Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

181 viewsJIS Z 3212-2000 Covered Electrodes For High Tensile Steel

JIS Z 3212-2000 Covered Electrodes For High Tensile Steel

Uploaded by

NGUYEN VINHJIS Z 3212-2000 Covered Electrodes for High Tensile Steel

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CSW-0021 MSDS GMAW (Mild Steel and High Tensile Strength Steel) (영문) - 2023.08.22Document7 pagesCSW-0021 MSDS GMAW (Mild Steel and High Tensile Strength Steel) (영문) - 2023.08.22NGUYEN VINHNo ratings yet

- Variable Displacement AC CompressorsDocument6 pagesVariable Displacement AC CompressorsNGUYEN VINHNo ratings yet

- ASME - IX - 2019 - Boiler - and - Pressure - Vessel (P-No. Listing)Document2 pagesASME - IX - 2019 - Boiler - and - Pressure - Vessel (P-No. Listing)NGUYEN VINHNo ratings yet

- MS-G-003 - General Method Statement For Horizontal PumpDocument19 pagesMS-G-003 - General Method Statement For Horizontal PumpNGUYEN VINHNo ratings yet

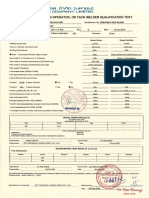

- Nguyen Van Kien (FCAW)Document1 pageNguyen Van Kien (FCAW)NGUYEN VINHNo ratings yet

- JIS G3443 1 UnlockedDocument19 pagesJIS G3443 1 UnlockedNGUYEN VINHNo ratings yet

- Stainless Steel Flux Cored Tig: Alloy Description and ApplicationDocument1 pageStainless Steel Flux Cored Tig: Alloy Description and ApplicationNGUYEN VINHNo ratings yet

- Method Statement For Static Equipment (T-4701, T-4302, D-4302, D-4304, D-4606) - 2 PDFDocument54 pagesMethod Statement For Static Equipment (T-4701, T-4302, D-4302, D-4304, D-4606) - 2 PDFNGUYEN VINHNo ratings yet

- TGX 308L 316L 309L 347Document2 pagesTGX 308L 316L 309L 347NGUYEN VINHNo ratings yet

- Ky Hieu Moi HanDocument16 pagesKy Hieu Moi HanNGUYEN VINHNo ratings yet

- NDT For QC Inspector: "Khuyeát Taät Haøn, Nguyeân Nhaân Vaø Caùch Khaéc Phuïc"Document41 pagesNDT For QC Inspector: "Khuyeát Taät Haøn, Nguyeân Nhaân Vaø Caùch Khaéc Phuïc"NGUYEN VINHNo ratings yet

JIS Z 3212-2000 Covered Electrodes For High Tensile Steel

JIS Z 3212-2000 Covered Electrodes For High Tensile Steel

Uploaded by

NGUYEN VINH0 ratings0% found this document useful (0 votes)

181 views12 pagesJIS Z 3212-2000 Covered Electrodes for High Tensile Steel

Original Title

JIS Z 3212-2000 Covered Electrodes for High Tensile Steel

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentJIS Z 3212-2000 Covered Electrodes for High Tensile Steel

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

181 views12 pagesJIS Z 3212-2000 Covered Electrodes For High Tensile Steel

JIS Z 3212-2000 Covered Electrodes For High Tensile Steel

Uploaded by

NGUYEN VINHJIS Z 3212-2000 Covered Electrodes for High Tensile Steel

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 12

JIS

JAPANESE

INDUSTRIAL

STANDARD

d and Publi hog qb

Japanese Standards Ass:

@JIS Z 3212-2

Covered electrodes for

high tensile strength steel

050928039204

o

Z 8212 : 2000

Foreword

This translation has been made based on the original Japanese Industrial

Standard revised by the Minister of International Trade and Industry

through deliberations at the Japanese Industrial Standards Committee

in accordance with the Industrial Standardization Law. Consequently

JIS Z 3212 : 1990 is replaced with JIS Z 8212 : 2000.

Attention is drawn to the possibility that some parts of this Standard

may conflict with a patent right, application for a patent after opening

to the public, utility model right or application for registration of utility

model after opening to the public which have technical properties. The

relevant Minister and the Japanese Industrial Standards Committee

are not responsible for identifying the patent right, application for a

patent after opening to the public, utility model right or application for

registration of utility model after opening to the public which have the

said technical properties.

‘This revision employs JIS Z 8200 : 1999 Welding consumables—Technical

delivery conditions for welding filler metals—Type of product, dimensions,

tolerances and marking as the normative reference.

