2 pagesKNER Propellant IgnitionBa RiNo ratings yet

- CH 5 Raw MillDocument11 pagesCH 5 Raw MillGaurav GuptaNo ratings yet

- Catalogo Importante para SierrasDocument32 pagesCatalogo Importante para SierrasDiego CarreñoNo ratings yet

- FCC Gasoline NaphthaDocument14 pagesFCC Gasoline NaphthaZiauddeen NoorNo ratings yet

- Building TechDocument2 pagesBuilding TechCathy CastilloNo ratings yet

- ALKANES Quiz SheetDocument5 pagesALKANES Quiz Sheetnajifaahmed223No ratings yet

- Fema 484 Part 2Document75 pagesFema 484 Part 2וויסאם חטארNo ratings yet

- Welding Consumables For Cast SteelDocument4 pagesWelding Consumables For Cast Steelmehul20110% (1)

- Nitoseal HP40: One Part, PU Based Building & Expansion Joint SealantDocument4 pagesNitoseal HP40: One Part, PU Based Building & Expansion Joint SealantkalidindivenkatarajuNo ratings yet

- Katalog Panasonic 2018.Document45 pagesKatalog Panasonic 2018.Irvan FauziNo ratings yet

- CNC 101Document13 pagesCNC 101Hendi RofiansyahNo ratings yet

- Gear Drive Problems: Dept. of Mech & Mfg. EnggDocument27 pagesGear Drive Problems: Dept. of Mech & Mfg. EnggomkardashetwarNo ratings yet

Section 5: 7 Corrosion Protection

Section 5: 7 Corrosion Protection

Uploaded by

murtada adamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section 5: 7 Corrosion Protection

Section 5: 7 Corrosion Protection

Uploaded by

murtada adamCopyright:

Available Formats

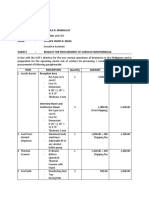

Document Responsibility: Piping Standards Committee SAES-L-470

Issue Date: 25 September 2012

Next Planned Update: 25 September 2017 Trenchless Pipelines Construction Requirements

stipulated in Section 5, the design drawings shall also show the size and

depth of the jacking and receiving pit.

The excavation and shoreing requirements for the jacking and receving

pits shall comply with SAES-A-114 and Saudi Aramco Safety

Management Guide No. 06-002-2008.

6.4.2 The receiving pit shall be completed before starting the micro tunneling

operation.

6.4.3 All required calculations shall be conducted such as the maximum

jacking resistance, the maximum allowable face pressure or slurry

pressure and the relationship between hydraulic jacking pressure and

force applied to pipe during jacking.

6.4.4 The Micro tunneling machine shall be equipped with a control system to

enable the drilling operator to monitor at all times the X-Y coordinates of

the boring head and its longitudinal inclination, the direction of rotation,

and all other aspects of the operation to ensure a successful boring process.

7 Corrosion Protection

7.1 The external surface of steel pipe and casing shall be coated with a factory

applied external corrosion protection coating in accordance with SAES-H-002.

7.2 All pressure pipes shall have an additional Abrasion Resistance Overlay (ARO)

coating or wrapping in accordance with SAES-H-002.

7.3 All field welds shall be NDT tested and accepted then coated with an approved

field corrosion protection coating in accordance with SAES-H-002 prior to

applying the ARO layer.

7.4 Cathodic protection of cased and uncased pipeline shall be in accordance with

SAES-X-400 and applicable Saudi Aramco Standard Drawings. Casing welded

to the carrier pipe shall be considered part of the pipeline. Casing electrically

isolated from the carrier pipe shall have a separate dedicated Cathodic

Protection system.

8 Testing and Inspection

8.1 Ensure that site conditions, preparations, and selected drilling rigs equipment are

per approved pipeline trenchless package.

8.2 All drilling tracking instruments shall be calibrated at site. All battery operated

instruments shall have fresh batteries installed before use.

