Professional Documents

Culture Documents

Stem-1 - Frac Tank

Stem-1 - Frac Tank

Uploaded by

Mohamed El-SawahOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stem-1 - Frac Tank

Stem-1 - Frac Tank

Uploaded by

Mohamed El-SawahCopyright:

Available Formats

STEM-I: SSF Mobile Frac Tank

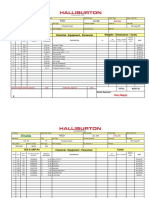

DISTRICT / LOCATION: SDGM-1095 / Site-26 HUBOMETER READING: 0183 km / m REPORT No.: Night Shift

UNIT DESCRIPTION: Frac Tank Date Last STEM-II: 09-May-2019 DATE: 22-Nov-2019

UNIT No.: SSF-51111F1059 DOT Paperwork Ok?: Yes / No / NA OPERATOR NAME: Mohamed Ismail

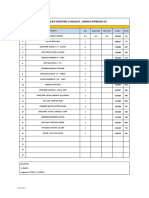

Review previous 2-3 STEM-I Reports - were previous deficiencies corrected? ASK IF IN DOUBT. Check Unit Maintenance & Operation Manuals

Check P Comments / Work Done / Outstanding Work

System / Component Guidelines on what to check Wear correct PPE Needs **Record operating oil pressures & temperatures, volumes of

Okay

Work fluid(s) added and parts used.

Unit is CLEAN with correct labeling. Wash with fresh water

Unit is PAINTED - no corroded or partially painted areas

Appearance & Tank body - visually check for damage (dents, scratches, holes, cracks) Ok

1

Cleanliness Walk around unit - check for leaks/damage: repair/report as required

No loose objects - do not use frac tank to transport fluids, sacks or drums

Walkways, Railings, Ladders & Grating - check for damage, secure & clean

2 Safety Equipment Wheel chocks - check x2 blocks available & in good condition Ok

Earth/Ground Cable - in place & connected to stake in ground

Trailer Brake Systems - check work okay when hooked up to tractor

Trailer Lights - confirm all working and lens caps undamaged

Tires, lugs, clamps - check for flats & damage and loose lugs or clamps Ok

3 Trailer Coupling Devices - check 5th-wheel, pin & latch mechanism okay

Air/Electric Hoses - connected to/from tractor/trailer, secure, no damage

Landing Gear, Legs & Pads - work ok, good condition, pins secured w/chain

Verify LP warning activates @ >/= 60psi, check for leaks, perform 4-point

Brakes, Tires & brake check, air comp. gives 120 psi. Ok

4

Wheels Tires, lugs, clamps - check for flats & damage and loose lugs or clamps

Mud Flaps - check condition

Visually inspect for noticable sag or lean

5 Suspension Check for cracked or broken parts or deflated/leaking air bags Ok

Tank Lining (if applicable) - check integrity of lining - no damage

Visually inspect for cleanliness & corrosion - walls of tank, corners free of

material build-up, suction pits clean Ok

6 Tank Interior Suction & Re-circulating lines - verify not damaged & secured

Access ladder (if applicable) - check integrity and no damage

Baffles (if present) - check condition is okay

Manifolds - no leaks from valves, end caps, flanged connections.

Ensure all connections are secured and comply with WS Std-18

Mounting brackets - visually check brackets for damage & cracks

Suction Manifolds BFVs - handles in place & open/close smoothly - grease as required.

7 Ok

Front and Rear Blind caps (2-piece) - in place as required: secured with chain

Unions - no burrs on wing nuts

Drip trays (if applicable) - check clean with no damage

Sample Points - check valve in good condition, no leaks & drip tray in use

Ensure all connections are secured and comply with WS Std-18

Mounting brackets - visually check brackets for damage & cracks

Re-Circulating BFVs - handles in place & open/close smoothly - grease as required.

8 Lines Blind caps (2-piece) - in place as required: secured with chain Ok

Unions - no burrs on wing nuts

Drip trays (if applicable) - check clean with no damage

Sample Points - check valve in good condition, no leaks & drip tray in use

Top Hatches - check hinges in good condition & hatches close securely

Inspection Ok

9 Rear/Front/Side Access - check no leaks, gaskets & bolts in good condition

Hatches Access ladders - verify condition & integrity

Mechanical - check lever moves freely & not obstructed (check inside tank)

Visual - check sight glass not broken & for cleanliness & function. Check # Sight glass is N/A

Fluid Level isolation valve(s) working & not leaking Ok

10

Indicator Verify lubricant in fluid level indicator system & lubricate as required.

