Professional Documents

Culture Documents

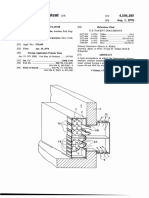

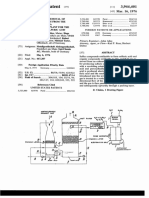

United States Patent (19) (11) Patent Number: 6,034,201: Schollhorn (45) Date of Patent: Mar. 7, 2000

United States Patent (19) (11) Patent Number: 6,034,201: Schollhorn (45) Date of Patent: Mar. 7, 2000

Uploaded by

Anonymous vWSYmP0 ratings0% found this document useful (0 votes)

14 views3 pagesThis patent describes an improved process for preparing urea-formaldehyde resins in large batches. Key steps include:

1) Heating solid paraformaldehyde to 60-120°C and adding urea to form a mixture, heating to 80-110°C.

2) Adding a methanolic guanine base to form a quanine-urea-formaldehyde mixture, heating until liquefied and cooled to 65°C.

3) Heating the mixture to boiling and condensing for 30-100 minutes. Additional urea is then added and condensed for 90-180 minutes.

Original Description:

Original Title

Us 6034201

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis patent describes an improved process for preparing urea-formaldehyde resins in large batches. Key steps include:

1) Heating solid paraformaldehyde to 60-120°C and adding urea to form a mixture, heating to 80-110°C.

2) Adding a methanolic guanine base to form a quanine-urea-formaldehyde mixture, heating until liquefied and cooled to 65°C.

3) Heating the mixture to boiling and condensing for 30-100 minutes. Additional urea is then added and condensed for 90-180 minutes.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

14 views3 pagesUnited States Patent (19) (11) Patent Number: 6,034,201: Schollhorn (45) Date of Patent: Mar. 7, 2000

United States Patent (19) (11) Patent Number: 6,034,201: Schollhorn (45) Date of Patent: Mar. 7, 2000

Uploaded by

Anonymous vWSYmPThis patent describes an improved process for preparing urea-formaldehyde resins in large batches. Key steps include:

1) Heating solid paraformaldehyde to 60-120°C and adding urea to form a mixture, heating to 80-110°C.

2) Adding a methanolic guanine base to form a quanine-urea-formaldehyde mixture, heating until liquefied and cooled to 65°C.

3) Heating the mixture to boiling and condensing for 30-100 minutes. Additional urea is then added and condensed for 90-180 minutes.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

US006034201A

United States Patent [19] [11] Patent Number: 6,034,201

Schollhorn [45] Date of Patent: Mar. 7, 2000

[54] PROCESS FOR PREPARING UREA- [56] References Cited

FORMALDEHYDE RESINS Us PATENT DOCUMENTS

[76] Inventor: Wolf-Dietrich Schollhorn, 5,010,164 4/1991 Schollhorn ............................ .. 528/243

Jakobstrasse, 29, Grunstadt, Germany P . E . _D T

rzmary xamzner uc ruong

[21] Appl. No.: 09/125,897 Attorney, Agent, or Firm—Staas & Halsey LLP

[22] PCT Filed: Feb. 19, 1997 [57] ABSTRACT

[86] PCT NO _ PCT/EP97/00805 Amethod of forming a urea formaldehyde resin includes the

" step of heating solid paraformaldehyde to a temperature of

§ 371 Date; Jan_ 15, 1999 60 to 120° C. Urea is added to the heated paraformaldehyde

to form a urea mixture, Which is dry mixed and heated until

§ 102(e) Date: Jan. 15, 1999 a temperature of 80 to 110° C. has been reached. After this,

a methanolic quanine base is added to the urea mixture to

[87] PCT Pub- N05 W097/31957 form a quanine-urea-formaldehyde mixture, Which is heated

until the quanine-urea-formaldehyde mixture is lique?ed

PCT Pub. Date: Sep. 4, 1997 and cooled to 65° C. Then, the quanine-urea-formaldehyde