Page 7 of 9

You might also like

- Method Statement For Prefabrication and Erection-PipingDocument10 pagesMethod Statement For Prefabrication and Erection-PipingAhmed Gomaa92% (61)

- Method Statement For Installation of Overhead CraneDocument88 pagesMethod Statement For Installation of Overhead CraneJohn100% (5)

- Electrical Feeder Method StatementDocument3 pagesElectrical Feeder Method StatementAngelo Castro100% (1)

- M 111 Tank Weld Repair ProcedureDocument8 pagesM 111 Tank Weld Repair ProcedureAAISATNo ratings yet

- Crude Manual 001 PDFDocument433 pagesCrude Manual 001 PDFJay Bhamre100% (1)

- Barrafer ADocument2 pagesBarrafer ADoby YuniardiNo ratings yet

- Ms For Demin Water Tank Modification Rev 1 Feb. 28 2011lastDocument9 pagesMs For Demin Water Tank Modification Rev 1 Feb. 28 2011lastsharif339100% (1)

- Cleaning Gauging Hydrautesting and Chemical CleaningDocument2 pagesCleaning Gauging Hydrautesting and Chemical CleaningJosephKaren LorzanoIlaganNo ratings yet

- OSHA Technical Manual PDFDocument102 pagesOSHA Technical Manual PDFAshish PatelNo ratings yet

- 2 Welding Procedure 2 PDFDocument6 pages2 Welding Procedure 2 PDFMustafa MubderNo ratings yet

- QYD-QCP-MS-001 Tank Shell Weld Repair Procedure-Method StatementDocument6 pagesQYD-QCP-MS-001 Tank Shell Weld Repair Procedure-Method StatementAbdul Khaleem KhanNo ratings yet

- Method Statement TrayDocument38 pagesMethod Statement Traywaseem kausar100% (1)

- Rotating Equip Installation Procedure - Method StatementDocument14 pagesRotating Equip Installation Procedure - Method StatementSonu Vakkayil MathewNo ratings yet

- MOS AG Drainage SystemDocument22 pagesMOS AG Drainage SystemAdrianaChivuNo ratings yet

- Method Statement For BACKFILLING WORKSDocument12 pagesMethod Statement For BACKFILLING WORKSYash Sharma50% (2)

- QCP-E-04 - Cable Install Proc - Issue 1Document10 pagesQCP-E-04 - Cable Install Proc - Issue 1Mohamed AliNo ratings yet

- Saes L 470Document9 pagesSaes L 470Jaseel KanhirathingalNo ratings yet

- Contractor Safety-OMR 2017 PDFDocument13 pagesContractor Safety-OMR 2017 PDFvaibhavharigarh100% (1)

- DCC T&C Ms-PlumbingDocument11 pagesDCC T&C Ms-Plumbing721917114 47100% (1)

- Cathodic Protection Galvanic Sacrificial SpecificationDocument6 pagesCathodic Protection Galvanic Sacrificial SpecificationMohamed Alkhawaga100% (1)

- Wick Drain SpecsDocument7 pagesWick Drain SpecsBiraj GautamNo ratings yet

- Saic H 2023Document2 pagesSaic H 2023Anish V NairNo ratings yet

- Gse Ms Ug 001 Rev 0 - Method Statement For Underground PipingDocument7 pagesGse Ms Ug 001 Rev 0 - Method Statement For Underground PipingsugumarNo ratings yet

- TS of Travelling TripperDocument10 pagesTS of Travelling TripperShashank HegdeNo ratings yet

- 40 05 57 23 - ELECTRIC MOTOR ACTUATORS - Rev02Document7 pages40 05 57 23 - ELECTRIC MOTOR ACTUATORS - Rev02adnanyaseenzrgrNo ratings yet

- Cathodic Protection Clarifier Specification-Jun 2010Document7 pagesCathodic Protection Clarifier Specification-Jun 2010656665665No ratings yet

- Field Sampling and Testing Manual Section 700 Miscellaneous ConstructionDocument34 pagesField Sampling and Testing Manual Section 700 Miscellaneous ConstructionFaruk AtalarNo ratings yet

- Saes L 470Document10 pagesSaes L 470abaanNo ratings yet

- Method Statement For CW INTAKE SCREEN WASH WATER SYSTEM FLUSHING BL.1 5 PDFDocument8 pagesMethod Statement For CW INTAKE SCREEN WASH WATER SYSTEM FLUSHING BL.1 5 PDFFredie UnabiaNo ratings yet

