Professional Documents

Culture Documents

B126 06 BT EE 02ev2 Desbloqueado

B126 06 BT EE 02ev2 Desbloqueado

Uploaded by

Laura Sofía VélezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B126 06 BT EE 02ev2 Desbloqueado

B126 06 BT EE 02ev2 Desbloqueado

Uploaded by

Laura Sofía VélezCopyright:

Available Formats

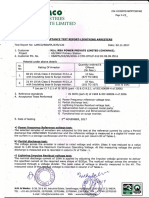

ELECTRICAL EQUIPMENT LABORATORY

ENERGY UNIT

Test report

No. B126-06-BT-EE-02Ev2 Page 1 of 19

Temperature rise test

TEST OBJECT: Gas filled metal-clad switchgear insulated in SF6 of 36

kV

DESIGNATION:

DESIGNATION: CGM3621 L and CGM3621 P

REQUESTED BY:

BY: Ormazabal y Cía., S.A.

Bº Basauntz, 2 – 48140 IGORRE (Vizcaya)

MANUFACTURER:

MANUFACTURER: Ormazabal y Cía., S.A.

STANDARD:

STANDARD: IEC 62271-200:2003

RECEIVING DATE:

DATE: November 15th 2006

TESTS DATE:

DATE: November 15th-21st 2006

The tests objects have been subjected to the tests required by theclient,

applying the procedures specified in the standard indicated before.

Result: The obtained results are shown in this report.

THIS DOCUMENT CONSISTS OF:

OF:

No. of pages: 19 (and Annex of 6 pages)

Drawings: Annex

Photographs: Annex

Estibaliz Montes Luis Martínez

Test Chief Head of Electrical Equipment Laboratory

Barakaldo, June 10th 2013

* The present report refers only and exclusively to the sample tested and at the moment and conditions in which the measures were made.

* The partial reproduction of the present document is categorically forbidden without the permission in writing of de LABEIN.

Printed by i:0#.w|velatia\ims 28/10/2016

INDEX

NDEX

1. TEST OBJECT DESIGNATION .................................................................... 3

2. TESTS PERFORMED. STANDARD .............................................................. 5

3. TEST DESCRIPTION ................................................................................. 6

4. RESULTS............................................................................................... 10

ANNEX DRAWINGS

PHOTOGRAPHS

Report No. B126-

B126-06-

06-BT-

BT-EE-

EE-02Ev2

02Ev2 Page 2 of 19

Printed by i:0#.w|velatia\ims 28/10/2016

1. TEST OBJECT DESIGNATION

DESIGNATION

GAS FILLED METAL-CLAD SWITCHGEAR INSULATED IN SF6.

The characteristics of the switchgears, provided by the manufacturer, are the

following:

Line switchgear

Designation: CGM3621 L

Type: CGM3621

Serial No.: 3621-1010

Rated voltage, Ur: 36 kV

Rated power frequency withstand voltage, Ud: 70 kV

Rated lightning impulse withstand voltage, Up: 170 kV

Rated normal current, Ir: 630 A

Rated short-time withstand current, 1s, Ik: 21 kA

Rated peak withstand current, Ip: 54.6 kA

Rated pressure for insulation, Pre: 0.13 MPa

Minimum pressure for insulation, Pme: 0.11 MPa

Rated frequency, fr: 50/60 Hz

Protection switchgear

Designation: CGM3621 P

Type: CGM3621

No.: 3621-1011

Rated voltage, Ur: 36 kV

Rated power frequency withstand voltage, Ud: 70 kV

Rated lightning impulse withstand voltage, Up: 170 kV

Rated frequency, fr: 50/60 Hz

Main busbar rated normal current, Ir: 630 A

Report No. B126-

B126-06-

06-BT-

BT-EE-

EE-02Ev2

02Ev2 Page 3 of 19

Printed by i:0#.w|velatia\ims 28/10/2016

Rated short-time withstand current, 1s, Ik: 21 kA

Rated peak withstand current, Ip: 54.6 kA

Transformer rated derivation current: 200 A

Rated pressure for insulation, Pre: 0.13 MPa

Minimum pressure for insulation, Pme: 0.11 MPa

The tests have been performed at minimum functional pressure of the test objects.

See photographs and drawings of the test objects in the annex.

Report No. B126-

B126-06-

06-BT-

BT-EE-

EE-02Ev2

02Ev2 Page 4 of 19

Printed by i:0#.w|velatia\ims 28/10/2016

2. TESTS PERFORMED.

PERFORMED. STANDARD

Test performed has been the following:

− Temperature rise test.

Test has been performed according to:

- IEC 62271-

62271-200:2003

200:2003,

:2003, “High

“High-

High-voltage switchgear and controlgear-

controlgear- Part 200:

AC metal-

metal-enclosed switchgear and controlgear for rated voltages above 1 kV

and up to and including 52 kV”.

kV”.

Quoted standard for the tests is the following:

- IEC 60694:2002, “Common specifications for high-voltage switchgear and

controlgear standards”.

The calculation of the uncertainties of the measurements is available.

