Professional Documents

Culture Documents

Lebracs Rubber Linings (P) LTD: Ref: Is 4682 (Part 1) & Bs 6374 (Part V)

Lebracs Rubber Linings (P) LTD: Ref: Is 4682 (Part 1) & Bs 6374 (Part V)

Uploaded by

VivekananthOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lebracs Rubber Linings (P) LTD: Ref: Is 4682 (Part 1) & Bs 6374 (Part V)

Lebracs Rubber Linings (P) LTD: Ref: Is 4682 (Part 1) & Bs 6374 (Part V)

Uploaded by

VivekananthCopyright:

Available Formats

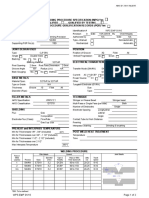

LeBracs Rubber Linings (P) Ltd

Document No. LRL-PRO-SPRK-001

SPARK TESTING PROCEDURE

REV- 0 Page 01 / 01

Ref: IS 4682 (PART 1) & BS 6374 (PART V)

It is essential that linings provide adequate protection to equipment under the conditions for which they are

designed. Therefore, there is a requirement that a lining is continuous i.e. from pin holes and cracks. Tests

which prove the continuity of the lining are necessary.

The approach to continuity testing is to consider the lining as an electrical insulator and search for holes by

testing to make electrical contact to the base metal through the lining by spark tester in which a current

discharge from a high frequency and high voltage with an A.C. source of 0 to 40 KV.

The voltage is adjusted as 5 KV i.e. a spark length of 5 mm per 1 mm thickness of lining.

For the compounds containing considerable amount of carbon black filler, the voltage should be 1.5 KV or a

spark length of 1.5 mm per 1 mm thickness of lining.

The electrodes used are generally of copper rod of 3 to 4 mm dia or copper mesh.

In general the instrument is having a single electrode and it can be choosen depending on the surface and

size of the contour of the surface. When using the ‘L’ shaped electrodes, the working length of electrodes

should be kept in between 150 mm to 200 mm.

In case of lining of pipes, the end of the electrodes should be shaped to fit loosely the inside circumference

of the pipe. The rod leading down the probe have to be insulated.

Before testing begins the surface shall be made dry and free from dirt.

After setting the spark tester to the correct voltage and frequency (frequency will be adjusted as per the

requirement of the spark intensity) for the thickness of rubber lining the electrode shall be taken around

continuously over the surface of the lining.

The tip of the electrode should not be kept at single point for longer period on any of the rubber as there is a

risk of puncturing the rubber by local burning.

ACCEPTANCE:

Normally, the violet spark discharges from the electrode is observed, when the job is without defect. Any

defect would be identified with bluish-white tracer spark discharge with crackling sound. This is to be

rectified as per approved procedure.

M/s LeBracs Rubber

You might also like

- Procedure For Handling, Storage & Transportations of Bare & Coated PipesDocument6 pagesProcedure For Handling, Storage & Transportations of Bare & Coated Pipeskbpatel123No ratings yet

- Method Statement - RT Lorad + CRTDocument4 pagesMethod Statement - RT Lorad + CRTMohdHuzairiRusli100% (4)

- Welding Defect - MACRO PDFDocument5 pagesWelding Defect - MACRO PDFAnonymous 4e7GNjzGWNo ratings yet

- Manual For Wire RopesDocument25 pagesManual For Wire RopesAnand Agrawal0% (1)

- INTERMEC EasyCoder PC4 Service ManualDocument114 pagesINTERMEC EasyCoder PC4 Service ManualC LNo ratings yet

- Chapter 30 Fundamental Principles of RadiobiologyDocument7 pagesChapter 30 Fundamental Principles of RadiobiologyMegNo ratings yet

- Ergonomic Interventions For Electricians in Fossil-Fueled Power PlantsDocument48 pagesErgonomic Interventions For Electricians in Fossil-Fueled Power PlantsSushayan HunsasukNo ratings yet