Support Mounts - verify no damage & secure

Tank Level Chart - is correct chart available & tank calibrated as per chart?

COMMENTS: Describe any additional checks performed, parts used or other corrective maintenance performed. Use STEM-I Continuation/Repair Report if necessary.

# Next Stem-2 >> May -2020

# Next Stem-3 >> May-2020

# KP Next Insp >> May-2020

# MPI Next Insp >> Apr-2020

OPERATOR SIGNATURE: JOB SUPERVISOR SIGNATURE: FSM / MSV SIGNATURE:

Mohamed Ismail

Date:

22-Nov-2019 Date: Date:

Operator confirms that required STEM-I maintenance checks were performed & corrected & noted, & the unit is ready for the next job. FSM/MSV confirms reported defects are repaired & documented in Fleet Assistant, unit is green tagged & ready for the next job.

Controlled document. Do not modify or change without permission. Ref No.: WS-STEM1-WPS-002-04 V3.0 30-Nov-09_RL

You might also like

- ELITE40 Operation Manual 1210Document57 pagesELITE40 Operation Manual 1210Edgar Castañeda100% (1)

- Checklist - ManitouDocument1 pageChecklist - ManitouKlizman Amine100% (1)

- Domnick Hunter ES2000 Series Oil Water Separators ManualDocument8 pagesDomnick Hunter ES2000 Series Oil Water Separators ManualMark CarterNo ratings yet

- Valvula Set StopDocument107 pagesValvula Set StopAngel LRNo ratings yet

- Fluke 719 721 750P Series CSA Certificate of ConformityDocument2 pagesFluke 719 721 750P Series CSA Certificate of ConformityMiguel Ruiz100% (1)

- Bomba Triplex TEEF 5 de in Gardner DenverDocument2 pagesBomba Triplex TEEF 5 de in Gardner DenverPeponSera100% (2)

- Stem Reports - Site 20Document4 pagesStem Reports - Site 20Mohamed El-SawahNo ratings yet

- Stem Reports - Site 20Document4 pagesStem Reports - Site 20Mohamed El-SawahNo ratings yet

- PQR Wps WPQ FormatDocument12 pagesPQR Wps WPQ FormatessnelsonNo ratings yet

- Math Quest Further Maths VCE 12 (2016 Edition)Document786 pagesMath Quest Further Maths VCE 12 (2016 Edition)NhiNo ratings yet

- STEM-I: CPF Cement Pump Float: HRDH-1856 / Site-26 22-Nov-2019 Night Shift CPF-377Document1 pageSTEM-I: CPF Cement Pump Float: HRDH-1856 / Site-26 22-Nov-2019 Night Shift CPF-377Mohamed El-SawahNo ratings yet

- Gagemaker Products: Thread FormDocument1 pageGagemaker Products: Thread FormCharles Guzman100% (1)

- Lavadora Secadora LG WD15EGS6 PDFDocument100 pagesLavadora Secadora LG WD15EGS6 PDFK-Search100% (1)

- Bomba Kobe T200 - Manual de PartesDocument13 pagesBomba Kobe T200 - Manual de PartesRonalRojas100% (1)

- Programming IPC & ACCUFRAC and Uploading - Downloading Parameters Into MCBDocument6 pagesProgramming IPC & ACCUFRAC and Uploading - Downloading Parameters Into MCBPeter SnellNo ratings yet

- Sae J2228 2011Document5 pagesSae J2228 2011Cristian GordilloNo ratings yet

- Wilden M8Document43 pagesWilden M8mauro_pm100% (1)

- UCI274H 25 TD EN - Rev - BDocument8 pagesUCI274H 25 TD EN - Rev - Bteja sri rama murthyNo ratings yet

- Spicer T210 R8341 Parts Manual PDFDocument25 pagesSpicer T210 R8341 Parts Manual PDFJoffre Lautaro Benavides SeminarioNo ratings yet

