Professional Documents

Culture Documents

This Is Trial Version: Cover Sheet

This Is Trial Version: Cover Sheet

Uploaded by

Amaresh NayakOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

This Is Trial Version: Cover Sheet

This Is Trial Version: Cover Sheet

Uploaded by

Amaresh NayakCopyright:

Available Formats

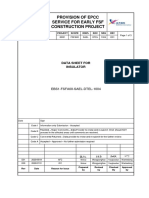

COVER SHEET

MBE DOCUMENT

1 A358 VD00 3 0002

NO.

MBE SO NO. A358

11 KV HT SWITCHGEAR (DESIGN INSTRUCTION

TITLE

SHEET, GA,SLD & MATERIAL LIST)

ASH HANDLING SYSTEM FOR 1980 MW (3x660) SUPERCRITICAL

PROJECT

THERMAL POWER PLANT AT BANAWALA, DIST MANSA, PUNJAB

CLIENT TALWANDI SABO POWER LIMITED (TSPL)

CONSULTANT DEVELOPMENT CONSULTANTS PVT. LTD.

TOTAL NO OF PREPARED BY APPROVED BY

SHEETS REV. NO. DATE

(EXCLUDING NAME SIGN NAME SIGN

COVER SHEET)

17 0 19.08.2011 S.K.SARBADHIKARI

17 1 14.10.2011 S.K.SARBADHIKARI

Mcnally Bharat THIS DOCUMENT IS MBE’S PROPERTY AND

Engineering Company Limited MUST NOT BE USED EXCEPT IN

CONNECTION WITH MBE’S WORK. USE OR

Ecospace Campus -2B 11F/12 (Old

PROJECT DIVISION DISCLOSURE OF THE CONTENTS OF THIS

Plot No. AA II/Blk 3), New Town DOCUMENT TO THIRD PARTY/IES

Rajarhat North 24 parganas.Kolkata - WITHOUT EXPRESS/WRITTEN PERMISSION

700 156, India. OF MBE IS STRICTLY PROHIBITED.

This is trial version

www.adultpdf.com

This is trial version

www.adultpdf.com

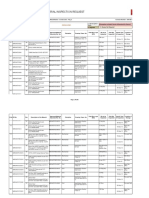

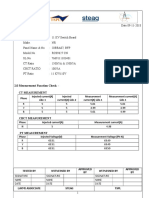

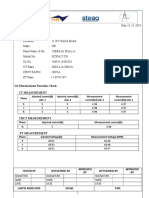

DESIGN INSTRUCTION SHEET (DIS)

Customer : MACNALLY BHARAT ENGG. COMPANY LTD

S.O. No : 7306043255

P.O. No : 1-14672 P.O.Date : 21/07/2011

Document No : MVISLO39SC43854-DIS Rev.No. : 1

Date : REVISED AS PER MBE'S

18.08.11 Rev.Description : COMMENTS DATED

14.09.2011

Comment

Product HWX

1.00.00 SYSTEM PARAMETERS

1.01.00 Ambient temperature

1.01.01 Reference ambient temperature for design 50 degree C

1.02.00 Main System 3-PHASE, 3 WIRE AC, 50 HZ, +/- 5% HZ

1.02.01 Rated operational voltage 11KV

1.02.02 Rated insulation voltage 12KV

1.02.03 Dry Frequence withstand voltage 35KV

1.02.04 Rated Impulse voltage 75KVP

1.02.05 Earthing system Low Resistance Earthed

1.02.06 Altitude Upto 1000 metre

1.02.07 If Altitude is above 1000M, Specify the Altitude

1.02.08 System fault level 50KA

1.02.09 Fault duration 1 Sec.

2.00.00 Construction

2.01.01 Type of Switchboard

SWITCHBOARD

2.02.01 Installation New Swbd.

2.02.02 Location Indoor

2.02.03 Mounting Floor mounted free standing

2.02.04 Lifting arrangenment 4 Nos. Lifting Strip are provided

2.02.05 Scope of additional base channel for embedment in Yes

2.02.06 Front access Hinged door

2.02.07 Rear access Bolted cover

2.02.08 Future extension Both sides

2.02.09 Alignment with existing board N/A

2.02.10 Recommended Front-side clearence: 1500 mm

2.02.11 Recommended Rear-side clearence: 1000mm

2.02.12 Recommended Top clearence: 1000mm

2.02.13 Busduct required for panel type N/A

2.02.14 Flange details of busduct availabe N/A

2.03.01 Degree of protection for enclosure IP4X

2.04.00 Painting

Procedure Pre-treatment & painting as per AREVA

2.04.01 standard.