- Remidol 4000Document6 pagesRemidol 4000maheshNo ratings yet

- Material Safety Data Sheet: Poly Cell AdhesiveDocument8 pagesMaterial Safety Data Sheet: Poly Cell AdhesiveMinh BảoNo ratings yet

- Revision Questions PA 10 Specific Page 23-12Document2 pagesRevision Questions PA 10 Specific Page 23-12Bayu Falen100% (2)

- Welding Procedure Specifications (Wps - 6G) : 2mm (Max)Document2 pagesWelding Procedure Specifications (Wps - 6G) : 2mm (Max)Gbenga Mobolade100% (1)

- PRIMER COAT-Zinc Anode 304 MZV - PDSDocument2 pagesPRIMER COAT-Zinc Anode 304 MZV - PDSMANIMARAN QCNo ratings yet

- Ut PWPS 001Document1 pageUt PWPS 001Goutam Kumar Deb100% (1)

- Table 5 - Wire Type IQI SelectionDocument3 pagesTable 5 - Wire Type IQI SelectionMehmet SoysalNo ratings yet

- 1012835-NEROMASTIC 400 (I) Component (B)Document4 pages1012835-NEROMASTIC 400 (I) Component (B)Srikanth GantaNo ratings yet

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Document17 pagesWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizNo ratings yet

- Vlosi Holiday Test Report No-16Document1 pageVlosi Holiday Test Report No-16Anonymous uJzSZ5100% (1)

- CV Painting InsulationDocument3 pagesCV Painting Insulationhamza brahmiNo ratings yet

- Report of Ultrasonic Flaw Detection Test of Weld JointDocument1 pageReport of Ultrasonic Flaw Detection Test of Weld Jointkevin desai100% (1)

- HSS (Heat-Shrinkable Sleeve) Installation ProcedureDocument60 pagesHSS (Heat-Shrinkable Sleeve) Installation ProcedureIntegrity EngineerNo ratings yet

- 1.4 Rope Access Job Method StatementDocument6 pages1.4 Rope Access Job Method StatementMohammad YusoffNo ratings yet

- Cswip - Section 09-Welding SymbolsDocument14 pagesCswip - Section 09-Welding SymbolsNsidibe Michael Etim100% (1)

- SNIS UT 578 - Steel PlatesDocument14 pagesSNIS UT 578 - Steel PlatesShailesh DeshmukhNo ratings yet

- Av 650 Recent MSDSDocument6 pagesAv 650 Recent MSDSMounir BoutaghaneNo ratings yet

- Lamtiation Ut ProcdureDocument12 pagesLamtiation Ut ProcduremnmsingamNo ratings yet

- Apcosil 605Document1 pageApcosil 605rihtak123No ratings yet

- Inspection Test Plan: 1. Surface Preparation 2. Coating Applications 3. Concrete Repair 1. Surface PreparationDocument17 pagesInspection Test Plan: 1. Surface Preparation 2. Coating Applications 3. Concrete Repair 1. Surface PreparationPrakash SIngh Rawal100% (1)

- 03 - Oven Calibration ProcedureDocument4 pages03 - Oven Calibration ProcedureSankar Muka0% (1)

- Insulation ProcedureDocument3 pagesInsulation ProcedurejunidomarNo ratings yet

- 6604 Issue 2 Testing of Insulating JointsDocument5 pages6604 Issue 2 Testing of Insulating Jointssaminasritn100% (1)

- OK-UT-04 - Ultrasonic Technique SheetDocument1 pageOK-UT-04 - Ultrasonic Technique SheetMike Boyes100% (1)

- APCS-22A HempelDocument3 pagesAPCS-22A Hempelarjunmohanan50% (2)

- Asme Sec V A-15-2006Document4 pagesAsme Sec V A-15-2006Muhammed Abo-FandoodNo ratings yet

- DMA For Austenitic Weld InspectionDocument17 pagesDMA For Austenitic Weld InspectionRupam BaruahNo ratings yet

