Professional Documents

Culture Documents

Pages From 112006967 PRV Sizing For Exchanger Tube Rupture 2

Pages From 112006967 PRV Sizing For Exchanger Tube Rupture 2

Uploaded by

Ghasem BashiriOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pages From 112006967 PRV Sizing For Exchanger Tube Rupture 2

Pages From 112006967 PRV Sizing For Exchanger Tube Rupture 2

Uploaded by

Ghasem BashiriCopyright:

Available Formats

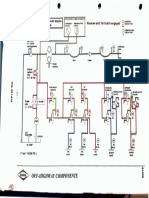

SincePCF1l > Pm the' pressure difference ofctp= }'i~ Pc"" 'Nil!

be the driving force of process fluid fl~iJlg across the tube where C

P SEr '" 150 psig

ture.,6 . ..'

d'

Combi

., , ~Iare ,; 2. Pressure reUefthrough PRY. The second PIl'S5UIl""liefU ten as:

--~--'---,

is the process fluld coming from the high pressure side, WL = 1

low pressure side flowing across the PRVor¥ice into lhe Uquh

.. ,Low pressure sIde. pressure side. . ' ,• .I simulatiol

, CWS CWA

Its flow mechanism is similar to the pressure "eliefthl:oughf,f

H contracta

tube rupture discussed previously; Again, the critical flow

' .. ; '. clition at the orifice must be checked for vapor piiase. Eq.· ~~l:~~~r~

, .

be rewritten as: which eVE

HIgh pressure sldo

'. ( 2 ·.· )~/(k-,l) ";, ,. similar tc

Design pressure of low pressUI'e'slde: 150 pslg

= K +I ' (2n Two-p

Operating pressure of high pressure sIde; 330 psig. .. P CFO P REL

where oYape

Fig. f -Process flow dlagraml . tube brec

'.:. " PRa = Relieving pressure.at·the low I!ressJre side oThe -

= 150'psig (110%)

. + 14;7

. psi area of 01

Flow direction = 179:7. 'p sia . \ Calcu

K = 1.1, rate of specific heats (from computer Wv= :

HIgh pressur!!

' ; . low pre ••ure

Back pressure " simulation results) where dl

side . ' side side ' ..

. ( 2 )1.1/(1.1-1) Liqui'

" PCFo . =179.7 - • .

, ' . 2.1 , . WL =:

, .. ""

= 105.07psia> where dJ

/

PCffl '" 201.54 psla

' ~~be rupture) • I-

• PCFO 1:1 195.07 psi!!

(PRVoriflce) , . I •

Since Pcra> PBACKJ the pressure

'1 ;.

~ere~ce,

_ ::

dp:::; PREt 7"

1

Total

Pcro , will be the driving force of process fluld flowing across',' ATOJj.1J

\ '

PBACK = 19.7 psla the PRY orifice." '. " ,. ".- YapOl

R= VI

Defining th'; relieving tlo~ for tube ruptUre cases. Wher

• . " J

bulk f1ul,

Yapor flowing through tube break without phase ch!lllg",-, ; pressure

, Heat e:JIchanger -' PAil . --, Crane Eq.. 3-22' can be· used for ~ompressible fluids flowing; , ing pre.,

through a sharp-edged orifice based on the assumption men.... . Thet

fig. 2~Pressure: profile'of. tube rupture •. tioned previously.•. I •. lated by

.. I, "'

., W v = 1,891YdZ C(dPIV)05 shownh

The whole flow mechanism can be handled as two pressure Only one cross-sectional area included.

• " .. , . ' I

reliefproccsses in a .seri~s· as shown in Figs. 1and 2. . where r= 1-0.317 dPIPIi ,. Notes. I

The pressure profile for' the two relief processes IS illus- The equation is summarized from the figures on page A-2b cuiating

trated in' the follo,ving'example: , " '. " Curre

of Crane' for Simplifying the lengthy calculations. .