- N5SC Swivel 1Document12 pagesN5SC Swivel 1Winda FaleviNo ratings yet

- Arrow CDocument118 pagesArrow CjulioramcaNo ratings yet

- B1a1 Pipe ClassDocument1 pageB1a1 Pipe Classbrujula27No ratings yet

- 673 - Remote IODocument21 pages673 - Remote IOIcemanNo ratings yet

- Manual de FPP TsDocument28 pagesManual de FPP TsAlexander CallaNo ratings yet

- Procedimiento Parker para Prueba de CilindrosDocument7 pagesProcedimiento Parker para Prueba de Cilindrosspider3486No ratings yet

- LEWA Ecoflow Variable Eccentric Pump Drive Type LDB: PerformanceDocument2 pagesLEWA Ecoflow Variable Eccentric Pump Drive Type LDB: PerformanceIoana PopescuNo ratings yet

- IDC 800HP Self-Prop Drilling Rig S&P CD S1 IntroDocument24 pagesIDC 800HP Self-Prop Drilling Rig S&P CD S1 IntroIDC-47No ratings yet

- Carpeta Tecnica Equipamiento Flush byDocument655 pagesCarpeta Tecnica Equipamiento Flush byFederico MoranNo ratings yet

- SPRAGUE J Pump BrochureDocument8 pagesSPRAGUE J Pump BrochurechauduonguyenNo ratings yet

- Doosan HP750WCU-T4F Operation and Maintenance ManualDocument138 pagesDoosan HP750WCU-T4F Operation and Maintenance ManualGonzalo GalvezNo ratings yet

- 120SXJ Maintenance and Service ManualDocument112 pages120SXJ Maintenance and Service ManualTecnico Reach Stacker Tecnico Reach StackerNo ratings yet

- Lux M10Document40 pagesLux M10simonNo ratings yet

- Booster Pumps MANUAL PDFDocument70 pagesBooster Pumps MANUAL PDFMallinatha PNNo ratings yet

- Dsa4 Side DoorDocument24 pagesDsa4 Side DoorДудла СтаніславNo ratings yet

- Guide Service de Balde AlemiteDocument14 pagesGuide Service de Balde AlemiteAH SergioNo ratings yet

- TT-560 Specifications PDFDocument2 pagesTT-560 Specifications PDFDidier MorenoNo ratings yet

- Copy of SCOPE OF WORK - SERVICE OFFERSDocument12 pagesCopy of SCOPE OF WORK - SERVICE OFFERSSandeep NikhilNo ratings yet

- Multiphase Pump MPC 208 - 38/1 / N: 1.0 Project DataDocument2 pagesMultiphase Pump MPC 208 - 38/1 / N: 1.0 Project DataRabah Semassel100% (1)

- ULTISEP Element Specification Sheet - GCA5536K10VDocument2 pagesULTISEP Element Specification Sheet - GCA5536K10Vaditya sigitNo ratings yet

- Mantenimiento Valvula by PassDocument29 pagesMantenimiento Valvula by PassUlices Mejia BautistaNo ratings yet

- Electronic Hand Control MH 2000Document3 pagesElectronic Hand Control MH 2000Christian ChumpitazNo ratings yet

- Manual Compressor Ingersoll RandDocument6 pagesManual Compressor Ingersoll RandJavier De La RosaNo ratings yet

- C0108031 O&M Manual y Curva Fabricante PDFDocument127 pagesC0108031 O&M Manual y Curva Fabricante PDFcesar100% (1)

- ARO Pump ManualDocument8 pagesARO Pump Manualrazaq athabNo ratings yet

- Getting Started With Visu+ Express and HMI: Quick Start GuideDocument64 pagesGetting Started With Visu+ Express and HMI: Quick Start GuideGustavo GamezNo ratings yet

- Stock List PDFDocument4 pagesStock List PDFAL Wahid SpareNo ratings yet

- TLDD-2016-2AAG-D06-0001 - Code 2Document5 pagesTLDD-2016-2AAG-D06-0001 - Code 2Cao Huu Tung100% (1)

- PDI TEE 165 Manual BookDocument34 pagesPDI TEE 165 Manual BookRiswan Park'Chu Young50% (2)

- Manual Técnico - Pump Haskel - MS 21Document14 pagesManual Técnico - Pump Haskel - MS 21Bruno Pacheco100% (1)

- Maintenance Interval Schedule c15 MCW PDFDocument3 pagesMaintenance Interval Schedule c15 MCW PDFVictor NunezNo ratings yet

