Professional Documents

Culture Documents

Design of Base Plate 2

Design of Base Plate 2

Uploaded by

Andro RebuyasOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Base Plate 2

Design of Base Plate 2

Uploaded by

Andro RebuyasCopyright:

Available Formats

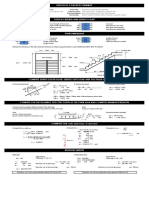

DESIGN OF BASE PLATE (PINNED SUPPORT)

ASpectrum Designs Plus Engineering Services Project Title: Proposed Two Storey Residential Building

Address: 8487 Sandoval Avenue, Pinagbuhatan, Pasig City 1602 Project Location: Villa Cuana Phase 1, Pinagbuhata, Pasig City 1602

Contact: 09982028893 Structural Engineer: Engr. Andro S Rebuyas, RCE, ME-1, RMP, M.Eng-SE

Gmail add: asrebuyas.wvc@gmail.com Membership: M.PICE, M.ASCE, M.PAMEA, M.FPEA, M.PSUMP, M.NAMPAP, M.SEAD

STAAD INPUT, WIND FACTOR AND CONNECTION CAPACITY

STAAD INPUT CONNECTION CAPACITY

Pv = 80.00 kN Horizontal Shear B= 98.80 kN Bearing

T= 61.05 kN Tension

WIND FACTOR S= 85.45 kN Shear

W= 306.89 kN Weld

WF = 1.00 Wind Factor

CONCRETE PEDESTAL AND COLUMN SECTION

CONCRETE PEDESTAL COLUMN SECTION

Grade = M25 Grade Grade = A36 Grade

f'c = 2.50 kN/cm2 Compressive Strength Fu = 40.00 kN/cm2 Steel Tensile Strength

L= 450 mm Length Fy = 24.80 kN/cm2 Steel Yield Strength

W= 250 mm Width S =150x150x4.5 Section =

A2 = 1125 cm2 (LxW) Area of Pedestal D/W= 150 mm Depth \ Width

WT = 4.5 mm Wall Thickness

BASE PLATE DIAGRAM

CONNECTION DETAILS AND WELD DATA

CONNECTION DETAILS WELD DATA

SBPC = SBC-115 Standard Base Plate Code 48.23 kN/cm2 For E70XX Electrode

BG = A36 Bolt Grade 0.3 x Fu kN/cm2 Allowable Stress in weld

Fu = 40.00 kN/cm2 Tensile Strength 14.47 kN/cm2 Allowable Stress in weld

Ft = 13.20 kN/cm2 Allowable Tensile Stress 5.00 mm Size of Weld

Fv = 6.80 kN/cm2 Allowable Shear Stress

A= 430 mm Width

B= 250 mm Length

tp = 16 mm Thickness

n= 4 mm Number of Holes

db = 20 mm Bolt Diamter

dh = 26 mm Hole Diameter

g= 300 mm Gage

p= 100 mm Pitch

ed1 65 mm Edge Distance

A1 = 1075 cm2 Area of Base Plate

BPG = A572 Base Plate Grade

Fu = 45.00 kN/cm2 Steel Tensile Strength

Fy = 34.50 kN/cm2 Steel Yield Strength

Fb = 25.88 kN/cm2 Steel bending Strength

AXIAL CAPACITY DUE TO CONCENTRIC BEARING PRESSURE, P1

P1 = 962.25 kN 0.35 fc' sqrt ( A2 x A1) <= 0.7 fc' A1

AXIAL CAPACITY DUE TO BASE PLATE BENDING (CANTILEVER TYPE), P2

m= 155.00 mm ( N - 0.80 d ) / 2 M / Zp < = 0.75 Fy = Fb

n= 65.00 mm ( B - 0.80 d ) / 2 Zp = tb2 / 6

Xc = 15.50 cm max ( m, n ) P2 = tb2 x Fb x N x B / 3 Xc2

M = f p Xc 2 / 2 P2 = 98.80 kN

fp = P2 / N B

M = P2 Xc2 / 2 N B

TENSILE CAPACITY, Pt

a= 72.25 mm (p - d + t) / 2 - 0.25 db

b = 217.75 mm (a + d - t)

L= 290 mm (p - db / 2)

M = P ab (b + a) / 2L2

Zp = bf tb2 / 6

Pt = fb x bf tp2 x 2 x L2 / [ 6 ab ( a + b ) ]