L Pre•• ..,.;, reUeftIll-ough t~be ruptt:re. When a tube rup- C ',,; 0.6, flow coefficient for square~edged orifices (from ., adopt th

tures, the process fluld at 330 psig or 344_7 psia wUl flow across f1owco[

Crane figures on page A-20r . ,

the tube ruptUre into the low pressure side. With a PRY installed critical :

d'=3.1416A vI4

at the low pressure side with a 'rellef pressure of 110% of its under tl

design pressure, i.e., PRF.L= 150 'psig (110%)+ 14.7 psi= 179.7. It should be noted 'that ~ritical pr~ssu~e must be checked sistent.

psia, the low pressure side will be unde.179.7 psia. But the flow since under critical flow condition the actual pressure at a Obvi,

may be controlled by' the. critlcal flow pressure at .the tube rupture opening (throat) cannot faU below the critical flow must b(

rupture for vapor phase, if the critical flow pressure is higher. pressure even if a much lower pressure exists downstream. 6 pressun

than the relieving pressure at the low pressure side. Incorrect use of the pressure at the low pressure side may mentiQ!

The critical flow pressure at the tube rupture can be cause oversizing the PRY. This common mistake should be the two.

expressed as the following, as recommended by API 520 Eq. I: avoided. . The

Combining aU the previously given variables, the previous across t

.( 2 )K/(K-l) equation can be rewritten as:

P CFR =P, - - (I) thevap.

K+I Wv ~ 1,444.6 Av(l-0.317 dPI P,) (dPI W V)O.5 (3) ommen

where . . .' uld rnti(

P, = Operating pressure at the high pressure side Uquld flowing through tube break without phase change. pressur

=344.7 psia Critical condition does not need to be considered for liquld flash in

K = 1.1, ratio of specific heats (from simulatlon results) flowing through the tube break without phase change. Crane This

Eq. 3-21' can be used for liquld flowing through a sharp-edged for the

. ' ( 2 )l.l/{l.l-ll orifice: pressUI'

PCFR =344 17 - ,

. 2.1 '. W L ~ 1,891 d' C (dP W L )O:5

as ahea

ture is v

= 201.54 psia .. Only one cross· sectional area inclUded.

uid rat

60 HYDROCARBON PROCESSING, 1992

You might also like

- Designing Pneumatic Conveying Systems: Cover StoryDocument11 pagesDesigning Pneumatic Conveying Systems: Cover StoryGhasem Bashiri100% (2)

- Dale Beggs 1 - Production Optimization Using Nodal Analysis (010-016)Document7 pagesDale Beggs 1 - Production Optimization Using Nodal Analysis (010-016)Luz Mary OrtegaNo ratings yet

- Strongholds of HeritageDocument9 pagesStrongholds of Heritageusman zafarNo ratings yet

- PRV Sizing For Exchanger Tube RuptureDocument5 pagesPRV Sizing For Exchanger Tube RuptureNavid Sajedi80% (5)

- Special Focus: Reboiler Pinch: An Approach To Optimize Flare System Design During FEEDDocument6 pagesSpecial Focus: Reboiler Pinch: An Approach To Optimize Flare System Design During FEEDGhasem Bashiri100% (1)

- She's Yours For The TakingDocument281 pagesShe's Yours For The TakingMichel Aus Lönneberga75% (8)

- Final PPT of Carbon NanotubesDocument29 pagesFinal PPT of Carbon Nanotubesmkumar_5481467% (3)

- The Secrets of Numerology Meanings Made EasyDocument8 pagesThe Secrets of Numerology Meanings Made Easydiana tolopia100% (3)

- Pogitive Displacement MachinesDocument38 pagesPogitive Displacement MachinesAli MohsinNo ratings yet

- CEGB Vol 3 TurbineDocument420 pagesCEGB Vol 3 Turbinesurendra7_14100% (9)

- A Series of Enthalpy-Entropy Charts For Natural Gases: f:1H, f:1M f:1MZDocument12 pagesA Series of Enthalpy-Entropy Charts For Natural Gases: f:1H, f:1M f:1MZDogui AldasNo ratings yet

- Ac-Machines-Transformerspdf 5addde227f8b9ae0198b4567Document19 pagesAc-Machines-Transformerspdf 5addde227f8b9ae0198b4567dummy accountNo ratings yet

