Professional Documents

Culture Documents

A First Course On Kinetics and Reaction Engineering Example 33.2

A First Course On Kinetics and Reaction Engineering Example 33.2

Uploaded by

Yeabsira WorkagegnehuCopyright:

Available Formats

You might also like

- Chapter Two Materials ManagementDocument40 pagesChapter Two Materials ManagementYeabsira WorkagegnehuNo ratings yet

- Homework 5Document24 pagesHomework 5gabriel toro bertel50% (4)

- Me328 - Carabiner Project 1Document20 pagesMe328 - Carabiner Project 1api-534925017No ratings yet

- Emergency Depressurization of Hydro Cracker ReactorsDocument8 pagesEmergency Depressurization of Hydro Cracker ReactorsShankarMukherjeeNo ratings yet

- CRS 60 Emulsified BitumenDocument1 pageCRS 60 Emulsified BitumenEng Venance MasanjaNo ratings yet

- 1 s2.0 S138589472033597X mmc1Document24 pages1 s2.0 S138589472033597X mmc1Tarık Bercan SarıNo ratings yet

- Probs Part IVDocument16 pagesProbs Part IVDenis TchioNo ratings yet

- Modeling Mass Transport With GNU OctaveDocument5 pagesModeling Mass Transport With GNU OctaveFaitiNo ratings yet

- Problem Set 9 - 3DSEDocument4 pagesProblem Set 9 - 3DSEJesseNo ratings yet

- HW 01Document2 pagesHW 01alon.brook-rayNo ratings yet

- Ma5156 PDFDocument3 pagesMa5156 PDFJsvijay KumarNo ratings yet

- Griffiths Problems 04.07Document3 pagesGriffiths Problems 04.07Ema MaharaniNo ratings yet

- Method I - Stokes' Law: AppendicesDocument4 pagesMethod I - Stokes' Law: AppendicesMartim LemeNo ratings yet

- PDE Using R PackageDocument12 pagesPDE Using R PackageThumper KatesNo ratings yet

- Ruy RYO JUANDocument30 pagesRuy RYO JUANJean-Daniel DjidaNo ratings yet

- Kechagias Pipiras 2018 MLRD PhaseDocument24 pagesKechagias Pipiras 2018 MLRD PhaseAdis SalkicNo ratings yet

- Tan Cot 2, 2 As X X SofxDocument6 pagesTan Cot 2, 2 As X X SofxVinayNo ratings yet

- Final Examination: 1 Rules (Requires Student Signature!)Document9 pagesFinal Examination: 1 Rules (Requires Student Signature!)Hernan Kennedy Ricaldi PorrasNo ratings yet

- AlbastamiDocument10 pagesAlbastamitarif ashtarNo ratings yet

- 15196-Article Text-42038-2-10-20200830Document13 pages15196-Article Text-42038-2-10-20200830Lokmane BouzahzahNo ratings yet

- BonuspresenceexercisesDocument6 pagesBonuspresenceexercisesFarhadul HaqueNo ratings yet

- Euler KortewegDocument10 pagesEuler KortewegGianfranco GambiniNo ratings yet

- Nozzle Flow With External ForcesDocument4 pagesNozzle Flow With External ForcesEihabARaoufMustafaNo ratings yet

- Spherical Waves: 1 The Helmholtz Wave Equation in Spherical CoordinatesDocument4 pagesSpherical Waves: 1 The Helmholtz Wave Equation in Spherical CoordinatesAnonymous BrUMhCjbiBNo ratings yet

- V. - A. - Marchenko - A. - Boutet - de - Monvel - H. - McKean - ( (BookFi) PDFDocument403 pagesV. - A. - Marchenko - A. - Boutet - de - Monvel - H. - McKean - ( (BookFi) PDFHerman HermanNo ratings yet

- Week 5Document14 pagesWeek 5Miriam JomonNo ratings yet

- HW 1 SolDocument3 pagesHW 1 SoljigyansuNo ratings yet

- NOTES - Prof RAND 2009 Separation of Variables and OrthogonalityDocument32 pagesNOTES - Prof RAND 2009 Separation of Variables and OrthogonalityHassen M OuakkadNo ratings yet

- Bifurcation Analysis of A Single Species Reacrion-Diffusion Model With Nonlocal DelayDocument33 pagesBifurcation Analysis of A Single Species Reacrion-Diffusion Model With Nonlocal DelaysecMC ussNo ratings yet

- Dyadic Wavelets and Refinable Functions On A Half-LineDocument30 pagesDyadic Wavelets and Refinable Functions On A Half-LineukoszapavlinjeNo ratings yet

- Exam 1Document2 pagesExam 1lookyoursoulNo ratings yet

- Dielectric Slab Waveguide: 1 Total Internal ReflectionDocument3 pagesDielectric Slab Waveguide: 1 Total Internal Reflectionjas dwanNo ratings yet

- Local Existence and Blow-Up Criterion of 3D Ideal Magnetohydrodynamics EquationsDocument8 pagesLocal Existence and Blow-Up Criterion of 3D Ideal Magnetohydrodynamics EquationsNo FaceNo ratings yet

- FirlsDocument39 pagesFirlsTseng KweiwenNo ratings yet

- 1 Solving Schroedinger's Equation For The Finite Square WellDocument5 pages1 Solving Schroedinger's Equation For The Finite Square WellskamaNo ratings yet

- JHBVGV 656Document6 pagesJHBVGV 656Luis MancillaNo ratings yet

- Example of BVP ProblemsDocument3 pagesExample of BVP ProblemsAbhishek KumarNo ratings yet

- Ps 1Document2 pagesPs 1RandomNo ratings yet

- QSP Examples1Document8 pagesQSP Examples1Utilities CoNo ratings yet

- Theoretische Physik 2: ElektrodynamikDocument8 pagesTheoretische Physik 2: ElektrodynamikJuan P HDNo ratings yet

- Exact Solutions of The Space-Time Fractional EqualDocument7 pagesExact Solutions of The Space-Time Fractional EqualAreesha NoorNo ratings yet