- Working Procedure of PipelineDocument12 pagesWorking Procedure of Pipelinevishal bailurNo ratings yet

- Method Statement For Fabrication and Erection of Demineralized Water TankDocument12 pagesMethod Statement For Fabrication and Erection of Demineralized Water TanksomiqatarNo ratings yet

- 03 38 16 - Post-Tensioned ConcreteDocument9 pages03 38 16 - Post-Tensioned ConcreteAnonymous swFolM3gXNo ratings yet

- Enk-Fab-Pg-006-Design and Fabrication of Metallic Vertical Storage TanksDocument16 pagesEnk-Fab-Pg-006-Design and Fabrication of Metallic Vertical Storage TanksEmic Fotografía y VideoNo ratings yet

- Saes H 204Document34 pagesSaes H 204heartbreakkid132No ratings yet

- POWERGRID Tech Spec For 765kV Reactor Rev 06Document70 pagesPOWERGRID Tech Spec For 765kV Reactor Rev 06sitam_nitj4202No ratings yet

- Rumaila Project: Document NumberDocument12 pagesRumaila Project: Document Numbernoor.albseerawiNo ratings yet

- NSH KBR Skop e 007 - Junction Boxes InstallationDocument6 pagesNSH KBR Skop e 007 - Junction Boxes InstallationFrancisco Severino Gatoc Jr.No ratings yet

- B2020-TDC-VF-009 Vessel Fabrication R0Document5 pagesB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam PrabhakaranNo ratings yet

- Saep 135Document8 pagesSaep 135Anonymous 4IpmN7OnNo ratings yet

- RTR Pipe Hydrotest ProcedureDocument13 pagesRTR Pipe Hydrotest ProcedureMohammad Rizwan0% (1)

- Saes B 057Document9 pagesSaes B 057HaleemUrRashidBangashNo ratings yet

- 4.1 - ANX-1 Definition of Mechanical Completion PDFDocument18 pages4.1 - ANX-1 Definition of Mechanical Completion PDFLegend AnbuNo ratings yet

- Saes B 064Document14 pagesSaes B 064Engr HafeezullahNo ratings yet

- Saep 35Document6 pagesSaep 35hendraox3996No ratings yet

- p103-Stts-gec-Asi-ms-ele-004 - Method Statement For Cable Laying On Cable TrayDocument6 pagesp103-Stts-gec-Asi-ms-ele-004 - Method Statement For Cable Laying On Cable TrayAnandu AshokanNo ratings yet

- Quick Guide To Saudi Aramco Standards and ProceduresDocument18 pagesQuick Guide To Saudi Aramco Standards and ProceduresJeck MaquitedNo ratings yet

- ASME B31.4 - 2006 (Excerpt - Pgs. 39, 40 & 41)Document3 pagesASME B31.4 - 2006 (Excerpt - Pgs. 39, 40 & 41)Paul CassellsNo ratings yet

- Method Statement For Installation of Emt Conduit-OldDocument13 pagesMethod Statement For Installation of Emt Conduit-OldSalman SaifuddinNo ratings yet

- Earthing and Lightning ProtectionDocument10 pagesEarthing and Lightning ProtectionqaqcmepteamNo ratings yet

- METHOD STATEMENT - PipingDocument12 pagesMETHOD STATEMENT - PipingAnonymous M5rHHKNo ratings yet

- Bridge Crane & Hoist InstallationDocument7 pagesBridge Crane & Hoist Installationnike_y2kNo ratings yet

- Method Statement For Scaffolding Works and Installation of Acoustic PanelsDocument8 pagesMethod Statement For Scaffolding Works and Installation of Acoustic PanelsSujan AugustinNo ratings yet

- Method Statement For Prefabrication and Erection PipingDocument10 pagesMethod Statement For Prefabrication and Erection PipingMidhun K ChandraboseNo ratings yet

- NSH KBR Skop e 009 - Bus Duct Installation and TestingDocument7 pagesNSH KBR Skop e 009 - Bus Duct Installation and TestingFrancisco Severino Gatoc Jr.No ratings yet

- Installation of Chain Link FenceDocument10 pagesInstallation of Chain Link FencevitamkupaNo ratings yet

