Professional Documents

Culture Documents

Laserlite Multiwall: Product Data Sheet

Laserlite Multiwall: Product Data Sheet

Uploaded by

Omer TahaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Laserlite Multiwall: Product Data Sheet

Laserlite Multiwall: Product Data Sheet

Uploaded by

Omer TahaCopyright:

Available Formats

PT. Impack Pratama Industri, Tbk.

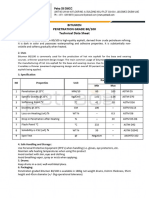

LASERLITE® MULTIWALL | Product Data Sheet

STANDARD SIZES TYPICAL PROPERTIES

Laserlite ® Multiwall is a twinwall-hollow structure polycarbonate sheet, Laserlite ® Multiwall is manufactured from best quality

making it lightweight and keeping thermal transmittance low. polycarbonate resin that providing good technical

properties. Making its applications is versatile to use in

many, like roofing, facades, canopy, gazebo, carports,

Thickness (mm) 6 8 10

partition walls, bus shelters, sport hall, green house,

Area Weight (Kg/m2) 1.3 1.5 1.7 swimming pool covers.

Width (mm) 2,100 2,100 2,100

Property Method Unit Value

Length (mm) Customized

Mechanical

U-Value (W/m2.°C) 3.7 3.3 3.17

Tensile strength at ASTM MPa 64

R-Value (m2.°C)/W) 0.270 0.303 0.316 yield D638

K-Value (W/m.°C) 0.022 0.026 0.032 Elongation at break ASTM % 90

D638

Sound Insulation (dB) 10 13 16

Flexural Strength ASTM MPa 93

D790

Clear 86% 86% 86%

Impact falling weight ASTM J 40

Grey Tint 13% 11% 9% D5420

Light

Transmission Bronze Tint 29% 25% 22% Thermal

Opal 21% 18% 16% Coefficient of thermal ISO 6946 mm/m/°C 0.065

expansion

Platinum 15% 13% 11%

Service temperature - °C -20 to

* Other sizes are available upon request, subject to minimum order quantity

120

and/or additional charge

Flammability

Horizontal burn UL94 mm <2.54

Vertical burn UL94 - V1

Class

Ignition temperature, ASTM °C 440

flash D1929

SOLAR PROPERTIES

Clear Laserlite ® Multiwall can achieve up to 86% light transmission, allowing sufficient daylight enterance when used as building material.

Tints and colors are also available to choose

Color Heat Transmission Solar Heat Gain Shading Coeficient

Clear 76% 0.789 0.907

Grey Tint 24% 0.473 0.544

Bronze Tint 30% 0.516 0.593

V24D18-MBP

Opal 29% 0.343 0.394

Platinum 16% 0.327 0.376

CHEMICAL RESISTANCE PRODUCT PERFORMANCE

Laserlite ® Multiwall like others may be affected by certain The UV cap material of Laserlite® Multiwall sheet is co-extruded on both

sides, providing excellent protection againts degradation and

subtances that may cause surface cracks. For general

discoloration caused by UV radiation in sunlight, after years of exposure

guidance, Laserlite® Multiwall can resist below chemicals: (evaluated according to ASTM D1925).The sheet shall not break due to

loss of impact strength as a result of weathering or as a result of impact

of hail measuring up to 25 mm diameter, attaining a velocity of up to 21

Resist towards Damaged by m/s. All above product performance is covered with 15 years of warranty.

Mineral acid low concentration alkali

Neutral & acidic salt solution Ammonia & amines

Oxidizing & reducing agents Aromatic or halogenated

solvents

Saturated, aliphatic Aldehydes, ketones and

hydrocarbons & alcohol esters

(except methanol)

Many oils, fats, waxes Methyl alcohol

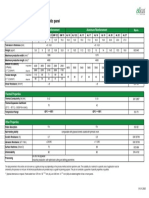

WIND LOAD

When doing sheet glazing with known wind load

and size of glazing spot, it is recommended to

set distance between shorter span:

Two Sides Clamped Arched Glazing

Four Sides Clamped Flat Glazing

Thick Sheet Center to Center Distance (mm)