Report No. B126-

B126-06-

06-BT-

BT-EE-

EE-02Ev2

02Ev2 Page 5 of 19

Printed by i:0#.w|velatia\ims 28/10/2016

3. TEST DESCRIPTION

The tests are carried out with the switchgear mounted with all of its equipment as

used in normal service, with all the phases and the rated current flowing through

the main circuit.

The bottom side of the switchgears is covered with a thermal insulator in order to

simulate equivalents operation conditions (see photographs in the annex).

The tests are carried out with three-phase circuits, with a power supply current

which has approximately a sine wave form and a frequency of 60 Hz.

Three consecutive tests have been carried out:

Test No. 1

Test scheme:

Short-circuit

The test currents are the following:

− Line switchgear: Ir = 630 A each phase

− Protection switchgear: If = 38.5 A each phase (out of phase 120º)

Fuses of 63 A are placed

Report No. B126-

B126-06-

06-BT-

BT-EE-

EE-02Ev2

02Ev2 Page 6 of 19

Printed by i:0#.w|velatia\ims 28/10/2016

The power supply is performed:

− Line switchgear: By means of 1 strip of 50X6 mm2 for each phase.

− Protection switchgear: By means of 1 strip of 30X10 mm2 for eac

phase.

Test No. 2

Test scheme:

Short-circuit

The test currents are the following:

− Line switchgear: Ir = 630 A each phase

− Protection switchgear: If = 46 A each phase (out of phase 120º)

Fuses of 80 A are placed

The power supply is performed:

− Line switchgear: By means of 1 strip of 50X6 mm2 for each phase.

− Protection switchgear: By means of 1 strip of 30X10 mm2 for eac

phase.

Report No. B126-

B126-06-

06-BT-

BT-EE-

EE-02Ev2

02Ev2 Page 7 of 19

Printed by i:0#.w|velatia\ims 28/10/2016

Test No. 3

Test scheme:

Short-circuit

The test currents are the following:

− Line switchgear: Ir = 630 A each phase

− Protection switchgear: If = 200 A each phase (out of phase 120º)

Links are placed

The power supply is performed:

− Line switchgear: By means of 1 strip of 50X6 mm2 for each phase.

− Protection switchgear: By means of 1 strip of 30X10 mm2 for eac

phase.

The three tests are performed indoors with an ambient substantially free from air

currents, excepting those generated by the heat of the object under test.

Provisional connections to the main circuit are performed in such a way that no

significant amount of heat is supplied or extracted from the object under test. The

temperature rise of the terminals of the main circuit and of the provisional

connections at a distance of 1m from the terminals must be measured and the

difference must be no more than 5 K.

Report No. B126-

B126-06-

06-BT-

BT-EE-

EE-02Ev2

02Ev2 Page 8 of 19

Printed by i:0#.w|velatia\ims 28/10/2016

The temperature of each element for which there are specified limits has to be

measured with thermocouples. See the thermocouples arrangement in the drawing

of the annex.

The ambient air temperature is the average temperature of the air outside the

switchgear enclosure. It is measured by means of three thermocouples equally

distributed around the object, at a height approximately equal to the average

height of its current-carrying parts and at a distance of about 1m from the object.

The thermocouples are protected against air currents and abnormal effects of

heat.

In order to avoid reading errors due to sudden changes of temperature,

thermocouples have been put into small bottles containing about 0.5 l of oil.

In the last quarter of the whole period of test, the variation of the air ambient

temperature has not exceeded 1K in 1 h.

The temperature-rise of each component refers to the air ambient temperature

outside the enclosure and must not exceed the specified limits.

The temperature-rise of accessible metallic parts will not exceed of 30 K. For

accessible metallic parts, not foreseen to be touched during its normal

performance, the temperature-rise limit may be 40 K.

Report No. B126-

B126-06-

06-BT-

BT-EE-

EE-02Ev2

02Ev2 Page 9 of 19

Printed by i:0#.w|velatia\ims 28/10/2016

4. RESULTS

CORRECT. The temperature-rise of each part of the switchgear for which limits

are specified (and whose values have been measured) does not

exceed these limits.

The results obtained in test No. 1 are shown in the following table.

TEMPERAURE RISE TEST 1 (FUSE 63 A) Ambient temperature: 21 ºC

Temperature rise

No. Switchgear Thermocouple location Limit (K)

(K)