- Wang 1969Document7 pagesWang 1969Haytham BouzidNo ratings yet

- PH474 and 574 HW SetDocument6 pagesPH474 and 574 HW SetlolnationNo ratings yet

- MATH3331Document6 pagesMATH3331liamsk8dudeNo ratings yet

- Practice - Questions - 2, System ScienceDocument3 pagesPractice - Questions - 2, System ScienceSONUNo ratings yet

- Quantum Physics III (8.06) - Spring 2016 Assignment 6Document5 pagesQuantum Physics III (8.06) - Spring 2016 Assignment 6bahadoor22i5583No ratings yet

- On The Conformal Anomaly From Higher Derivative Gravity in Ads/Cft CorrespondenceDocument21 pagesOn The Conformal Anomaly From Higher Derivative Gravity in Ads/Cft CorrespondenceGwzthabvo JaimeNo ratings yet

- Solutions To Course Work 1: in GRDocument19 pagesSolutions To Course Work 1: in GRRoy VeseyNo ratings yet

- Natural and Step Responses For RLC Circuits: A D X DT DX DTDocument2 pagesNatural and Step Responses For RLC Circuits: A D X DT DX DTfarazhumayunNo ratings yet

- 1 SCHR Odinger's Equation: One-Dimensional, Time-Dependent VersionDocument9 pages1 SCHR Odinger's Equation: One-Dimensional, Time-Dependent VersionArpita AwasthiNo ratings yet

- Reger-Gorder2013 Article Lane-EmdenEquationsOfSecondKinDocument14 pagesReger-Gorder2013 Article Lane-EmdenEquationsOfSecondKinveeramNo ratings yet

- Helium-4 Nuclear Ground State and QCDDocument4 pagesHelium-4 Nuclear Ground State and QCDfaizee1985No ratings yet

- Attractor BoundaryDocument13 pagesAttractor BoundaryNicolas DemidovNo ratings yet

- The SCHR Odinger Equation On A Compact Manifold: Strichartz Estimates and Applications by Nicolas Burq, Patrick G Erard and Nikolay TzvetkovDocument17 pagesThe SCHR Odinger Equation On A Compact Manifold: Strichartz Estimates and Applications by Nicolas Burq, Patrick G Erard and Nikolay Tzvetkovpipul36No ratings yet

- Linear-Phase Fir Filter Design by Least Squares: Ivan SelesnickDocument9 pagesLinear-Phase Fir Filter Design by Least Squares: Ivan SelesnickWaqas AhmadNo ratings yet

- Thermo Stat3Document4 pagesThermo Stat3Hagere EthiopiaNo ratings yet

- Examples2 PDFDocument2 pagesExamples2 PDFManuel OosNo ratings yet

- 1 Past and Current Research: Peyam Ryan TabrizianDocument5 pages1 Past and Current Research: Peyam Ryan TabrizianAbhiyan PaudelNo ratings yet

- MCP-15-10 11th (J-Batch) Code-A WADocument10 pagesMCP-15-10 11th (J-Batch) Code-A WARaju SinghNo ratings yet

- Massachusetts Institute of Technology: Solution For Problem 1Document7 pagesMassachusetts Institute of Technology: Solution For Problem 1Jeniffer OngNo ratings yet

- CL 701: Computational Methods For Chemical Engineering ODE-IVP and F (X) 0: Exercise ProblemsDocument6 pagesCL 701: Computational Methods For Chemical Engineering ODE-IVP and F (X) 0: Exercise ProblemschandrahasNo ratings yet

- Partial Differential Equations May 2018Document2 pagesPartial Differential Equations May 2018mk.kanna10hockeyNo ratings yet

- Green's Function Estimates for Lattice Schrödinger Operators and Applications. (AM-158)From EverandGreen's Function Estimates for Lattice Schrödinger Operators and Applications. (AM-158)No ratings yet

- Production and Project Management: by Ebise G. (MSC.)Document67 pagesProduction and Project Management: by Ebise G. (MSC.)Yeabsira WorkagegnehuNo ratings yet

- Welcome To OUR PresentationDocument20 pagesWelcome To OUR PresentationYeabsira WorkagegnehuNo ratings yet

- CAgrochem PesticidesDocument4 pagesCAgrochem PesticidesYeabsira WorkagegnehuNo ratings yet

- Well-Come To Our Presentation!Document19 pagesWell-Come To Our Presentation!Yeabsira WorkagegnehuNo ratings yet

- Making and Recycling Paper at HomeDocument12 pagesMaking and Recycling Paper at HomeYeabsira WorkagegnehuNo ratings yet

- FiltrationDocument22 pagesFiltrationYeabsira WorkagegnehuNo ratings yet

- Mechanical Micro Processes in A FluidDocument22 pagesMechanical Micro Processes in A FluidYeabsira Workagegnehu100% (2)

- Jimma University: Jimma Institute of Technology School of Chemical EngineeringDocument7 pagesJimma University: Jimma Institute of Technology School of Chemical EngineeringYeabsira WorkagegnehuNo ratings yet

- A Production of Biodiesel From Waste Cotton Seed Oil and Testing On Small Capacity Diesel EngineDocument8 pagesA Production of Biodiesel From Waste Cotton Seed Oil and Testing On Small Capacity Diesel EngineYeabsira WorkagegnehuNo ratings yet

- My Power PointDocument82 pagesMy Power PointYeabsira WorkagegnehuNo ratings yet

- 1120 PaperDocument17 pages1120 PaperYeabsira WorkagegnehuNo ratings yet

- Numbers and DistributionDocument1 pageNumbers and DistributionYeabsira WorkagegnehuNo ratings yet

- Angel Super Alcohol Active Dry Yeast (Molasses Base) - Fuel Ethanel - Angel Yeast CoDocument1 pageAngel Super Alcohol Active Dry Yeast (Molasses Base) - Fuel Ethanel - Angel Yeast CoAmit SinNo ratings yet