Thick Wind Center to Center Distance ness Arched

ness Load (mm) Between Shorter Span (mm) -Curva Wind Load (kg/m2)

(mm) (kg/m2) According to a:b* Ratio ture

Radius 60 80 100 120 140 160 180 200

1:1 1:1.5 1:>1.5 (mm)

6 60 1,050 920 610

6 1,500 1,450 1,100 900 750 660 570 500 450

80 950 850 570

2,000 920 750 600 530 450 450 450 450

100 900 780 530

2,500 650 550 450 450 450 450 450 450

8 60 1,250 1,100 720

4,000 420 350 - - - - - -

80 1,150 1,020 655

6,000 420 350 - - - - - -

100 1,075 940 610

8 1,500 2,000 1,700 1,350 1,160 1,000 880 800 720

120 1,020 900 570

2,000 1,480 1,150 920 780 680 600 550 550

140 970 830 535

2,500 1,100 830 650 550 550 550 550 550

160 930 780 510

4,000 560 500 - - - - - -

10 60 1,500 1,150 815 6,000 540 480 - - - - - -

80 1,375 1,070 730 10 1,500 2,100 2,100 1,700 1,500 1,300 1,150 1,000 900

100 1,280 950 670 2,000 2,000 1,600 1,280 1,080 930 830 750 680

120 1,215 920 620 2,500 1,530 1,150 950 800 700 630 620 560

140 1,160 850 585 4,000 680 550 500 450 - - - -

160 1,110 800 545 6,000 640 520 500 450 - - - -

180 1,070 760 520

200 - - -

*a = represents the center to center distance of

glazing profiles on the short glazing side i.e.

width of the sheet.

*b = represents the center to center distance of

glazing profiles on the long glazing side i.e.

Length of sheet.

V24D18-MBP

Information contained herein is intended only for evaluation by technically skilled persons, with any use thereof to be at their discretion. While we believe

such information is reliable, PT. Impack Pratama Industri, Tbk. or its agents shall have no liability for result obtained or damages resulting from such use.

Nothing in this document should be contrued as a warranty or guarantee by PT. Impack Pratama Industri, Tbk. The only applicable warranty will be those

issued in writting by PT. Impack Pratama based on the product and usage environment specified.

www.impack-pratama.com

You might also like

- FR Gboard Tds21Document1 pageFR Gboard Tds21rangarajan1989100% (1)

- Unit 1 Mod 1 Redox Reactions RevisedDocument2 pagesUnit 1 Mod 1 Redox Reactions RevisedDaniel McknightNo ratings yet

- Adding A New Dimension To Impact Resistant Glazing and CladdingDocument1 pageAdding A New Dimension To Impact Resistant Glazing and CladdingOmer TahaNo ratings yet

- Tuflite Panel 18mm (5W) Data SheetDocument3 pagesTuflite Panel 18mm (5W) Data Sheetsankara narayananNo ratings yet

- Um180821 TDS Tpu 95a RB V11Document3 pagesUm180821 TDS Tpu 95a RB V11Steven DonosoNo ratings yet

- TDS BOPP Blanco LSG57 y 60 - EUDocument2 pagesTDS BOPP Blanco LSG57 y 60 - EUEmmanuel AlvarezNo ratings yet

- Ge Structured Products: The Polarflex 42U Blanking Panel Uses Lexan Fr65Document2 pagesGe Structured Products: The Polarflex 42U Blanking Panel Uses Lexan Fr65Ionut DeaconuNo ratings yet

- Tuflite Panel 8mm (4W) Data SheetDocument3 pagesTuflite Panel 8mm (4W) Data Sheetsankara narayananNo ratings yet

- LTL - MeDocument2 pagesLTL - MeQUALITY CONTROLNo ratings yet

- A2 Technical Specifications - en 4Document1 pageA2 Technical Specifications - en 4Anuja JadhavNo ratings yet

- Policarbonato Macizo Polygal Plazit PDFDocument4 pagesPolicarbonato Macizo Polygal Plazit PDFnicolas peraltaNo ratings yet

