Professional Documents

Culture Documents

0%(1)0% found this document useful (1 vote)

99 viewsHindustan Hydraulics GS Series

Hindustan Hydraulics GS Series

Uploaded by

SandeepNairHhgs

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Study On Round Rice Straw Bale Wrapping Silage Technology and FacilitiesDocument8 pagesStudy On Round Rice Straw Bale Wrapping Silage Technology and FacilitiesSandeepNairNo ratings yet

- Employees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationDocument3 pagesEmployees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationSandeepNairNo ratings yet

- New Holland Roll Baler: Roll Baler 125 Roll Baler 125 Combi Roll Baler 135 UltraDocument20 pagesNew Holland Roll Baler: Roll Baler 125 Roll Baler 125 Combi Roll Baler 135 UltraSandeepNairNo ratings yet

- Maize Baler Wrapper: Model Tsw2021Document4 pagesMaize Baler Wrapper: Model Tsw2021SandeepNairNo ratings yet

- Particulars िववरण Deposit जमा Withdraw िनकासी Pension contribution पेंशन अंशदानDocument3 pagesParticulars िववरण Deposit जमा Withdraw िनकासी Pension contribution पेंशन अंशदानSandeepNairNo ratings yet

- Directorate, Medical and Health Services : Laxmi Nagar, Ajmer Road, Jaipur 302006Document29 pagesDirectorate, Medical and Health Services : Laxmi Nagar, Ajmer Road, Jaipur 302006SandeepNairNo ratings yet

- List of Ala-Carte FTA ChannelsDocument5 pagesList of Ala-Carte FTA ChannelsSandeepNairNo ratings yet

- Physical World, Units & Measurements Notes (English)Document11 pagesPhysical World, Units & Measurements Notes (English)SandeepNairNo ratings yet

- Spec Silage Making MachineDocument2 pagesSpec Silage Making MachineSandeepNairNo ratings yet

- IF (Rudyard Kipling) TextDocument2 pagesIF (Rudyard Kipling) TextSandeepNair100% (1)

- Cummins Common Rail SystemDocument36 pagesCummins Common Rail SystemSandeepNairNo ratings yet

- Annexure-1 For 750 T Press Hot PressingDocument1 pageAnnexure-1 For 750 T Press Hot PressingSandeepNairNo ratings yet

- Bhawani Shanker Sharma, President NSI 2015Document7 pagesBhawani Shanker Sharma, President NSI 2015SandeepNairNo ratings yet

- Prime Hydraulics CatalogueDocument8 pagesPrime Hydraulics CatalogueSandeepNairNo ratings yet

- Grocery Flyer TemplateDocument1 pageGrocery Flyer TemplateSandeepNairNo ratings yet

- Hydraulic PumpDocument16 pagesHydraulic PumpSandeepNair100% (1)

- Big Savings All Day: Shoppers ExpressDocument1 pageBig Savings All Day: Shoppers ExpressSandeepNairNo ratings yet

- CII DatabaseDocument1,192 pagesCII DatabaseSandeepNairNo ratings yet

- 1300878119-Customer Product List - MalayalamDocument1 page1300878119-Customer Product List - MalayalamSandeepNair100% (1)

- 5 Year MCH Neurosurgery BOSDocument123 pages5 Year MCH Neurosurgery BOSSandeepNairNo ratings yet

Hindustan Hydraulics GS Series

Hindustan Hydraulics GS Series

Uploaded by

SandeepNair0%(1)0% found this document useful (1 vote)

99 views6 pagesHhgs

Original Title

Hindustan_Hydraulics_GS_Series

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHhgs

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0%(1)0% found this document useful (1 vote)

99 views6 pagesHindustan Hydraulics GS Series

Hindustan Hydraulics GS Series

Uploaded by

SandeepNairHhgs

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 6

CNC/NC Hydraulic

Shearing Machine

|

\\

'

il

A‘

nit

riti

itt

i}

LNG

1

VL

©

HINDUSTAN HYDRAULICS

MANUFACTURING EXCELLENCE

6 mmx 310mm

Hindustan Hydraulics with its 25 years of long experience in manufacturing of NC Hycraulic Guillotine Shears

guarantees a product with engineering excellence, relablty and performance with precision for jong and extensive

use.