2.04.02 Material Powder coating with texture finish

2 04 03

2.04.03 Shade

Sh d : PPanell E

Enclosure

l RAL 7032

2.04.04 Shade : TRUCK RAL-7032

2.05.00 Name Plate

2.05.01 Panel & Breaker rating plate Anodized Aluminium

2.05.02 Colour of lettering White letter on Black back ground

2.05.03 Size of lettering / Name Plate Variable as per visibility

2.05.04 Location Panel-- Breaker Chamber Door & Breaker --

side plate of Breaker

2.05.05 Identification of Electrical equipment mounted in the Self-adhesive stickers

2.05.06 Colour of lettering White letter on Black back ground

2.05.07 Location Back side & inside of Inst. Chamber Door

2.05.08 Feeder Name Plate Acrylic

2.05.09 Colour of lettering White letter on Black back ground

2.05.10 Location On front & rear

2.05.11 DANGER plate Aluminium

2.05.12 Colour of lettering Red letter on yellow back ground

2.05.13 Location On rear top & bottom withdrawable cover

2.06.01 Sheet Steel Thickness of various parts For both load bearing & non-load bearing

members - 2 mm

2.06.02 LT Chamber Sheet Steel thickness LV Door -2.5 mm ,Wiring trough cover-

This is trial version

www.adultpdf.com

2.08.01 Close Door Operation YES

2.09.01 Padlocking of LT Door NO

3.00.00 Busbars / Connection

3.01.00 Main Busbar

3.01.01 Rated short time withstand current 50KA

3.01.02 Duration of short time rating 1 Sec.

3.01.03 Temperature Limit As per IS/IEC-694 105 Deg. C for Tin

,115 Deg. C for Silver Plated Joints

3.01.04 Rated current 1250A

3.01.05 Material Copper

3.01.06 Cross-section for each phase 1X60X16 Sq.mm.

3.01.07 Plating (Joint Surface only) Tin

3.01.08 Insulation (except at joints and tap - offs) Heat Shrinkable Sleeves

3.01.09 Insulation at tap - offs HT tape & Monoplast compound

3.01.10 Insulation at B/B joints only HT tape & monoplast compound

3 01 11

3.01.11 Colour

C l coding

di Colour

C l coding

di at suitable

i bl llocation

i

3.02.00 Earth Busbar

3.02.01 Rating short time withstand current 50KA

3.02.02 Rated short circuit duration 1 Sec

3.02.03 Material/size 1x50x6 sq mm CU

3.02.04 Plating (Joint Surface only) TIN

3.02.05 Extension of earth bus bar outside the switchboard To be provided on both sides with Fish

Plate of CU

3.03.00 Connection (from CB/VC to CT/Power Cable terminal

3.03.01 Material Copper

3.03.02 Plating (Joint Surface only) Tin

3.03.03 Insulation (except at joints and tap - offs) Heat Shrinkable Sleeves

3.03.04 Size Depends on CT primary current

4.00.00 Wiring

4.01.01 Wire type NON-FRLS

4.01.02 Insulation grade 1100V

4.02.00

4 02 00 CT Ckt.