- UK NatureFlex NMDocument2 pagesUK NatureFlex NMRic MnsNo ratings yet

- UK NatureFlex NMDocument2 pagesUK NatureFlex NMjituniNo ratings yet

- Matrox TDS PDFDocument1 pageMatrox TDS PDFrajanarenderNo ratings yet

- Trelleborg Dielectric MattingDocument2 pagesTrelleborg Dielectric MattingStephenNo ratings yet

- Ultra Soft Thermal Pad: Features ApplicationDocument1 pageUltra Soft Thermal Pad: Features ApplicationMalek Ellouz (Jay)No ratings yet

- JUNE2020 Transparent Noise Barrier Technical Datasheet Final ReducedDocument2 pagesJUNE2020 Transparent Noise Barrier Technical Datasheet Final Reducedionut cerneaNo ratings yet

- Bopp Matt Film, Both Sides Heat Sealable, Treated: PropertiesDocument2 pagesBopp Matt Film, Both Sides Heat Sealable, Treated: PropertiesMatteo DMNo ratings yet

- Matrox SE TDS PDFDocument1 pageMatrox SE TDS PDFrajanarenderNo ratings yet

- Properties Alupex A2 Catalog 2017Document1 pageProperties Alupex A2 Catalog 2017singhmohinderpal53No ratings yet

- Exeet PC: Polycarbonate Normal Grade SheetDocument2 pagesExeet PC: Polycarbonate Normal Grade SheetMuhammad Arif HernomoNo ratings yet

- PBT GF30 - Vampter 3026 V0 DFDocument1 pagePBT GF30 - Vampter 3026 V0 DFarmandoNo ratings yet

- TDS-GEOPROTEC-GS3000S-22-01 Rev.01Document1 pageTDS-GEOPROTEC-GS3000S-22-01 Rev.01AMINNo ratings yet

- Coextruded Biaxially Oriented PP Film For Tobacco Wrapping: Technical DataDocument2 pagesCoextruded Biaxially Oriented PP Film For Tobacco Wrapping: Technical DataJan GawełNo ratings yet

- Ultra-Soft Thermal Conductive PadDocument2 pagesUltra-Soft Thermal Conductive PadArunkumar PBNo ratings yet

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 pagesDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNo ratings yet

- Ficha Técnica SUNLITE - X - Lite - 16 - Data - SheetDocument1 pageFicha Técnica SUNLITE - X - Lite - 16 - Data - Sheetinmaangulo060382No ratings yet

- Rowad HDSDocument1 pageRowad HDSsellami walidNo ratings yet

- Vampamid 6 0024 V0Document1 pageVampamid 6 0024 V0Plasticos CusenNo ratings yet

- Roxul Comfortboard 80: Insulated SheathingDocument1 pageRoxul Comfortboard 80: Insulated SheathingMark RauNo ratings yet

- Bitumen 80 100Document1 pageBitumen 80 100latexNo ratings yet

- Custom Made Movement Joint ProfileDocument2 pagesCustom Made Movement Joint Profileemrah turerNo ratings yet

- Hdpe p702bk DatasheetDocument1 pageHdpe p702bk Datasheetphanplastic299No ratings yet

- Denso Butyl 30 TapeDocument2 pagesDenso Butyl 30 TapeBenjamin AmezquitaNo ratings yet

- Polyshade: Laissez Entrer La NatureDocument2 pagesPolyshade: Laissez Entrer La NaturePedro Pablo Riofrio AguilarNo ratings yet

- Solvay Specialty Polymers Xydar G 930 Liquid Crystal Polymer LCP NbspUnverified DataDocument4 pagesSolvay Specialty Polymers Xydar G 930 Liquid Crystal Polymer LCP NbspUnverified DataFAUSANo ratings yet

- BLADE 3 Highbay - Industrial Lamp v3.1Document1 pageBLADE 3 Highbay - Industrial Lamp v3.1MacneoNo ratings yet

- 2013 02 DNT 063 LIDA Elgard Grid ConcreteDocument1 page2013 02 DNT 063 LIDA Elgard Grid ConcretehrrlsiteNo ratings yet