- PDFDocument2 pagesPDFaup100% (1)

- Windsor Saber SX24Document72 pagesWindsor Saber SX24Nestor Marquez-DiazNo ratings yet

- Manual de Operación & Mantenimiento EEG 345Document47 pagesManual de Operación & Mantenimiento EEG 345juan0377No ratings yet

- 1 August 2 2011 6 03 30Document2 pages1 August 2 2011 6 03 30Jayesh SanganiNo ratings yet

- Tabela de Kit de ManutençãoDocument2 pagesTabela de Kit de ManutençãoRicardo Nunes Pereira JuniorNo ratings yet

- Pat List-Timas-Desalter PDFDocument14 pagesPat List-Timas-Desalter PDFrizky efrinaldoNo ratings yet

- 2022.4 Bulletin On Update of Specifications of Oil and Fluid For Changan Automobile in Overseas MarketDocument14 pages2022.4 Bulletin On Update of Specifications of Oil and Fluid For Changan Automobile in Overseas MarketAmr Mousa100% (1)

- TLS 450 Guide PDFDocument127 pagesTLS 450 Guide PDFMimid SbihiNo ratings yet

- National 165T5 J165 Triplex SpecsDocument2 pagesNational 165T5 J165 Triplex SpecsCamilo Andres Cardozo FajardoNo ratings yet

- DW402 - Pulidor DewaltDocument3 pagesDW402 - Pulidor DewaltJorge Adalberto Lugo QuinteroNo ratings yet

- Stem-I: Sus - Centrifugal Pump Unit (Diesel Driven)Document1 pageStem-I: Sus - Centrifugal Pump Unit (Diesel Driven)Mohamed El-Sawah0% (1)

- Stem-1 MPF342 - 18-FebDocument1 pageStem-1 MPF342 - 18-FebMohamed El-SawahNo ratings yet

- C-Pump Pre Job Check ListDocument3 pagesC-Pump Pre Job Check ListAhmed ElkashifNo ratings yet

- 75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Document1 page75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Mohamed El-SawahNo ratings yet

- 5'' Liner - 2009Document4 pages5'' Liner - 2009Mohamed El-SawahNo ratings yet

- Fu-10, 75914199-2,, Pressre Test, 20-May-2024Document1 pageFu-10, 75914199-2,, Pressre Test, 20-May-2024Mohamed El-SawahNo ratings yet

- 09Document1 page09Mohamed El-SawahNo ratings yet

- 18Document1 page18Mohamed El-SawahNo ratings yet

- 20Document1 page20Mohamed El-SawahNo ratings yet

- QAF5153 Rev.0 Pre-Mobilization Inspection Checklist - Guidelines - 1Document1 pageQAF5153 Rev.0 Pre-Mobilization Inspection Checklist - Guidelines - 1Mohamed El-SawahNo ratings yet

- CMT Squeeze 03Document1 pageCMT Squeeze 03Mohamed El-SawahNo ratings yet

- Stem-1 MPF342 - 18-FebDocument1 pageStem-1 MPF342 - 18-FebMohamed El-SawahNo ratings yet

- QAF5174 Rev 0 Crane Forklift Ops JSADocument90 pagesQAF5174 Rev 0 Crane Forklift Ops JSAMohamed El-SawahNo ratings yet

- Z BS ChecklistDocument1 pageZ BS ChecklistMohamed El-SawahNo ratings yet

- Stem-I: Sus - Centrifugal Pump Unit (Diesel Driven)Document1 pageStem-I: Sus - Centrifugal Pump Unit (Diesel Driven)Mohamed El-Sawah0% (1)

- QAF5175 Rev 0 Crane - Inspection - ChecklistDocument2 pagesQAF5175 Rev 0 Crane - Inspection - ChecklistMohamed El-SawahNo ratings yet

- Self-Assessment Exposure Checklist For Quest Exemption Jan 2020Document1 pageSelf-Assessment Exposure Checklist For Quest Exemption Jan 2020Mohamed El-SawahNo ratings yet

- QAF5180 Rev0 First Aid Kit Inventory Sheet - ARAMCO TYPEDocument1 pageQAF5180 Rev0 First Aid Kit Inventory Sheet - ARAMCO TYPEMohamed El-SawahNo ratings yet