Pt = 61.05 kN

ANCHOR BOLT CAPACITIES

Tc = 165.88 kN Ft x Ab x n Tensile Capacity

Sc = 85.45 kN Fv x Ab x n Shear Capacity

Poc = [ ( p x db ) x Le ] x u x n Pull Out Capacity

Poc = 166.90 kN Pull Out Capacity

fv = 6.37 kN/cm2 Pv / Ab n Calculated Shear Stress / Bolt

Ts = [ ( 0.43 Fu ) - ( 1.8 fv ) ] Allowable Tensile Stress with Shear

Ts = 5.74 kN/cm2 Allowable Tensile Stress with Shear

Tcws = Ts x Ab x n Tension Capacity with Shear

Tcws = 72.14 kN Tension Capacity with Shear

WELDS

Lw = 600 mm Length of Weld 4d

Wc = 306.89 kN Weld Capacity 0.707 x S x Fw x Lw

This Spreadsheets is licensed only to Engr. Andro S. Rebuyas, RCE, ME-1, RMP, M.Eng-SE

You might also like

- Analysis and Design of (Concentric, Edge, Corner) Footing: Sample Structural ManilaDocument3 pagesAnalysis and Design of (Concentric, Edge, Corner) Footing: Sample Structural ManilaAndro RebuyasNo ratings yet

- Cantilever Sheet Pile DesignDocument14 pagesCantilever Sheet Pile DesignMaltesh H100% (3)

- Design of Base Plate 3Document2 pagesDesign of Base Plate 3Andro RebuyasNo ratings yet

- Design of Base Plate 1Document2 pagesDesign of Base Plate 1Andro RebuyasNo ratings yet

- Column Base Plate Design CalculationDocument3 pagesColumn Base Plate Design CalculationPilippenge Asanka Iraj LaknathaNo ratings yet

- Design of Moment ConnectionDocument2 pagesDesign of Moment Connectiongops1963No ratings yet

- Design of Moment and Shear ConnectionDocument4 pagesDesign of Moment and Shear ConnectionAndro RebuyasNo ratings yet

- FFB4Document8 pagesFFB4prajjwal patidarNo ratings yet

- Final MatDocument10 pagesFinal MatxyxyquazNo ratings yet

- Steel Column DesignDocument4 pagesSteel Column DesignEly Jane DimaculanganNo ratings yet

- FND BoltDocument1 pageFND BoltArunkumar RackanNo ratings yet

- Wind CalculatorDocument12 pagesWind Calculatorilyasmd7No ratings yet

- Base Plate DesignDocument14 pagesBase Plate Designsoumi bhattacharyaNo ratings yet

- Space 2001Document43 pagesSpace 2001Nguyen Duc CuongNo ratings yet

- Isolated Footing DesignDocument5 pagesIsolated Footing DesignTONY BOULOSNo ratings yet

- Standard Isolated Footing f1Document11 pagesStandard Isolated Footing f1Saajan bhathalNo ratings yet

- Design of Steel Beam (Asd) : Case 1: LC LB Lu Case 2: LB LC and Non-CompactDocument2 pagesDesign of Steel Beam (Asd) : Case 1: LC LB Lu Case 2: LB LC and Non-CompactAndro RebuyasNo ratings yet

- Design of Moment Connection 2Document2 pagesDesign of Moment Connection 2gops1963No ratings yet

- Design Paameter (European Code) en 1993Document16 pagesDesign Paameter (European Code) en 1993Birendra2706No ratings yet

- Column Base PlateDocument3 pagesColumn Base PlatePurnima ArkalgudNo ratings yet

- Base Plate DesignDocument4 pagesBase Plate DesignAnonymous 1HFV185Sl4No ratings yet

- Column Splicing Structural Analysis and Computation ReportDocument41 pagesColumn Splicing Structural Analysis and Computation ReportForceNo ratings yet

- Anchor Bolt As Per BS CodeDocument16 pagesAnchor Bolt As Per BS Codesuvodip khanNo ratings yet

- Beam Design TorsionDocument20 pagesBeam Design Torsionmailmaverick8167100% (1)

- Thrust Block 12.5degDocument3 pagesThrust Block 12.5degbalu rNo ratings yet

- Wind Design - ASCE 7-16Document22 pagesWind Design - ASCE 7-16Nguyen Tan PhatNo ratings yet