1 CGM3621 L Upper busbar - 75

2 CGM3621 L Upper busbar 42 75

3 CGM3621 L Upper busbar 42 75

4 CGM3621 L Upper fixed contact 48 65

5 CGM3621 L Switch Upper fixed contact 48 65

6 CGM3621 L Switch Upper fixed contact 49 65

7 CGM3621 L Switch Moving contact 52 65

8 CGM3621 L Switch Moving contact 51 65

9 CGM3621 L Switch Moving contact 49 65

10 CGM3621 L Switch Lower fixed contact 48 65

11 CGM3621 L Switch Lower fixed contact 47 65

12 CGM3621 L Switch Lower fixed contact 46 65

13 CGM3621 L Switch Lower busbar Connection 46 75

14 CGM3621 L Switch Lower busbar Connection 46 75

15 CGM3621 L Switch Lower busbar Connection 46 75

16 CGM3621 L Lower busbar Bushings Connection - 75

17 CGM3621 L Lower busbar Bushings Connection 42 75

18 CGM3621 L Lower busbar Bushings Connection 41 75

19 CGM3621 L Indoor ambient upper zone 35 -

20 CGM3621 L Indoor ambient lower zone 20 -

Report No. B126-

B126-06-

06-BT-

BT-EE-

EE-02Ev2

02Ev2 Page 10 of 19

Printed by i:0#.w|velatia\ims 28/10/2016

1 CGM3621 P Switch Upper fixed contact 42 65

2 CGM3621 P Switch Upper fixed contact 41 65

3 CGM3621 P Switch Upper fixed contact 41 65

4 CGM3621 P Switch Moving contact 40 65

5 CGM3621 P Switch Moving contact 39 65

6 CGM3621 P Switch Moving contact 38 65

7 CGM3621 P Switch Fuse holder busbar connection 34 75

8 CGM3621 P Switch Fuse holder busbar connection 35 75

9 CGM3621 P Upper busbar 48 75

10 CGM3621 P Upper busnar 50 75

11 CGM3621 P Upper busbar 52 75

12 CGM3621 P Fuse holder busbar Switch connection 33 75

13 CGM3621 P Fuse holder busbar Switch connection 33 75

14 CGM3621 P Fuse holder busbar Switch connection 37 75

15 CGM3621 P Switch Lower fixed contact 37 65

16 CGM3621 P Switch Lower fixed contact 36 65

17 CGM3621 P Switch Lower fixed contact 29 65

18 CGM3621 P Switch Fuse holder busbar connection 34 75

19 CGM3621 P Fuse holder Bushings Connection Phase R 33 75

20 CGM3621 P Connection Bushings Fuse holder 11 75

21 CGM3621 P Connection Bushings Fuse holder - 75

22 CGM3621 P Connection Bushings Fuse holder 12 75

23 CGM3621 P Indoor ambient 11 -

45 CGM3621 P Fuse holder Back contact 43 65

46 CGM3621 P Fuse holder Back contact 44 65

47 CGM3621 P Fuse holder Back contact 38 65

48 CGM3621 P Fuse-carrier carriage Moving contact 38 65

49 CGM3621 P Fuse-carrier carriage Moving contact 44 65

50 CGM3621 P Fuse-carrier carriage Moving contact 44 65

51 CGM3621 P Fuse-carrier carriage Front contact 52 65

52 CGM3621 P Fuse-carrier carriage Front contact 55 65

Report No. B126-

B126-06-

06-BT-

BT-EE-

EE-02Ev2

02Ev2 Page 11 of 19

Printed by i:0#.w|velatia\ims 28/10/2016

53 CGM3621 P Fuse-carrier carriage Front contact 57 65

CGM3621 P Enclosure front zone 11 30

CGM3621 P Enclosure back zone 19 40

CGM3621 P Enclosure lateral left 20 40

CGM3621 L Enclosure lateral right 18 40

CGM3621 L Incoming connection Phase S 66 75

Incoming connection at a distance of 1 m

CGM3621 L 67 Note (1)

Phase S

CGM3621 P Incoming connection Phase S 20 75

Incoming connection at a distance of 1 m

CGM3621 P 21 Note (1)

Phase S

Note (1): The difference between the temperature rises of the terminals of the main

circuit and of the provisional connections at a distance of 1 m from the

terminal is no more than 5 K.

Report No. B126-

B126-06-

06-BT-

BT-EE-

EE-02Ev2

02Ev2 Page 12 of 19

Printed by i:0#.w|velatia\ims 28/10/2016

The results obtained in test No. 2 are shown in the following table

TEMPERATURE RISE TEST 2 (FUSE 80 A) Ambient temperature:

21 ºC

Temperature rise

No. Switchgear Thermocouple location Limit (K)

(K)