Hydraulic Guilotine shears from Hindustan Hydraulics meet the highest demands of the sheet metal industry. Output-

cutting quality and efficiency with precision being the decisive criterion. The strong and rigid construction combined

with easy and safe machine operations, ensures a long service life. Very precise machining ofthe fabricated structure

(guarantees working surfaces to achieve blade clearance of required tolerances,

Rapid blade setting mechanism

The adjustable eccentric pivots of swing beam

pormits rapid setting ofthe blade gap clearance within

seconds. The pivot is rotated until pointer

cortesponds to the thickness of the material to be

sheared. This setting is only necessary at one side of

the shear as it automatically adjusts blade gap over

the entire machine length. The cut results achieved

are very precise & burr -Iree. The fast return of the

cutter beams assisted through the charged nitrogen

accumulator.

Due to simultaneous withdrawal of backguage &

coutter beam, the cut pieces do not jammed between

two blades or between blades and backguage

stopper.

16mm x 4100 mm

Blade Gap

Blade Gap

Too Small

Too Big

Blade Gap

Correct

ADVANTAGES OF OUR SHEARS

+ Rapid blade gap adjustment

* Lowmaintenance compact andrelable hydraulic system

* Cutting neitumination

* Very accurate NC Backguage systemwith accuracy of 0.1 mm

+ Adjustable stroke length

* Hydraulic clamps nterocked with cutter beam

+ Fineadjusimentot blades with blade fixtures

+ Burr-sree &dstortion free shearresuls

+ Shearing accuracy resulsbette:than DIN Standards

+ Swing away backguage feature

© Experience of over 1000 supplies

Fear View of Machine

SCHNEIDER CONTROLLER

Optionally available CNC shear

enables all the required and

desired parameters Ike blade gap,

stroke length, backguage & no. of

strokes etc. to be set through CNC

Unit, The backguage in this

particular case is on cual ball

screw with AC servo drive, The

material library stroke counter and Electrical blade clearance is accurately adjustable through

parameter storage are. slanderd CNC controller, as per the parameters fed like thickness &

features of the CNC controller

the required correction. in any UTS of the material to be sheared. The mechanism is very

working parameter can be directly quick and accurate even after long use. Possibility of accidents

given fo the controller due to manual adjustment is negligible

STANDARD SCOPE OF SUPPLY

OPTIONAL ACCESSORIES

© Setof shear blades mounted on the machine

© CNC Controller

© NC.controller Schneider touch

© Electrical blade clearance

* NC backguage 10-1000 mm on hardened & rolled dual lead

screw, © Ball screw backguage with AC servo drive

© Seethrough finger guard © Squaring arm of different length

+ Shadow!ine faciity .

‘Support arm of different length

+ Rapid blade gap adjustment © Handling rollers

* Foot pedal unit © Synthetic cups:

* Stroke length control © Tumbler stops

© Squaring arm—1 mtr—1

savaningamm tem tne © Angle indicator

* Complete machine with hydraulic and electrical safeties

© Material handling options

* One set of eperational & maintenance manual * Pneumatic sheet support systems

+ Sheet support cum stacking system.

© CE Marking

OPTIONAL ACCESSORIES

Support Arm Roller Table

—_ &

Tumbler Stop

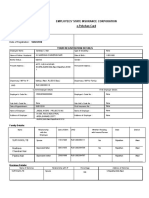

TECHNICAL SPECIFICATIONS

pasty utr Capa

Synthetic Cup

Handling Roller

oer Dinensens

es

cere

5100 mm x 10 mm.

ur 8 mtr long shearing machines are offered with very rigid guiding to the cutter beam. Very accurate machining of the

fabricated structure ensures smooth & precise shear results. The stroke length control over long shears ensures longer lfe of

blade & machine, while requirement is to shear smaller lengths hereby increasing productivity. These long shears are

designed for minimum deflection under constant maxinum load conditions, The upper blades are mounted on special

fixture which is machined to form a helix so that upper blade movement is in perfect perpendicularity over the entire blade

length at the point of contact. Both the upper and lower trapezoidal blades have two cutting edges with grinding tolerances.