- Footing DesignsDocument2 pagesFooting DesignsVishwajith KadriNo ratings yet

- Reinforcement: V, F: Project: Staircase Design - STC 1Document4 pagesReinforcement: V, F: Project: Staircase Design - STC 1zzweirdozzNo ratings yet

- Slab Design:-Out House Room: (One Long & One Short Edge Discontineous) (Two Way)Document12 pagesSlab Design:-Out House Room: (One Long & One Short Edge Discontineous) (Two Way)shiv kumarNo ratings yet

- Isolated Footing ExcelDocument41 pagesIsolated Footing ExcelMohammed Saleem Syed KhaderNo ratings yet

- XyzDocument64 pagesXyzP S HARSHITANo ratings yet

- Engineering and Development Corporation of The Philippines: H P H PDocument2 pagesEngineering and Development Corporation of The Philippines: H P H Pmark ignacioNo ratings yet

- DESIGN OF SLAB - ContdDocument4 pagesDESIGN OF SLAB - ContdmeenuNo ratings yet

- Staircase Design PDFDocument2 pagesStaircase Design PDFAjit Yadav100% (1)

- MCR Footing DesignDocument5 pagesMCR Footing DesignAswin KumarNo ratings yet

- 40 Seismic ASCE 7-02-05Document2 pages40 Seismic ASCE 7-02-05mohamedabdelalNo ratings yet

- Connection v1.3Document14 pagesConnection v1.3Trần Minh ChiếnNo ratings yet

- PedestalP2 - (350x350) 7Document23 pagesPedestalP2 - (350x350) 7Feroz Khan PatthanNo ratings yet

- Anchor Bolt Design For Portal and Connecting BridgeDocument2 pagesAnchor Bolt Design For Portal and Connecting BridgeAbhinav YadavNo ratings yet

- Loadings On Beam:: The Staircase Is Modeled and Designed in STAAD With The Following LoadsDocument2 pagesLoadings On Beam:: The Staircase Is Modeled and Designed in STAAD With The Following Loadsjayant mahoreNo ratings yet

- Design of I-Shape Column Base Plate With Moment and Axial CompressionDocument2 pagesDesign of I-Shape Column Base Plate With Moment and Axial CompressionAndro RebuyasNo ratings yet

- Site: Date: Job No. Designer: Sheet No.: Calculation/ SketchDocument6 pagesSite: Date: Job No. Designer: Sheet No.: Calculation/ SketchAlma M. LaraNo ratings yet

- Base Plate For VIEW - C & View X-XDocument6 pagesBase Plate For VIEW - C & View X-XEmdadul HuqNo ratings yet

- Isolated Footing Design Hos RcclargerDocument29 pagesIsolated Footing Design Hos RcclargerJayant ChaudharyNo ratings yet

- Selender For Regtangular ColDocument3 pagesSelender For Regtangular Colsaddamalsayadi38100% (1)

- Rean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionDocument11 pagesRean'S Building 5/24/2002 Angle Plate Design: Framed Beam Connectionmhel_almoNo ratings yet

- Base Plate DesignDocument1 pageBase Plate DesignShuvo ShahaNo ratings yet

- Calculation For Rafter-Column ConnectionDocument6 pagesCalculation For Rafter-Column ConnectionpriantomoNo ratings yet

- 6.continous Frame Girder DesignDocument2 pages6.continous Frame Girder DesignReuben James BangaoilNo ratings yet

- Cantilever BeamDocument3 pagesCantilever BeamFeliciano Esteban DominguezNo ratings yet

- Calculation Sheet: Yb For UB BeamDocument2 pagesCalculation Sheet: Yb For UB BeamrammohanNo ratings yet

- WALLPRES ExcavationDocument11 pagesWALLPRES ExcavationShekh Muhsen Uddin AhmedNo ratings yet

- Base Plate With BoltsDocument3 pagesBase Plate With BoltsAbu KhatriNo ratings yet

- Client Comment Response - DG FoundationDocument7 pagesClient Comment Response - DG FoundationAnnelzNo ratings yet

- Base Plate1Document6 pagesBase Plate1jobees7850No ratings yet

- As-Check Punching TrueDocument1 pageAs-Check Punching TrueAnonymous FuZIBPNo ratings yet

- Design of Cold-Formed Purlins: Section AdequateDocument1 pageDesign of Cold-Formed Purlins: Section AdequateAndro RebuyasNo ratings yet