- TOEFL Reading - LIGHTNINGDocument6 pagesTOEFL Reading - LIGHTNINGHannah LinNo ratings yet

- Nonferrous Metals and Alloys: Production, General Properties, and ApplicationsDocument13 pagesNonferrous Metals and Alloys: Production, General Properties, and Applicationsvicki20julyNo ratings yet

- EKO BESTWAY PROJECT - PPSXDocument22 pagesEKO BESTWAY PROJECT - PPSXJunaid MazharNo ratings yet

- 1 CastoStar XHDDocument4 pages1 CastoStar XHDMohamed AdelNo ratings yet

- Exp3 SeparationofSpinachPigmentsbyColumnChromatographyDocument4 pagesExp3 SeparationofSpinachPigmentsbyColumnChromatographyAnanda AzhariNo ratings yet

- En Hybridur 580 Americas Datasheet PDFDocument4 pagesEn Hybridur 580 Americas Datasheet PDFMohammad Doost MohammadiNo ratings yet

- Basis of DesignDocument181 pagesBasis of Designjinesh245100% (3)

- Solsperse 40000Document2 pagesSolsperse 40000Shane ElixesNo ratings yet

- First Page PDFDocument1 pageFirst Page PDFRamesh BajrangNo ratings yet

- Details Provided On Test Certificate of Ambica SteelsDocument5 pagesDetails Provided On Test Certificate of Ambica Steelskuldeep SinghNo ratings yet

- NptelDocument2 pagesNptelscorpionarnoldNo ratings yet

- Final Research. Banana Floor WaxDocument10 pagesFinal Research. Banana Floor WaxjanezpersonalzNo ratings yet

- ASTM D511.Standard Test Methods For Calcium and Magnesium in WaterDocument9 pagesASTM D511.Standard Test Methods For Calcium and Magnesium in WaterMohamed HegazyNo ratings yet

- Chapter 2 BLMs AnswersDocument3 pagesChapter 2 BLMs AnswershelloblargNo ratings yet

- Chemistry - CalculationsDocument48 pagesChemistry - Calculationssgw67No ratings yet

- XRD BasicsDocument5 pagesXRD Basics777894292No ratings yet

- Aluminium + Iron (III) Oxide Iron + Aluminium OxideDocument5 pagesAluminium + Iron (III) Oxide Iron + Aluminium OxideTaha Abid AbbasiNo ratings yet

- Drum PHHDocument13 pagesDrum PHHNguyen HaiNo ratings yet

- Pulp Mill and Chemical Recovery Control With Advanced Analyzers - From Trees To Final ProductDocument9 pagesPulp Mill and Chemical Recovery Control With Advanced Analyzers - From Trees To Final ProductLarisse BatalhaNo ratings yet

- Determination of Elemental Sulfur Deposition Rates For Different Natural Gas CompositionsDocument5 pagesDetermination of Elemental Sulfur Deposition Rates For Different Natural Gas CompositionsFabian de Jesus Orozco MartinezNo ratings yet

- 40 MGD RITHALA MRM - REPORT-Jan20Document248 pages40 MGD RITHALA MRM - REPORT-Jan20Manish KaushikNo ratings yet

- TUTORIAL Test Rig LabDocument3 pagesTUTORIAL Test Rig LabFatih RushdiNo ratings yet

- 1st Seminar MicroscopeDocument50 pages1st Seminar MicroscopeManas DixitNo ratings yet

- MSDS Slideway Oil Iso VG 68 - 031115Document6 pagesMSDS Slideway Oil Iso VG 68 - 031115Rini SiskayantiNo ratings yet

- Air PolutionDocument18 pagesAir PolutionNur Atikah AbdullahNo ratings yet

- 2014 PTQ q1Document156 pages2014 PTQ q1Milind ShahNo ratings yet

A First Course On Kinetics and Reaction Engineering Example 33.2

A First Course On Kinetics and Reaction Engineering Example 33.2

Uploaded by

Yeabsira WorkagegnehuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A First Course On Kinetics and Reaction Engineering Example 33.2

A First Course On Kinetics and Reaction Engineering Example 33.2

Uploaded by

Yeabsira WorkagegnehuCopyright:

Available Formats

A First Course on Kinetics and Reaction Engineering

Example 33.2

Problem Purpose

This problem will help you determine whether you have mastered the learning objectives for this

unit. Specifically, it illustrates the use of the axial dispersion model and shows how it will predict results

intermediate between a CSTR and a PFR for an appropriate value of the dispersion coefficient.

Problem Statement

The reaction between A and B produces the desired product, D according to reaction (1), but B also

decomposes according to reaction (2), generating the undesired product U. When the reactions take

place in a constant density solution, the heat of reaction is so small that the reactions are effectively

isothermal. Reaction (1) is first order in each of the two reactants, second order overall. Reaction (2) is

second order in B. At the process temperature the rate coefficient for reaction (1) is 8 x 10-2 L mol-1 min-1

and that for reaction (2) is 4 x 10-2 L mol-1 min-1. When a CSTR is used, the selectivity is 6.32 mol D per

mol U at 90% conversion of B, and when a PFR is used at the same conversion, the selectivity is 3.03

mol D per mol U. Compare these selectivities to the selectivity predicted by the axial dispersion model

when the axial dispersion coefficient is equal to 4 dm2 s-1. The feed to the 35 dm long tubular reactor will

be taken from a tank that contains a solution of A and B with equal concentrations of 0.75 M and flow with

a superficial velocity of 0.1 dm s-1. (The flow rate and reactor length were chosen to give a conversion of

ca. 90% to permit an equitable comparison to the PFR and CSTR selectivities.)

A+B→D (1)

2B→U (2)

Problem Analysis

The problem statement instructs us to use the axial dispersion model to compute the selectivity. It

also states that the reactions occur isothermally. To solve the problem, axial dispersion model mole

balances will need to be written for at least two of the reagents that participate in the reactions. Those

equations can be solved to find the concentrations of D and U at the reactor outlet, allowing the

calculation of the selectivity.