- How To Size Pump Suction PipingDocument2 pagesHow To Size Pump Suction PipingShebnemNo ratings yet

- Production-Systems Analysis For Fractured Wells: James HuntDocument7 pagesProduction-Systems Analysis For Fractured Wells: James Huntmanuel cabarcasNo ratings yet

- Sae As21 PDFDocument5 pagesSae As21 PDFfarhad pashaei mehrNo ratings yet

- Refrigeration CapoteDocument51 pagesRefrigeration CapoteMichelle Angela Cabrera GabisNo ratings yet

- W S B Anced Pressure Drilling?: 1969 American Institute of Mining, Metallurgical, and Petroleum Engineers, IncDocument8 pagesW S B Anced Pressure Drilling?: 1969 American Institute of Mining, Metallurgical, and Petroleum Engineers, IncfuatNo ratings yet

- Expt 9Document5 pagesExpt 9alaa AlobeidyeenNo ratings yet

- AscoDocument1 pageAscoSudipto MajumderNo ratings yet

- Week 5 Reservoir Deliverability Gas WellDocument29 pagesWeek 5 Reservoir Deliverability Gas Welldaffa teguhNo ratings yet

- ME 307 2013-2014 Fall Week 4th RecitationDocument6 pagesME 307 2013-2014 Fall Week 4th RecitationAhmed Mohamed SalihNo ratings yet

- Beg 2018 XXDocument42 pagesBeg 2018 XXFranz Gustavo Vargas MamaniNo ratings yet

- Scan 01-Aug-2022Document5 pagesScan 01-Aug-2022KULDEEP SOLANKINo ratings yet

- C# ProgramsDocument3 pagesC# ProgramsVarshini VarshaNo ratings yet

- Theoretical Basis of IsochronalDocument3 pagesTheoretical Basis of IsochronalBayu PamungkasNo ratings yet

- Spe 1676 PaDocument3 pagesSpe 1676 PaFernando Ledesma SolaecheNo ratings yet

- BHP Gas WellsDocument3 pagesBHP Gas WellsAdelia Dwi cahyaniNo ratings yet

- Gas Well Deliverability II 2018Document55 pagesGas Well Deliverability II 2018Johny ImitazNo ratings yet

- Function Test Cert. DHSV v-11 April 07,2023Document1 pageFunction Test Cert. DHSV v-11 April 07,2023muhamad.iqbaaal11No ratings yet

- 2-5L To 3-7L MerCruiser MCM 470 Installation ManualDocument23 pages2-5L To 3-7L MerCruiser MCM 470 Installation ManualGerrit DekkerNo ratings yet

- Parcial Mecánica de FluidosDocument3 pagesParcial Mecánica de FluidosIñigoNo ratings yet

- Lee 1981Document16 pagesLee 1981andi suntoroNo ratings yet

- Function Test Cert. DHSV v-14 April 05,2023Document1 pageFunction Test Cert. DHSV v-14 April 05,2023muhamad.iqbaaal11No ratings yet

- Fluid Reci PumpDocument12 pagesFluid Reci PumpMaxiNo ratings yet

- Flugel-Design Jet PumpsDocument67 pagesFlugel-Design Jet PumpsAnonymous hHWOMl4FvNo ratings yet

- Rac QPDocument8 pagesRac QPLove InfinityNo ratings yet

- Exercises For The Course f7017t Water TurbinesDocument26 pagesExercises For The Course f7017t Water Turbineslij Get BiruNo ratings yet

- 4 - 12 미소열Document3 pages4 - 12 미소열이동근No ratings yet

- Abhi JournalDocument16 pagesAbhi JournalAnkit Jerome FargoseNo ratings yet

- Hydraulic Calculation and RefernceDocument7 pagesHydraulic Calculation and RefernceSherwin SolisNo ratings yet

- RINA NAVAL ARCHITECT OCT 1986 SCANNED Propeller Correction Shallow PDFDocument2 pagesRINA NAVAL ARCHITECT OCT 1986 SCANNED Propeller Correction Shallow PDFBinod SahNo ratings yet