1 CGM3621 L Upper busbar - 75

2 CGM3621 L Upper busbar 43 75

3 CGM3621 L Upper busbar 43 75

4 CGM3621 L Upper fixed contact 50 65

5 CGM3621 L Switch Upper fixed contact 50 65

6 CGM3621 L Switch Upper fixed contact 50 65

7 CGM3621 L Switch Moving contact 53 65

8 CGM3621 L Switch Moving contact 52 65

9 CGM3621 L Switch Moving contact 50 65

10 CGM3621 L Switch Lower fixed contact 50 65

11 CGM3621 L Switch Lower fixed contact 49 65

12 CGM3621 L Switch Lower fixed contact 49 65

13 CGM3621 L Switch Lower busbar Connection 48 75

14 CGM3621 L Switch Lower busbar Connection 47 75

15 CGM3621 L Switch Lower busbar Connection 48 75

16 CGM3621 L Lower busbar Bushings Connection - 75

17 CGM3621 L Lower busbar Bushings Connection 44 75

18 CGM3621 L Lower busbar Bushings Connection 43 75

19 CGM3621 L Indoor ambient upper zone 36 -

20 CGM3621 L Indoor ambient lower zone 22 -

Report No. B126-

B126-06-

06-BT-

BT-EE-

EE-02Ev2

02Ev2 Page 13 of 19

Printed by i:0#.w|velatia\ims 28/10/2016

1 CGM3621 P Switch Upper fixed contact 40 65

2 CGM3621 P Switch Upper fixed contact 39 65

3 CGM3621 P Switch Upper fixed contact 40 65

4 CGM3621 P Switch Moving contact 38 65

5 CGM3621 P Switch Moving contact 37 65

6 CGM3621 P Switch Moving contact 36 65

7 CGM3621 P Switch Fuse holder busbar connection 33 75

8 CGM3621 P Switch Fuse holder busbar connection 33 75

9 CGM3621 P Upper busbar 48 75

10 CGM3621 P Upper busnar 50 75

11 CGM3621 P Upper busbar 52 75

12 CGM3621 P Fuse holder busbar Switch connection 31 75

13 CGM3621 P Fuse holder busbar Switch connection 30 75

14 CGM3621 P Fuse holder busbar Switch connection 33 75

15 CGM3621 P Switch Lower fixed contact 34 65

16 CGM3621 P Switch Lower fixed contact 35 65

17 CGM3621 P Switch Lower fixed contact 18 65

18 CGM3621 P Switch Fuse holder busbar connection 32 75

19 CGM3621 P Fuse holder Bushings Connection Phase R 30 75

20 CGM3621 P Connection Bushings Fuse holder 11 75

21 CGM3621 P Connection Bushings Fuse holder - 75

22 CGM3621 P Connection Bushings Fuse holder 11 75

23 CGM3621 P Indoor ambient 11 -

45 CGM3621 P Fuse holder Back contact 38 65

46 CGM3621 P Fuse holder Back contact 38 65

47 CGM3621 P Fuse holder Back contact 33 65

48 CGM3621 P Fuse-carrier carriage Moving contact 34 65

49 CGM3621 P Fuse-carrier carriage Moving contact 40 65

50 CGM3621 P Fuse-carrier carriage Moving contact 39 65

51 CGM3621 P Fuse-carrier carriage Front contact 46 65

52 CGM3621 P Fuse-carrier carriage Front contact 49 65

53 CGM3621 P Fuse-carrier carriage Front contact 50 65

Report No. B126-

B126-06-

06-BT-

BT-EE-

EE-02Ev2

02Ev2 Page 14 of 19

Printed by i:0#.w|velatia\ims 28/10/2016

CGM3621 P Enclosure front zone 11 30

CGM3621 P Enclosure back zone 18 40

CGM3621 P Enclosure lateral left 17 40

CGM3621 L Enclosure lateral right 18 40

CGM3621 L Incoming connection Phase S 45 75

Incoming connection at a distance of 1 m

CGM3621 L 46 Note (1)

Phase S

CGM3621 P Incoming connection Phase S 4 75

Incoming connection at a distance of 1 m

CGM3621 P 8 Note (1)

Phase S

Note

Note (1): The difference between the temperature rises of the terminals of the main

circuit and of the provisional connections at a distance of 1 m from the

terminal is no more than 5 K.

Report No. B126-

B126-06-

06-BT-

BT-EE-

EE-02Ev2

02Ev2 Page 15 of 19

Printed by i:0#.w|velatia\ims 28/10/2016

The results obtained in test No. 3 are shown in the following table

TEMPERATURE RISE TEST 3 (LINKS 200 A) Ambient temperature:

19 ºC

Temperature rise

Nº Switchgear Thermocouple location Limit (K)

(K)