Problem Solution

The following quantities are given in the problem statement: k1 = 8 x 10-2 L mol-1 min-1, k2 = 4 x 10-2

L mol-1 min-1, Dax = 4 dm2 s-1, L = 35 dm, CA,feed = 0.75 mol L-1, CB,feed = 0.75 mol L-1, us = 0.1 dm s-1. The

problem states that the density of the solution is constant, so the volumetric flow rate and the superficial

velocity are also constant.

The general form of the axial dispersion model mole balance is given in equation (1). In the present

problem, there are two reactions taking place, so the summation expands to two term. In addition, the

superficial velocity is a constant and can be taken outside of the derivative. Mole balances of the form

AFCoKaRE, Example 33.2 1

A First Course on Kinetics and Reaction Engineering

given in equation (1) can be written for each of the reagents, A, B, D and U, leading to equations (2)

through (5).

d 2 Ci d

−Dax 2 + ( usCi ) = ∑ ν i, j rj (1)

dz dz j=all

reactions

d 2C A dC

−Dax 2

+ us A = −r1 (2)

dz dz

d 2C B dC

−Dax 2

+ us B = −r1 − 2r2 (3)

dz dz

d 2C D dC

−Dax 2

+ us D = r1 (4)

dz dz

d 2CU dC

−Dax 2

+ us U = r2 (5)

dz dz

We will use the Danckwerts boundary conditions to solve the mole balances. The general form of

the Danckwerts boundary conditions are given in equations (6) and (7). Those equations can be used to

write the boundary conditions for A, B, D and U, as given in equations (8) through (15), where the

equations were also re-arranged so there is a zero on the right of the equals sign.

dCi

at z = 0; usCi ( z = 0 ) − Dax = usCi, feed (6)

dz z=0

dCi

at z = L; =0 (7)

dz z=L

dC A

usC A ( 0 ) − Dax − usC A, feed = 0 (8)

dz z=0

dC A

=0 (9)

dz z=L

dC B

usC B ( 0 ) − Dax − usC B, feed = 0 (10)

dz z=0

dC B

=0 (11)

dz z=L

dC D

usC D ( 0 ) − Dax − usC D, feed = 0 (12)

dz z=0

AFCoKaRE, Example 33.2 2

A First Course on Kinetics and Reaction Engineering

dC D

=0 (13)

dz z=L

dCU

usCU ( 0 ) − Dax − usCU , feed = 0 (14)

dz z=0

dCU

=0 (15)

dz z=L

Some of the boundary conditions are specified at z = 0 while other are specified at z = L, making

the set of ordinary differential equation (ODEs) to be solved mixed boundary value ODEs. We will solve

these equations numerically (see Supplemental Unit S6). No matter what software is used, solving

equations (2) through (5) numerically will require us to provide code that is given values for the dependent

variable and its derivatives as a function of the independent variable and that uses those values to

evaluate the ODEs and the boundary conditions.

In the present case, the four quantities appearing in the ODEs other than the derivatives,

dependent variables and independent variable are the axial dispersion coefficient, the superficial velocity

and the rates of the two reactions. The first two are constants that were given in the problem statement,

as listed above. The problem specifies the reaction orders, and the rate coefficients are given (they are

constant since the reaction occurs isothermally). Thus, the rates can be calculated using equations (16)

and (17). All of the quantities appearing in the boundary conditions are known constants whose values

are given in the problem statement.

r1 = k1C AC B (16)

r2 = k2C B2 (17)

Thus, at this point the code needed to solve the the axial dispersion model mole balances

numerically can be written and the equations can be solved. Doing so yields the concentrations of A, B, D

and U as a function of axial position within the reactor. The resulting values of the concentrations of D and

U at the reactor outlet can be used to compute the selectivity according to equation (18). Doing so, one

finds the selectivity to equal 3.4 mol D per mol U. Recall that at the same conversion the selectivity in a

PFR is 3.03 and when a CSTR is used it equals 6.32. As expected, the axial dispersion model yields a

selectivity intermediate between a PFR and a CSTR because the amount of back-mixing in the axial

dispersion model is intermediate between the zero back-mixing of the PFR and the complete back-mixing

of the CSTR.

CD ( L )

SD U = (18)

CU ( L )

AFCoKaRE, Example 33.2 3

A First Course on Kinetics and Reaction Engineering

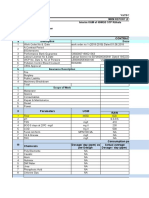

Calculation Details Using MATLAB

The axial dispersion mole balance design equation is a mixed boundary ODE. The solution of

mixed boundary ODEs is described in Supplemental Unit S6, which also provides template files for

solving them. There are two template files provided. One is used if the ODE contains the reciprocal of the

independent variable which causes a singularity at the point where that variable equals zero. Examining

equations (2) through (5), it can be seen that the reciprocal of z is not present. Therefore the code

presented here was generated by modifying the MATLAB template file SolvBVDif.m, a copy of which was

saved as Example_33_2_ad.m and modified to solve this problem. The modified file accompanies this

solution.