[30] Foreign Application Priority Data mixture is heated until it boils, at Which point it is condensed

for a period of 30 to 100 minutes. After this, additional urea

Feb. 27, 1996 [DE] Germany ......................... .. 196 O7 252 is added to the liqui?ed urea mixture to form a urea enriched

7 mixture. The urea enriched mixture is condensed for 90 to

[51] Int. Cl. ..................................................... .. C08G 4/00 180 minutes‘ After Condensation, the urea enriched mixture

U-S. Cl. ........................ ..528/268; 528/502 R; 528/503 buffered

is buffered

mixturelactic

is cooled.

acid to form a buffered mixture‘

[58] Field of Search ................................... .. 528/243, 254,

528/256, 257, 266, 268, 503, 259, 502 R 13 Claims, No Drawings

6,034,201

1 2

PROCESS FOR PREPARING UREA c) A 32% methanolic guanine base is added in the

FORMALDEHYDE RESINS corresponding molar ratio to the heated mixture and

heated further, Whereby Within 10 minutes the mixture

BACKGROUND OF THE INVENTION is lique?ed and in spite of the added thermal energy, is

1. Field of the Invention cooled to 65° C., and the mixture is heated by the

This invention relates to a novel method for the manu further additional of thermal energy to the boiling range

facture of urea formaldehyde resins as Well as these resins of approximately 103 to 110° C., and is condensed in

themselves. the ?rst condensation stage, Whereby the beginning of

the Condensation Period I is arbitrarily set at a tem

2. Description of the Related Art

10 perature of 90° C., and the Condensation Period I is 30

The closest prior art is European Patent 0 319 751, Which to 100 minutes, preferably 50 to 85 minutes.

describes urea formaldehyde resin, its manufacture and use.

d) FolloWing the end of the Condensation Period I, a

claim 1 of European Patent 0 319 751 relates to a strongly second quantity of urea, dicyandiamide etc. is added to

exothermically hardening urea formaldehyde resin obtained the boiling mixture in a corresponding molar ratio, and

by the condensation of urea With formaldehyde in an alka 15 is condensed in a second condensation stage for 90 to

line environment Which can be obtained by performing a 180 minutes at a condensation temperature of 105 to

?rst Condensation Stage I as folloWs: 120° C.

a) Condensation of 0.2 to 0.7, preferably 0.5 M01 urea e) FolloWing the end of Condensation Period II, the

With 1.2 to 3 Mol, preferably 1.7 to 2.2 M01 formal solution is buffered at boiling heat With lactic acid, and

dehyde in the form of solid paraformaldehyde, in an 20 the resin is cooled for approximately 120 minutes to

exclusively alkaline medium, With an initial pH of approximately 25 ° C.

8—12, and preferably 9—11. The molar quantities used theoretically are the same as in

b) in the presence of 1 to 10 m Mol NaOH and 10 to 80 the reference cited by the closest prior art, Which is Euro

M01 NH3, or in the presence of 2.5 to 50 m Mol guanine pean Patent 0 319 780.

base and 0 to 80 m Mol NH3 per Mol of formaldehyde. 25

DETAILED DESCRIPTION OF THE

c) at a condensation temperature (I) of 90 to 110 ° C.

PREFERRED EMBODIMENT

d) at a condensation period (I) of 10 to 100 minutes,

preferably 15 to 70 minutes, folloWed by a Second The essence of this invention is explained in greater detail

Condensation stage II is conducted as folloWs: beloW on the basis of the folloWing exemplary embodiments

30 Which represent the preferred embodiments.

e) admixture of an additional 0.2 to 0.7 M01, preferably

Exemplary Embodiment I

0.5 M01 urea.

1) 482 kg of paraformaldehyde is heated to 90° C.