Ckt

4.02.01 Source for above CTs

4.02.02 Arrangement for distribution Flexible control wire of 2.5 sq.mm

4.02.03 Wire designation "D" Ferrule--- Measurement, "C" Ferrule---

Protection, "A" Ferrule--- Differential

Protection

4.02.04 Colour of wire & band Phase -Red, Yellow & Blue with blue Band

4.03.00 PT Ckt.

4.03.01 Voltage 110V AC

4.03.02 Source for above Line PT / Bus PT as per scheme

4.03.03 Arrangement for distribution Flexible control wire of 1.5 sq.mm

4.03.04

4.03.05 Wire designation "E" Ferrule

4.03.06 Colour of wire & band Phase -Red, Yellow & Blue with blue Band

This is trial version

www.adultpdf.com

4.04.00 A.C. Single phase

4.04.01 Voltage 230V AC

4.04.02 Source for above From external

4.04.03 Arrangement for distribution Flexible control wire of 2.5 sq.mm name as

Buswire

4.04.04 Wire designation "H" Ferrule

4.04.05 Colour of wire & band Black with blue band

4.05.00 D.C. Supply

4.05.01 Voltage 220V DC

4.05.02 Source for above From external

4.05.03 Arrangement for distribution Flexible control wire of 2.5 sq.mm name as

Buswire

4.05.04 Wire designation "J" Ferrule

4.05.05 Colour of wire & band Grey with blue band

4.06.00 CB Closing / Tripping

4.06.01 Voltage 220V DC

4 06 02

4.06.02 Source for above From external

4.06.03 Arrangement for distribution Flexible control wire of 2.5 sq.mm

4.06.04 Wire designation "K" Ferrule

4.06.05 Colour of wire & band Grey with blue band

4.07.00 Indication / Annunciation

4.07.01 Voltage 220V DC

4.07.02 Source for above From external

4.07.03 Arrangement for distribution Flexible control wire of 2.5 sq.mm

4.07.04 Wire designation "L" Ferrule

4.07.05 Colour of wire & band Grey with blue band

5.01.00 Termination arrangements cables

5.01.01 Power cable entry from Bottom

5.01.02 Control cable entry from Bottom

5.01.03 Glands / Lugs Scope of MBE

5.01.04 Drilling of gland plate Customer's Scope

5.01.05 Cable end termination kits Scope of MBE

5.02.00 Power Terminal

5.02.01 Type Fixed (except CB & Drawout type PT)

5.02.02 Hole size of HT cable termination Suitable for 1-M20 screw.

5.03.00 Control cable terminals

5.03.01 Type of terminal for CB Feeders Pin type( Plug & socket arrangement) for

CB

5.03.02 Type of Fixed terminals Screw type (Connectwell/Elmex) CST6 or

equivalent) with PIN lugs , 800V, 41A

5.03.03 Material type Melamine

5.03.04 Terminal size suitable for 2x2.5 sq.mm flexible wire.

5.03.05 Type of terminals for CT /PT Disconnecting screw type

(Connectwell/Elmex) CLTDM4 or

equivalent),800V, 45 A

5.04.00 Earthing terminals

5.04.01 Earthing connection of HT Chamber Door Through braided copper

5.04.02 Earthing connection of LT Chamber Door Through braided copper

5.04.03 Arrangement for connection to external earthing grid. One hole with bolt/nut/washer on earth

busbar at each end of the board are

provided

5.04.04 Earthing connection of non-current carrying metal parts of Through mounting screw

equipment

5.04.05 Star Point Earthing of CTs ,PTs & Electrical equipment Wire looping to earthing stud

with metallic case.

5 04 06

5.04.06 Colour

C l off earthing

thi wire

i Green

G

6.00.00 IS/ IEC References

6.01.01 Panel IEC 62271-200

6.01.02 Circuit Breaker IS 13118 / IEC 62271-100

6.01.03 Current Transformers IS 2705 / IEC 66044-1

6.01.04 Potential Transformers IS 3156 / IEC 66044-2

Additional point

1. For MAKE of equipments refer legend sheet.

2. 20% Spare terminals shall be provided subject to

maximum 200Nos.

3. STC OF CT WILL BE 50KA/1SEC

4. CLOSED DOOR OPERATION IS APPLICABLE ONLY IN

TEST & SERVICE POSITION.

This is trial version

www.adultpdf.com

This is trial version

www.adultpdf.com

This is trial version

www.adultpdf.com

This is trial version

www.adultpdf.com

This is trial version

www.adultpdf.com

This is trial version

www.adultpdf.com

This is trial version

www.adultpdf.com

This is trial version

www.adultpdf.com

This is trial version

www.adultpdf.com

This is trial version

www.adultpdf.com

This is trial version

www.adultpdf.com

This is trial version

www.adultpdf.com

This is trial version

www.adultpdf.com

This is trial version

www.adultpdf.com

You might also like

- Amfori Bsci System Manual Guides English 2023 2Document78 pagesAmfori Bsci System Manual Guides English 2023 2vnarula1528No ratings yet

- Icf Vendor List 2022Document30 pagesIcf Vendor List 2022Tarique AshrafNo ratings yet

- AMBPL Busduct SpecsDocument5 pagesAMBPL Busduct SpecsPrasadNo ratings yet

- Over All Drawings of PMCC-4 Panel-R0Document27 pagesOver All Drawings of PMCC-4 Panel-R0GreenOlive ControlsNo ratings yet

- Over All Drawings of PMCC-5 Panel-R0Document24 pagesOver All Drawings of PMCC-5 Panel-R0GreenOlive ControlsNo ratings yet

- Datasheet For Distribution BoardsDocument4 pagesDatasheet For Distribution BoardsEvren GürbüzNo ratings yet

- D-CAB-132-PEST7-1200 (Rev.0-2016)Document11 pagesD-CAB-132-PEST7-1200 (Rev.0-2016)Anonymous kjvaeVJNNo ratings yet

- Data Sheet FOR High Mast Lighting System: Indian Oil Corporation LimitedDocument8 pagesData Sheet FOR High Mast Lighting System: Indian Oil Corporation Limitedbiswajit biswasNo ratings yet

- Field Inspection Report: Location: JV GAS in Amenas. Costumer: KBRDocument11 pagesField Inspection Report: Location: JV GAS in Amenas. Costumer: KBRhicham boutoucheNo ratings yet