- DESIGN OF COMBINED FOOTING (SlabDocument7 pagesDESIGN OF COMBINED FOOTING (SlabmeenuNo ratings yet

- Mill BuildingDocument135 pagesMill BuildingKaraline MarcesNo ratings yet

- Design of Combine Footing GridDocument2 pagesDesign of Combine Footing GridsharathkammarNo ratings yet

- Client: Reem General Contracting Est. Al Jubail, Dammam, Commercial Street Kingdom of Saudi Arabia Al KhobarDocument3 pagesClient: Reem General Contracting Est. Al Jubail, Dammam, Commercial Street Kingdom of Saudi Arabia Al KhobarUday UdmaleNo ratings yet

- Base PlateDocument29 pagesBase PlateRakesh SharmaNo ratings yet

- Design of Steel ColumnDocument1 pageDesign of Steel ColumnAndro RebuyasNo ratings yet

- Design of I-Shape Column Base Plate With Moment and Axial CompressionDocument2 pagesDesign of I-Shape Column Base Plate With Moment and Axial CompressionAndro RebuyasNo ratings yet

- Analysis and Design of Raft Foundation (4 Columns in 1 Foundation Only)Document5 pagesAnalysis and Design of Raft Foundation (4 Columns in 1 Foundation Only)Andro Rebuyas100% (1)

- Design of Two Way SlabDocument1 pageDesign of Two Way SlabAndro RebuyasNo ratings yet

- Design of Reinforced Concrete Beam: 2 Legs Number of Ties (Vertical) 2 Legs Number of Ties (Horizontal)Document3 pagesDesign of Reinforced Concrete Beam: 2 Legs Number of Ties (Vertical) 2 Legs Number of Ties (Horizontal)Andro RebuyasNo ratings yet

- Design of Moment and Shear ConnectionDocument4 pagesDesign of Moment and Shear ConnectionAndro RebuyasNo ratings yet

- Design of Column SpliceDocument2 pagesDesign of Column SpliceAndro Rebuyas100% (1)

- Design of Reinforced Concrete BeamDocument2 pagesDesign of Reinforced Concrete BeamAndro RebuyasNo ratings yet

- Design of StairsDocument2 pagesDesign of StairsAndro RebuyasNo ratings yet

- Column Design Under Combined Axial Compression and Biaxial Bending MomentsDocument2 pagesColumn Design Under Combined Axial Compression and Biaxial Bending MomentsAndro RebuyasNo ratings yet

- Design of Cold-Formed Purlins: Section AdequateDocument1 pageDesign of Cold-Formed Purlins: Section AdequateAndro RebuyasNo ratings yet

- Design of One Way SlabDocument1 pageDesign of One Way SlabAndro RebuyasNo ratings yet

- Design of Concrete Stairway: LoadingDocument1 pageDesign of Concrete Stairway: LoadingAndro RebuyasNo ratings yet

- Design of Beam To Column SpliceDocument1 pageDesign of Beam To Column SpliceAndro RebuyasNo ratings yet

- Design of End Plate ConnectionDocument2 pagesDesign of End Plate ConnectionAndro RebuyasNo ratings yet

- Design of Steel Beam (Asd) : Case 1: LC LB Lu Case 2: LB LC and Non-CompactDocument2 pagesDesign of Steel Beam (Asd) : Case 1: LC LB Lu Case 2: LB LC and Non-CompactAndro RebuyasNo ratings yet

- Design of Base Plate 3Document2 pagesDesign of Base Plate 3Andro RebuyasNo ratings yet

- Design of Base Plate 1Document2 pagesDesign of Base Plate 1Andro RebuyasNo ratings yet

- Analysis and Design of Reinforced Concrete Corbel: ElevationDocument1 pageAnalysis and Design of Reinforced Concrete Corbel: ElevationAndro RebuyasNo ratings yet

- Design of Composite Steel DeckDocument1 pageDesign of Composite Steel DeckAndro Rebuyas0% (1)

- Homework Michael X FarhanDocument7 pagesHomework Michael X FarhanAdib RizqullohNo ratings yet

- Reinforced Concrete KhmerDocument628 pagesReinforced Concrete KhmerCheng Por Eng100% (2)

- Haydar 2018Document13 pagesHaydar 2018fahmi aballiNo ratings yet

- Chapter 17 - Concrete PavementsDocument18 pagesChapter 17 - Concrete PavementsDiyoke HenryNo ratings yet