f) at a condensation temperature (I) of 100 to 120° C. 2) 250 kg of urea and

g) for an additional condensation period (II) of 1.5 to 5 30 kg of dicyandiamide are added and intensively mixed

hours. 35 With the paraformaldehyde, and heated for 15 minutes to

This method of the prior art for the manufacture of approximately 90° C.

strongly exothermically hardening urea formaldehyde resins 3) 24 kg of 32% methanolic guanine base is added and

Works in tWo condensation stages and is Well suited for use intensively mixed. The temperature drops to approxi

on a laboratory scale or a small industrial scale, Whereby the mately 65° C.

respective amounts manufactured can be approximately 100 40 4) When a temperature of 90° C. is reached, the Conden

kg. sation Period I begins, boiling range approximately 10.

It has since been found, hoWever, that this method of the 5) 250 kg of urea is added after the end of Condensation

prior art cannot be used under industrial conditions, i.e. for Period I, namely 75 minutes, and dissolved. The tempera

batches in the range of tons, or at least not optimally, ture drops to approximately 90 ° C. The Condensation

because the resulting resins cannot alWays be used for the 45 Period II, namely 120 minutes, begins upon the addition

manufacture of high-quality foam products. of the urea. Aboiling range of approximately 114 to 110°

SUMMARY OF THE INVENTION C. is reached. Condensation Period II is 120 minutes.

6) 3.43 kg of 85% lactic acid is required for buffering in the

The object of this invention is therefore to dramatically boiling heat

improve the method described in European Patent 0 319 751 50 7) Cooling of the resin for approximately 120 minutes to

so that it can be used on an industrial scale, and Whereby the approximately 25° C.

resins manufactured according to this invention can be used The resulting resin has a viscosity of 240 dPas at 25° C.

for the manufacture of high-quality foam products in the The reactivity is 43 ° C.

same manner as those that Were obtained on a laboratory or Exemplary Embodiment II

small industrial scale using the method described in Euro 55 1) 675 kg of paraformaldehyde is heated to 90 ° C.

pean Patent 0 319 751. 2) 350 kg of urea and dicyandiamide are added and inten

The invention teaches the folloWing method for the sively mixed With the paraformaldehyde, and heated for

accomplishment of the object described above: 15 minutes to approximately 90° C.

a) Paraformaldehyde is provided in solid form and is 3) 33.6 kg of 32% methanolic guanine base is added and

heated to a temperature of 60 to 120° C., preferably to 60 intensively mixed. The temperature drops to approxi

80 to 100° C. mately 65° C.

b) Urea and, if necessary, dicyandiamide and melamine in 4) The Condensation Period I of 75 minutes begins When a

corresponding molar quantities are added to the heated temperature of 90° C. is reached. The boiling range is

paraformaldehyde and are intensively dry-mixed and from 107 to 103° C.

heated until, after approximately 15 minutes, a tem 65 5) 360 kg of urea is added and dissolved after Condensation

perature of 80 to 110° C., preferably 85 to 100° C. has Period I. The temperature drops to approximately 90° C.

been reached. Condensation Period II begins after the addition of the

6,034,201

3 4

urea and lasts 120 minutes at a condensation temperature 7. Amethod of forming a urea formaldehyde resin accord

of 114 to 110° C. ing to claim 1, Wherein the boiling point of the quanine

6) 4.8 kg of 85% lactic acid is required for buffering in the urea-formaldehyde mixture in step (c) is approximately 103

boiling heat. to 110° C.