- As BuiltDocument12 pagesAs BuiltAnurag PandeyNo ratings yet

- 2313-4040-001 Rev NaDocument16 pages2313-4040-001 Rev NaSUBAS CHANDRA BEHERANo ratings yet

- UBL DEB-E-6-M2-DS-MS3-001-G DataSheet Mechanical Steam Separator Rev.A IFRDocument5 pagesUBL DEB-E-6-M2-DS-MS3-001-G DataSheet Mechanical Steam Separator Rev.A IFRAndi Candra IrawanNo ratings yet

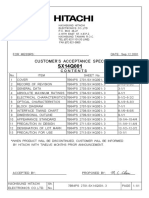

- Customer'S Acceptance SpecificationsDocument29 pagesCustomer'S Acceptance SpecificationsSalah ElaydiNo ratings yet

- Corrigendum and Revised Price BidDocument58 pagesCorrigendum and Revised Price BidPiyush MahanaNo ratings yet

- PT Amman Mineral Nusa Tenggara Batu Hijau Project SpecificationDocument6 pagesPT Amman Mineral Nusa Tenggara Batu Hijau Project Specificationelia nugraha adiNo ratings yet

- D-AAA-SWG-MV-SWST-WD (Rev.0-2015)Document14 pagesD-AAA-SWG-MV-SWST-WD (Rev.0-2015)Muhammad hussainNo ratings yet

- SR 02072023 Energize New Cable & RMUDocument3 pagesSR 02072023 Energize New Cable & RMUSofea Amani Muhammad HaswandiNo ratings yet

- Eeam Q 012Document15 pagesEeam Q 012史海云No ratings yet

- Specification For 11/0.433 KV Distribution Transformers, Dry Type (Cast Resin), Ground Mounted For Indoor ApplicationsDocument10 pagesSpecification For 11/0.433 KV Distribution Transformers, Dry Type (Cast Resin), Ground Mounted For Indoor ApplicationsIhab Shawkiه8No ratings yet

- 0186-LIS-CMI-033-054-0020 - Rev04 - Main Steel Structure Manufacturing Item ListDocument53 pages0186-LIS-CMI-033-054-0020 - Rev04 - Main Steel Structure Manufacturing Item ListsergioNo ratings yet

- Specification For Approval: DC FanDocument13 pagesSpecification For Approval: DC FanElias CoelhoNo ratings yet

- OPGW Earth Wire Suspension Set - (180 951-254)Document11 pagesOPGW Earth Wire Suspension Set - (180 951-254)MohammadEhtashamNo ratings yet

- BK91-1306-BSC-000-PUR-TBE-0001 - Technical Bid Evaluation Prefabricated Modular BuildingDocument14 pagesBK91-1306-BSC-000-PUR-TBE-0001 - Technical Bid Evaluation Prefabricated Modular BuildingSudeepDPoojaryNo ratings yet

- Ebs1 Fsfa00 Sael Dtel 1004 d01 Data Sheet For InsulatorDocument3 pagesEbs1 Fsfa00 Sael Dtel 1004 d01 Data Sheet For InsulatorAouse YasinNo ratings yet

- Buildings: Slamet ProjectDocument2 pagesBuildings: Slamet ProjectSlamet MujamilNo ratings yet

- 9017-M-PDS-ELENS03A-I15-013: M/S Larsen & ToubroDocument3 pages9017-M-PDS-ELENS03A-I15-013: M/S Larsen & ToubroPrasenjit GopeNo ratings yet

- EeeDocument7 pagesEeeRashid MujahidNo ratings yet

- Screenshot 2023-10-21 at 12.23.52Document9 pagesScreenshot 2023-10-21 at 12.23.52Praygod MnjokavaNo ratings yet

- MNP DS 4042Document3 pagesMNP DS 4042Dinesh RajNo ratings yet

- Plant TS PVB El Evd LPF 001 00Document18 pagesPlant TS PVB El Evd LPF 001 00rahul rNo ratings yet

- P01696-0019-4 - AsBuilt Painting ProcedureDocument2 pagesP01696-0019-4 - AsBuilt Painting ProcedureMahmoud GaberNo ratings yet

- D-AAA-CAB-ACC-LV (Rev.0-2019) BM-ALDocument8 pagesD-AAA-CAB-ACC-LV (Rev.0-2019) BM-ALWael AlmassriNo ratings yet

- 11 Annexure 2 To TS 2 DAS-EW-0013-CAB-04Document3 pages11 Annexure 2 To TS 2 DAS-EW-0013-CAB-04tafseerahmed86No ratings yet