In order to use the template file, the second-order ODEs of equations (2) through (5) must be

reduced to a set of first order ODEs, and the boundary conditions must be re-written in terms of the new

dependent variables. This is a straightforward process and is explained in Supplemental Unit S6. We

begin by defining CA′ as in equation (19). With that definition, the second derivative of CA with respect to z

will equal the first derivative of CA′ with respect to z, as shown in equation (20). Substitution of equations

(19) and (20) into equation (2) leads to equation (21). Analogous treatment of the mole balances on B, D

and U leads to equations (22) though (27).

dC A

= C A′ (19)

dz

d 2C A dC A′

= (20)

dz 2 dz

dC A′ dC A′ r1 + usC A′

−Dax + usC A′ = −r1 ⇒ = (21)

dz dz Dax

dC B

= C B′ (22)

dz

dC B′ r1 + 2r2 + usC B′

= (23)

dz Dax

dC D

= C D′ (24)

dz

dC D′ −r1 + usC D′

= (25)

dz Dax

dCU

= CU′ (26)

dz

dCU′ −r2 + usCU′

= (27)

dz Dax

AFCoKaRE, Example 33.2 4

A First Course on Kinetics and Reaction Engineering

Thus, the four second order ODEs, equations (2) through (5), are equivalent to the eight first order

ODEs, equations (19) and (21) through (27). Similarly substituting equation (19), and its equivalents for B,

D and U, into the original boundary conditions, equations (8) through (15), leads to the corresponding

boundary conditions in terms of the new dependent variables, equations (28) and (through).

dC A

usC A ( 0 ) − Dax − usC A, feed = 0 ⇒ usC A ( 0 ) − Dax C A′ ( 0 ) − usC A, feed = 0 (28)

dz z=0

dC A

=0 ⇒ C A′ ( L ) = 0 (29)

dz z=L

usC B ( 0 ) − Dax C B′ ( 0 ) − usC B, feed = 0 (30)

C B′ ( L ) = 0 (31)

usC D ( 0 ) − Dax C D′ ( 0 ) − usC D, feed = 0 (32)

C D′ ( L ) = 0 (33)

usCU ( 0 ) − Dax CU′ ( 0 ) − usCU , feed = 0 (34)

CU′ ( L ) = 0 (35)

With the equations in this form, the modification of SolvBVDif.m can be undertaken. To begin, the

initial comment was replaced, the function definition was changed so there are no return values and the

known constants from the problem statement were entered. These modifications can be seen in Listing 1.

% Modified version of the MATLAB template file SolvBVDif.m used to model

% the tubular reactor with axial dispersion in Example 33.2 of "A First

% Course on Kinetics and Reaction Engineering."

%

function Example_33_2_ad

% Known quantities and constants (in consistent units)

k1 = 8e-2; % dm3/mol/min

k2 = 4e-2; % dm3/mol/min

CAfeed = 0.75; % mol/dm3

CBfeed = 0.75; % mol/dm3

CDfeed = 0.0; % mol/dm3

CUfeed = 0.0; % mol/dm3

us = 0.1 * 60; % dm/min

L = 350.0; % dm

Dax = 4. * 60; % dm2/min

Listing 1. Modified initial comment and function statement followed by entry of known constants.

AFCoKaRE, Example 33.2 5

A First Course on Kinetics and Reaction Engineering

The second modification occurs within an internal function named bvodes; this is where the ODEs

are evaluated. This internal function is passed values of the independent and dependent variables (as x

and y, respectively). I like to extract the dependent variables from the vector y, giving them more

meaningful names. In this case I extracted them into variables named CA, CA_prime, etc. After doing

that, the rates of the two reactions can be calculated using equations (16) and (17). If the ODEs have

been written with one derivative on the left of the equals sign and everything else on the right side of the

equals sign, as in equations (19) and (21) through (27), the right hand sides of those ODEs can then be

evaluated and returned in the column vector named dydx. All this is shown in Listing 2.

% Function that evaluates the derivatives

function dydx = bvodes(x,y)

CA = y(1);

CA_prime = y(2);

CB = y(3);

CB_prime = y(4);

CD = y(5);

CD_prime = y(6);

CU = y(7);

CU_prime = y(8);

r1 = k1*CA*CB;

r2 = k2*CB^2;

dydx = [

CA_prime

(us*CA_prime + r1)/Dax;

CB_prime

(us*CB_prime + r1 + 2*r2)/Dax;

CD_prime

(us*CD_prime - r1)/Dax;

CU_prime

(us*CU_prime - r2)/Dax;

];

end % of internal function bvodes

Listing 2. Modified version of the internal function bvodes.

The third modification occurs within an internal function named bvs; this is where the boundary

conditions are evaluated. This internal function is passed the values of the dependent variables (CA, CA′,

CB, CB′, CD, CD′, CU and CU′) at z = 0 in a vector named y_at_start and it is passed the values of the

same dependent variables at z = L in a vector named y_at_end. I extracted the dependent variables

from the two vectors, giving them more meaningful names. Notice that in equations (28) through (35) the

boundary equations have been written with a zero on the right hand side of the equations. The

modification of internal function bvs involves evaluating the left hand side of each of those equations and

returning them in the form of a column vector named res. (The variable name “res” stands for “residual,”

AFCoKaRE, Example 33.2 6

A First Course on Kinetics and Reaction Engineering

because if the boundary condition is satisfied it will equal zero, otherwise it will be the residual, non-zero

value.) The modifications to internal function bvs are shown in Listing 3.

% Function that calculates the errors at the boundaries

function res = bvs(y_at_start,y_at_end)

CA_inlet = y_at_start(1);

CA_prime_inlet = y_at_start(2);

CB_inlet = y_at_start(3);

CB_prime_inlet = y_at_start(4);

CD_inlet = y_at_start(5);

CD_prime_inlet = y_at_start(6);

CU_inlet = y_at_start(7);

CU_prime_inlet = y_at_start(8);

CA_outlet = y_at_end(1);

CA_prime_outlet = y_at_end(2);

CB_outlet = y_at_end(3);

CB_prime_outlet = y_at_end(4);

CD_outlet = y_at_end(5);

CD_prime_outlet = y_at_end(6);

CU_outlet = y_at_end(7);

CU_prime_outlet = y_at_end(8);

res = [

us*CA_inlet - Dax*CA_prime_inlet - us*CAfeed;

CA_prime_outlet;

us*CB_inlet - Dax*CB_prime_inlet - us*CBfeed;

CB_prime_outlet;

us*CD_inlet - Dax*CD_prime_inlet - us*CDfeed;

CD_prime_outlet;

us*CU_inlet - Dax*CU_prime_inlet - us*CUfeed;

CU_prime_outlet;

];

end % of internal function bvs

Listing 3. Modified version of the internal function bvs.