1 CGM3621 L Upper busbar - 75

2 CGM3621 L Upper busbar 42 75

3 CGM3621 L Upper busbar 41 75

4 CGM3621 L Upper fixed contact 48 65

5 CGM3621 L Switch Upper fixed contact 49 65

6 CGM3621 L Switch Upper fixed contact 50 65

7 CGM3621 L Switch Moving contact 52 65

8 CGM3621 L Switch Moving contact 52 65

9 CGM3621 L Switch Moving contact 50 65

10 CGM3621 L Switch Lower fixed contact 49 65

11 CGM3621 L Switch Lower fixed contact 49 65

12 CGM3621 L Switch Lower fixed contact 49 65

13 CGM3621 L Switch Lower busbar Connection 47 75

14 CGM3621 L Switch Lower busbar Connection 47 75

15 CGM3621 L Switch Lower busbar Connection 47 75

16 CGM3621 L Lower busbar Bushings Connection - 75

17 CGM3621 L Lower busbar Bushings Connection 44 75

18 CGM3621 L Lower busbar Bushings Connection 43 75

19 CGM3621 L Indoor ambient upper zone 36 -

20 CGM3621 L Indoor ambient lower zone 21 -

Report No. B126-

B126-06-

06-BT-

BT-EE-

EE-02Ev2

02Ev2 Page 16 of 19

Printed by i:0#.w|velatia\ims 28/10/2016

1 CGM3621 P Switch Upper fixed contact 46 65

2 CGM3621 P Switch Upper fixed contact 46 65

3 CGM3621 P Switch Upper fixed contact 48 65

4 CGM3621 P Switch Moving contact 45 65

5 CGM3621 P Switch Moving contact 45 65

6 CGM3621 P Switch Moving contact 44 65

7 CGM3621 P Switch Fuse holder busbar connection 48 75

8 CGM3621 P Switch Fuse holder busbar connection 51 75

9 CGM3621 P Upper busbar 52 75

10 CGM3621 P Upper busnar 55 75

11 CGM3621 P Upper busbar 57 75

12 CGM3621 P Fuse holder busbar Switch connection 37 75

13 CGM3621 P Fuse holder busbar Switch connection 48 75

14 CGM3621 P Fuse holder busbar Switch connection 52 75

15 CGM3621 P Switch Lower fixed contact 46 65

16 CGM3621 P Switch Lower fixed contact 47 65

17 CGM3621 P Switch Lower fixed contact 41 65

18 CGM3621 P Switch Fuse holder busbar connection 38 75

19 CGM3621 P Fuse holder Bushings Connection Phase R 30 75

20 CGM3621 P Connection Bushings Fuse holder 24 75

21 CGM3621 P Connection Bushings Fuse holder - 75

22 CGM3621 P Connection Bushings Fuse holder 19 75

23 CGM3621 P Indoor ambient 11 -

45 CGM3621 P Fuse holder Back contact 30 65

46 CGM3621 P Fuse holder Back contact 30 65

47 CGM3621 P Fuse holder Back contact 27 65

48 CGM3621 P Fuse-carrier carriage Moving contact 42 65

49 CGM3621 P Fuse-carrier carriage Moving contact 45 65

50 CGM3621 P Fuse-carrier carriage Moving contact 46 65

51 CGM3621 P Fuse-carrier carriage Front contact 41 65

52 CGM3621 P Fuse-carrier carriage Front contact 45 65

53 CGM3621 P Fuse-carrier carriage Front contact 45 65

Report No. B126-

B126-06-

06-BT-

BT-EE-

EE-02Ev2

02Ev2 Page 17 of 19

Printed by i:0#.w|velatia\ims 28/10/2016

CGM3621 P Enclosure front zone 8 30

CGM3621 P Enclosure back zone 17 40

CGM3621 P Enclosure lateral left 15 40

CGM3621 L Enclosure lateral right 17 40

CGM3621 L Incoming connection Phase S 45 75

Incoming connection at a distance of 1 m

CGM3621 L 46 Note (1)

Phase S

CGM3621 P Incoming connection Phase S 18 75

Incoming connection at a distance of 1 m

CGM3621 P 15 Note (1)

Phase S

Nota (1): The difference between the temperature rise of the terminals of the main

circuit and of the provisional connections at a distance of 1 m from the

terminal is no more than 5 K.

Report No. B126-

B126-06-

06-BT-

BT-EE-

EE-02Ev2

02Ev2 Page 18 of 19

Printed by i:0#.w|velatia\ims 28/10/2016

Verification of the resistance of the main circuit

CORRECT. The values measured before the beginning of the test and after the

end of the temperature-rise test do not differ by more than 20 %.

Values of resistance in µΩ.

CGM3621 P

Before the temperature rises After the temperature rises

Phase R-r Phase S-s Phase T-t Phase R-r Phase S-s Phase T-t

968 976 1144 963 999 1086

CGM3621 L

Before the temperature rises After the temperature rises

Phase R-r Phase S-s Phase T-t Phase R-r Phase S-s Phase T-t

157 157 160 167 163 172

Report No. B126-

B126-06-

06-BT-

BT-EE-

EE-02Ev2

02Ev2 Page 19 of 19

Printed by i:0#.w|velatia\ims 28/10/2016

Report No. B126-

B126-06-

06-BT-

BT-EE-

EE-02Ev2

02Ev2 Annex. Page 1 of 6

Printed by i:0#.w|velatia\ims 28/10/2016

Report No. B126-

B126-06-

06-BT-

BT-EE-

EE-02Ev2

02Ev2 Annex. Page 2 of 6

Printed by i:0#.w|velatia\ims 28/10/2016

Test objects

Report No. B126-

B126-06-

06-BT-

BT-EE-

EE-02Ev2

02Ev2 Annex. Page 3 of 6

Printed by i:0#.w|velatia\ims 28/10/2016

Test arrangement

Report No. B126-

B126-06-

06-BT-

BT-EE-

EE-02Ev2

02Ev2 Annex. Page 4 of 6

Printed by i:0#.w|velatia\ims 28/10/2016

Short-

Short-circuit 1L1P

Report No. B126-

B126-06-

06-BT-

BT-EE-

EE-02Ev2

02Ev2 Annex. Page 5 of 6

Printed by i:0#.w|velatia\ims 28/10/2016

Fuse 63 A

Fuse 80 A

Report No. B126-

B126-06-

06-BT-

BT-EE-

EE-02Ev2

02Ev2 Annex. Page 6 of 6

Printed by i:0#.w|velatia\ims 28/10/2016

You might also like

- Merc Training ManualDocument80 pagesMerc Training ManualDanesh F.Khambatta93% (14)