- QCP-S-000-5520-176 Rev A (Elect - Power & Control Cable)Document15 pagesQCP-S-000-5520-176 Rev A (Elect - Power & Control Cable)arockiyathassNo ratings yet

- Catalyst Loading by Sock Method Single Bed Reactor Normal AtmosphereDocument5 pagesCatalyst Loading by Sock Method Single Bed Reactor Normal Atmospherevishal bailurNo ratings yet

- Saudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1Document6 pagesSaudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1sureshNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Denso-Protal-7200 Rev - 1607.22Document2 pagesDenso-Protal-7200 Rev - 1607.22gabriel PantojaNo ratings yet

- Quickmast 341Document2 pagesQuickmast 341rakeshNo ratings yet

- Reasoned Document IRS M-39-2020Document42 pagesReasoned Document IRS M-39-2020Metal deptNo ratings yet

- Fading of InoculationDocument2 pagesFading of Inoculationarnaldorcr8646No ratings yet

- Berger Decorative Price List March 2020Document1 pageBerger Decorative Price List March 2020Muskaan ZahraNo ratings yet

- Assignment/ Tugasan - Occupational SafetyDocument20 pagesAssignment/ Tugasan - Occupational SafetyAerein SylvesterNo ratings yet

- Procurement Request 01032021 1Document3 pagesProcurement Request 01032021 1Christine Benito EstebanNo ratings yet

- Guide For The Gas Shielded Arc Welding of Aluminum and Aluminum Alloy PipeDocument38 pagesGuide For The Gas Shielded Arc Welding of Aluminum and Aluminum Alloy PipeCGRRNo ratings yet

- 440C 1Document4 pages440C 1svk1234No ratings yet

- Introduction To Ductile IronDocument8 pagesIntroduction To Ductile IronNatalino FonsecaNo ratings yet

- Finkelstein Metals Black - WebDocument6 pagesFinkelstein Metals Black - WebFernando RomeroNo ratings yet

- BME RFI Template - Supplier Profile - 2021Document30 pagesBME RFI Template - Supplier Profile - 2021Amir KaračićNo ratings yet

- Tolerance Notes: VFA12-HD VFA12-HDDocument5 pagesTolerance Notes: VFA12-HD VFA12-HDneil gonzalesNo ratings yet

- Lectures 20,21 and 22Document20 pagesLectures 20,21 and 22viky kavaNo ratings yet

- Venkatesh. B Asst. Prof Textile TechnologyDocument14 pagesVenkatesh. B Asst. Prof Textile TechnologyVenkatesh BairabathinaNo ratings yet

- Brochure WEBDocument6 pagesBrochure WEBManivannanMudhaliarNo ratings yet

- KNER Propellant IgnitionDocument2 pagesKNER Propellant IgnitionBa RiNo ratings yet

- CH 5 Raw MillDocument11 pagesCH 5 Raw MillGaurav GuptaNo ratings yet

- Catalogo Importante para SierrasDocument32 pagesCatalogo Importante para SierrasDiego CarreñoNo ratings yet

- FCC Gasoline NaphthaDocument14 pagesFCC Gasoline NaphthaZiauddeen NoorNo ratings yet

- Building TechDocument2 pagesBuilding TechCathy CastilloNo ratings yet

- ALKANES Quiz SheetDocument5 pagesALKANES Quiz Sheetnajifaahmed223No ratings yet

- Fema 484 Part 2Document75 pagesFema 484 Part 2וויסאם חטארNo ratings yet

- Welding Consumables For Cast SteelDocument4 pagesWelding Consumables For Cast Steelmehul20110% (1)

- Nitoseal HP40: One Part, PU Based Building & Expansion Joint SealantDocument4 pagesNitoseal HP40: One Part, PU Based Building & Expansion Joint SealantkalidindivenkatarajuNo ratings yet

- Katalog Panasonic 2018.Document45 pagesKatalog Panasonic 2018.Irvan FauziNo ratings yet

- CNC 101Document13 pagesCNC 101Hendi RofiansyahNo ratings yet

- Gear Drive Problems: Dept. of Mech & Mfg. EnggDocument27 pagesGear Drive Problems: Dept. of Mech & Mfg. EnggomkardashetwarNo ratings yet