The fourth modification involves creating an initial mesh of points within the reactor where the

values of the dependent variables will be calculated. As can be seen in Listing 4. I chose to simply use

100 points between z = 0 and z = L. The fifth modification involves providing a guess for the value of the

dependent variables at those mesh points. You only provide a single guess for each dependent variable,

and that same guess is used at all of the mesh points. As can be seen in Listing 4, I used the feed

concentration of A as my guess for the each of the concentrations, and I used the rate of the first reaction

at the feed concentration divided by the superficial velocity as my guess for the the Ci′ dependent

variables. (Example 33.1 explains how I came up this this guess, but in the end it is simply a guess; you

can use any guess that leads to a converged solution.)

AFCoKaRE, Example 33.2 7

A First Course on Kinetics and Reaction Engineering

% Set up the initial mesh

x_range_low = 0.0;

x_range_high = L;

n_mesh_points = 100.;

% The next line creates an array for the independent variable

x = linspace(x_range_low,x_range_high,n_mesh_points);

% Guesses

yinit = [

CAfeed

k1*CAfeed*CBfeed/us

CAfeed

k1*CAfeed*CBfeed/us

CAfeed

k1*CAfeed*CBfeed/us

CAfeed

k1*CAfeed*CBfeed/us

];

Listing 4. Modification to set up the initial mesh and provide guesses.

The final modification occurs after the equations have been solved. In this case it involves using the

result to calculate the selectivity. I also calculated the conversion of B to make sure it was near 90% so

that it could be equitably compared to the PFR and CSTR selectivities given in the problem statement.

These modifications can be seen in Listing 5.

% Create a structure containing the mesh and guesses

solinit=bvpinit(x,yinit);

% Solve the odes

result = bvp4c(@bvodes,@bvs,solinit);

convB = 100*(CBfeed - result.y(3,end))/CBfeed

sel = result.y(5,end)/result.y(7,end)

end % of file Example_33_2_ad.m

Listing 5. Modification to assign values to the return variables.

After saving the modified template file, it can be executed by typing “Example_33_2_ad” at the

MATLAB command prompt. Doing so generates the output in Listing 6.

AFCoKaRE, Example 33.2 8

A First Course on Kinetics and Reaction Engineering

>> Example_33_2_ad

convB =

89.8138

sel =

3.4215

Listing 6. Output from the execution of Example_33_2_ad.m

AFCoKaRE, Example 33.2 9

You might also like

- Chapter Two Materials ManagementDocument40 pagesChapter Two Materials ManagementYeabsira WorkagegnehuNo ratings yet

- Homework 5Document24 pagesHomework 5gabriel toro bertel50% (4)

- Me328 - Carabiner Project 1Document20 pagesMe328 - Carabiner Project 1api-534925017No ratings yet

- Emergency Depressurization of Hydro Cracker ReactorsDocument8 pagesEmergency Depressurization of Hydro Cracker ReactorsShankarMukherjeeNo ratings yet

- CRS 60 Emulsified BitumenDocument1 pageCRS 60 Emulsified BitumenEng Venance MasanjaNo ratings yet

- 1 s2.0 S138589472033597X mmc1Document24 pages1 s2.0 S138589472033597X mmc1Tarık Bercan SarıNo ratings yet

- Probs Part IVDocument16 pagesProbs Part IVDenis TchioNo ratings yet

- Modeling Mass Transport With GNU OctaveDocument5 pagesModeling Mass Transport With GNU OctaveFaitiNo ratings yet

- Problem Set 9 - 3DSEDocument4 pagesProblem Set 9 - 3DSEJesseNo ratings yet

- HW 01Document2 pagesHW 01alon.brook-rayNo ratings yet

- Ma5156 PDFDocument3 pagesMa5156 PDFJsvijay KumarNo ratings yet

- Griffiths Problems 04.07Document3 pagesGriffiths Problems 04.07Ema MaharaniNo ratings yet

- Method I - Stokes' Law: AppendicesDocument4 pagesMethod I - Stokes' Law: AppendicesMartim LemeNo ratings yet

- PDE Using R PackageDocument12 pagesPDE Using R PackageThumper KatesNo ratings yet

- Ruy RYO JUANDocument30 pagesRuy RYO JUANJean-Daniel DjidaNo ratings yet

- Kechagias Pipiras 2018 MLRD PhaseDocument24 pagesKechagias Pipiras 2018 MLRD PhaseAdis SalkicNo ratings yet

- Tan Cot 2, 2 As X X SofxDocument6 pagesTan Cot 2, 2 As X X SofxVinayNo ratings yet

- Final Examination: 1 Rules (Requires Student Signature!)Document9 pagesFinal Examination: 1 Rules (Requires Student Signature!)Hernan Kennedy Ricaldi PorrasNo ratings yet

- AlbastamiDocument10 pagesAlbastamitarif ashtarNo ratings yet

- 15196-Article Text-42038-2-10-20200830Document13 pages15196-Article Text-42038-2-10-20200830Lokmane BouzahzahNo ratings yet

- BonuspresenceexercisesDocument6 pagesBonuspresenceexercisesFarhadul HaqueNo ratings yet

- Euler KortewegDocument10 pagesEuler KortewegGianfranco GambiniNo ratings yet

- Nozzle Flow With External ForcesDocument4 pagesNozzle Flow With External ForcesEihabARaoufMustafaNo ratings yet

- Spherical Waves: 1 The Helmholtz Wave Equation in Spherical CoordinatesDocument4 pagesSpherical Waves: 1 The Helmholtz Wave Equation in Spherical CoordinatesAnonymous BrUMhCjbiBNo ratings yet

- V. - A. - Marchenko - A. - Boutet - de - Monvel - H. - McKean - ( (BookFi) PDFDocument403 pagesV. - A. - Marchenko - A. - Boutet - de - Monvel - H. - McKean - ( (BookFi) PDFHerman HermanNo ratings yet