7) Cooling of the resin for approximately 120 minutes to 8. Amethod of forming a urea formaldehyde resin accord

approximately 25° C. ing to claim 1, Wherein urea is added in step (d) While the

The resin has a viscosity of 145 dPas at 25° C. The quanine-urea-formaldehyde mixture is boiling.

reactivity is 42° C. 9. Amethod of forming a urea formaldehyde resin accord

The reactivity is measured in the same manner as ing to claim 1, Wherein dicyandiamine is added in step

described in European Patent 0 139 751 [sic] 10 10. A method of forming a urea formaldehyde resin

The resins manufactured using the method claimed by the according to claim 1, Wherein the urea enriched mixture is

invention are Well suited for the manufacture of high-quality condensed at a temperature of 105 to 120° C. in step

foams, as described in European Patent 0 319 751. 11. A method of forming a urea formaldehyde resin

These products can also be processed as described in this according to claim 1, Wherein the buffered urea mixture is

European Patent 0 319 751. 15 cooled in step (e) for approximately 120 minutes.

I claim: 12. A method of forming a urea formaldehyde resin

1. A method of forming a urea formaldehyde resin com according to claim 1, Wherein the buffered urea mixture is

prising the steps of: cooled in step (e) to approximately 25° C.

a) heating solid paraformaldehyde to a temperature of 60 13. A method of forming a urea formaldehyde resin by the

to 120° C.; 20 condensation of urea With formaldehyde resin, comprising

b) adding urea to the heated paraformaldehyde to form a the steps of:

urea mixture and dry-mixing and heating the urea (a) heating solid paraformaldehyde to a temperature of 60

mixture until a temperaature of 80 to 110° C. has been to 120° C.;

reached; (b) adding urea, dicyandiamide and melamine in corre

25

c) after step (b), adding a methanolic quanine base to the sponding molar quantities to the heated paraformalde

urea mixture to form a quanine-urea-formaldehyde hyde to form a urea mixture;

mixture and heating until the quanine-urea (c) intensively dry-mixing and heating the urea mixture

formaldehyde mixture is lique?ed and cooled to 65° C., for approximately 15 minutes until a temperature of 80

and then heating the quanine-urea-formaldehyde mix 30

to 110° C. has been reached;

ture until it boils, and then condensing the quanine (d) after step (c), adding a methanolic quanine base in the

urea-formaldehyde mixture for a period of 30 to 100 corresponding molar ratio to the urea mixture to form

minutes; a quanine-urea-formaldehyde mixture and heating for

d) after step (c), adding additional urea to the quanine approximately 10 minutes until the quanine-urea

urea-formaldehyde mixture to form a urea enriched 35 formaldehyde mixture is lique?ed and cooled to 65 ° C.;

mixture, and then condensing the urea enriched mixture (e) after step (d), heating the quanine-urea-formaldehyde

for 90 to 180 minutes; and mixture further to approximately 103 to 110° C., until

e) after step (d), buffering the urea enriched mixture With it boils;

lactic acid to form a buffered mixture, and then cooling (f) When the temperature of the quanine-urea

the buffered mixture. 40 formaldehyde mixture reaches 90° C. in step (e), con

2. Amethod of forming a urea formaldehyde resin accord densing the quanine-urea-formaldehyde mixture for a

ing to claim 1, Wherein the solid paraformaldehyde is heated period of 30 to 100 minutes;

to a temperature of 80—100° C. (g) after step (f), adding additional urea and dicyandia

3. Amethod of forming a urea formaldehyde resin accord mide in a corresponding molar ratio to the quanine

ing to claim 1, Wherein dicyandiamine and melamine are 45

urea-formaldehyde mixture While it is boiling to form

added in step a urea enriched mixture;

4. Amethod of forming a urea formaldehyde resin accord

ing to claim 1, Wherein a 32% methanolic quanine base is (h) condensing the urea enriched mixture for 90 to 180

used in step minutes at a condensation temperature of 105 to 120°

5. Amethod of forming a urea formaldehyde resin accord 50 C.;

ing to claim 1, Wherein condensation is started in step (c) (i) after step (h), buffering the urea enriched mixture With

When the temperature of the quanine-urea-formaldehyde lactic acid to form a buffered mixture; and

mixture reaches 90° C. cooling the buffered mixture for approximately 120

6. Amethod of forming a urea formaldehyde resin accord minutes, to reach a temperature of approximately 25°

ing to claim 1, Wherein the quanine-urea-formaldehyde 55 C.

mixture is condensed in step (c) for a period of 50 to 85

minutes.