- Lexan™ Exell™ D - Sheet DatasheetDocument3 pagesLexan™ Exell™ D - Sheet DatasheetAmritraj CharlesNo ratings yet

- TDS HBMDocument1 pageTDS HBMP Singh KarkiNo ratings yet

- Technical Data Sheet - Nylon X: 3D Printing FilamentDocument1 pageTechnical Data Sheet - Nylon X: 3D Printing FilamentSteven DonosoNo ratings yet

- Technical Data Sheet - Nylon X: 3D Printing FilamentDocument1 pageTechnical Data Sheet - Nylon X: 3D Printing FilamentwidyarahmahNo ratings yet

- KXNEDocument2 pagesKXNEJan GawełNo ratings yet

- NYTRO® 11GBX-US (English) PDSDocument2 pagesNYTRO® 11GBX-US (English) PDSRHETT BUTLERNo ratings yet

- Data Teknis Hive Honeycomb KoreaDocument70 pagesData Teknis Hive Honeycomb KoreailhamhanafyNo ratings yet

- Rilsan Fine Powders Physical PropertiesDocument2 pagesRilsan Fine Powders Physical Propertiesธนาชัย เต็งจิรธนาภาNo ratings yet

- ThermaCool Gap Filler BRO 1372Document8 pagesThermaCool Gap Filler BRO 1372xingdrewNo ratings yet

- Profile 45 250 Sandwich Panel Techincal DatasheetDocument2 pagesProfile 45 250 Sandwich Panel Techincal DatasheetEle SultanaNo ratings yet

- Technical Characteristics 2020 ENDocument1 pageTechnical Characteristics 2020 ENezzularabNo ratings yet

- ELECMATDocument1 pageELECMATjosip022No ratings yet

- Nominal Engineering Properties of Ryton R-4: Data SheetDocument4 pagesNominal Engineering Properties of Ryton R-4: Data SheetRakeshNo ratings yet

- Aluminum Oxide, Al O Ceramic PropertiesDocument5 pagesAluminum Oxide, Al O Ceramic PropertiesNursyifa KamiliaNo ratings yet

- Commercial 95 340 - Product Profile - Rev. 13 Gale - May 2013Document1 pageCommercial 95 340 - Product Profile - Rev. 13 Gale - May 2013Aqil GhaffarNo ratings yet

- Datasheet SaphirAF 2016 EN v1Document2 pagesDatasheet SaphirAF 2016 EN v1André CardosoNo ratings yet

- Datasheet SD Ferralium 255 SD50 BarDocument4 pagesDatasheet SD Ferralium 255 SD50 Barpranav kariaNo ratings yet

- Verplen E2560ADocument1 pageVerplen E2560Amarcohang00No ratings yet

- Technical Data Sheet Polycarbonate: Benefits ApplicationsDocument2 pagesTechnical Data Sheet Polycarbonate: Benefits ApplicationsjackNo ratings yet

- ABS-M30: Real Production-Grade ThermoplasticDocument2 pagesABS-M30: Real Production-Grade ThermoplasticqualityfreekNo ratings yet

- Kocetal K700 Property DataDocument1 pageKocetal K700 Property DataRanjan GnanaoliNo ratings yet

- Functional Polymer Coatings: Principles, Methods, and ApplicationsFrom EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsRating: 1 out of 5 stars1/5 (1)

- Technical Information KORLOY: EndmillDocument540 pagesTechnical Information KORLOY: EndmillTony HumblotNo ratings yet

- Discussion Saponification of SoapDocument3 pagesDiscussion Saponification of Soappijechad0% (1)

- United States: Patent OfficeDocument4 pagesUnited States: Patent OfficesherlybonitaNo ratings yet

- Recognizing Types of Chemical Reactions HomeworkDocument6 pagesRecognizing Types of Chemical Reactions Homeworkafmtneeic100% (1)

- HPLC TroubleshootingDocument67 pagesHPLC TroubleshootingRaju NallaNo ratings yet