- Side View Camera E70, E71Document23 pagesSide View Camera E70, E71Zainal ArifinNo ratings yet

- Electrostatic Discharge Immunity TestDocument6 pagesElectrostatic Discharge Immunity Testratheesh vidyadharanNo ratings yet

- 2902 Instruction ManualDocument11 pages2902 Instruction ManualGeo TogNo ratings yet

- 1.6 Kva Transformer Testing ReportDocument5 pages1.6 Kva Transformer Testing ReportVikrant DeshmukhNo ratings yet

- Est Report: Dielectric TestsDocument17 pagesEst Report: Dielectric TestsLaura Sofía VélezNo ratings yet

- ABB Elektrik Sanayi A.S.: Type Test DocumentationDocument1 pageABB Elektrik Sanayi A.S.: Type Test DocumentationsoltaniNo ratings yet

- RAP-37R-G76-365: Test Report IPMR 064/B/06 Qualification Type Test Report For Composite Insulator ProductsDocument17 pagesRAP-37R-G76-365: Test Report IPMR 064/B/06 Qualification Type Test Report For Composite Insulator ProductsZineddine BENOUADAHNo ratings yet

- 8035739Document37 pages8035739khuong phạmNo ratings yet

- Low Voltage SwitchboardDocument21 pagesLow Voltage Switchboardvenkatesh waranNo ratings yet

- TFR - 200903156 - 003 (Dien Moi-Dielectric - IP)Document18 pagesTFR - 200903156 - 003 (Dien Moi-Dielectric - IP)Nguyen ngoc thongNo ratings yet

- Lot 2: Supply, Install and Commission of 90/120mva, 220/33Kv Transformer Complete With Switchgears at Bulynhulu SubstationDocument2 pagesLot 2: Supply, Install and Commission of 90/120mva, 220/33Kv Transformer Complete With Switchgears at Bulynhulu SubstationericmNo ratings yet

- 22kV GTPDocument41 pages22kV GTPSundaresan Sabanayagam100% (1)

- Test Facilities Condition Monitoring Infrastructure: ComponentsDocument2 pagesTest Facilities Condition Monitoring Infrastructure: ComponentsKiranNo ratings yet

- 编 号 (No.) : LNDK-TSFA-DQ-*** 密 级 (Security) : 版 本 (Version) :Document21 pages编 号 (No.) : LNDK-TSFA-DQ-*** 密 级 (Security) : 版 本 (Version) :刘佳No ratings yet

- 卷二Document572 pages卷二ashraful tanvirNo ratings yet

- Test Report - X18155 - 1Document4 pagesTest Report - X18155 - 1Manuel A. Silva PainénNo ratings yet

- Switch BoardDocument20 pagesSwitch BoardAkhil NairNo ratings yet

- 编 号 (No.) : LNDK-TSFA-DQ-*** 密 级 (Security) : 版 本 (Version) :Document21 pages编 号 (No.) : LNDK-TSFA-DQ-*** 密 级 (Security) : 版 本 (Version) :刘佳No ratings yet

- 04 Manual Operacion CBGS-2Document60 pages04 Manual Operacion CBGS-2cachiletNo ratings yet

- TR - K480TB - G - K800PB - G-CA022-95.240UN5 - 12 - 7 - 22 (24) KV - HD 629.1 - Table 7-D1 CO A2017-038 Rev.0 - 0.0.0 - 20191126141303Document57 pagesTR - K480TB - G - K800PB - G-CA022-95.240UN5 - 12 - 7 - 22 (24) KV - HD 629.1 - Table 7-D1 CO A2017-038 Rev.0 - 0.0.0 - 20191126141303Compatibilidade DieletricaNo ratings yet

- Flusarc Compact CBCC Technical Data SheetDocument6 pagesFlusarc Compact CBCC Technical Data SheetYalem Alemayehu100% (1)

- Silicon Rubber Composite InsulatorDocument16 pagesSilicon Rubber Composite InsulatorRuchir BhoglekarNo ratings yet

- Acsr Canna 933 Tip Test Raporu PDFDocument13 pagesAcsr Canna 933 Tip Test Raporu PDFelsayedNo ratings yet

- Marlim Azul Project (CC 1X1 565 MW) : Technical Data Sheet For 22Kv IpbDocument12 pagesMarlim Azul Project (CC 1X1 565 MW) : Technical Data Sheet For 22Kv Ipbsanjayprakash1979No ratings yet

- Section-7.3 Substation EquipmentDocument84 pagesSection-7.3 Substation EquipmentBRB CABLENo ratings yet

- Annexure - C List of SpecificationsDocument26 pagesAnnexure - C List of SpecificationsRajesh VauNo ratings yet

- I. Iger - Internal Fault PerformanceDocument9 pagesI. Iger - Internal Fault PerformanceDalibor MarkovicNo ratings yet