You might also like

- A Learning Plan in Grade 8 PersuasiveDocument6 pagesA Learning Plan in Grade 8 PersuasiveYannah Jovido50% (2)

- Audio Information and MediaDocument2 pagesAudio Information and Mediajosefalarka75% (4)

- Comptia Security Sy0 601 Exam Objectives (2 0)Document24 pagesComptia Security Sy0 601 Exam Objectives (2 0)tha_flameNo ratings yet

- US5364986Document4 pagesUS5364986Alam IlhamNo ratings yet

- Ulllted States Patent (19) (11) Patent Number: 6,153,168: Seitz Et Al. (45) Date of Patent: Nov. 28, 2000Document6 pagesUlllted States Patent (19) (11) Patent Number: 6,153,168: Seitz Et Al. (45) Date of Patent: Nov. 28, 2000GraciaVelitarioNo ratings yet

- United States Patent (19) : (45) Date of Patent: Oct. 13, 1998Document9 pagesUnited States Patent (19) : (45) Date of Patent: Oct. 13, 1998andresNo ratings yet

- Patent - Graphite Manufacturing ProcessDocument4 pagesPatent - Graphite Manufacturing ProcessAbrizal HaryadiNo ratings yet

- United States Patent (191: Schaper Et A1Document3 pagesUnited States Patent (191: Schaper Et A1Juan Pablo EspinosaNo ratings yet

- Chemically Gassed Emulsion ExplosiveDocument5 pagesChemically Gassed Emulsion ExplosiveManh Loc PhanNo ratings yet

- United States Patent (191: (211 Appl - No.:420,307 (30) Foreign Application Priority DataDocument7 pagesUnited States Patent (191: (211 Appl - No.:420,307 (30) Foreign Application Priority DataLatifah Nurul HudaNo ratings yet

- United States Patent (19) : MitchellDocument4 pagesUnited States Patent (19) : Mitchellrichris orvanidisNo ratings yet

- US7169959Document3 pagesUS7169959Alam IlhamNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument5 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentLechugaGuerreroHerreraNo ratings yet

- US6060550Document4 pagesUS6060550VivekPatilNo ratings yet

- US5127236Document8 pagesUS5127236ivanlawms6745No ratings yet

- OA17038ADocument28 pagesOA17038AOwais AhmedNo ratings yet

- Us 5710333Document4 pagesUs 5710333JennikNo ratings yet

- Us 6034269Document5 pagesUs 6034269Rahmat SunaryaNo ratings yet

- Us 4772757Document8 pagesUs 4772757Naomi HerreraNo ratings yet

- CokeDocument6 pagesCokeDendy Wahyu RadityaNo ratings yet

- United States Patent Office: Patented Aug. 17, 1965Document2 pagesUnited States Patent Office: Patented Aug. 17, 1965Vinod AvNo ratings yet

- Us 4072717Document7 pagesUs 4072717Елжбета ЭлиасбергNo ratings yet

- KKKK Us4081426Document9 pagesKKKK Us4081426هیمن مNo ratings yet

- Patent Pabrik Pthalic Anhydride Proses Von HeydenDocument7 pagesPatent Pabrik Pthalic Anhydride Proses Von HeydenFaizhal DimazNo ratings yet

- United States Patent (19) : (54) Roasting of MolybdeniteDocument8 pagesUnited States Patent (19) : (54) Roasting of MolybdeniteLuis Felipe SANo ratings yet

- United States Patent (19) : Filed: Apr. 20, 1977 57Document5 pagesUnited States Patent (19) : Filed: Apr. 20, 1977 57Iqbal KhanNo ratings yet