Date of Establishment: 1961-01-01

Date of Revision: 2000-11-20

Date of Public Notice in Official Gazette: 2000-11-20

Investigated by: Japanese Industrial Standards Committee

Divisional Council on Welding

JIS Z 3212:2000, First English edition published in 2002-02

Translated and published by: Japanese Standards Association

41-24, Akasaka, Minato-ku, Tokyo, 107-8440 JAPAN

In the event of any doubts arising as to the contents,

the original JIS is to be the final authority.

© Jsa 2002

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or

utilized in any form or by any means, electronic o mechanical, including photocopying and

microfilm, without permission in writing from the publisher

Printed in Japan

JAPANESE INDUSTRIAL STANDARD @ JIS Z 3212: 2000

Covered electrodes for

high tensile strength steel

1 Scope This Japanese Industrial Standard specifies the covered electrodes (here-

after referred to as “electrodes”) to be used for welding of high tensile strength steel

of 490 N/mm? grade to 780 N/mm? grade.

2 Normative references The standards listed in Attached Fig. 1 contain provisions

which, through reference in this Standard, constitute provisions of this Standard. The

most recent editions of the standards (including amendments) shalll be applied.

8 Classification The electrodes shall be classified as given in Table 1 according

to the tensile strength of deposited metal, system of coating flux.

‘The applied welding positions and the types of current shalll be as given in Table 1.

Table 1 Classification of electrodes

Classification ‘System of coating flux Welding position | ‘Type of current,

‘5001 Timenite [_F.V, ©, and 1 |_ AC or Dey

5003 Lime titania FV, 0, and H | ACorDC(@)

5016 Low hydrogen FV, 0, end H | ACorDOCH

Dssi6

Dssié

De216

7016

i616

Ds016

5026 Iron powder low hydrogen F and H AC or DCH)

5326

5826

‘6226

‘5000 Special FV, OandH | ACorDci)

‘DB000 ‘or one of these

Remarks 1 The symbols shall be provided as the following example.

Example: D 50 16

77

‘—— System of coating flux

|

l

Level of minimum tensile strength

of deposited metal

Covered electrode

2 Symbols used for the welding positions are as follows:

F: flat, V: vertical, O: overhead, H: horizontal or hori-

zontal fillet

However, among welding positions shown in Table 1, V and

do not apply to the electrode whose diameter exceeds 5.0 mm,

as a rule,

2

Z 8212 : 2000

3. The welding position for D5026, D5326, D5826 and D6226 shall

be mainly the horizontal fillet.

4 The symbols to be used for the types of current are as follows:

AC: alternating current (+),

DC (+): direct current (electrode positive and electrode nega-

tive),

DC (+): direct current (electrode positive)

4 Quality

4.1 Covering The covering shall be in accordance with 3 of JIS Z 3200.

4.2 Mechanical properties The tensile strength, yield point or 0.2 % proof stress,

elongation, and Charpy absorpted energy of the deposited metals shall conform to

Table 2, when tested in accordance with the method of 6.2.

Table 2 Mechanical properties of deposited metals

Classifi- ‘Tensile test Impact test

cetlon ["rensile | Yield point or | Elongation | Test tom-| Charpy _ |

strength | 0.2 % proof % perature | absorpted

Nimm? | stress() sc | energy

| Nimmt J

[390 min. | 20min 0 | amin,

| s90min. | 20min 0 | 47min.

390 min, | 23 min 0 | 47min.

0min | 20min | 0 | Amin

490 min. 18 min. 5 “|

500 min. | 17min. | —20

550min, | 16min 20

620 min. i ‘15 min. 20

‘65min | 15min | —20

390 min. — 0

+440 min a 0

490 min, =

500 min, 20

390 min. ~ 0 Z

8000 | 780 min. | 665 min. | 19 min. o | s4min

Note () Yield point or 0.2 % proof stress shall be stated in

the test results report or the like.

3

7.8212 : 2000

4.3 Bending performance The bending performance of welded joint shall be free

from cracks of over 3.0 mm in length in any direction or detrimental defects on the

outer bent surface when tested in accordance with the method of 6.3,

4.4 Hydrogen content in deposited metal When tested in accordance with the

method of 6.4, the hydrogen content per 100 g of the deposited metal for electrodes

of low-hydrogen system, iron powder low-hydrogen system and D8000 shall conform

to the values in Table 3.

Table 3. Hydrogen content in deposited metal

Unit: mi/100 g

Classification | Hydrogen content

5016 15 max

D5s16 12 max

5816 10 max

e216 9 max

Droi6 9 max,

Di6i6

DB0I6

5026

5826

[ D5826 ~

6226

‘D8000 6 max

5 Dimensions and tolerances The dimensions and tolerances of electrodes shall

be in accordance with 2 of JIS Z 3200. The representative dimensions are as given

in Table 4.