- Week 5Document14 pagesWeek 5Miriam JomonNo ratings yet

- HW 1 SolDocument3 pagesHW 1 SoljigyansuNo ratings yet

- NOTES - Prof RAND 2009 Separation of Variables and OrthogonalityDocument32 pagesNOTES - Prof RAND 2009 Separation of Variables and OrthogonalityHassen M OuakkadNo ratings yet

- Bifurcation Analysis of A Single Species Reacrion-Diffusion Model With Nonlocal DelayDocument33 pagesBifurcation Analysis of A Single Species Reacrion-Diffusion Model With Nonlocal DelaysecMC ussNo ratings yet

- Dyadic Wavelets and Refinable Functions On A Half-LineDocument30 pagesDyadic Wavelets and Refinable Functions On A Half-LineukoszapavlinjeNo ratings yet

- Exam 1Document2 pagesExam 1lookyoursoulNo ratings yet

- Dielectric Slab Waveguide: 1 Total Internal ReflectionDocument3 pagesDielectric Slab Waveguide: 1 Total Internal Reflectionjas dwanNo ratings yet

- Local Existence and Blow-Up Criterion of 3D Ideal Magnetohydrodynamics EquationsDocument8 pagesLocal Existence and Blow-Up Criterion of 3D Ideal Magnetohydrodynamics EquationsNo FaceNo ratings yet

- FirlsDocument39 pagesFirlsTseng KweiwenNo ratings yet

- 1 Solving Schroedinger's Equation For The Finite Square WellDocument5 pages1 Solving Schroedinger's Equation For The Finite Square WellskamaNo ratings yet

- JHBVGV 656Document6 pagesJHBVGV 656Luis MancillaNo ratings yet

- Example of BVP ProblemsDocument3 pagesExample of BVP ProblemsAbhishek KumarNo ratings yet

- Ps 1Document2 pagesPs 1RandomNo ratings yet

- QSP Examples1Document8 pagesQSP Examples1Utilities CoNo ratings yet

- Theoretische Physik 2: ElektrodynamikDocument8 pagesTheoretische Physik 2: ElektrodynamikJuan P HDNo ratings yet

- Exact Solutions of The Space-Time Fractional EqualDocument7 pagesExact Solutions of The Space-Time Fractional EqualAreesha NoorNo ratings yet

- Wang 1969Document7 pagesWang 1969Haytham BouzidNo ratings yet

- PH474 and 574 HW SetDocument6 pagesPH474 and 574 HW SetlolnationNo ratings yet

- MATH3331Document6 pagesMATH3331liamsk8dudeNo ratings yet

- Practice - Questions - 2, System ScienceDocument3 pagesPractice - Questions - 2, System ScienceSONUNo ratings yet

- Quantum Physics III (8.06) - Spring 2016 Assignment 6Document5 pagesQuantum Physics III (8.06) - Spring 2016 Assignment 6bahadoor22i5583No ratings yet

- On The Conformal Anomaly From Higher Derivative Gravity in Ads/Cft CorrespondenceDocument21 pagesOn The Conformal Anomaly From Higher Derivative Gravity in Ads/Cft CorrespondenceGwzthabvo JaimeNo ratings yet

- Solutions To Course Work 1: in GRDocument19 pagesSolutions To Course Work 1: in GRRoy VeseyNo ratings yet

- Natural and Step Responses For RLC Circuits: A D X DT DX DTDocument2 pagesNatural and Step Responses For RLC Circuits: A D X DT DX DTfarazhumayunNo ratings yet

- 1 SCHR Odinger's Equation: One-Dimensional, Time-Dependent VersionDocument9 pages1 SCHR Odinger's Equation: One-Dimensional, Time-Dependent VersionArpita AwasthiNo ratings yet

- Reger-Gorder2013 Article Lane-EmdenEquationsOfSecondKinDocument14 pagesReger-Gorder2013 Article Lane-EmdenEquationsOfSecondKinveeramNo ratings yet

- Helium-4 Nuclear Ground State and QCDDocument4 pagesHelium-4 Nuclear Ground State and QCDfaizee1985No ratings yet

- Attractor BoundaryDocument13 pagesAttractor BoundaryNicolas DemidovNo ratings yet

- The SCHR Odinger Equation On A Compact Manifold: Strichartz Estimates and Applications by Nicolas Burq, Patrick G Erard and Nikolay TzvetkovDocument17 pagesThe SCHR Odinger Equation On A Compact Manifold: Strichartz Estimates and Applications by Nicolas Burq, Patrick G Erard and Nikolay Tzvetkovpipul36No ratings yet

- Linear-Phase Fir Filter Design by Least Squares: Ivan SelesnickDocument9 pagesLinear-Phase Fir Filter Design by Least Squares: Ivan SelesnickWaqas AhmadNo ratings yet

- Thermo Stat3Document4 pagesThermo Stat3Hagere EthiopiaNo ratings yet

- Examples2 PDFDocument2 pagesExamples2 PDFManuel OosNo ratings yet

- 1 Past and Current Research: Peyam Ryan TabrizianDocument5 pages1 Past and Current Research: Peyam Ryan TabrizianAbhiyan PaudelNo ratings yet

- MCP-15-10 11th (J-Batch) Code-A WADocument10 pagesMCP-15-10 11th (J-Batch) Code-A WARaju SinghNo ratings yet

- Massachusetts Institute of Technology: Solution For Problem 1Document7 pagesMassachusetts Institute of Technology: Solution For Problem 1Jeniffer OngNo ratings yet

- CL 701: Computational Methods For Chemical Engineering ODE-IVP and F (X) 0: Exercise ProblemsDocument6 pagesCL 701: Computational Methods For Chemical Engineering ODE-IVP and F (X) 0: Exercise ProblemschandrahasNo ratings yet

- Partial Differential Equations May 2018Document2 pagesPartial Differential Equations May 2018mk.kanna10hockeyNo ratings yet