- US5093538Document6 pagesUS5093538PrimoNo ratings yet

- US4555564Document7 pagesUS4555564Narayana mahantyNo ratings yet

- United States Patent (19) : Oftring Et AlDocument12 pagesUnited States Patent (19) : Oftring Et AljerryNo ratings yet

- 1585827821conversion ProcessesDocument7 pages1585827821conversion Processesحسين مهديNo ratings yet

- United States PatentDocument3 pagesUnited States PatentSmokeNo ratings yet

- Petroleum Refining L 4Document18 pagesPetroleum Refining L 4Karrar Alka'byNo ratings yet

- US4232179Document10 pagesUS423217931415No ratings yet

- US4343954 FormaldehydeDocument4 pagesUS4343954 FormaldehydeRuchita PoilkarNo ratings yet

- United States Patent (19) : 11 Patent Number: 45 Date of PatentDocument3 pagesUnited States Patent (19) : 11 Patent Number: 45 Date of Patentrianne nabilahNo ratings yet

- United States Patent (191: (56) References CitedDocument6 pagesUnited States Patent (191: (56) References Citedandrew22No ratings yet

- Thermal Cracking and Coking: RefineryDocument12 pagesThermal Cracking and Coking: RefineryWaisi WaisiNo ratings yet

- United States Patent (19) : Brady (45) Aug. 28, 1973Document4 pagesUnited States Patent (19) : Brady (45) Aug. 28, 1973Vansala GanesanNo ratings yet

- Us4643848 Fumaric RosinDocument5 pagesUs4643848 Fumaric RosinPudien MuhamadNo ratings yet

- United States Patent: Bartholomé Et AlDocument8 pagesUnited States Patent: Bartholomé Et AlWidya Isti AriantiNo ratings yet

- United States Patent: (73) Assignee Sidney Cooke Chemicals Pty. Ltd. Assistant Examiner-Sidney MarantzDocument4 pagesUnited States Patent: (73) Assignee Sidney Cooke Chemicals Pty. Ltd. Assistant Examiner-Sidney MarantzAti Devara RachmawatiNo ratings yet

- Riedl 1980 US4225520 PDFDocument6 pagesRiedl 1980 US4225520 PDFManuel GonzalezNo ratings yet

- United States Patent (10) Patent No.: US 8,158,822 B2Document4 pagesUnited States Patent (10) Patent No.: US 8,158,822 B2JFPacNo ratings yet

- United States Patent (19) : Filed. Oct. 5, 1977Document3 pagesUnited States Patent (19) : Filed. Oct. 5, 1977Alexander Franco CastrillonNo ratings yet

- 1015/2731 106/243 101% Anhydrides.:l Htel Modifliedl 1gollyamidesare Obtailrlledlb2yDocument10 pages1015/2731 106/243 101% Anhydrides.:l Htel Modifliedl 1gollyamidesare Obtailrlledlb2yalfredo torresNo ratings yet

- The Herring Group, Inc.: Professional Support ServicesDocument24 pagesThe Herring Group, Inc.: Professional Support ServicesskluxNo ratings yet

- US Patent of Sorbitol ProductionDocument6 pagesUS Patent of Sorbitol ProductionDeri AlvianNo ratings yet

- Patente US5958744Document12 pagesPatente US5958744Estefania Angel ClavijoNo ratings yet

- United States Patent (19) : Keough (45) Date of Patent: Mar. 10, 1987Document11 pagesUnited States Patent (19) : Keough (45) Date of Patent: Mar. 10, 1987113314No ratings yet

- US3903185Document6 pagesUS3903185Muhammad Akbar FahleviNo ratings yet

- US5741956 PentaerythritolDocument5 pagesUS5741956 PentaerythritolRuchita PoilkarNo ratings yet

- US3870756 (Sudah)Document4 pagesUS3870756 (Sudah)aris_nurhidayatNo ratings yet

- CHP Cleavage by Shell MarkedDocument6 pagesCHP Cleavage by Shell MarkedHARSH DHOLAKIYANo ratings yet