- M I:.t.oso: - RJ - RJ - rJ1Document1 pageM I:.t.oso: - RJ - RJ - rJ1Dennis CaravakisNo ratings yet

- 3 Phase Induction MotorDocument5 pages3 Phase Induction MotorMridul BhardwajNo ratings yet

- ME 307 2013-2014 Fall Week 7th RecitationDocument14 pagesME 307 2013-2014 Fall Week 7th RecitationYeiner MachadoNo ratings yet

- Digitalização 7 de Nov de 2017Document1 pageDigitalização 7 de Nov de 2017Anderson OliveiraNo ratings yet

- 1983 SPE12518 Whitson IPRDocument60 pages1983 SPE12518 Whitson IPRPorfirio AguileraNo ratings yet

- Gas Well Deliverability I 2018Document33 pagesGas Well Deliverability I 2018Johny Imitaz0% (1)

- Celculation of Static Press',, Re Gradients Iu Gas Wellis: Gas Wp.L1SDocument14 pagesCelculation of Static Press',, Re Gradients Iu Gas Wellis: Gas Wp.L1SFernando Ledesma SolaecheNo ratings yet

- Verification of Bernoulli's Theorem: Experiment No: 7 DateDocument6 pagesVerification of Bernoulli's Theorem: Experiment No: 7 Datesreeramkishore22No ratings yet

- Chapter 2 - Free-Piston Stirling EnginesDocument77 pagesChapter 2 - Free-Piston Stirling EnginesOnur GençoğluNo ratings yet

- Excerpts CCDocument2 pagesExcerpts CCrdenNo ratings yet

- Notes 7Document12 pagesNotes 7Qixian FengNo ratings yet

- Fouling in Axial Compressor of Gas Turbines NuovoDocument19 pagesFouling in Axial Compressor of Gas Turbines NuovoTabiquera Guadalupe Victoria Texcoco De MoraNo ratings yet

- Well Test Previous Year QuestionDocument13 pagesWell Test Previous Year QuestionDiptoNo ratings yet

- Imperial Portables Typewriter Instructions ManualDocument5 pagesImperial Portables Typewriter Instructions Manualgerrit griekspoorNo ratings yet

- Kelin EffectDocument4 pagesKelin EffectJeevanNo ratings yet

- Week 2 Reservoir DeliverabilityDocument43 pagesWeek 2 Reservoir Deliverabilitydaffa teguhNo ratings yet

- Volume 2 Notes On GermanDocument103 pagesVolume 2 Notes On GermanKasa Satu100% (1)

- Ciclo BraytonDocument8 pagesCiclo BraytonFabian BarajasNo ratings yet

- MESB374 System Modeling and Analysis: Hydraulic (Fluid) SystemsDocument16 pagesMESB374 System Modeling and Analysis: Hydraulic (Fluid) Systemsعلي كامل الاسديNo ratings yet

- Model of The Coronary Circulation Based On Pressure Dependence of Coronary Resistance and ComplianceDocument15 pagesModel of The Coronary Circulation Based On Pressure Dependence of Coronary Resistance and Compliancedr ruchiNo ratings yet

- B. VQ-D.: T:?Siffit'l Inff::'j:lDocument1 pageB. VQ-D.: T:?Siffit'l Inff::'j:landrewNo ratings yet

- The Continental Risque: An Isaac Biddlecomb NovelFrom EverandThe Continental Risque: An Isaac Biddlecomb NovelRating: 3.5 out of 5 stars3.5/5 (11)

- Safeguarding Rotating Equipment in Ethylene PlantsDocument3 pagesSafeguarding Rotating Equipment in Ethylene PlantsGhasem BashiriNo ratings yet

- PSVPlus V7 Fact SheetDocument4 pagesPSVPlus V7 Fact SheetGhasem BashiriNo ratings yet

- Attachment No.2Document1 pageAttachment No.2Ghasem BashiriNo ratings yet

- Polypropylene Impact Copolymer: Ihs ChemicalDocument11 pagesPolypropylene Impact Copolymer: Ihs ChemicalGhasem BashiriNo ratings yet