- Table 5 Wire Type IQI Selection Table 1Document3 pagesTable 5 Wire Type IQI Selection Table 1Kali AbdennourNo ratings yet

- Wps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Document2 pagesWps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Touil HoussemNo ratings yet

- Quality Tool Box Meeting - FormatDocument2 pagesQuality Tool Box Meeting - FormatRam100% (2)

- Nitocote ET402: Constructive SolutionsDocument3 pagesNitocote ET402: Constructive SolutionsGavriel Ng100% (1)

- RT Acceptance Criteria: API-1104 AWS D1.1Document1 pageRT Acceptance Criteria: API-1104 AWS D1.1Shabbir ali100% (1)

- Approved Structural Steel-Welding Procedures - Stud WeldingDocument3 pagesApproved Structural Steel-Welding Procedures - Stud Weldingans44155100% (2)

- Back Gouging ProcedureDocument2 pagesBack Gouging ProcedureVishal SharmaNo ratings yet

- DFT Measurement Worksheet: Paint InspectionDocument1 pageDFT Measurement Worksheet: Paint Inspectionjay nathNo ratings yet

- Shielding Gases ACM Vs CO2Document34 pagesShielding Gases ACM Vs CO2ukavathekar100% (2)

- Galvanizing Procedure (5400)Document5 pagesGalvanizing Procedure (5400)Syed Muzammil100% (2)

- 3LPE Repair ProcedureDocument3 pages3LPE Repair Procedurelhanx2No ratings yet

- Saferad ProcedureDocument19 pagesSaferad ProcedureExsan OthmanNo ratings yet

- 5.2.3.1equipment For High Voltage Spark TestingDocument5 pages5.2.3.1equipment For High Voltage Spark TestingManriquez AndresNo ratings yet

- Cover Sheet: Zapsib-2 ProjectDocument12 pagesCover Sheet: Zapsib-2 ProjectAkhtar AnsariNo ratings yet

- Kerosene Leak TestDocument4 pagesKerosene Leak Testskc50% (2)

- Zinc Anode 304 NPC Coating Zinc Anode 304 NPC Coating: Berger Industrial Manual Berger Industrial ManualDocument1 pageZinc Anode 304 NPC Coating Zinc Anode 304 NPC Coating: Berger Industrial Manual Berger Industrial Manualআফজাল -উল ইসলাম নূর0% (1)

- WPS Format For Asme Ix - Wps - Fcaw GmawDocument1 pageWPS Format For Asme Ix - Wps - Fcaw GmawThe Welding Inspections CommunityNo ratings yet

- F-035 (Valve Erection Format)Document1 pageF-035 (Valve Erection Format)Rajeev Kumar100% (1)

- Welding Electrode Selection Table - Piping StudyDocument1 pageWelding Electrode Selection Table - Piping StudySujay AsukarNo ratings yet

- Procedure of UT-TestDocument2 pagesProcedure of UT-TestJohn ShermanNo ratings yet

- Bgas Test 1 PDFDocument14 pagesBgas Test 1 PDFMathew CherianNo ratings yet

- GRP Lamination Processing - Instructions PDFDocument34 pagesGRP Lamination Processing - Instructions PDFmuhammadkashikNo ratings yet

- Is-4826 Hot Dipped Galvanized CoatingsDocument11 pagesIs-4826 Hot Dipped Galvanized CoatingspankajnbiNo ratings yet

- Radiographic Testing: Inspection ReportDocument2 pagesRadiographic Testing: Inspection Reportsuria qaqcNo ratings yet

- NEW - ALL Codes For Accptance Criteria For RTDocument4 pagesNEW - ALL Codes For Accptance Criteria For RTBALA CHANDAR M100% (1)

- 355 SaDocument2 pages355 Sakhalid764100% (1)

- Section13 Spark TestingDocument3 pagesSection13 Spark TestingGustavoNo ratings yet

- How To Use A Holiday DetectorDocument5 pagesHow To Use A Holiday DetectorSyed SulaimanNo ratings yet