- United States Patent (19) 11 Patent Number: 5,269,839: Sodhi 45) Date of Patent: Dec. 14, 1993Document4 pagesUnited States Patent (19) 11 Patent Number: 5,269,839: Sodhi 45) Date of Patent: Dec. 14, 1993Alexander Franco CastrillonNo ratings yet

- US4454277Document5 pagesUS4454277Aji SyarifudinNo ratings yet

- US5481059 Settling Aids Ashes SlurryDocument4 pagesUS5481059 Settling Aids Ashes SlurryDavid Diaz PadillaNo ratings yet

- Individual AssignmentDocument1 pageIndividual Assignmentsarah sharilNo ratings yet

- United States Patent: (56) Unlte F Ences Cllated and Subsequently Upwardly Through A Packing LayerDocument8 pagesUnited States Patent: (56) Unlte F Ences Cllated and Subsequently Upwardly Through A Packing LayerDita Baeti PridianaNo ratings yet

- Us 4479925Document5 pagesUs 4479925Katherine Benavides VillenaNo ratings yet

- Us6210562 PDFDocument8 pagesUs6210562 PDFSyuhadah NoordinNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2009/0030201 A1Document6 pagesPatent Application Publication (10) Pub. No.: US 2009/0030201 A1Aquae Tyo WijiantoNo ratings yet

- The Steam Engine Explained and Illustrated (Seventh Edition) With an Account of its Invention and Progressive Improvement, and its Application to Navigation and Railways; Including also a Memoir of WattFrom EverandThe Steam Engine Explained and Illustrated (Seventh Edition) With an Account of its Invention and Progressive Improvement, and its Application to Navigation and Railways; Including also a Memoir of WattNo ratings yet

- CEPCI August 2020Document1 pageCEPCI August 2020Husni RadiyanNo ratings yet

- Us 5684118Document5 pagesUs 5684118Anonymous vWSYmPNo ratings yet

- The Sdgs and Sustainable Fertilizer ProductionDocument6 pagesThe Sdgs and Sustainable Fertilizer ProductionAnonymous vWSYmPNo ratings yet

- United States Patent (191: Graves (45) Date of Patent: Oct. 7, 1997Document6 pagesUnited States Patent (191: Graves (45) Date of Patent: Oct. 7, 1997Anonymous vWSYmPNo ratings yet

- Iiiiiiiiiiiiiiii: United States Patent 1191Document10 pagesIiiiiiiiiiiiiiii: United States Patent 1191Anonymous vWSYmPNo ratings yet

- Adhesives Part 1Document6 pagesAdhesives Part 1Anonymous vWSYmPNo ratings yet

- Summer 2014: Opportunities For US Building Materials in The Chinese Senior Housing MarketDocument8 pagesSummer 2014: Opportunities For US Building Materials in The Chinese Senior Housing MarketAnonymous vWSYmPNo ratings yet

- 2009 Wood Market Trend in JapanDocument38 pages2009 Wood Market Trend in JapanAnonymous vWSYmPNo ratings yet

- Equipment New Reweble Energy PDFDocument76 pagesEquipment New Reweble Energy PDFsugeng wahyudiNo ratings yet

- Process Equipment Cost EstimationDocument80 pagesProcess Equipment Cost EstimationKSSri100% (4)

- 1Document7 pages1Anonymous vWSYmPNo ratings yet

- E13 Wood AdhesionDocument174 pagesE13 Wood AdhesionAnonymous vWSYmPNo ratings yet

- Selective Oxidation of Methylal As A New Catalytic Route To Concentrated FormaldehydeDocument5 pagesSelective Oxidation of Methylal As A New Catalytic Route To Concentrated FormaldehydeAnonymous vWSYmPNo ratings yet

- UpsDocument31 pagesUpsThuyaNo ratings yet

- Ent Secretory Otitis MediaDocument3 pagesEnt Secretory Otitis MediaIrena DayehNo ratings yet