- WCECS2010 pp710-716Document7 pagesWCECS2010 pp710-716Ghasem BashiriNo ratings yet

- Attachment No.1Document1 pageAttachment No.1Ghasem BashiriNo ratings yet

- Pages From API-668-2019Document1 pagePages From API-668-2019Ghasem BashiriNo ratings yet

- 372h - Optimal Synthesis of Cooling Water Systems: Tuesday, November 12, 2019 3:30 PM - 5:00 PMDocument3 pages372h - Optimal Synthesis of Cooling Water Systems: Tuesday, November 12, 2019 3:30 PM - 5:00 PMGhasem BashiriNo ratings yet

- Development of A Molecular Kinetic Model and Tuning of Its Required Kinetic Parameters For Thermal Cracking of Light HydrocarbonsDocument22 pagesDevelopment of A Molecular Kinetic Model and Tuning of Its Required Kinetic Parameters For Thermal Cracking of Light HydrocarbonsGhasem BashiriNo ratings yet

- 218 API S 521: Figure F.3-Approximate Flame Distortion Due To Lateral Wind On Jet Velocity From Flare StackDocument1 page218 API S 521: Figure F.3-Approximate Flame Distortion Due To Lateral Wind On Jet Velocity From Flare StackGhasem BashiriNo ratings yet

- Guidelines For Pressure Relief and Effluent Handling SystemsDocument1 pageGuidelines For Pressure Relief and Effluent Handling SystemsGhasem BashiriNo ratings yet

- Cracking Hydrocarbon Feedstock With A Heavy TailDocument4 pagesCracking Hydrocarbon Feedstock With A Heavy TailGhasem BashiriNo ratings yet

- Chemical Engineering Science: M. Gholami, M.R. Talaie, S. RoodpeymaDocument8 pagesChemical Engineering Science: M. Gholami, M.R. Talaie, S. RoodpeymaGhasem BashiriNo ratings yet

- Engineering Progress: Disposal SystemsDocument1 pageEngineering Progress: Disposal SystemsGhasem BashiriNo ratings yet

- Contactor Vol 4 No 5Document2 pagesContactor Vol 4 No 5Ghasem BashiriNo ratings yet

- WebtocDocument4 pagesWebtocGhasem BashiriNo ratings yet

- q3 cGBPariantDocument4 pagesq3 cGBPariantGhasem BashiriNo ratings yet

- Point and Area Sources: Flashing Flow in PipesDocument1 pagePoint and Area Sources: Flashing Flow in PipesGhasem BashiriNo ratings yet

- FFS - Home Work No.1Document2 pagesFFS - Home Work No.1Ghasem BashiriNo ratings yet

- Pages From 112006967-PRV-Sizing-for-Exchanger-Tube-RuptureDocument1 pagePages From 112006967-PRV-Sizing-for-Exchanger-Tube-RuptureGhasem BashiriNo ratings yet

- Pages From 112006967-PRV-Sizing-for-Exchanger-Tube-Rupture-4Document1 pagePages From 112006967-PRV-Sizing-for-Exchanger-Tube-Rupture-4Ghasem BashiriNo ratings yet

- Pages From 112006967 PRV Sizing For Exchanger Tube Rupture 3Document1 pagePages From 112006967 PRV Sizing For Exchanger Tube Rupture 3Ghasem BashiriNo ratings yet

- Metals Daily: Honda Motor To Produce Nickel-Cobalt Alloy From Recycling Lithium-Ion Batteries by 2025Document26 pagesMetals Daily: Honda Motor To Produce Nickel-Cobalt Alloy From Recycling Lithium-Ion Batteries by 2025Ghasem BashiriNo ratings yet

- CH CH CH CH (CH) N G.Natta : Shore ADocument9 pagesCH CH CH CH (CH) N G.Natta : Shore AGhasem BashiriNo ratings yet

- Brief Description of Ipt: Head OfficeDocument2 pagesBrief Description of Ipt: Head OfficeGhasem BashiriNo ratings yet

- Isotonix OPC-3 Sep 2016Document4 pagesIsotonix OPC-3 Sep 2016Pching Yong100% (1)