- D6304-20 Determination of Water in Petroleum by Karl Fisher Titration (Upgrade Feb 2021)Document10 pagesD6304-20 Determination of Water in Petroleum by Karl Fisher Titration (Upgrade Feb 2021)ridermateNo ratings yet

- Chemical Properties and Nutritional Factors of Pressed-Cake From TeaDocument8 pagesChemical Properties and Nutritional Factors of Pressed-Cake From TeaAndrea Fonnegra ValenciaNo ratings yet

- TDS - Total - Lubrilam Cleaner H1 - 1XQ - 201412 - enDocument1 pageTDS - Total - Lubrilam Cleaner H1 - 1XQ - 201412 - enVelibor KaranovicNo ratings yet

- Jurnal SemestaDocument7 pagesJurnal SemestaSteven Raynaldo HNo ratings yet

- Synthesis & Mathematical Modeling of PET Via Direct EsterificationDocument10 pagesSynthesis & Mathematical Modeling of PET Via Direct EsterificationMARKASGEORGENo ratings yet

- 30-05-21 SR - Super60 (In Coming) Jee-Adv 2017 P2 WTA-32 Question PaperDocument18 pages30-05-21 SR - Super60 (In Coming) Jee-Adv 2017 P2 WTA-32 Question PaperLikith Sai JonnaNo ratings yet

- 2 1 The Diagrams Show Four Different Methods of Collecting GasesDocument12 pages2 1 The Diagrams Show Four Different Methods of Collecting GasesMujeeb SiddiqueNo ratings yet

- Schubert PDFDocument66 pagesSchubert PDFdattu33No ratings yet

- Dulux Spalling DocumentDocument3 pagesDulux Spalling Documentashish100% (1)

- 39 Mar 24Document918 pages39 Mar 24hikamuddin38No ratings yet

- Safety Data Sheet: Citric Acid AnhydrousDocument5 pagesSafety Data Sheet: Citric Acid AnhydrousNinaNo ratings yet

- Cationic FinishingDocument3 pagesCationic FinishingAzmain IktedarNo ratings yet

- Chromatography: Organized By: Badahdah, M. S. & Alghazzawi, W. M. 1Document17 pagesChromatography: Organized By: Badahdah, M. S. & Alghazzawi, W. M. 1sivaNo ratings yet

- Publishedarticle38 SeleniumreviewDocument5 pagesPublishedarticle38 SeleniumreviewOlvira EsaNo ratings yet

- Usp36-Nf31 02 877Document2 pagesUsp36-Nf31 02 877rahulnarkhede01No ratings yet

- 3M 286Q Polishing Paper DatashtDocument2 pages3M 286Q Polishing Paper DatashtchainleighNo ratings yet

- Stimuli-Responsive Microgels For The Loading and Release of Functional Compounds - Fundamental Concepts and ApplicationsDocument23 pagesStimuli-Responsive Microgels For The Loading and Release of Functional Compounds - Fundamental Concepts and Applicationsalchemik1515No ratings yet

- Chem PracDocument35 pagesChem PracVilina Nayan BhayaniNo ratings yet

- Kinetics QPDocument22 pagesKinetics QPdovidNo ratings yet

- Biochem - Enzymes Report ScriptDocument5 pagesBiochem - Enzymes Report ScriptIan IglesiaNo ratings yet

- Rev.I 112014 HTK Ultra Strip 100 EnglDocument1 pageRev.I 112014 HTK Ultra Strip 100 EnglycwbycwbNo ratings yet

- Arihant CBSE ChaterWise Solved Paper Chemistry 12 2019-2020Document502 pagesArihant CBSE ChaterWise Solved Paper Chemistry 12 2019-2020poliovacjieNo ratings yet

- Alkaloids: DR N AhmedDocument23 pagesAlkaloids: DR N AhmedMohammad SamirNo ratings yet

- Sodium Pyrophosphate Decahydrate: (Diphosphoric Acid, Tetrasodium Salt, Decahydrate)Document2 pagesSodium Pyrophosphate Decahydrate: (Diphosphoric Acid, Tetrasodium Salt, Decahydrate)jycortesNo ratings yet