Shearing results are distortion tree, burr free and dimensionally results are better than DIN standards. These shears are with

differential hydraulic cylinders so that pressure in both remains same while cutting different lengths

‘Tho singlo set up machining of shear structure is very critical in ensuring accurate shearing results over long period. The intial

perfect machining results in accurate moving paris and long performance,

CUSTOMIZED SOLUTIONS

ai Hana Sey Senge ‘tet Sppart Cum Steg Systm

tL

cay Pat Super Soon

Vaccum Sat aning| netesed Tou Darth

ar agama ror Gang Table

HINDUSTAN HYDRAULICS

HeaD OFFICE

( Roat, Suranass Jalandhar 149027 Punjab smal: nfo@inautanydauics.com

‘Web: weningustanhyctaies com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Study On Round Rice Straw Bale Wrapping Silage Technology and FacilitiesDocument8 pagesStudy On Round Rice Straw Bale Wrapping Silage Technology and FacilitiesSandeepNairNo ratings yet

- Employees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationDocument3 pagesEmployees' State Insurance Corporation E-Pehchan Card: Insured Person: Insurance No.: Date of RegistrationSandeepNairNo ratings yet

- New Holland Roll Baler: Roll Baler 125 Roll Baler 125 Combi Roll Baler 135 UltraDocument20 pagesNew Holland Roll Baler: Roll Baler 125 Roll Baler 125 Combi Roll Baler 135 UltraSandeepNairNo ratings yet

- Maize Baler Wrapper: Model Tsw2021Document4 pagesMaize Baler Wrapper: Model Tsw2021SandeepNairNo ratings yet

- Particulars िववरण Deposit जमा Withdraw िनकासी Pension contribution पेंशन अंशदानDocument3 pagesParticulars िववरण Deposit जमा Withdraw िनकासी Pension contribution पेंशन अंशदानSandeepNairNo ratings yet

- Directorate, Medical and Health Services : Laxmi Nagar, Ajmer Road, Jaipur 302006Document29 pagesDirectorate, Medical and Health Services : Laxmi Nagar, Ajmer Road, Jaipur 302006SandeepNairNo ratings yet

- List of Ala-Carte FTA ChannelsDocument5 pagesList of Ala-Carte FTA ChannelsSandeepNairNo ratings yet

- Physical World, Units & Measurements Notes (English)Document11 pagesPhysical World, Units & Measurements Notes (English)SandeepNairNo ratings yet

- Spec Silage Making MachineDocument2 pagesSpec Silage Making MachineSandeepNairNo ratings yet

- IF (Rudyard Kipling) TextDocument2 pagesIF (Rudyard Kipling) TextSandeepNair100% (1)

- Cummins Common Rail SystemDocument36 pagesCummins Common Rail SystemSandeepNairNo ratings yet

- Annexure-1 For 750 T Press Hot PressingDocument1 pageAnnexure-1 For 750 T Press Hot PressingSandeepNairNo ratings yet

- Bhawani Shanker Sharma, President NSI 2015Document7 pagesBhawani Shanker Sharma, President NSI 2015SandeepNairNo ratings yet

- Prime Hydraulics CatalogueDocument8 pagesPrime Hydraulics CatalogueSandeepNairNo ratings yet

- Grocery Flyer TemplateDocument1 pageGrocery Flyer TemplateSandeepNairNo ratings yet

- Hydraulic PumpDocument16 pagesHydraulic PumpSandeepNair100% (1)

- Big Savings All Day: Shoppers ExpressDocument1 pageBig Savings All Day: Shoppers ExpressSandeepNairNo ratings yet

- CII DatabaseDocument1,192 pagesCII DatabaseSandeepNairNo ratings yet

- 1300878119-Customer Product List - MalayalamDocument1 page1300878119-Customer Product List - MalayalamSandeepNair100% (1)

- 5 Year MCH Neurosurgery BOSDocument123 pages5 Year MCH Neurosurgery BOSSandeepNairNo ratings yet