- 02 Introduction To Numerical AnalysisDocument27 pages02 Introduction To Numerical AnalysisBruhNo ratings yet

- An Essay On AdvertisementDocument6 pagesAn Essay On Advertisementafhbctdfx100% (2)

- Letter of DiscrepancyDocument1 pageLetter of DiscrepancyImam MekarNo ratings yet

- Chapter 5 - Genes, Culture, and GenderDocument32 pagesChapter 5 - Genes, Culture, and Genderm100% (1)

- Example Lab ReportDocument20 pagesExample Lab ReportbobtentpegNo ratings yet

- Medix Biochemica Product CatalogueDocument72 pagesMedix Biochemica Product Catalogueapoorva.saradigiNo ratings yet

- AU200 Maintenance ManualDocument138 pagesAU200 Maintenance ManualramiroNo ratings yet

- Transformation of Green Areas in Urban Landscape of Lucknow: Need For Holistic Intervention With Respect To River GomtiDocument10 pagesTransformation of Green Areas in Urban Landscape of Lucknow: Need For Holistic Intervention With Respect To River GomtiASHUTOSH SINGHNo ratings yet

- Competitive Exams Bluetooth Functioning: ExamraceDocument4 pagesCompetitive Exams Bluetooth Functioning: ExamraceRaja PosupoNo ratings yet

- Physics Mechanical Properties of Solids (Practice Problems) : Important FormulaeDocument2 pagesPhysics Mechanical Properties of Solids (Practice Problems) : Important FormulaeSarunkumar Balath100% (1)

- Project Report On Ferric and Non Ferric AlumDocument6 pagesProject Report On Ferric and Non Ferric AlumEIRI Board of Consultants and Publishers100% (1)

- Prueba - Inequalities - QuizletDocument14 pagesPrueba - Inequalities - QuizletNICOLAS CASTELLANOS TAMAYONo ratings yet

- Haptics: Science, Technology, ApplicationsDocument571 pagesHaptics: Science, Technology, ApplicationsPul50No ratings yet

- Geological Chance of SuccessDocument11 pagesGeological Chance of SuccesssarapkanNo ratings yet

- E0234 PPTDocument41 pagesE0234 PPTjerry.sharma0312No ratings yet

- Essay On U.N.H.R.C Report On Ficancialization of HousingDocument3 pagesEssay On U.N.H.R.C Report On Ficancialization of HousingMuhammad EhtishamNo ratings yet

- Skin Tear Prevention - Strategies For Preventing Skin Injury in At-Risk PopulationsDocument10 pagesSkin Tear Prevention - Strategies For Preventing Skin Injury in At-Risk PopulationsCarolina RodriguezNo ratings yet

- Prof. Stefano Benedicenti: Dean of Endodotic, Restorative and Laser Dental DepartmentDocument7 pagesProf. Stefano Benedicenti: Dean of Endodotic, Restorative and Laser Dental DepartmentAsif IqbalNo ratings yet

- R S Aggarwal Solution Class 11 Maths Chapter 30 StatisticsDocument29 pagesR S Aggarwal Solution Class 11 Maths Chapter 30 StatisticsTushar RanaNo ratings yet

- HerzogDocument28 pagesHerzogSreekanth RaviNo ratings yet

- Computer Pilot Magazine Vol Iss Mar Apr 2011Document92 pagesComputer Pilot Magazine Vol Iss Mar Apr 2011Guilherme SoaresNo ratings yet

- EmudiagDocument33 pagesEmudiagPABLO IVAN TELLO SANDOVALNo ratings yet

- Laghu Siddhanta Kaumudi - Shared Q&A Sheet - 01 - SamjnaprakaranamDocument40 pagesLaghu Siddhanta Kaumudi - Shared Q&A Sheet - 01 - SamjnaprakaranamOnkar YemulNo ratings yet

- Appendix 1: I. Exercise ToleranceDocument5 pagesAppendix 1: I. Exercise Tolerancejfcule1No ratings yet

- Simple Present ActivitiesDocument1 pageSimple Present ActivitiesMaximiliano ParedesNo ratings yet