- DCR - LGE001-CSA-CAL-103 150 KV Switchyard Structure Calculation - Lightning Arrester (LA) Rev 1Document7 pagesDCR - LGE001-CSA-CAL-103 150 KV Switchyard Structure Calculation - Lightning Arrester (LA) Rev 1Rhadityo Shakti BudimanNo ratings yet

- BTLD Presentation 2Document23 pagesBTLD Presentation 2Yos Wita SantosoNo ratings yet

- 2 Solid and Hollow Block MSDocument7 pages2 Solid and Hollow Block MSGaneshNo ratings yet

- Design Calculation BCN-14 A & B R0Document236 pagesDesign Calculation BCN-14 A & B R0kushaljp8989No ratings yet

- Method Statement FOR Installation of Electrical Earthing System SP-2Document10 pagesMethod Statement FOR Installation of Electrical Earthing System SP-2Mohammad Fazal KhanNo ratings yet

- 00114-L2-CHO-SS0-5000-J-002-RA & S-002-RA - FOUNDATION OF 33-15kV 7.5MVA POWERTRANSFORMERDocument12 pages00114-L2-CHO-SS0-5000-J-002-RA & S-002-RA - FOUNDATION OF 33-15kV 7.5MVA POWERTRANSFORMERAllan MwesigwaNo ratings yet

- D-AAA-CAB-LV-DB-4C-25upto400 - Al (Rev 0-2019)Document8 pagesD-AAA-CAB-LV-DB-4C-25upto400 - Al (Rev 0-2019)Wael AlmassriNo ratings yet

- OPGW Earth Wire Tension Set For Branching Two OPGW Earth Wires - (180 953-593)Document12 pagesOPGW Earth Wire Tension Set For Branching Two OPGW Earth Wires - (180 953-593)MohammadEhtashamNo ratings yet

- Piping Material SpecificationDocument120 pagesPiping Material SpecificationMubashir fareedNo ratings yet

- Khulna 150Mw Peaking Power Plant Project (Package 1A)Document4 pagesKhulna 150Mw Peaking Power Plant Project (Package 1A)A. K. M. FaisalNo ratings yet

- Transformer SpecificationDocument24 pagesTransformer Specificationamrit90320No ratings yet

- DIF-0015-ELC-ES-0002 Cathodic Protection - Rev0Document7 pagesDIF-0015-ELC-ES-0002 Cathodic Protection - Rev0wado11No ratings yet

- APS104-06 Paint System - Steel WorkDocument9 pagesAPS104-06 Paint System - Steel WorkJose MachadoNo ratings yet

- Data Sheet, Gad, Sizing Calculation, Terminal Arrangement, Support Details of Bus Duct For New IntakeDocument2 pagesData Sheet, Gad, Sizing Calculation, Terminal Arrangement, Support Details of Bus Duct For New IntakeBasabRajNo ratings yet

- Palu-3 Coal Fired Steam Power Plant (2 X 50 MW) : Comments Resolution SheetsDocument5 pagesPalu-3 Coal Fired Steam Power Plant (2 X 50 MW) : Comments Resolution SheetsAnto DamanikNo ratings yet

- Record No: 01 Issue No 1 Rev 0 Date of Issue: 21 Feb 2019 Page No: 01 of 01 Project D/N No. Employer Date Engineer To AttentionDocument2 pagesRecord No: 01 Issue No 1 Rev 0 Date of Issue: 21 Feb 2019 Page No: 01 of 01 Project D/N No. Employer Date Engineer To Attentionras9098No ratings yet

- MNP DS 4015Document3 pagesMNP DS 4015Dinesh RajNo ratings yet

- List of Drawings For Approval / Reference / Manufacturing PurposeDocument3 pagesList of Drawings For Approval / Reference / Manufacturing PurposeSUMIT JAINNo ratings yet

- 15Document2 pages15Bruno AbudNo ratings yet

- MOC JHA JADE MECH EQP MDS 16ST-0101 R0 DM Water Feed TankDocument4 pagesMOC JHA JADE MECH EQP MDS 16ST-0101 R0 DM Water Feed Tanksanjay wakchoureNo ratings yet

- MNP DS 4024Document4 pagesMNP DS 4024Dinesh RajNo ratings yet

- Ext Boq SheetDocument28 pagesExt Boq SheetpurchasehydNo ratings yet

- 11.tec-Saukem-Loi003-I01-006 V1 R4Document23 pages11.tec-Saukem-Loi003-I01-006 V1 R4Purushothaman SeenuNo ratings yet

- TMR-VDR-DW-NDM-0001 - RD - FC - Duct L DC. FMKZ 25 4E 6, W Fan FMZ 831, 11 KW, BC 01A 01BDocument5 pagesTMR-VDR-DW-NDM-0001 - RD - FC - Duct L DC. FMKZ 25 4E 6, W Fan FMZ 831, 11 KW, BC 01A 01BTree PniNo ratings yet