- 60 KV and 20 KV SA Factory Test ReportsDocument2 pages60 KV and 20 KV SA Factory Test Reportsvinoth madhavanNo ratings yet

- Short-Circuit Current Making and Breaking TestsDocument16 pagesShort-Circuit Current Making and Breaking TestsFelipe Mafioletti Schuartz100% (1)

- Cable SizingDocument24 pagesCable SizingPrashant Kumar Punia100% (2)

- 545 E. Algonquin RD., Arlington Heights, IL 60005Document7 pages545 E. Algonquin RD., Arlington Heights, IL 60005flysch_ukNo ratings yet

- Medium Voltage, Arc-Proof, Air-Insulated, Metal-Clad Switchgear and Controlgear Up To 12kVDocument20 pagesMedium Voltage, Arc-Proof, Air-Insulated, Metal-Clad Switchgear and Controlgear Up To 12kVnp1101992No ratings yet

- TJ - Ii.i: Medium Voltage Cables (Factory Acceptance Test)Document4 pagesTJ - Ii.i: Medium Voltage Cables (Factory Acceptance Test)Mohammed AL-HejeriNo ratings yet

- Kaplar 2011Document6 pagesKaplar 2011mkk.net.pkNo ratings yet

- P112-Ixs120bp036p112 R2Document7 pagesP112-Ixs120bp036p112 R2tao zhangNo ratings yet

- 2N3054 2N3054A Silicon NPN Power Transistors DescriptionDocument4 pages2N3054 2N3054A Silicon NPN Power Transistors DescriptionMuhammadNo ratings yet

- Specification 33KV GIS ZX0.2Document16 pagesSpecification 33KV GIS ZX0.2BADRI VENKATESHNo ratings yet

- Circuit Breaker SpecificationDocument60 pagesCircuit Breaker SpecificationYash YadavNo ratings yet

- Acb VCBDocument4 pagesAcb VCBAbhay KumarNo ratings yet

- 2.package-20 Vol - 2 of 2Document302 pages2.package-20 Vol - 2 of 2Wahed ImtiazNo ratings yet

- KONCAR Type Test Report IEC XHE 49-A 022519Document8 pagesKONCAR Type Test Report IEC XHE 49-A 022519BorisNo ratings yet

- Pump ATEX, IEC, Test ReportsDocument49 pagesPump ATEX, IEC, Test ReportsPhúc Phạm ThànhNo ratings yet

- Specification For MV Switchboards / Motor Control CentresDocument33 pagesSpecification For MV Switchboards / Motor Control CentresDanish MohammedNo ratings yet

- 869 PowerQualityTests - IEC255-11 - 07 - 03 - 14 - r002Document18 pages869 PowerQualityTests - IEC255-11 - 07 - 03 - 14 - r002andrez880103No ratings yet

- Switch Gear MonitoringDocument20 pagesSwitch Gear MonitoringUmair Khalique ArainNo ratings yet

- Automotive Dual-Line TVS in SOT323-3L For CAN Bus: Esdcanxx-2BwyDocument14 pagesAutomotive Dual-Line TVS in SOT323-3L For CAN Bus: Esdcanxx-2BwyЕвгений ИвановNo ratings yet

- Red670 M1Document8 pagesRed670 M1Lindo PatoNo ratings yet

- Site Test Report: Accuracy Testing of Energy Meter - ElsterDocument4 pagesSite Test Report: Accuracy Testing of Energy Meter - Elstersalman100% (1)

- Isa Cba 1000 ManualDocument29 pagesIsa Cba 1000 ManualYugie OktavianaNo ratings yet

- AC Combiner Box Specification 400vac)Document7 pagesAC Combiner Box Specification 400vac)emilNo ratings yet

- 170300917sha-001 1PDocument91 pages170300917sha-001 1PAlejandro Pedro Mundaca MalcaNo ratings yet

- Nader NDB2 63 Products SpecificationsDocument6 pagesNader NDB2 63 Products SpecificationsLuis CruzNo ratings yet

- Va2-Dn04-p0ab-140028 - Inspection and Test Procedure For Manufacturing of Power and Control Cable For 500kv Ais - Rev.bDocument14 pagesVa2-Dn04-p0ab-140028 - Inspection and Test Procedure For Manufacturing of Power and Control Cable For 500kv Ais - Rev.bAnh Ngọc NguyễnNo ratings yet

- PGCIL 33KV GIS SpecDocument21 pagesPGCIL 33KV GIS SpecManohar PotnuruNo ratings yet

- Current TransformersDocument36 pagesCurrent Transformers322399mk7086No ratings yet

- List of Standards For Elecrical Equipment - App2 PDFDocument16 pagesList of Standards For Elecrical Equipment - App2 PDFJ. Jorge Torres100% (1)

- HS21 P1112Document20 pagesHS21 P1112MarioNo ratings yet

- Field-Testing of Power Semiconductor Modules: Application NoteDocument11 pagesField-Testing of Power Semiconductor Modules: Application NotecsystemsNo ratings yet

- 301 CSBattery IEC60896-21 2004 OPZV 2V Test Report PDFDocument13 pages301 CSBattery IEC60896-21 2004 OPZV 2V Test Report PDFABID TRADERSNo ratings yet