- Gaon - Cables and Wires - CatalogDocument18 pagesGaon - Cables and Wires - Catalogphyo7799100% (2)

- Efficient Formation of Storage Classes For Warehouse Storage LocationDocument10 pagesEfficient Formation of Storage Classes For Warehouse Storage LocationhmtnslNo ratings yet

- ElectrostaticsDocument18 pagesElectrostaticsQasim Anwar ChaudaryNo ratings yet

- Labsheet QuestionDocument12 pagesLabsheet QuestionHasif AimanNo ratings yet

- Presentation On Derivation of Navier Stokes EquationsDocument17 pagesPresentation On Derivation of Navier Stokes Equationsabubakari meregulwaNo ratings yet

- Çoh - KRK Çek - Ki : HKKJR LJDKJDocument2 pagesÇoh - KRK Çek - Ki : HKKJR LJDKJRahul KumarNo ratings yet

- Craig Hacking KiosksDocument54 pagesCraig Hacking KioskschepimancaNo ratings yet

- Load Security On Double-Deck TrailersDocument66 pagesLoad Security On Double-Deck TrailerspetruNo ratings yet

- (Ted M. Knowlton, Chair) Proceedings of InternationalDocument832 pages(Ted M. Knowlton, Chair) Proceedings of InternationalAbshar ParamaNo ratings yet

- Manual LapSim 2013 enDocument68 pagesManual LapSim 2013 enShefin ShukkoorNo ratings yet

- Pds Insulyte 9Document1 pagePds Insulyte 9pulakjaiswal85No ratings yet

- Bhiwandi WH1Document10 pagesBhiwandi WH1HashirNo ratings yet

- CST Design Studio - WorkflowDocument102 pagesCST Design Studio - WorkflowNurSalahuddinNo ratings yet

- Siemens Data Center Whitepaper Aluminium Versus CopperDocument9 pagesSiemens Data Center Whitepaper Aluminium Versus CopperlongplNo ratings yet

- Viva Voce QuestionsDocument4 pagesViva Voce QuestionsHumera Fatima100% (2)

- Jordan Nesmith Resume 23 01 09Document1 pageJordan Nesmith Resume 23 01 09jordan217221No ratings yet

- Neural Network Programming With Java - Sample ChapterDocument25 pagesNeural Network Programming With Java - Sample ChapterPackt PublishingNo ratings yet

- FirewoodDocument108 pagesFirewoodCal02100% (1)

- Technical Specifications-PlumbingDocument52 pagesTechnical Specifications-Plumbingpandey71087100% (1)

- Extraction of Spots in Biological Images Using Multiscale ProductsDocument8 pagesExtraction of Spots in Biological Images Using Multiscale ProductsKhalifa BakkarNo ratings yet

- Differential Equations in Applied Chemistry PDFDocument129 pagesDifferential Equations in Applied Chemistry PDFAlejandro Monroy VergaraNo ratings yet

- Ae4450z Es1bDocument6 pagesAe4450z Es1bAndres VargazNo ratings yet

- Chap 13Document20 pagesChap 13api-26355935No ratings yet

- Nonlinear Op-Amp Circuits: - Most Typical Applications Require Op Amp and Its Components To Act LinearlyDocument31 pagesNonlinear Op-Amp Circuits: - Most Typical Applications Require Op Amp and Its Components To Act LinearlyBeth ValerdiNo ratings yet

- Vistapro User Guide: 6.0Document40 pagesVistapro User Guide: 6.0Pedro QuintalNo ratings yet

- EX4-EX8 Electrical Control ValvesDocument2 pagesEX4-EX8 Electrical Control Valvescesar luis gonzalez rodriguezNo ratings yet

- Road RIPorter 12.4 Winter Solstice 2007Document24 pagesRoad RIPorter 12.4 Winter Solstice 2007Wildlands CPRNo ratings yet

- 1HSM 9543 12-00en Section EXLIM Q-EDocument7 pages1HSM 9543 12-00en Section EXLIM Q-EEmir AyubNo ratings yet