- Material Inspection Request RegisterDocument256 pagesMaterial Inspection Request RegisterMohamed ThowfeekNo ratings yet

- MQ SP e 6001 Rev 2 PDFDocument41 pagesMQ SP e 6001 Rev 2 PDFHafed BaccoucheNo ratings yet

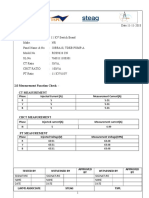

- Phase Injected Current (A) Measurement Current (A) R 5 4.99 Y 5 4.99 B 5 4.99Document3 pagesPhase Injected Current (A) Measurement Current (A) R 5 4.99 Y 5 4.99 B 5 4.99Amaresh NayakNo ratings yet

- Phase Injected Current (A) Measurement Current (A) R 5 5.01 Y 5 5.01 B 5 5.02Document3 pagesPhase Injected Current (A) Measurement Current (A) R 5 5.01 Y 5 5.01 B 5 5.02Amaresh NayakNo ratings yet

- SPR, RCS-9627CN, NoDocument5 pagesSPR, RCS-9627CN, NoAmaresh NayakNo ratings yet

- Phase Injected Current (A) Measurement Current (A) R 5 5.00 Y 5 5.00 B 5 5.01Document3 pagesPhase Injected Current (A) Measurement Current (A) R 5 5.00 Y 5 5.00 B 5 5.01Amaresh NayakNo ratings yet

- Phase Injected Current (A) Measurement Current (A) R 5 5.00 Y 5 5.00 B 5 5.01Document3 pagesPhase Injected Current (A) Measurement Current (A) R 5 5.00 Y 5 5.00 B 5 5.01Amaresh NayakNo ratings yet

- Phase Injected Current (A) Measurement Current (A) R 5 5.01 Y 5 5.02 B 5 5.04Document3 pagesPhase Injected Current (A) Measurement Current (A) R 5 5.01 Y 5 5.02 B 5 5.04Amaresh NayakNo ratings yet

- Phase Injected Current (A) Measurement Current (A) R 5 5.01 Y 5 5.02 B 5 5.04Document3 pagesPhase Injected Current (A) Measurement Current (A) R 5 5.01 Y 5 5.02 B 5 5.04Amaresh NayakNo ratings yet

- Phase Injected Current (A) Measurement Current (A) R 5 4.98 Y 5 4.98 B 5 4.98Document3 pagesPhase Injected Current (A) Measurement Current (A) R 5 4.98 Y 5 4.98 B 5 4.98Amaresh NayakNo ratings yet

- Phase Injected Current (A) Measurement Current (A) R 5 5.03 Y 5 5.04 B 5 5.01Document3 pagesPhase Injected Current (A) Measurement Current (A) R 5 5.03 Y 5 5.04 B 5 5.01Amaresh NayakNo ratings yet

- Phase Injected Current (A) Measurement Current (A) R 5 5.01 Y 5 5.02 B 5 5.01Document3 pagesPhase Injected Current (A) Measurement Current (A) R 5 5.01 Y 5 5.02 B 5 5.01Amaresh NayakNo ratings yet

- Phase Injected Current (A) Measurement Current (A) R 5 5.01 Y 5 5.01 B 5 5.01Document3 pagesPhase Injected Current (A) Measurement Current (A) R 5 5.01 Y 5 5.01 B 5 5.01Amaresh NayakNo ratings yet

- Tested by Witnessed by Approved BY Witnessed by Approved BY Signature Siginature Siginature Name Name Name Date Date Date Laxmi Associate Steag TSPLDocument4 pagesTested by Witnessed by Approved BY Witnessed by Approved BY Signature Siginature Siginature Name Name Name Date Date Date Laxmi Associate Steag TSPLAmaresh NayakNo ratings yet

- Tested by Witnessed by Approved BY Witnessed by Approved BY Signature Siginature Siginature Name Name Name Date Date Date Laxmi Associate Steag TSPLDocument5 pagesTested by Witnessed by Approved BY Witnessed by Approved BY Signature Siginature Siginature Name Name Name Date Date Date Laxmi Associate Steag TSPLAmaresh NayakNo ratings yet

- Tested by Witnessed by Approved BY Witnessed by Approved BY Signature Siginature Siginature Name Name Name Date Date Date Laxmi Associate Steag TSPLDocument5 pagesTested by Witnessed by Approved BY Witnessed by Approved BY Signature Siginature Siginature Name Name Name Date Date Date Laxmi Associate Steag TSPLAmaresh NayakNo ratings yet