- Department of Civil Engineering Subject Name: Basic Civil Engineering Question Bank Unit 1 Part I - 2 Marks QuestionsDocument7 pagesDepartment of Civil Engineering Subject Name: Basic Civil Engineering Question Bank Unit 1 Part I - 2 Marks QuestionsM.suresh SureshNo ratings yet

- Brosur PC PilesDocument6 pagesBrosur PC PileshedyNo ratings yet

- 6 BAA4513 Mat FoundationDocument41 pages6 BAA4513 Mat FoundationAizat HermanNo ratings yet

- CV Bhineka 21 Hari FS 4.5Document1 pageCV Bhineka 21 Hari FS 4.5ppg.desyaalfatih82No ratings yet

- ACI SP-2 (1999) ACI Manual Concrete InspectionDocument218 pagesACI SP-2 (1999) ACI Manual Concrete Inspectionguolun luoNo ratings yet

- Design Example - Deep Mass Concrete Pad BaseDocument5 pagesDesign Example - Deep Mass Concrete Pad BaseAnonymous xcFcOgMi100% (1)

- A Case Study On The Application of Passive Control and Seismic Isolation Techniques To Cable-Stayed Bridges - A Comparative Investigation Through Non-Linear Dynamic AnalysesDocument21 pagesA Case Study On The Application of Passive Control and Seismic Isolation Techniques To Cable-Stayed Bridges - A Comparative Investigation Through Non-Linear Dynamic AnalysesJuan Patricio ReyesNo ratings yet

- Table 1: Initial SDL and LLDocument2 pagesTable 1: Initial SDL and LLMuhamad Amirul Md. RazdiNo ratings yet

- Tehrathum Dist. Hospital DPR 2080-2-32Document1 pageTehrathum Dist. Hospital DPR 2080-2-32Chainlink EngineeringNo ratings yet

- 12.11 Design Guidelines For Stifflegs and Box CulvertsDocument6 pages12.11 Design Guidelines For Stifflegs and Box CulvertsDave ThompsonNo ratings yet

- Tegframe Framing System BrochureDocument20 pagesTegframe Framing System BrochureDoug WeirNo ratings yet

- S-01foundation Lay-Out Lift & Typical Beam Column Details PDFDocument1 pageS-01foundation Lay-Out Lift & Typical Beam Column Details PDFHardik Sorathiya100% (1)

- CE 311 MODULE 4 - Structural Analysis of FramesDocument23 pagesCE 311 MODULE 4 - Structural Analysis of FramesBryanHarold BrooNo ratings yet

- AISC 360 - Moment Connection Design ExampleDocument10 pagesAISC 360 - Moment Connection Design ExamplegireeshaNo ratings yet

- 16 - Presentation - NVF Annual Bridge Confererence 2014Document47 pages16 - Presentation - NVF Annual Bridge Confererence 2014Federico.IoriNo ratings yet

- Compilation of Plates Mondal FestejoDocument88 pagesCompilation of Plates Mondal FestejoMineski Prince GarmaNo ratings yet

- Edoc - Pub - Is 10262 2019 PDFDocument44 pagesEdoc - Pub - Is 10262 2019 PDFDharmendra SahuNo ratings yet

- Methodology - Static Load Test PDFDocument5 pagesMethodology - Static Load Test PDFEngr. MahmudNo ratings yet

- 6 PDFDocument1 page6 PDFLady Mae BrigoliNo ratings yet

- 3466 B 1 e 3 Faac 64 Aeb 5 FCDocument28 pages3466 B 1 e 3 Faac 64 Aeb 5 FCapi-522826730No ratings yet

- ETABS 18.0.2-Report ViewerDocument10 pagesETABS 18.0.2-Report ViewerFady MagdyNo ratings yet

- Jurnal SkripsiDocument6 pagesJurnal SkripsiKokoh Tiodito PamungkasNo ratings yet

- Halfen Cast-In Channels: HTA-CE 50/30P HTA-CE 40/22PDocument92 pagesHalfen Cast-In Channels: HTA-CE 50/30P HTA-CE 40/22PTulusNo ratings yet

- Flat Plate Apartments: Considered Slab AreaDocument6 pagesFlat Plate Apartments: Considered Slab AreaLavender HoneyNo ratings yet

- Slab On GradeDocument954 pagesSlab On Graderadem3100% (3)