4

Z 3212 : 2000

‘Table 4 Representative dimensions of electrodes

Unit: mm

Diameter engi

26 | 00 a0

32 [900 as0 400 450 |

40 400 450.550

45 ~]'a00 450 550 700

| so 00 450 50 700] |

35 00 700 900

60 100 700 900

oa 700900

70 700 900

wo | 450 560700 900

6 Tests

6.1 General

6.1.1 The test plates to be used for the tests of electrodes shall conform to Table 5.

However, for the plates used for the tensile and impact tests of the deposited metal,

$8400 of JIS G 3101, SM400A to C or SM490A to C of JIS G 3106 may be used

after buttering the groove surface and the surface of the backing metal with two or

more layers, each being 3 mm and over in thickness

Table 5 Test plates

‘Type of test Test plate

Tensile test | Rolled steels having a tensile strength of the same

Impact test _| deeree as that of the deposited metal.

Bend test | Rolled steels having a tensile strength of the same

degree as or higher than that of the deposited metal,

Hydrogen | SM400 A to C of JIS G 8106

content test

6.1.2 Electrodes and welding positions for tests The diameters of electrodes

and welding positions for tests shall be as follows.

a) The tensile test, impact test of deposited metal and the bend test of weld joint

shall be carried out on electrodes whose diameter is 4.0 mm or 5.0 mm as a rep-

resentative of all the diameters. However, when the maximum diameter is less

than 4,0 mm, the test may be performed on that maximum diameter as a rep-

resentative.

b)

5

2.3212: 2000

The welding positions shall be as shown in Table 6.

Table 6 Welding positions in various tests

Classifi: | Tensile test | Impact test | Bend test | Hydrogen

cation content test

‘D501 F F v,0 =

5003,

5016 F F y,

5316

Dssi6, |

Dezis

1016

D7616

8016

5026 F F F

5326

Dss26

6226

‘5000 F F F, Vor 0 =

‘8000 F F F, Vor 0 F

6.2 Tensile test and impact test of deposited metal The tensile test and impact

test of deposited metal shall be as follows.

For items other than a) to e), the test shall be performed in accordance with JIS

Z31it

a)

b)

°)

4)

e)

6.3

a)

‘The thickness of the test plate shall be 20 mm for the diameter of 4.0 mm or

5.0 mm, and 12 mm for the maximum diameter of 2.6 mm and 3.2 mm.

‘The tensile test piece shall be No. Al of JIS Z 3111 for the test plate of 20 mm

in thickness, No. A2 of JIS Z 3111 for the test plate of 12 mm in thickness.

The impact test piece shall be No. 4 test piece of JIS Z 3111.

The number of layers shall be four or more. The number of passes of each layer

shall be one to two passes for the first layer and two to three passes for the

second and successive layers.

The welding operation shall start after the test plates are preheated to 100°C

+ 10°C and the interpass temperature shall be kept at 100°C + 10°C.

The test piece or the test material cut for taking the test piece may be main-

tained at a temperature of 100°C + 5 °C for within 24h to expel hydrogen.

Bend test of weld joint The bend test of the weld joint shall be as follows.

‘The bend test method shall be in accordance with the roller bend test method

of JIS Z 8122. However, the bending radius shall be as given in Table 7.

6

Z 8212 : 2000

Table 7 Bending radius

Unit: mm

Classification | Bending radius

5016 3

5316

5816

e216

7016 at

7616

ps016

5026 ae

5326

5826

6226

5000 3

8000 4

Remarks: ¢ is the thickness of

a test piece.

b) The dimensions of the test piece shall be as shown in Fig. 1.

Unit: mm

40

40.0100,

Remarks: Roundness at edge of section, r< 1.5

Fig. 1 Shape and dimensions of test piece

c) ‘The groove angle of the test plate shall be 60° and the distance between roots

shall be the same as or under the outer diameter of the covering of rod.

4) The dimensions of the test material shall be as shown in Fig. 2. When the tack

welding of the groove is required, this shall be performed on the portions to be

removed at both ends of the test plate.

e)

8)

7

2.3212 : 2000

Unit: mm

|

3 tt

F| Diseara

3 Face bend tact pleoe at el

Fo eH

Root bend test piece gs

Discard Kee

i L Et

Reinforcement 3

ofvweld, max. \ 3

= min | *

250 min.

Fig. 2. Dimensions of test material and

sampling locations of test pieces

‘The positions of the test plates shall be as shown in Fig. 3. The test plates

shall either be restrained in advance or be given preset distortion so that the

angular deformation does not exceed 5 degrees.

Place the plate

Place the plate

feral horizontally

Make the axis of

‘welding vertically

Flat (F) ‘Vertical (V) Overhead (0)

Fig. 3 Positions of test plate in welding

‘The number of weld layers shall be three or more. The welding operation shall

start after the test plates are preheated to 100°C + 10 °C and the interpass

temperature shall be 100 °C to 150°C. The test plates and the test pieces shall

not be subjected to stress relieving treatment.