- Tested by Witnessed by Approved BY Witnessed by Approved BY Signature Siginature Siginature Name Name Name Date Date Date Laxmi Associate Steag TSPLDocument5 pagesTested by Witnessed by Approved BY Witnessed by Approved BY Signature Siginature Siginature Name Name Name Date Date Date Laxmi Associate Steag TSPLAmaresh NayakNo ratings yet

- Tested by Witnessed by Approved BY Witnessed by Approved BY Signature Siginature Siginature Name Name Name Date Date Date Laxmi Associate Steag TSPLDocument5 pagesTested by Witnessed by Approved BY Witnessed by Approved BY Signature Siginature Siginature Name Name Name Date Date Date Laxmi Associate Steag TSPLAmaresh NayakNo ratings yet

- Tested by Witnessed by Approved BY Witnessed by Approved BY Signature Siginature Siginature Name Name Name Date Date Date Laxmi Associate Steag TSPLDocument5 pagesTested by Witnessed by Approved BY Witnessed by Approved BY Signature Siginature Siginature Name Name Name Date Date Date Laxmi Associate Steag TSPLAmaresh NayakNo ratings yet

- Tested by Witnessed by Approved BY Witnessed by Approved BY Signature Siginature Siginature Name Name Name Date Date Date Laxmi Associate Steag TSPLDocument5 pagesTested by Witnessed by Approved BY Witnessed by Approved BY Signature Siginature Siginature Name Name Name Date Date Date Laxmi Associate Steag TSPLAmaresh NayakNo ratings yet

- Tested by Witnessed by Approved BY Witnessed by Approved BY Signature Siginature Siginature Name Name Name Date Date Date Laxmi Associate Steag TSPLDocument5 pagesTested by Witnessed by Approved BY Witnessed by Approved BY Signature Siginature Siginature Name Name Name Date Date Date Laxmi Associate Steag TSPLAmaresh NayakNo ratings yet

- Tested by Witnessed by Approved BY Witnessed by Approved BY Signature Siginature Siginature Name Name Name Date Date Date Laxmi Associate Steag TSPLDocument5 pagesTested by Witnessed by Approved BY Witnessed by Approved BY Signature Siginature Siginature Name Name Name Date Date Date Laxmi Associate Steag TSPLAmaresh NayakNo ratings yet

- Tested by Witnessed by Approved BY Witnessed by Approved BY Signature Siginature Siginature Name Name Name Date Date Date Laxmi Associate Steag TSPLDocument2 pagesTested by Witnessed by Approved BY Witnessed by Approved BY Signature Siginature Siginature Name Name Name Date Date Date Laxmi Associate Steag TSPLAmaresh NayakNo ratings yet

- Phase Injected Current (A) Measurement Current (A) R 5 4.96 Y 5 4.97 B 5 4.96Document2 pagesPhase Injected Current (A) Measurement Current (A) R 5 4.96 Y 5 4.97 B 5 4.96Amaresh Nayak0% (1)

- Phase Injected Current (A) Measurement Current (A) R 5 5.00 Y 5 5.00 B 5 5.01Document3 pagesPhase Injected Current (A) Measurement Current (A) R 5 5.00 Y 5 5.00 B 5 5.01Amaresh NayakNo ratings yet

- JSW Protection Settings-SIEMENSDocument41 pagesJSW Protection Settings-SIEMENSAmaresh NayakNo ratings yet

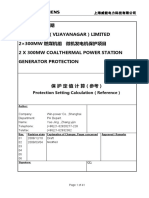

- Generator Protection Unit#3 KMPCLDocument15 pagesGenerator Protection Unit#3 KMPCLAmaresh Nayak100% (1)

- Calculating Sheet and Setting List For Protection of #01/#02 Startup/Standby TransformerDocument46 pagesCalculating Sheet and Setting List For Protection of #01/#02 Startup/Standby TransformerAmaresh NayakNo ratings yet

- Generator complete-ALSTOMDocument107 pagesGenerator complete-ALSTOMAmaresh NayakNo ratings yet

- Time Limit Cooperating Diagram For Overcurrent and Ground Protection of Auxiliary Power SystemDocument9 pagesTime Limit Cooperating Diagram For Overcurrent and Ground Protection of Auxiliary Power SystemAmaresh NayakNo ratings yet

- Calculating Sheet and Setting List For Protection of #01/#02 Startup/Standby TransformerDocument46 pagesCalculating Sheet and Setting List For Protection of #01/#02 Startup/Standby TransformerAmaresh NayakNo ratings yet

- 100 STATOR EF P345 With 20HZ INJECTION Apr 09Document6 pages100 STATOR EF P345 With 20HZ INJECTION Apr 09Amaresh NayakNo ratings yet