- PTS MATH GRADE 3 ICP (2022-2023) - Abidah FixDocument4 pagesPTS MATH GRADE 3 ICP (2022-2023) - Abidah FixAnita Noor Maidah S.Pd.i. SD Lab UMNo ratings yet

- Sir Syed University of Engineering & Technology.: OGDCL Internship Report 2021Document16 pagesSir Syed University of Engineering & Technology.: OGDCL Internship Report 2021Aisha KhanNo ratings yet

- Sample QuestionDocument2 pagesSample QuestionSiddartha CHNo ratings yet

- 12feb Quickref Views enDocument148 pages12feb Quickref Views enprakash2709No ratings yet

- Reducing Major Defects in Radiators Manufacturing: Kumar P., Sonawane B.S., Sontakke R.R., Surves.B., Wasnik A.RDocument5 pagesReducing Major Defects in Radiators Manufacturing: Kumar P., Sonawane B.S., Sontakke R.R., Surves.B., Wasnik A.RKrushnaNo ratings yet

- 03 - Literature ReviewDocument9 pages03 - Literature ReviewKhant Wai YanNo ratings yet

- Conceptual FrameworkDocument4 pagesConceptual FrameworkEustass KiddNo ratings yet

- South Oil Company (SOC) : SOC Contract No.: CSSP-ITT-04Document19 pagesSouth Oil Company (SOC) : SOC Contract No.: CSSP-ITT-04Kingsley BaptistaNo ratings yet

- YCT Heat Transfer NEET JEE Questions PracticeDocument81 pagesYCT Heat Transfer NEET JEE Questions Practicedrsantanuchakraborty91No ratings yet

- The-Impact-On-Load-balancing-In-Cloud-Computing 2020Document5 pagesThe-Impact-On-Load-balancing-In-Cloud-Computing 2020Nikola JovanovicNo ratings yet

- Manual C28 Plus enDocument28 pagesManual C28 Plus enSveto SlNo ratings yet

- Partnership in Class Questions 2015Document3 pagesPartnership in Class Questions 2015Nella KingNo ratings yet

- Power Electronics: Thyristor Controlled Power For Electric MotorsDocument10 pagesPower Electronics: Thyristor Controlled Power For Electric Motorsshahab moinNo ratings yet

- Electrical Circuit Lab ManualDocument38 pagesElectrical Circuit Lab Manualecessec67% (3)

- SoftOne BlackBook ENG Ver.3.3 PDFDocument540 pagesSoftOne BlackBook ENG Ver.3.3 PDFLiviu BuliganNo ratings yet

- EDU CAT EN DF1 FI V5R19 Toprint PDFDocument14 pagesEDU CAT EN DF1 FI V5R19 Toprint PDF3pherNo ratings yet

- A Human Orrery: Materials PreparationDocument4 pagesA Human Orrery: Materials Preparationari sudrajatNo ratings yet

- Kingsmill Materia MedicaDocument32 pagesKingsmill Materia Medicamax quayleNo ratings yet

- Fallas VenezuelaDocument20 pagesFallas VenezuelaDaniel Quintana GaviriaNo ratings yet

- Springer Nature Latex TemplateDocument13 pagesSpringer Nature Latex TemplateAndres FloresNo ratings yet

- Form Service A40gDocument1 pageForm Service A40gBrando ImanuelNo ratings yet

- Piping Stress AnalysisDocument10 pagesPiping Stress AnalysisM Alim Ur Rahman100% (1)

- Laurel Doll Amigurumi Free PatternDocument21 pagesLaurel Doll Amigurumi Free PatternHuyền TrangNo ratings yet

- Science TE804Document15 pagesScience TE804carolynhart_415No ratings yet

- Maximo Training Material Day 2Document41 pagesMaximo Training Material Day 2ckombo9912100% (2)