- Green's Function Estimates for Lattice Schrödinger Operators and Applications. (AM-158)From EverandGreen's Function Estimates for Lattice Schrödinger Operators and Applications. (AM-158)No ratings yet

- Production and Project Management: by Ebise G. (MSC.)Document67 pagesProduction and Project Management: by Ebise G. (MSC.)Yeabsira WorkagegnehuNo ratings yet

- Welcome To OUR PresentationDocument20 pagesWelcome To OUR PresentationYeabsira WorkagegnehuNo ratings yet

- CAgrochem PesticidesDocument4 pagesCAgrochem PesticidesYeabsira WorkagegnehuNo ratings yet

- Well-Come To Our Presentation!Document19 pagesWell-Come To Our Presentation!Yeabsira WorkagegnehuNo ratings yet

- Making and Recycling Paper at HomeDocument12 pagesMaking and Recycling Paper at HomeYeabsira WorkagegnehuNo ratings yet

- FiltrationDocument22 pagesFiltrationYeabsira WorkagegnehuNo ratings yet

- Mechanical Micro Processes in A FluidDocument22 pagesMechanical Micro Processes in A FluidYeabsira Workagegnehu100% (2)

- Jimma University: Jimma Institute of Technology School of Chemical EngineeringDocument7 pagesJimma University: Jimma Institute of Technology School of Chemical EngineeringYeabsira WorkagegnehuNo ratings yet

- A Production of Biodiesel From Waste Cotton Seed Oil and Testing On Small Capacity Diesel EngineDocument8 pagesA Production of Biodiesel From Waste Cotton Seed Oil and Testing On Small Capacity Diesel EngineYeabsira WorkagegnehuNo ratings yet

- My Power PointDocument82 pagesMy Power PointYeabsira WorkagegnehuNo ratings yet

- 1120 PaperDocument17 pages1120 PaperYeabsira WorkagegnehuNo ratings yet

- Numbers and DistributionDocument1 pageNumbers and DistributionYeabsira WorkagegnehuNo ratings yet

- Angel Super Alcohol Active Dry Yeast (Molasses Base) - Fuel Ethanel - Angel Yeast CoDocument1 pageAngel Super Alcohol Active Dry Yeast (Molasses Base) - Fuel Ethanel - Angel Yeast CoAmit SinNo ratings yet

- TOEFL Reading - LIGHTNINGDocument6 pagesTOEFL Reading - LIGHTNINGHannah LinNo ratings yet

- Nonferrous Metals and Alloys: Production, General Properties, and ApplicationsDocument13 pagesNonferrous Metals and Alloys: Production, General Properties, and Applicationsvicki20julyNo ratings yet

- EKO BESTWAY PROJECT - PPSXDocument22 pagesEKO BESTWAY PROJECT - PPSXJunaid MazharNo ratings yet

- 1 CastoStar XHDDocument4 pages1 CastoStar XHDMohamed AdelNo ratings yet

- Exp3 SeparationofSpinachPigmentsbyColumnChromatographyDocument4 pagesExp3 SeparationofSpinachPigmentsbyColumnChromatographyAnanda AzhariNo ratings yet

- En Hybridur 580 Americas Datasheet PDFDocument4 pagesEn Hybridur 580 Americas Datasheet PDFMohammad Doost MohammadiNo ratings yet

- Basis of DesignDocument181 pagesBasis of Designjinesh245100% (3)

- Solsperse 40000Document2 pagesSolsperse 40000Shane ElixesNo ratings yet

- First Page PDFDocument1 pageFirst Page PDFRamesh BajrangNo ratings yet

- Details Provided On Test Certificate of Ambica SteelsDocument5 pagesDetails Provided On Test Certificate of Ambica Steelskuldeep SinghNo ratings yet

- NptelDocument2 pagesNptelscorpionarnoldNo ratings yet

- Final Research. Banana Floor WaxDocument10 pagesFinal Research. Banana Floor WaxjanezpersonalzNo ratings yet

- ASTM D511.Standard Test Methods For Calcium and Magnesium in WaterDocument9 pagesASTM D511.Standard Test Methods For Calcium and Magnesium in WaterMohamed HegazyNo ratings yet

- Chapter 2 BLMs AnswersDocument3 pagesChapter 2 BLMs AnswershelloblargNo ratings yet

- Chemistry - CalculationsDocument48 pagesChemistry - Calculationssgw67No ratings yet

- XRD BasicsDocument5 pagesXRD Basics777894292No ratings yet

- Aluminium + Iron (III) Oxide Iron + Aluminium OxideDocument5 pagesAluminium + Iron (III) Oxide Iron + Aluminium OxideTaha Abid AbbasiNo ratings yet

- Drum PHHDocument13 pagesDrum PHHNguyen HaiNo ratings yet

- Pulp Mill and Chemical Recovery Control With Advanced Analyzers - From Trees To Final ProductDocument9 pagesPulp Mill and Chemical Recovery Control With Advanced Analyzers - From Trees To Final ProductLarisse BatalhaNo ratings yet

- Determination of Elemental Sulfur Deposition Rates For Different Natural Gas CompositionsDocument5 pagesDetermination of Elemental Sulfur Deposition Rates For Different Natural Gas CompositionsFabian de Jesus Orozco MartinezNo ratings yet

- 40 MGD RITHALA MRM - REPORT-Jan20Document248 pages40 MGD RITHALA MRM - REPORT-Jan20Manish KaushikNo ratings yet

- TUTORIAL Test Rig LabDocument3 pagesTUTORIAL Test Rig LabFatih RushdiNo ratings yet

- 1st Seminar MicroscopeDocument50 pages1st Seminar MicroscopeManas DixitNo ratings yet

- MSDS Slideway Oil Iso VG 68 - 031115Document6 pagesMSDS Slideway Oil Iso VG 68 - 031115Rini SiskayantiNo ratings yet

- Air PolutionDocument18 pagesAir PolutionNur Atikah AbdullahNo ratings yet

- 2014 PTQ q1Document156 pages2014 PTQ q1Milind ShahNo ratings yet