- Diesel Fuel Oil System Commissioing ProcedureDocument34 pagesDiesel Fuel Oil System Commissioing ProcedureAdelNo ratings yet

- Case 1 - MGN 301Document2 pagesCase 1 - MGN 301Arshdeep BhullarNo ratings yet

- Content Analysis of Nivea DeoDocument8 pagesContent Analysis of Nivea Deoindumeet singhNo ratings yet

- ANSWER SHEET ME CDFDocument3 pagesANSWER SHEET ME CDFNemo SecretNo ratings yet

- Scratch Detection and Removal From Old VideosDocument19 pagesScratch Detection and Removal From Old VideosAmit KumarNo ratings yet

- Batang Ii Es Training Development Work Financial PlanDocument5 pagesBatang Ii Es Training Development Work Financial PlanMARGIE RIVERANo ratings yet

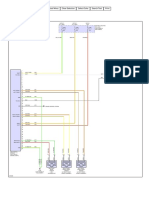

- Toggle Select Wire Mode Hide All Non Selected Wires Clear Selection Select Color Search Text PrintDocument2 pagesToggle Select Wire Mode Hide All Non Selected Wires Clear Selection Select Color Search Text PrintFelix VelasquezNo ratings yet

- BOOK 09 - MaintananceDocument15 pagesBOOK 09 - MaintananceShau WilliamNo ratings yet

- Syllabus:: Punyashlok Ahilyadevi Holkar Solapur University, SolapurDocument22 pagesSyllabus:: Punyashlok Ahilyadevi Holkar Solapur University, SolapurRohan YadavNo ratings yet

- Analysis of Algorithms and AsymptoticsDocument9 pagesAnalysis of Algorithms and AsymptoticsAijin JiangNo ratings yet

- APQP - Oct 18Document41 pagesAPQP - Oct 18Damodaran RajanayagamNo ratings yet

- Jasiora: Perkembangan Filsafat Ilmu Dalam Perspektifteknologi DigitalDocument15 pagesJasiora: Perkembangan Filsafat Ilmu Dalam Perspektifteknologi DigitalZAINUL ANWARNo ratings yet

- The Private 5G Revolution: Dr. Andreas MuellerDocument19 pagesThe Private 5G Revolution: Dr. Andreas MuellertmaillistNo ratings yet

- 2205 80x86 - FeaturesDocument23 pages2205 80x86 - Featuresnirmal23No ratings yet

- S Giáo D C Và Đào T o Thái BìnhDocument6 pagesS Giáo D C Và Đào T o Thái BìnhHoàng Minh TríNo ratings yet

- Designing Web Based Library Management System IJERTV9IS100131Document7 pagesDesigning Web Based Library Management System IJERTV9IS100131FirinsifNo ratings yet

- W206 Service ManualDocument17 pagesW206 Service ManualFermin Tafur LliuyaNo ratings yet

- 1.PR-GM 01 Procedure TemplateDocument5 pages1.PR-GM 01 Procedure TemplateFULGENCE RUHARARANo ratings yet

- App Inventor + Iot: Control RGB Led With Micro:Bit I/O Pins: Level: AdvancedDocument11 pagesApp Inventor + Iot: Control RGB Led With Micro:Bit I/O Pins: Level: AdvancedThanh Pham MinhNo ratings yet

- Lab Session 2: Introduction To The DSP56800E AssemblyDocument14 pagesLab Session 2: Introduction To The DSP56800E AssemblyBryan DavisNo ratings yet

- L02 R02D01 Fos 00 XX DWG Ar 52004Document1 pageL02 R02D01 Fos 00 XX DWG Ar 52004Osama KheadryNo ratings yet

- Superlite ShapesDocument72 pagesSuperlite Shapesdennis moreyNo ratings yet

- Buildings 12 00838 v2Document21 pagesBuildings 12 00838 v2Mia S. RetomeNo ratings yet

- Halima RPT - 2Document17 pagesHalima RPT - 2mtoto mdogoNo ratings yet

- 1546 SK LWS BOP ManualDocument41 pages1546 SK LWS BOP ManualAlexander DonatoNo ratings yet

- 2021 MBA DM & E-Commerce Unit 1Document26 pages2021 MBA DM & E-Commerce Unit 1Sushant SinghNo ratings yet

- Computer Science and Engineering (Curclm)Document25 pagesComputer Science and Engineering (Curclm)ABHISHEK CARMEL KURIANNo ratings yet

- Thermodynamic Properties of Water Tabulation From The lAPWS Formulation 1 995 - NistirDocument102 pagesThermodynamic Properties of Water Tabulation From The lAPWS Formulation 1 995 - NistirViajante_santosNo ratings yet

- Tcu11 08 08-1Document12 pagesTcu11 08 08-1moquddes akramNo ratings yet