- Power Line Chokes: A Í Püééí A Í PüééíDocument6 pagesPower Line Chokes: A Í Püééí A Í PüééíMajNo ratings yet

- Electromagnetic Compatibility (EMC) Design and Test Case AnalysisFrom EverandElectromagnetic Compatibility (EMC) Design and Test Case AnalysisNo ratings yet

- AA Tower Test ReportDocument88 pagesAA Tower Test ReportLaura Sofía VélezNo ratings yet

- 1 - SWL-05PRO DatasheetDocument11 pages1 - SWL-05PRO DatasheetLaura Sofía VélezNo ratings yet

- Key Findings 2018: Global Energy and CO2 Status Report 2018 Energy DemandDocument27 pagesKey Findings 2018: Global Energy and CO2 Status Report 2018 Energy DemandLaura Sofía VélezNo ratings yet

- (Trafo Katk-85-190-205)Document1 page(Trafo Katk-85-190-205)Laura Sofía VélezNo ratings yet

- AFS Contactors For Safety Applications: Catalog - January 2018Document24 pagesAFS Contactors For Safety Applications: Catalog - January 2018Laura Sofía VélezNo ratings yet

- 4100/4120-Series Mapnet Ii /idnet Quad Isolator Modules Installation InstructionsDocument22 pages4100/4120-Series Mapnet Ii /idnet Quad Isolator Modules Installation InstructionsMohamed AhmedNo ratings yet

- Ficha Tecnica Hipot DCDocument2 pagesFicha Tecnica Hipot DCOmar GutierrezNo ratings yet

- Cvmk2: Three-Phase Power Analyzer, Assembly On Panel or Din RailDocument2 pagesCvmk2: Three-Phase Power Analyzer, Assembly On Panel or Din RailRodrigo PardoNo ratings yet

- ABET Course Syllabus Template: ECE341: Energy ConversionDocument6 pagesABET Course Syllabus Template: ECE341: Energy Conversionchristine booduanNo ratings yet

- Wireless Notice Board Based On Arduino ADocument4 pagesWireless Notice Board Based On Arduino ASAAASNo ratings yet

- Tabaco National High School Tabaco CityDocument15 pagesTabaco National High School Tabaco CityBjen BeaNo ratings yet

- 9BM979277LB143354 - Linea M-110 IDocument2 pages9BM979277LB143354 - Linea M-110 Imatias cruzNo ratings yet

- Andres Ceballos 2023 ResumeDocument1 pageAndres Ceballos 2023 Resumeapi-645228695No ratings yet

- Analytical Chemistry ConceptsDocument12 pagesAnalytical Chemistry ConceptsElijah Alves100% (4)

- Crouse Hinds Led Family BrochureDocument44 pagesCrouse Hinds Led Family Brochurepatilshailesh123No ratings yet

- Condition For Boost ChargeDocument4 pagesCondition For Boost ChargeAssistant Manager PI NishatabadNo ratings yet

- A Compact Hilbert Curve Fractal Antenna On Metamaterial Using CSRRDocument6 pagesA Compact Hilbert Curve Fractal Antenna On Metamaterial Using CSRRfahmiNo ratings yet

- Assign CSDocument9 pagesAssign CSAarsh ShayaanNo ratings yet

- Instruction Manual: Deckma Hamburg GMBHDocument25 pagesInstruction Manual: Deckma Hamburg GMBHabuzer1981No ratings yet

- Implementation of High-k/Metal Gates in High-Volume ManufacturingDocument5 pagesImplementation of High-k/Metal Gates in High-Volume ManufacturingA J AYNo ratings yet

- Chapter 5 Lecture PowerPointDocument34 pagesChapter 5 Lecture PowerPointKarthik IlangoNo ratings yet

- 06.wiring Diagram R1Document1 page06.wiring Diagram R1azret rezaNo ratings yet

- P1470Document6 pagesP1470Priya SingNo ratings yet

- CLMD4A AutomotiveG9 10Document25 pagesCLMD4A AutomotiveG9 10Eiay CommsNo ratings yet

- Bum 64Document74 pagesBum 64sylvain poujadeNo ratings yet

- Experiment Voltaic CellDocument4 pagesExperiment Voltaic CellGreanna Friva Bt. JainalNo ratings yet

- Smart Learning Code ListDocument12 pagesSmart Learning Code ListDejan VuporaNo ratings yet

- Write A Term Paper On TransformerDocument5 pagesWrite A Term Paper On Transformerc5se0nsw100% (1)

- Ilovepdf MergedDocument4 pagesIlovepdf MergedRani KurniaNo ratings yet

- Manual Parameter 828DDocument898 pagesManual Parameter 828DSam eagle goodNo ratings yet

- Sanyo Vhr-H774ev M264evDocument46 pagesSanyo Vhr-H774ev M264evAna OmicevicNo ratings yet

- 05 - Driver For HVAC SamsungDocument9 pages05 - Driver For HVAC SamsungGentrit FejzaNo ratings yet