- STEM-I: CPF Cement Pump Float: HRDH-1856 / Site-26 22-Nov-2019 Night Shift CPF-377Document1 pageSTEM-I: CPF Cement Pump Float: HRDH-1856 / Site-26 22-Nov-2019 Night Shift CPF-377Mohamed El-SawahNo ratings yet

- QAF 2001 Rev. 1 Batch Mixer PM1 ChecklistDocument1 pageQAF 2001 Rev. 1 Batch Mixer PM1 ChecklistMohamed El-SawahNo ratings yet

- Aspj 810Document2 pagesAspj 810Иван ФиличевNo ratings yet

- UNIT IV 4 DempsterShaferTheoryDocument19 pagesUNIT IV 4 DempsterShaferTheorySravani Srav100% (1)

- Control of Bacterial Exoelectrogenesis by c-AMP-GMP: A B D CDocument6 pagesControl of Bacterial Exoelectrogenesis by c-AMP-GMP: A B D CAshesh BasnetNo ratings yet

- Pass - FinalDocument36 pagesPass - FinalEleanor De Ramos0% (1)

- Chi SquareDocument2 pagesChi SquarePrasanth Kurien Mathew100% (3)

- Coil-Type Heat Exchanger PDFDocument2 pagesCoil-Type Heat Exchanger PDFRuben100% (1)

- Cloned SPM Question (Paper 1) : SolutionDocument4 pagesCloned SPM Question (Paper 1) : SolutionPtn ParthibanNo ratings yet

- Antena WindomDocument17 pagesAntena WindomJack RodriguezNo ratings yet

- Concrete Constitutive RelationshipsDocument8 pagesConcrete Constitutive Relationshipsukyo0801No ratings yet

- TTLA0561Document111 pagesTTLA0561Valourdos Lukas100% (1)

- Physics IDocument2 pagesPhysics IRex LopezNo ratings yet

- Gothic Shawl PatternDocument4 pagesGothic Shawl PatternRooNo ratings yet

- Class e Instructions Rev2aDocument29 pagesClass e Instructions Rev2aZeljko PetkovicNo ratings yet

- Experimental ResearchDocument22 pagesExperimental ResearchCuteepie Sucheta MondalNo ratings yet

- 50481C, Analog Devices 3B Backplane Power Supplies AEROJETDocument7 pages50481C, Analog Devices 3B Backplane Power Supplies AEROJETenticoNo ratings yet

- The Paper 114 PDFDocument32 pagesThe Paper 114 PDFeu mesmoNo ratings yet

- Handout Residue TheoremDocument4 pagesHandout Residue TheoremGabo del NorteNo ratings yet

- Greeting and FarewellDocument42 pagesGreeting and FarewellJose Peña100% (1)

- Artificial Skin For Sweating Guarded Hotplates and Manikins Based On Weft Knitted FabricsDocument16 pagesArtificial Skin For Sweating Guarded Hotplates and Manikins Based On Weft Knitted FabricsAndrej DjurasicNo ratings yet

- Group Assignment MBADocument14 pagesGroup Assignment MBAMr. JahirNo ratings yet

- Introduction To MicrowaveDocument15 pagesIntroduction To MicrowaveShimaa ashrafNo ratings yet

- Customer Churn Prediction Project: Group CDocument16 pagesCustomer Churn Prediction Project: Group CRohit NNo ratings yet

- Subodh Lab Pricelist Rev1Document7 pagesSubodh Lab Pricelist Rev1anubhavlNo ratings yet

- PIC Indiividual File and Group FileDocument23 pagesPIC Indiividual File and Group FileAbhishek DhavareNo ratings yet

- No Course Course Description Credit HourDocument3 pagesNo Course Course Description Credit HourfazaseikoNo ratings yet

- Eu-Type Examination Certificate: Issued by Nmi Certin B.V.Document7 pagesEu-Type Examination Certificate: Issued by Nmi Certin B.V.Kashif VohraNo ratings yet

- Chapter 5.pptx Risk and ReturnDocument25 pagesChapter 5.pptx Risk and ReturnKevin Kivanc IlgarNo ratings yet

- 1.7 Mathematical Analysis of Non Recursive AlgorithmDocument7 pages1.7 Mathematical Analysis of Non Recursive AlgorithmsaiNo ratings yet