From the test material with which the welding operation has completed, two

bend test pieces shall be taken by machine cut or thermal cutting as shown in

Fig. 2. However, in the case of the thermal cutting, the heat-affected zone pro-

duced by cutting shall be removed.

8.

23212 : 2000

h)

‘The reinforcement of weld and backing metal shall be removed to the extent of

the surface of base metal. The bend test pieces shall be finished to a thickness

of 9.0 mm to 10.0 mm on the back side for the face bend test and the face side

for the root bend test.

6.4 Hydrogen content test of deposited metal The test method shall be in

accordance with JIS Z 3118. However, when the maximum diameter is less than

4.0 mm, the test may be performed on that maximum diameter.

7

a)

b)

8

Inspection The inspection shall be as follows.

The covering and the dimensions of electrodes shall meet the requirements of

4.1 and 5 respectively.

‘The results of tensile and impact tests of the deposited metal, bend test of the

weld joint and hydrogen content test for the electrodes shall satisfy the require-

ments of 4.2, 4.8 and 4.4 respectively. However, the hydrogen content test ap-

plies to the electrodes of low hydrogen system, iron powder low hydrogen system

and D8000. In case of failure in any one of the above tests, that retest may be

conducted only once and the result shall meet the requirements.

Packaging The packaging shall be in accordance with 5 of JIS Z 3200

Designation The products shall be designated by the class of electrodes, type

of current, diameter and length.

Example: D5016 — AC — 5.0 — 400

Sn

Class of Type of Diameter Length

electrode current

10 Marking The marking shall be in accordance with 4 of JIS Z 3200.

Attached Table 1 Normative references

JIS G 3101 Rolled steels for general structure

JIS G 3106 Rolled steels for welded structure

JIS Z 3111 Methods of tension and impact tests for deposited metal

JIS Z 3118 Method of measurement for hydrogen evolved from steel welds

JIS Z 3122 Methods of bend test for butt welded joint

JIS Z 3200 Welding consumables—Technical delivery conditions for weld-

ing filler metals—Type of product, dimensions, tolerances and

marking

Errata for JIS (English edition) are printed in Standardization Journal, published monthly

by the Japanese Standards Association, and also provided to subscribers of JIS (English

edition) in Monthly Information.

Errata will be provided upon request, please contact:

Standardization Promotion Department, Japanese Standards Association

41-24, Akasaka, Minato-ku, Tokyo, 107-8440 JAPAN,

TEL. 03-3583-8002 FAX. 03-3583-0462

100% Recyeled paper

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CSW-0021 MSDS GMAW (Mild Steel and High Tensile Strength Steel) (영문) - 2023.08.22Document7 pagesCSW-0021 MSDS GMAW (Mild Steel and High Tensile Strength Steel) (영문) - 2023.08.22NGUYEN VINHNo ratings yet

- Variable Displacement AC CompressorsDocument6 pagesVariable Displacement AC CompressorsNGUYEN VINHNo ratings yet

- ASME - IX - 2019 - Boiler - and - Pressure - Vessel (P-No. Listing)Document2 pagesASME - IX - 2019 - Boiler - and - Pressure - Vessel (P-No. Listing)NGUYEN VINHNo ratings yet

- MS-G-003 - General Method Statement For Horizontal PumpDocument19 pagesMS-G-003 - General Method Statement For Horizontal PumpNGUYEN VINHNo ratings yet

- Nguyen Van Kien (FCAW)Document1 pageNguyen Van Kien (FCAW)NGUYEN VINHNo ratings yet

- JIS G3443 1 UnlockedDocument19 pagesJIS G3443 1 UnlockedNGUYEN VINHNo ratings yet

- Stainless Steel Flux Cored Tig: Alloy Description and ApplicationDocument1 pageStainless Steel Flux Cored Tig: Alloy Description and ApplicationNGUYEN VINHNo ratings yet

- Method Statement For Static Equipment (T-4701, T-4302, D-4302, D-4304, D-4606) - 2 PDFDocument54 pagesMethod Statement For Static Equipment (T-4701, T-4302, D-4302, D-4304, D-4606) - 2 PDFNGUYEN VINHNo ratings yet

- TGX 308L 316L 309L 347Document2 pagesTGX 308L 316L 309L 347NGUYEN VINHNo ratings yet

- Ky Hieu Moi HanDocument16 pagesKy Hieu Moi HanNGUYEN VINHNo ratings yet

- NDT For QC Inspector: "Khuyeát Taät Haøn, Nguyeân Nhaân Vaø Caùch Khaéc Phuïc"Document41 pagesNDT For QC Inspector: "Khuyeát Taät Haøn, Nguyeân Nhaân Vaø Caùch Khaéc Phuïc"NGUYEN VINHNo ratings yet